Touch automatic spraying and dust-settling device

A spray dust reduction and automatic technology, applied in safety devices, dust prevention, mining equipment, etc., can solve the problems of inconvenient relocation, inconvenient installation and use, and high failure rate of equipment, so as to reduce the workload of installation and maintenance , Easy to install and move, low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

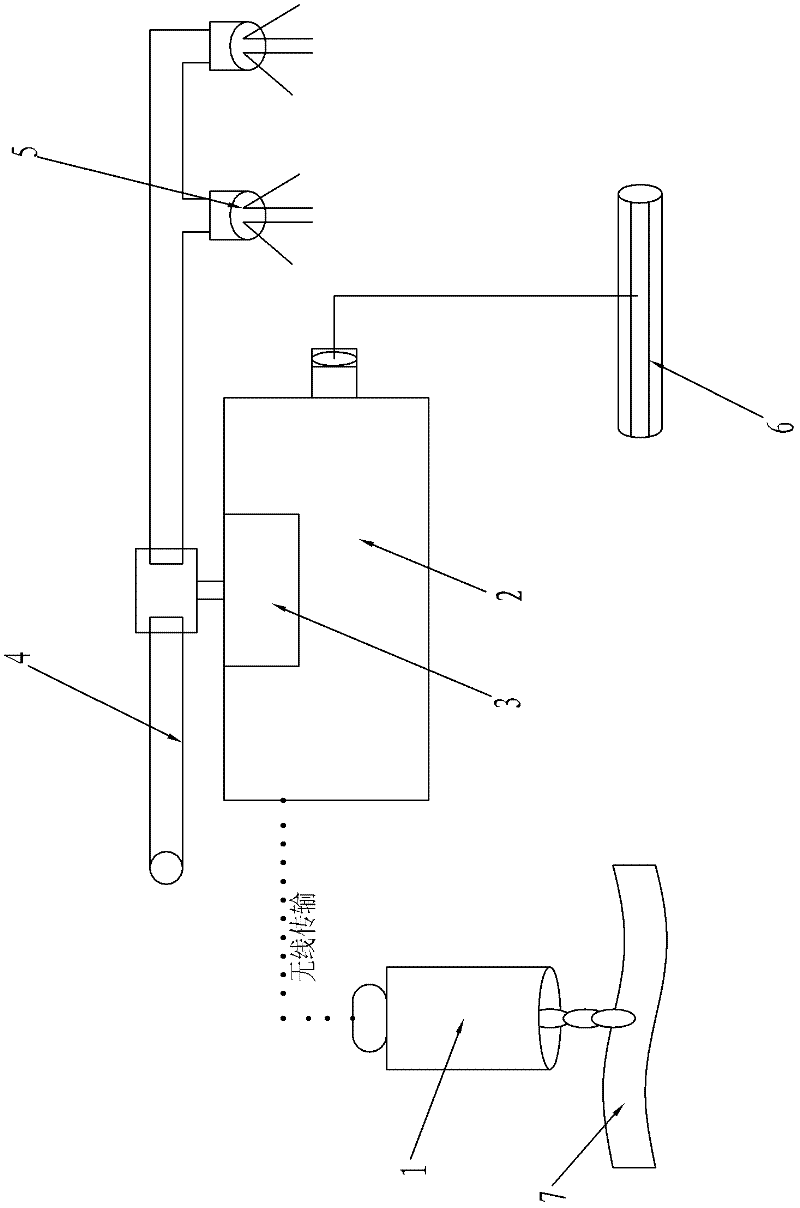

[0025] Such as figure 1 As shown, the touch automatic spray dust suppression device of the present invention includes a touch sensor 1, a main control box 2, a solenoid valve 3, a water supply pipeline 4 and a plurality of nozzles 5, the main control box 2 and the touch sensor 1 adopt a wireless communication mode, and the main control box 2 The control box 2 and the solenoid valve 3 are provided with an integrated structure, the water supply pipeline 4 is connected with the solenoid valve 3 , and a plurality of nozzles 5 are arranged on the water supply pipeline 4 .

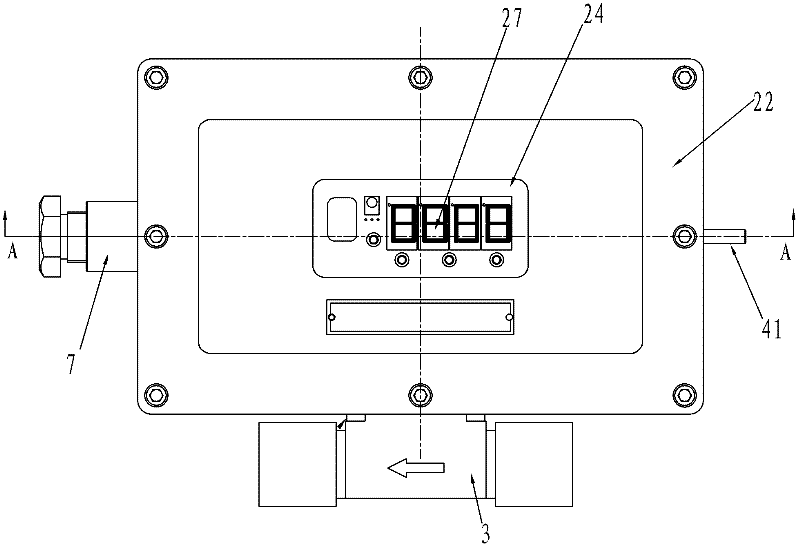

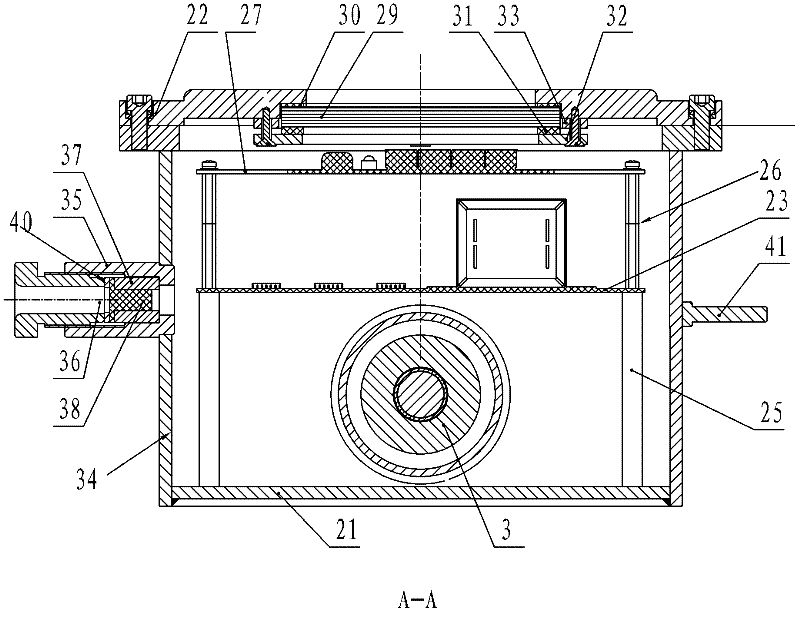

[0026] combine figure 2 , 3 As shown, the main control box 2 includes a box base 21, a cover plate 22, a control panel 23, and a glass window 24. The box base 21 and the cover plate 22 are fixedly connected by bolts, and two installation columns are fixed on the inner bottom surface of the box base 21. 25. The control board 23 is fixed on the top of the mounting column 25 by the studs 26, and the display boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com