Multi-point partial pre-fastening method with adjustable load sharing mechanism

A load-sharing, multi-point technology, applied to the measurement of the property and force of piezoelectric devices, can solve the problems of preload and structural parameter adjustment, structural parameter adjustment, and sensitive unit difficulties, etc., to achieve simple structure, Good preload effect and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

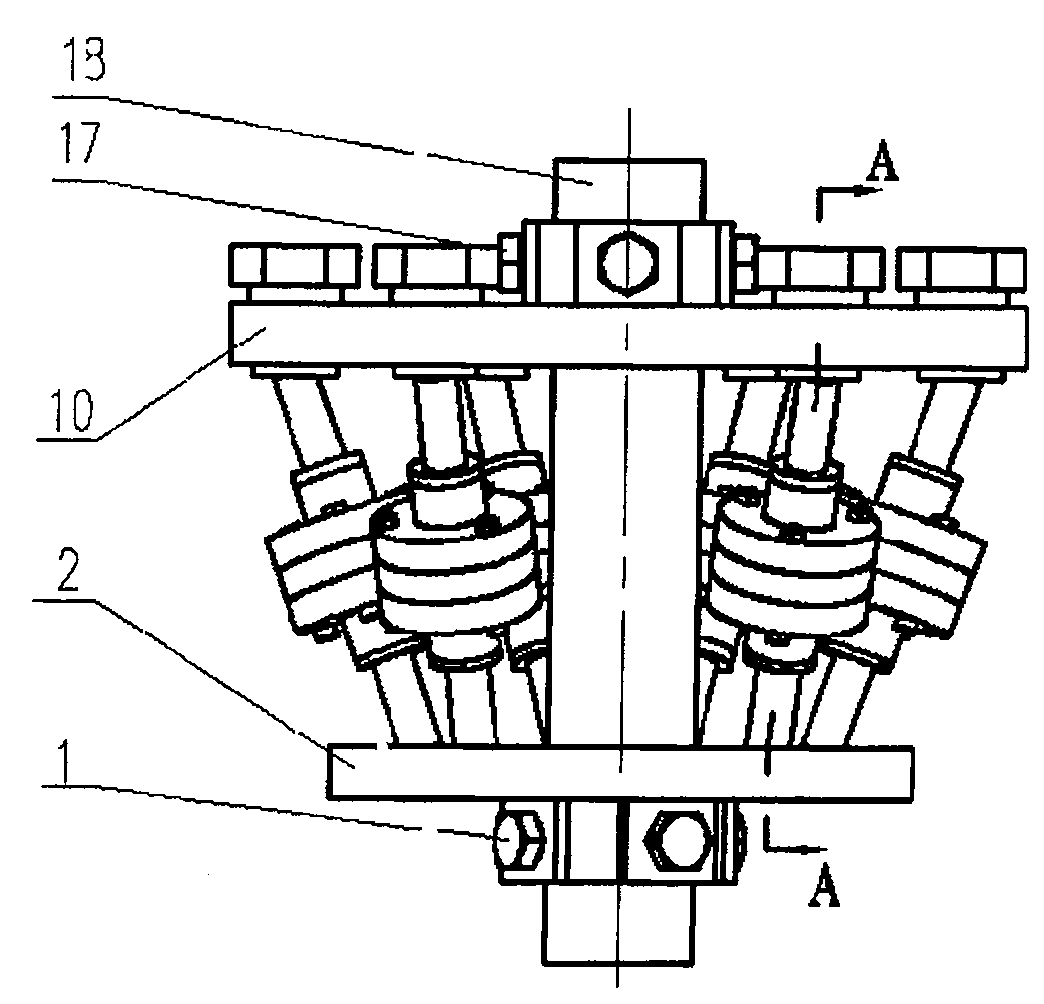

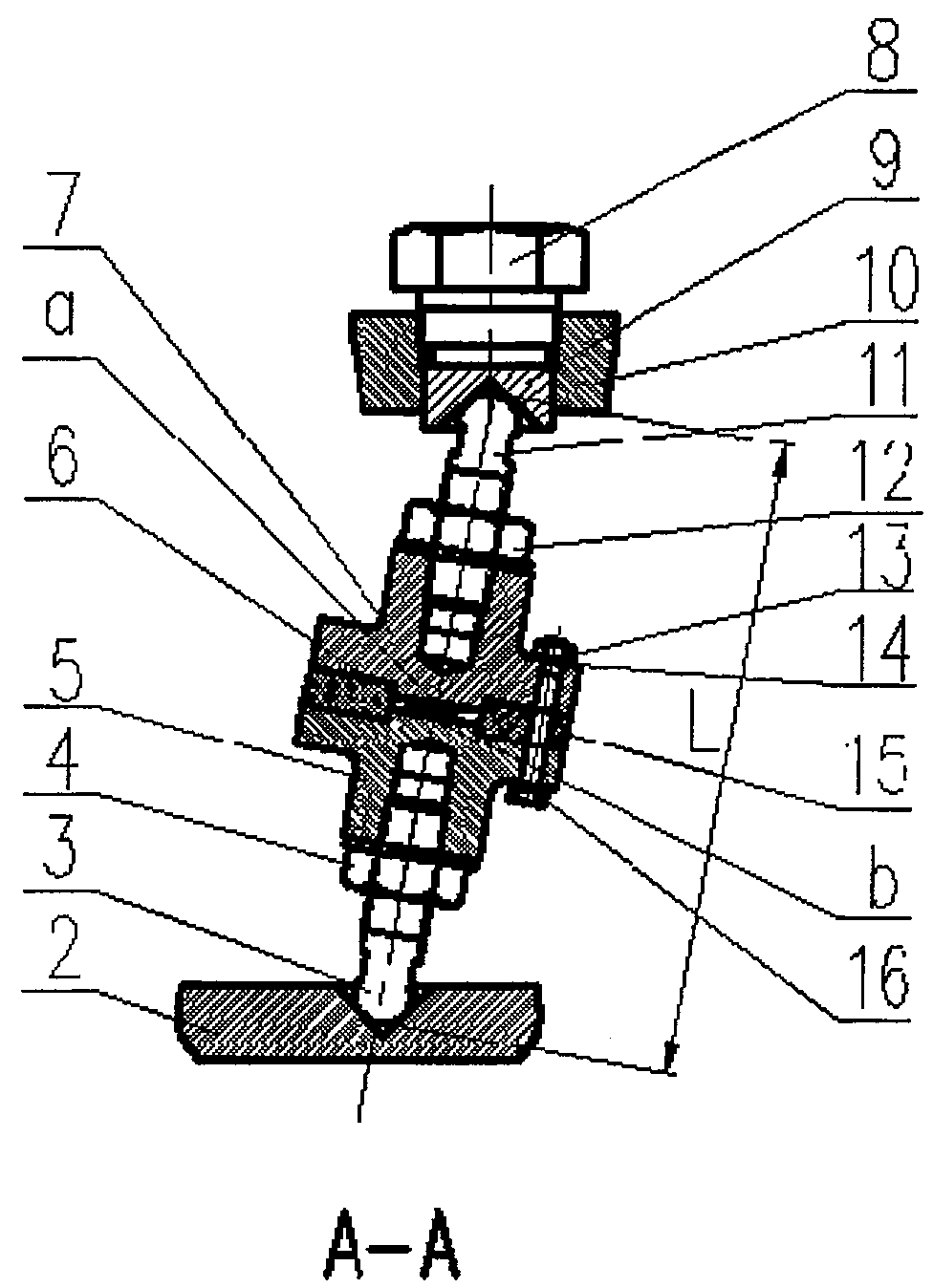

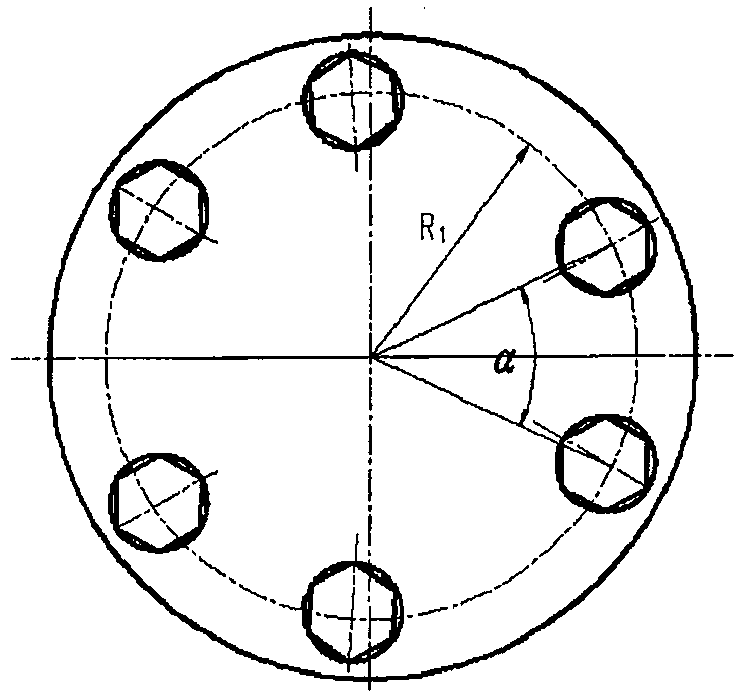

[0018] Example 1: Take the length from the centerline of the threaded hole on the upper platform of the mechanism to the center of the upper platform as R 1 =0.16m, the length from the centerline of the conical groove of the lower platform to the center of the lower platform is R 2=0.098m, the angle between the two ball joints of the upper platform α=5π / 18, the angle between the two ball joints of the lower platform β=π / 6, the length of the measuring rod is adjusted to L=0.21m, see the attached image 3 , 4 . Since |α-β|=π / 9, the condition of 0°av =(R 1 +R 2 +L) / 3 get, l av =(0.16+0.098+0.21) / 3, namely: 1 av =0.156, so, l 1 =R 1 / l av =1.026, l 2 =R 2 / l av =0.628, l 3 =L / l av =1.346, can be obtained by calculation, μ = l 1 2 + l 2 2 - 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com