An operation and maintenance method for a double-shake, multi-gear, stably supported ball valve

A multi-position, ball-supporting technology, applied in the direction of valve operation/release device, valve details, valve device, etc., can solve the problems of inflexible closing, single function, failure of valve seat system, etc., to improve stability and convenience High performance, compact and stable structure, good preload performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

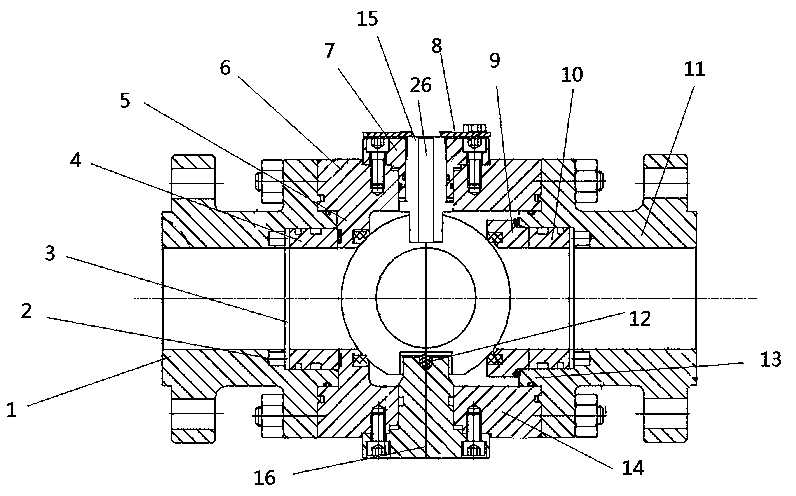

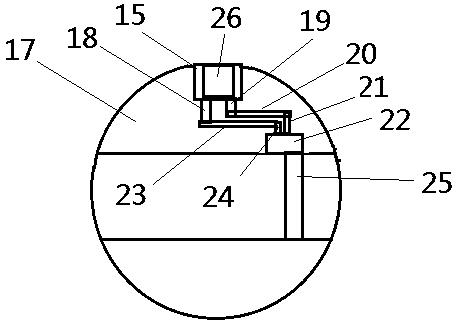

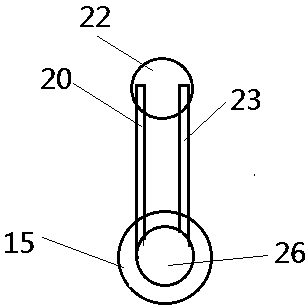

[0037] As shown in the figure: an operation and maintenance method for a double-shake, multi-gear, stable-support ball valve. The ball valve includes a left flange, a pretensioner, a spacer ring, a left pressure ring, a convex valve seat, an upper valve body, and a shaft sleeve. , connecting plate, right valve seat, right pressure ring, pressure plate flange, lower spring, left protrusion, lower valve body, outer valve stem, lower valve shaft, ball, first long rod, first short rod, upper connection Rod, second long rod, secondary shaft, lower connecting rod, second short rod, auxiliary valve plate, inner valve rod; operation and maintenance methods include ball valve operation method, multi-gear adjustment method, ball valve installation method;

[0038] As shown in the figure: the left flange is located on the left side of the upper and lower valve bodies, the pressure plate flange is located on the right side of the upper and lower valve bodies, the shaft sleeve is fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com