Chemical waste residue and sludge drying device

A technology of sludge drying and drying equipment, which is applied in dehydration/drying/concentrated sludge treatment, waste fuel, petroleum industry, etc. It can solve the problems of increased wear, optimization, and small scale of drying equipment, so as to achieve easy maintenance, The effect of reducing drying cost and flexible driving mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The examples are only used to explain the present invention, not to limit the protection scope of the present invention.

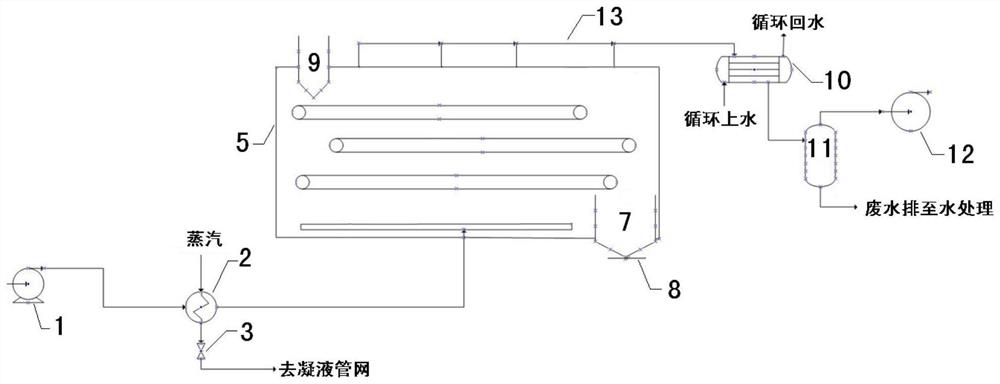

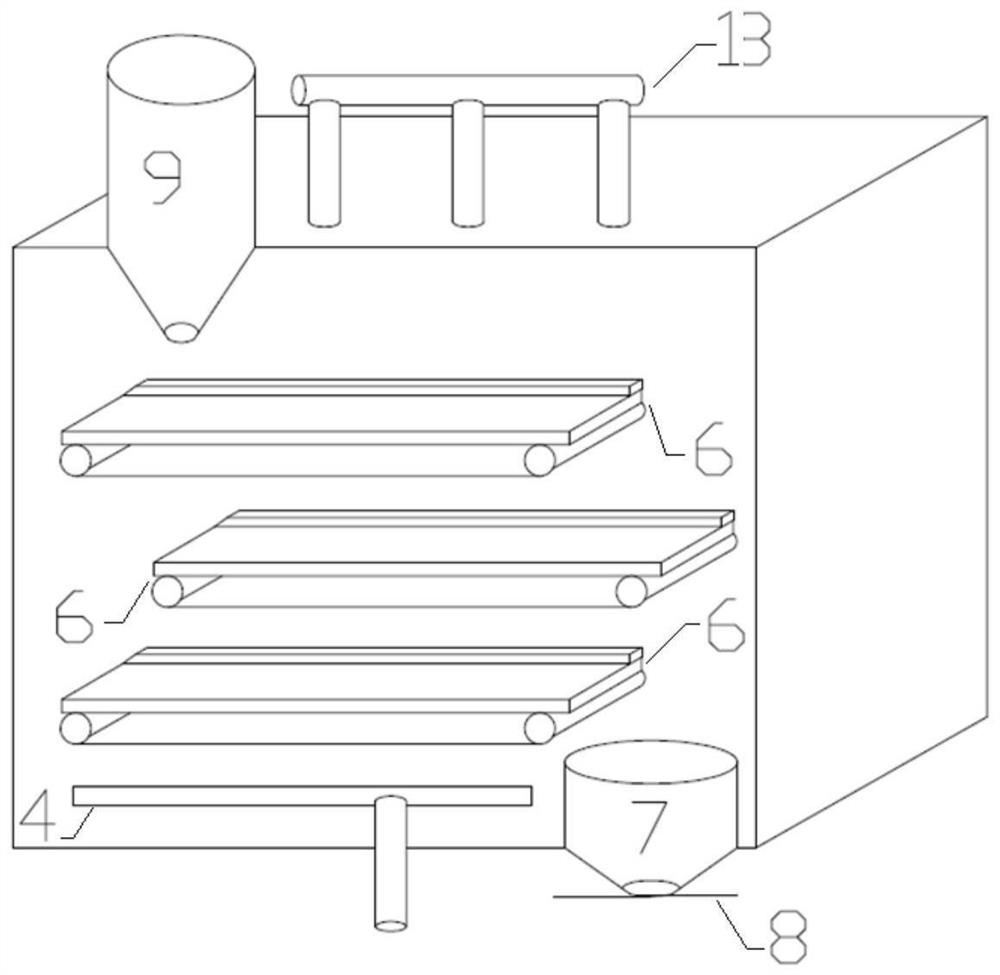

[0033] (1) Structural design and working principle of the drying device

[0034] see figure 1 , The chemical waste residue and sludge drying device of the present invention mainly includes a hot air supply system, a material drying system and a hot air cooling system. The hot air supply system mainly includes a blower 1, an air heater 2 and a drainage facility 3, the air heater 2 is connected to the air outlet of the blower 1, and the air inlet of the blower 1 sucks outside air and pressurizes it and sends it into the air heater 2 , in the air heater 2, the inhaled air is heated by steam, and the obtained hot air is sent into the material drying system, and after the material (waste residue, sludge) is dried, a relatively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com