Method for preparing novel plasticizer by using waste polyurethane

A polyurethane and plasticizer technology, applied in the field of preparing high molecular weight plasticizers from waste polyurethane, can solve the problems of high hydrolysis conditions and equipment requirements, not being widely used, and difficult disposal of three wastes, etc., achieving significant social Benefits and economic benefits, realize the effect of high efficiency of waste utilization and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0012] A kind of method utilizing waste polyurethane to prepare novel plasticizer, comprises the following sequential steps:

[0013] (1) Weigh 100 parts of crushed waste polyurethane hard (soft) foam, 15 parts of dimethylethanolamine, and 0.1 part of potassium hydroxide (KOH);

[0014] (2) In the degradation reactor, the temperature is 100-190°C and the pressure is 0.1 MPa. After the degradation reaction for 30 minutes, some degradation products are released by filtration;

[0015] (3) After step (2), put in the crushed waste polyurethane hard (soft) foam, and filter to release some degradation products;

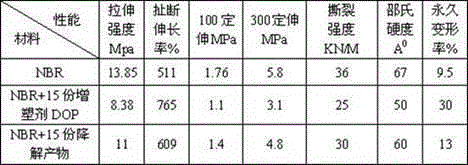

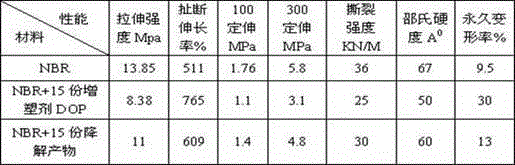

[0016] (4) Ingredients according to the basic formula: nitrile rubber (NBR-41) 100, accelerator CZ 1.2, zinc oxide (ZnO) 5, stearic acid (SA) 2, anti-aging agent (RD) 1, accelerator TMTD 0.5 , carbon black 30, sulfur (S) 1.5;

[0017] (5) Add the degradation product in (3) to the compound rubber in (4) and mix for 4-8 minutes, add accelerators TMTD and S after mixing even...

specific Embodiment approach 2

[0024] A kind of method utilizing waste polyurethane to prepare novel plasticizer, comprises the following sequential steps:

[0025] (1) Take by weighing 100 parts of waste polyurethane elastomers of pulverization respectively, 15 parts of copolyether glycols, 0.1 part of dibutyltin dilaurate;

[0026] (2) In the degradation reactor, the temperature is 140-240 °C, the pressure is 0.1 MPa, after the degradation reaction for 30 minutes, filter and release part of the degradation products;

[0027] (3) After step (2), put in the pulverized waste polyurethane elastomer while filtering to release some degradation products;

[0028] (4) Ingredients according to the basic formula: nitrile rubber (NBR-41) 100, accelerator CZ 1.2, zinc oxide (ZnO) 5, stearic acid (SA) 2, anti-aging agent (RD) 1, accelerator TMTD 0.5 , carbon black 30, sulfur (S) 1.5;

[0029] (5) Add the degradation product in (3) to the rubber compound in (4) and mix for 4-8 minutes, add accelerators TMTD and S aft...

specific Embodiment approach 3

[0037] A kind of method utilizing waste polyurethane to prepare novel plasticizer, comprises the following sequential steps:

[0038] (1) Take by weighing 100 parts of waste polyurethane fibers of pulverization, 15 parts of triethylenetetramine, and 0.1 part of sodium methoxide;

[0039] (2) In the degradation reactor, under the conditions of temperature 120-200 ° C and pressure 0.1 MPa, after 30 minutes of degradation reaction, filter and release part of the degradation products;

[0040] (3) After step (2), put in the pulverized waste polyurethane fiber, and filter to release some degradation products;

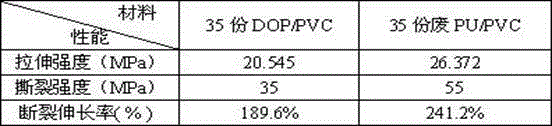

[0041] (4) Ingredients according to the basic formula: PVC (polyvinyl chloride), 100; DOP, 40; tri-salt, 1.5; di-salt, 1.0; zinc stearate, 1; stearic acid, 0.5; paraffin 0.5;

[0042] (5) Add the degradation product in (3) to the mixing material in (4) and knead for 4 minutes at a temperature of 150°C. After kneading evenly, the next piece is ready for use;

[0043] (6) On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com