A working method of a two-way driving operation system

A technology of operating system and working method, applied in the direction of engine components, fluid pressure actuating devices, cocks including cutting devices, etc., can solve the problems of inflexible closing, insufficient flexibility, failure of valve seat system, etc., and achieve compact and stable structure , Changeable drive mode, reduce the effect of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

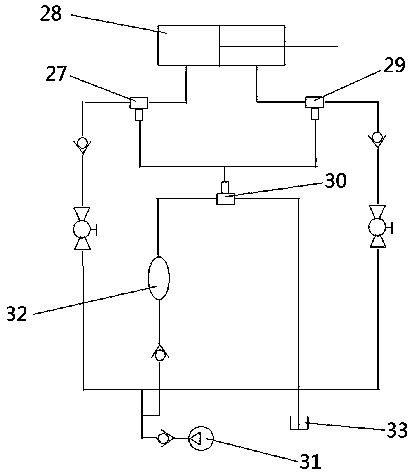

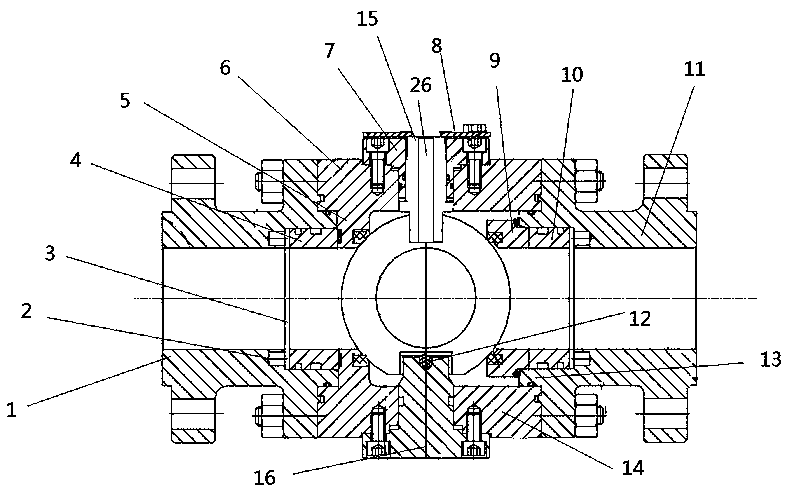

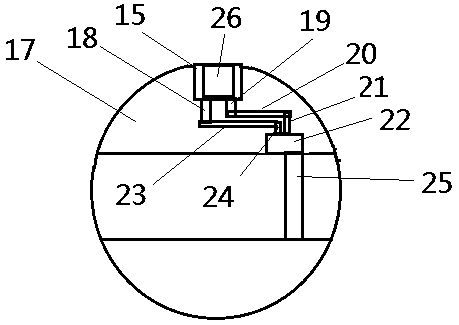

[0041] As shown in the figure: a working method of a two-way drive operation system, the operation system includes a ball valve, a first three-way valve, a second three-way valve, a third three-way valve, a hydraulic cylinder, a hydraulic pump, and an accumulator , Fuel tank; The working method includes a multi-gear driving method, a pressure relief energy storage method;

[0042] As shown in the figure: the hydraulic pump outputs hydraulic oil through the one-way valve, and the hydraulic oil output from the hydraulic pump is respectively connected to the two chambers of the hydraulic cylinder through two parallel passages. There are said ball valves, a one-way valve and a first three-way valve are connected in series between one ball valve and one chamber of the hydraulic cylinder, and a one-way valve and a second three-way valve are connected in series between the other ball valve and another chamber of the hydraulic cylinder. One-way valve; the third ends of the first three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com