Preparation method and protective film of microlens array structure

A microlens array and protective film technology, applied in the field of microfluidics, can solve the problems of processing shape accuracy, surface quality control, manufacturing cost and efficiency defects, limiting the development and application of microlens arrays, complex processing procedures, etc. The effect of reducing preparation cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

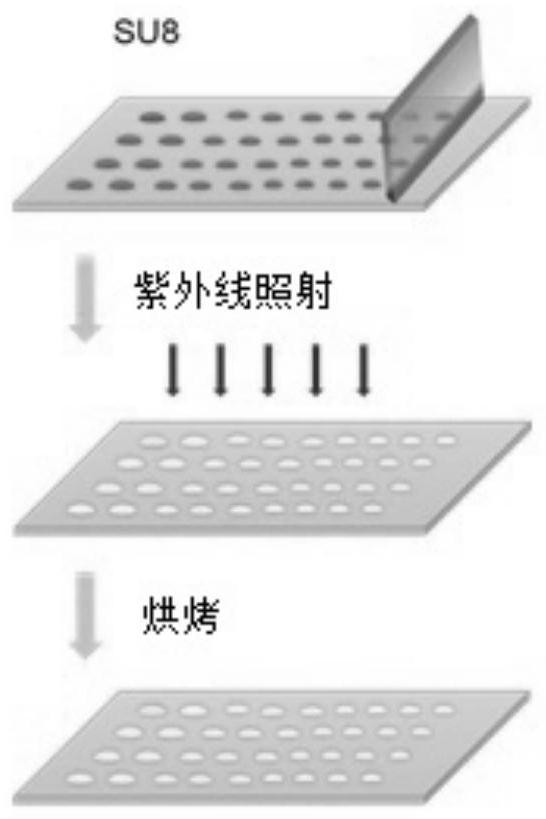

[0044] This embodiment relates to a method for preparing a silicon wafer template for the preparation of a microlens array structure, which is combined with figure 1 As shown in, the preparation method of the silicon wafer template specifically includes the following steps:

[0045] Step a: modifying the silicon wafer to make the surface of the silicon wafer non-wetting;

[0046] Step b: preparing circular patterns arranged in an array on the surface of the non-wetting silicon wafer to form a patterned surface;

[0047] Step c: coating SU8 photoresist on the patterned surface to form an array of SU8 photoresist droplets;

[0048] Step d: Expose to ultraviolet light and heat at 95° C. to obtain a silicon wafer template with a cured SU8 convex lens array.

[0049] Among them, in the above preparation steps, step a preferably uses 1H, 1H, 2H, 2H-perfluorooctyltriethoxysilane (POTS) to modify the silicon wafer, and step b preferably uses photolithography technology in a non-wett...

Embodiment 2

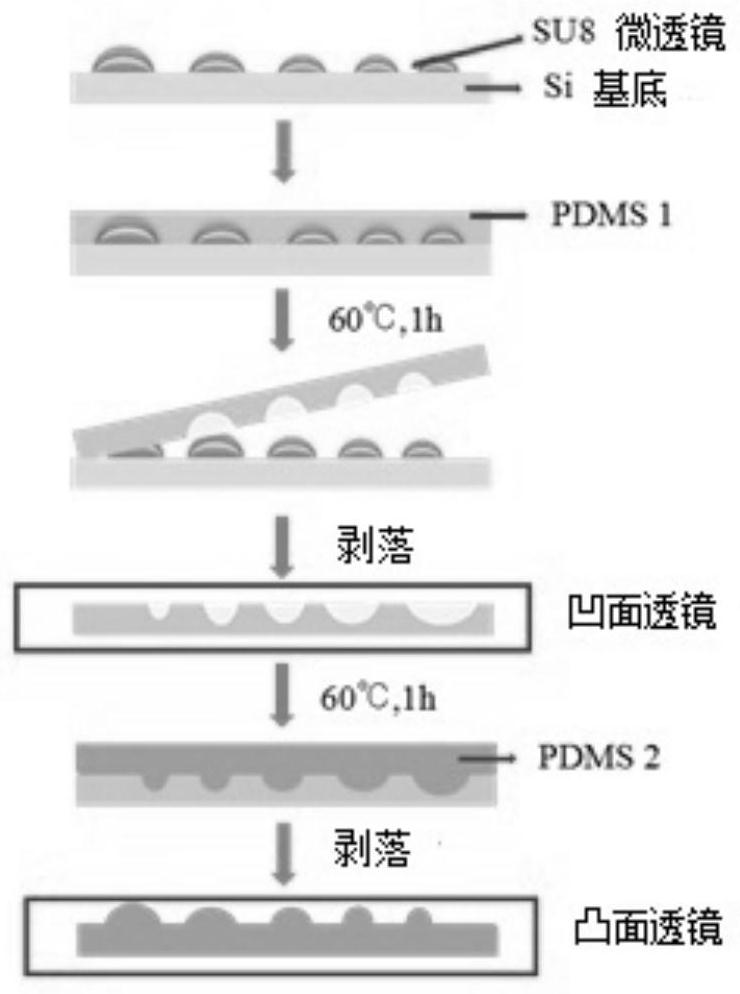

[0061] This embodiment relates to a preparation method of a microlens array structure, which method includes firstly adopting the preparation method in Embodiment 1 to prepare a silicon wafer template with a cured SU8 convex lens array, and as figure 2 As shown, the preparation method of the microlens array structure in this embodiment further includes:

[0062] Step e: Mix the PDMS prepolymer and the curing agent in a mass ratio of 10:1 and stir evenly, remove the air bubbles and pour it on the silicon wafer template with the SU8 convex lens array, and place it at room temperature to fully spread the PDMS;

[0063] Step f: heating and curing at 60° C., uncovering the poured PDMS to obtain a flexible PDMS microlens array, and the microlens array is a concave lens array.

[0064] Among them, the prepolymer and curing agent of the above-mentioned PDMS are also the main agent and curing agent mentioned in other appellations, and after the prepolymer and curing agent are mixed ev...

Embodiment 3

[0097] This embodiment relates to a protective film containing a microlens array, which can be used for LED lighting equipment, and electronic products such as mobile phones, tablet computers, smart watches, displays, etc. The display screen is protected to reduce or avoid external damage.

[0098] The protective film of this embodiment has a film-like substrate layer, and in addition to the substrate layer, like the existing commonly used screen protective film such as mobile phones, the protective film of this embodiment also includes the substrate layer of course. Other functional layers such as release film are attached to the surfaces on both sides to achieve different protective properties of the protective film. In addition, for the display screen protection screen of this embodiment, its main inventive point is that a microlens array is prepared on the substrate layer, so that the light transmittance of the protective film can be increased, thereby improving the applic...

PUM

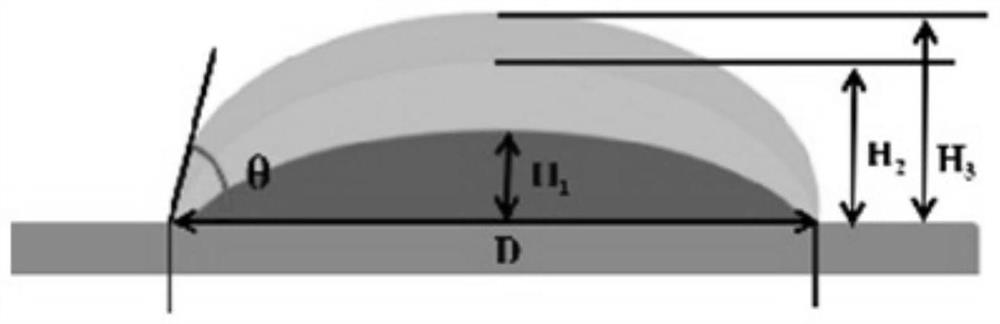

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com