Patents

Literature

57results about How to "Reduce degradation cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing Fe3+doped TiO2 hollow sphere catalyst and application thereof

InactiveCN101890350AEmission reductionNo pollution in the processWater/sewage treatment by irradiationEnergy based wastewater treatmentHydrolysisPhotocatalytic degradation

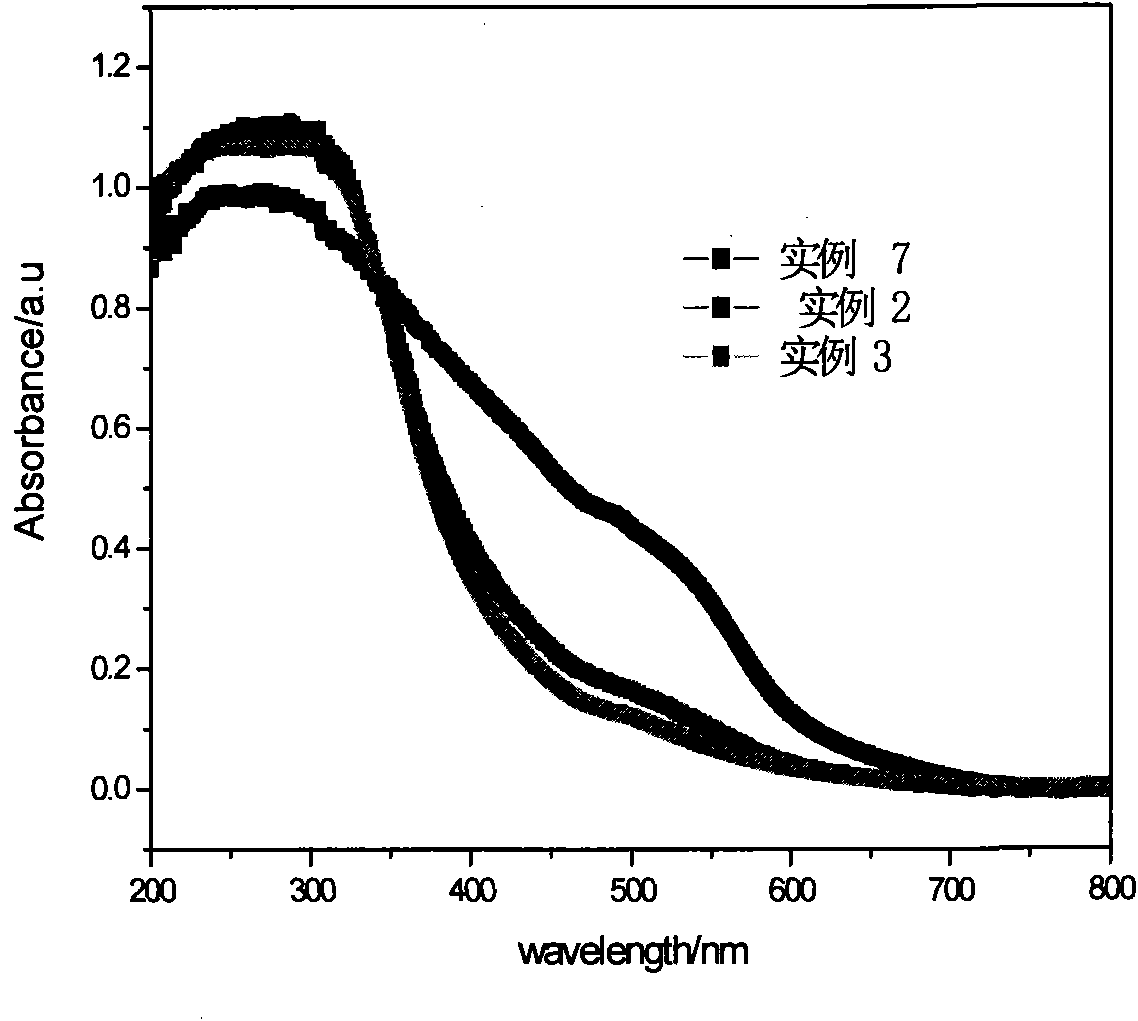

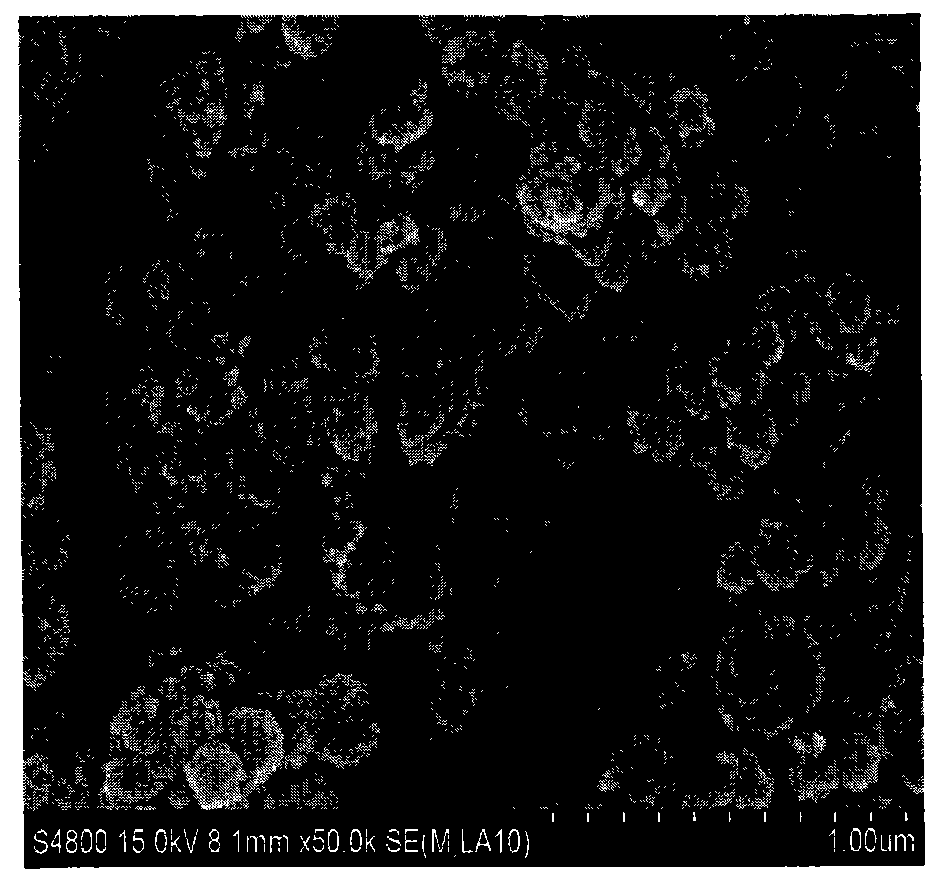

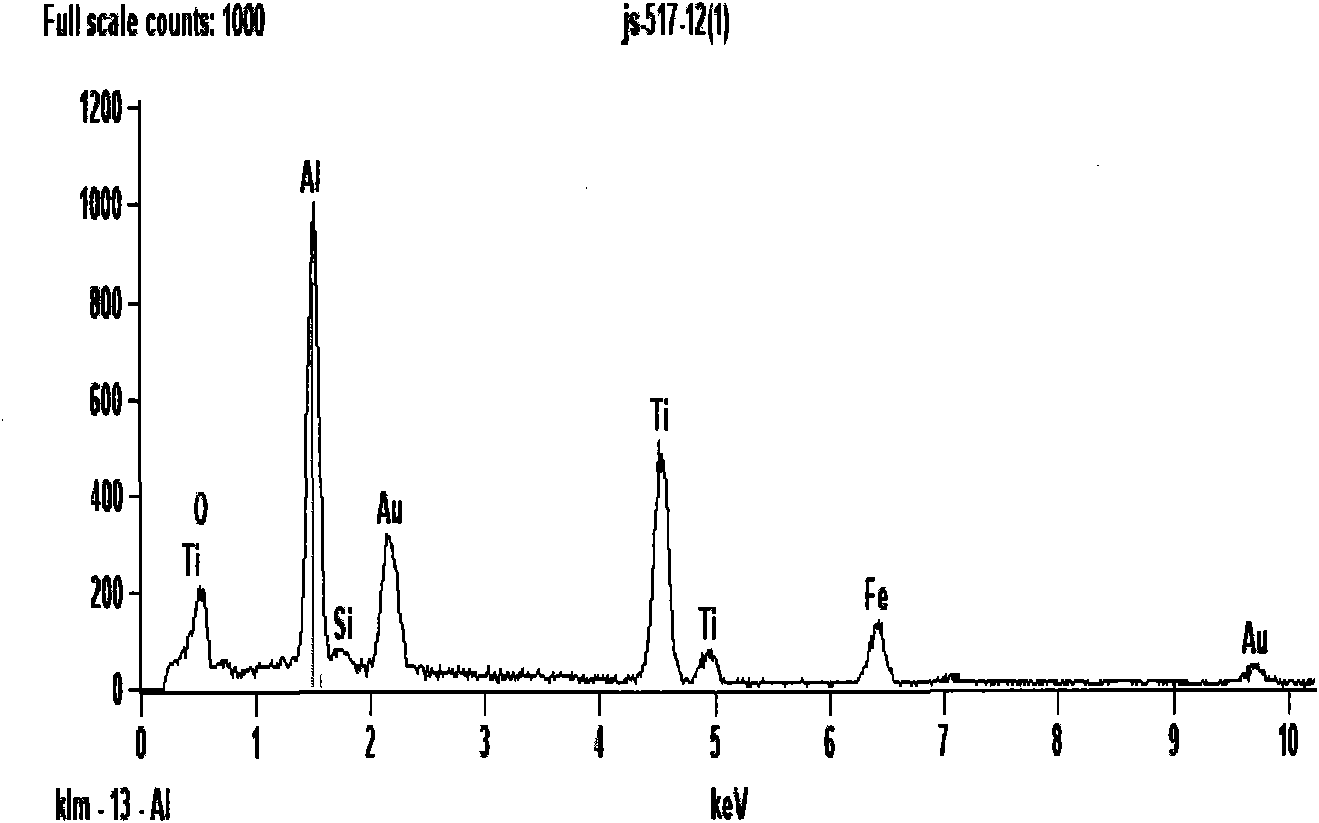

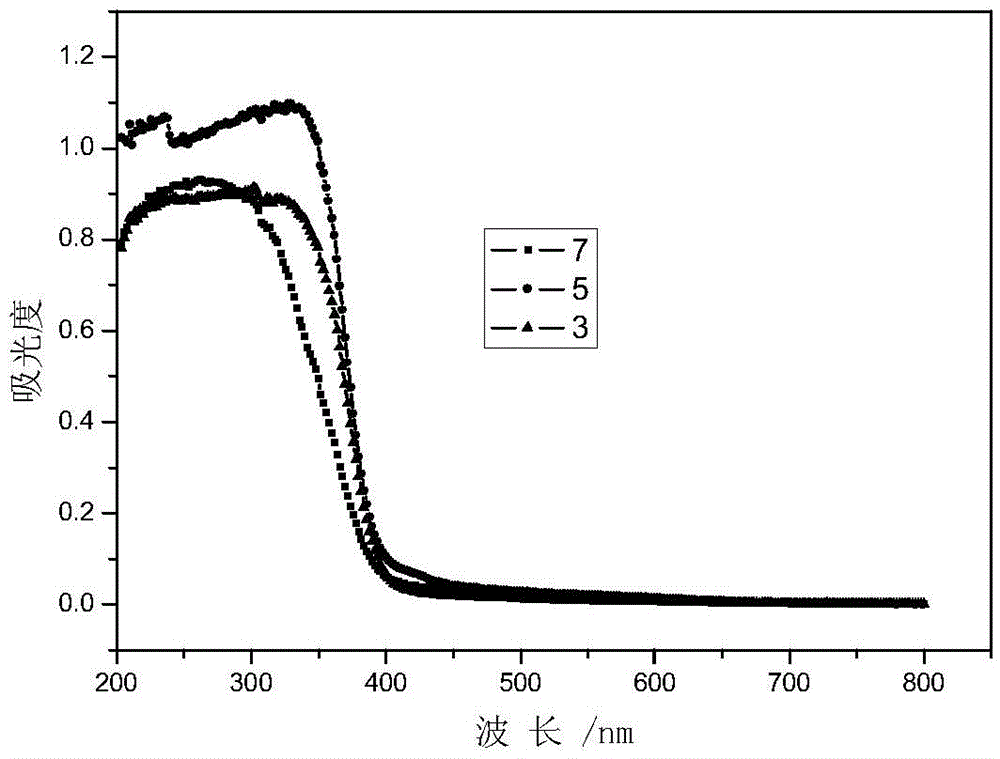

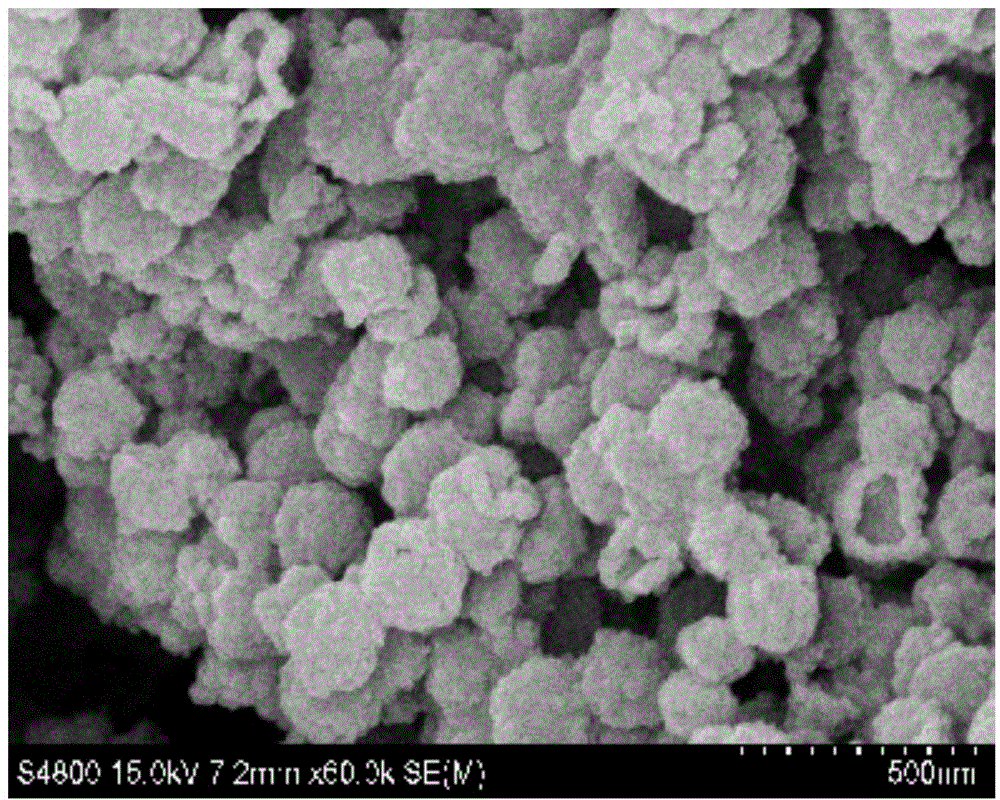

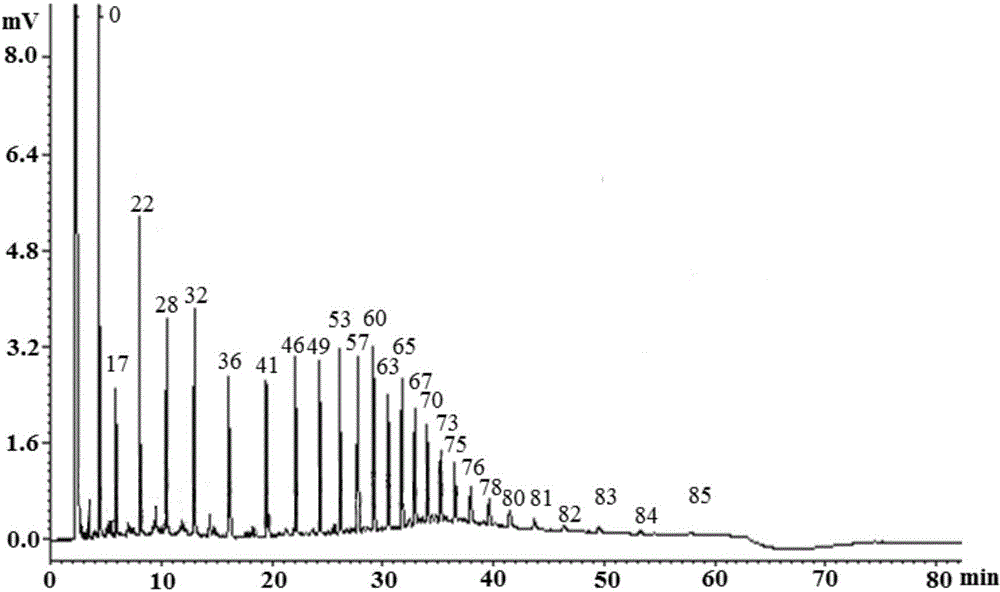

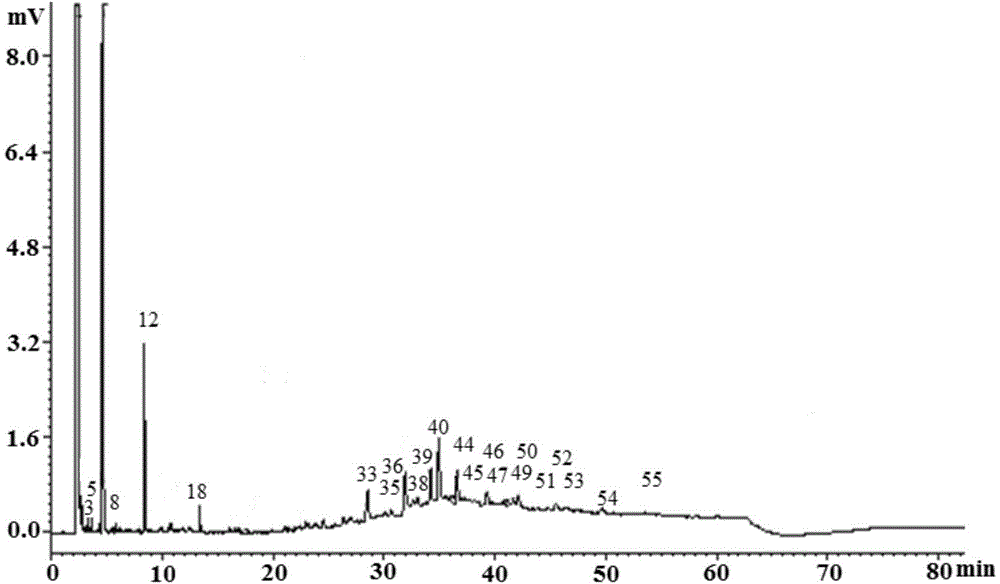

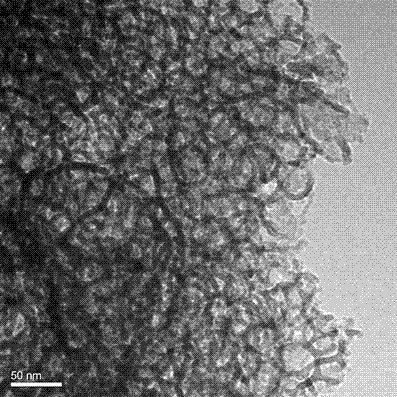

The invention discloses a method for preparing a novel Fe3+-doped TiO2 opened-port or closed-port hollow sphere composite catalyst, which comprises the following steps of: preparing a Fe3+-doped carbon / titanium dioxide nuclear shell particle by using a template method-hydrolysis cladding method and calcining for 2-4h at certain temperature to obtain the Fe3+-doped TiO2 opened-port or closed-port hollow sphere composite catalyst. The method can be applied to solar visible light catalytic degradation cation blue dye solution. In the invention, the Fe3+-doped TiO2 composite hollow sphere is prepared from ferric sources, titanium sources and carbon spheres with low cost, thereby the invention has the advantages of no pollution caused by used raw materials, simple process of method, no pollutant emission in the preparation process, short preparation period, less energy consumption and low cost, and can realize scale preparation, and the invention belongs to the green synthesis technology. A light absorption side of the composite light catalyst carries out red shift to a visible light region after the doping of Fe3+, so that the utilization ratio of the solar visible light is improved and the degradation efficiency under the visible light is greatly improved.

Owner:JIANGSU UNIV

Preparation and application of Sr<2+>-doped TiO2 composite hollow sphere photocatalyst

InactiveCN103599810ANo pollution in the processNo emissionsPhysical/chemical process catalystsWater/sewage treatment by irradiationPtru catalystPollutant emissions

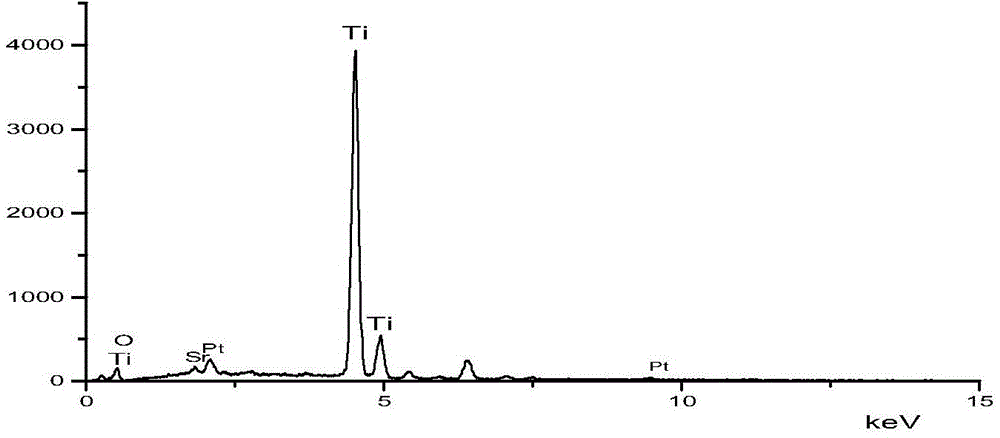

The invention discloses a preparation method of a Sr<2+>-doped TiO2 composite hollow sphere photocatalyst, and belongs to the environmental protection field. The method comprises the following steps: adopting a template method-hydrolysis coating method to prepare a Sr<2+>-doped C / TiO2 core-shell particle, and calcining the particle at a certain temperature for a certain time to obtain the Sr<2+>-doped TiO2 composite hollow sphere photocatalyst. The Sr<2+>-doped TiO2 composite hollow sphere photocatalyst prepared in the invention can be used in the visible photocatalysis degradation of a cationic dye solution. The method has the advantages of pollution-free raw materials, simple technology, no emission of pollutants in the preparation process, short preparation period, less energy consumption and low cost, is a green synthesis technology, and can realize the large scale preparation. The doping of Sr<2+> improves the visible response of the photocatalyst, improves the lives of electrons and cavities, promotes the transmission of photoelectrons and substantially improves the visible photocatalytic activity of the catalyst.

Owner:JIANGSU UNIV

Preparation method of petroleum-degrading acinetobacter junii bacillus

InactiveCN104450583ALow priceReduce degradation costBacteriaContaminated soil reclamationCooking & bakingMicrobial agent

The invention discloses a preparation method of petroleum-degrading acinetobacter junii bacillus, relates to a preparation method of a petroleum-degrading bacterial agent, and is used for solving the problems that transportation and storage are inconvenient due to the fact that the petroleum is directly degraded by using the bacterial fermentation liquor, the injuries to human bodies are relatively large, and a traditional microbial agent is low in cost. The method comprises the following steps: 1, selecting acinetobacter junii, inoculating into a culture medium, and cultivating to obtain a first-stage seed solution; 2, adding the first-stage seed solution into a fermentation culture medium, and cultivating to obtain a bacterial fermentation liquor; and 3, sterilizing corncob powder, rice bran and wheat bran, mixing any two of the corncob powder, the rice bran and the wheat bran, adding the bacterial fermentation liquor, sodium chloride and monopotassium phosphate to the mixture, mixing evenly, baking, and hermetically storing, so as to obtain the petroleum-degrading acinetobacter junii bacillus. The petroleum-degrading acinetobacter junii bacillus has the advantages of being low in price, easy to degrade, and free of secondary pollution; meanwhile, the soil fertility can be improved; and the method is applied to degradation of petroleum.

Owner:DAQING BRANCH OF HEILONGJIANG ACAD OF SCI

Waste biomass base degradation masterbatch, and preparation method, application and application method thereof

The invention relates to the technical field of degradable polymer materials, and in particular, relates to a waste biomass base degradation masterbatch, and a preparation method, an application and an application method thereof. The waste biomass base degradation masterbatch is prepared from the following raw materials in parts by weight: 5-25 parts of a waste biomass base, 5-15 parts of starch, 1-10 parts of a mineral powder, 0.1-3 parts of an ultraviolet photocatalytic degradation agent, 0.1-2 parts of an oxidation degradation aid, and 10-45 parts of biodegradable resin. With adopting of the application method, the waste biomass base degradation masterbatch prepared by the preparation method is used for degrading plastics and can be used for treating waste, that is to say, the waste biomass base can be used for degrading plastics which cannot be degraded, and an environmental-protection film product which can be used is prepared; and in addition, the application method is simple, and the raw material is the waste biomass base, so the cost for degrading the plastics is low.

Owner:东莞市标塑新材料有限公司

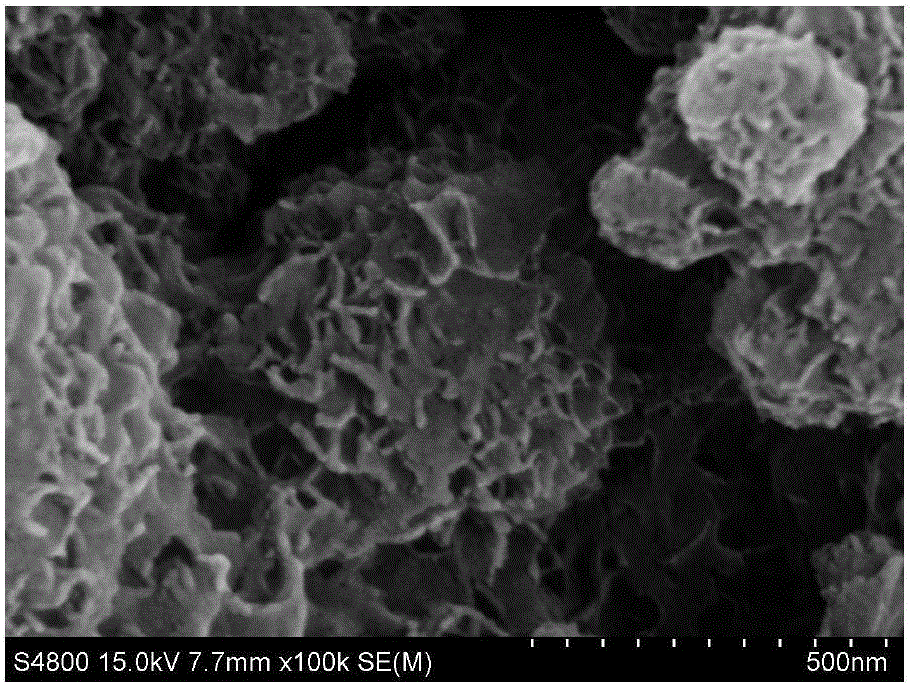

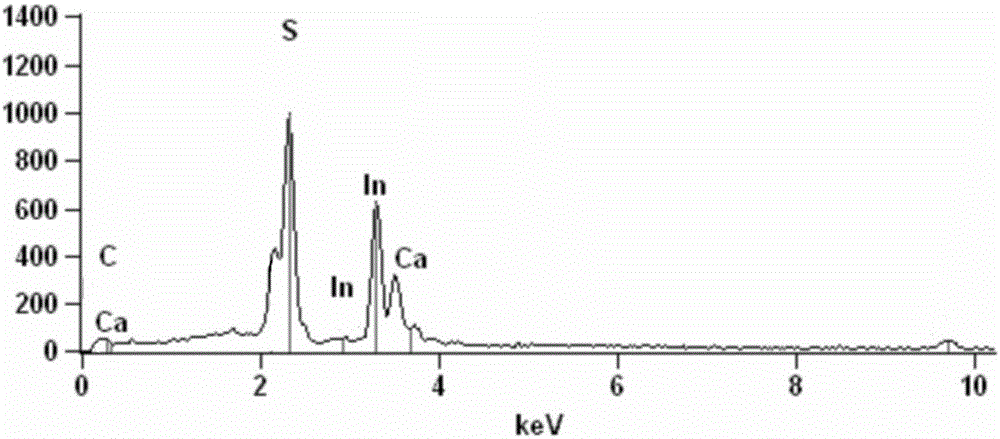

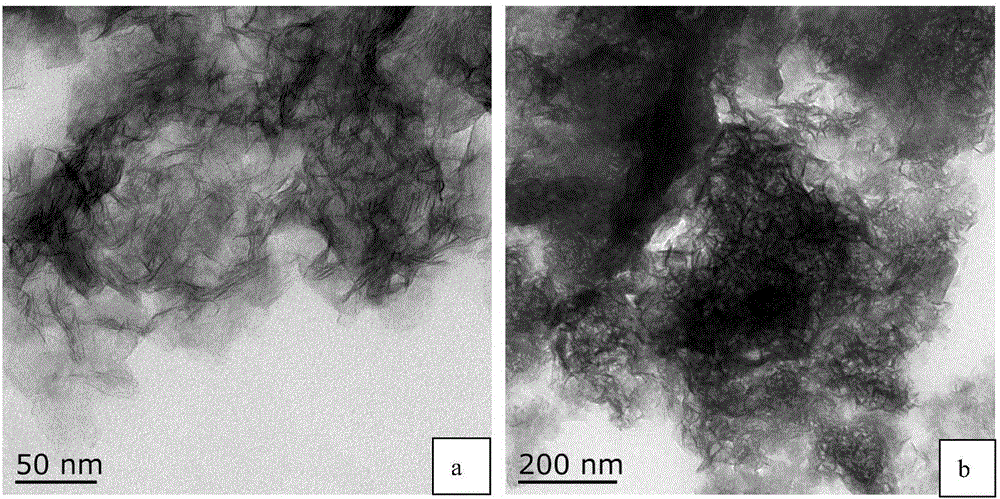

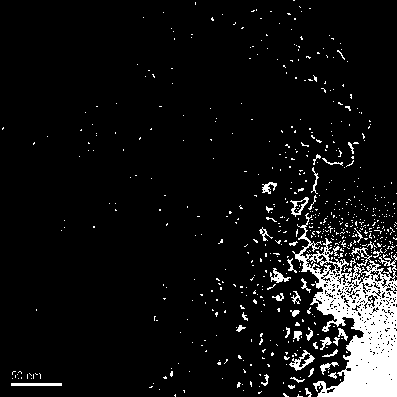

Method for preparing carbon quantum dot/flower-shaped indium and calcium sulfide composite photocatalysts and application thereof

ActiveCN106268869ANo emissionsLow costPhysical/chemical process catalystsWater/sewage treatment by irradiationIndiumTetracycline Hydrochloride

The invention discloses a method for preparing novel carbon quantum dot / flower-shaped indium and calcium sulfide (CQDs / CaIn2S4) composite photocatalysts, and belongs to the field of environmental protection. The method includes preparing the CQDs / CaIn2S4 composite photocatalysts by the aid of in-situ hydrothermal processes at certain temperatures. The CQDs / CaIn2S4 composite photocatalysts prepared by the aid of the method can be applied to catalytically degrading tetracycline hydrochloride solution under the sunlight or visible light. The method has the advantages that the method includes simple technologies, is free of pollutant discharge in preparation procedures and is short in preparation period and low in energy consumption and cost, is a green synthesis technique, and the carbon quantum dot / flower-shaped indium and calcium sulfide composite photocatalysts can be prepared on a large scale; the visible light response and the adsorption capacity of the carbon quantum dot / flower-shaped indium and calcium sulfide composite photocatalysts can be improved after CQDs (carbon quantum dots) are compounded, the service lives of electrons-holes can be prolonged, photoelectron transmission can be promoted, and the visible light photocatalytic activity of the carbon quantum dot / flower-shaped indium and calcium sulfide composite photocatalysts can be greatly improved.

Owner:JIANGSU UNIV

Method for degrading aflatoxin in peanut kernels

The invention discloses a method for degrading aflatoxin in peanut kernels, which comprises the following steps: enabling alcoholic solution to full contact with peanut kernels; separating the peanut kernels from the alcoholic solution; and drying the peanut kernels separated from the alcoholic solution in vacuum. When the method is used, the degradation rate of the aflatoxin in the peanut kernels by the alcoholic solution can reach above 98.5%. The method has the advantages of simple and easy operation, high degradation efficiency and low degradation cost, and can not cause residuals of noxious solvents. The method is novel, practical and reliable, and is suitable for industrialized application.

Owner:青岛天祥食品集团有限公司

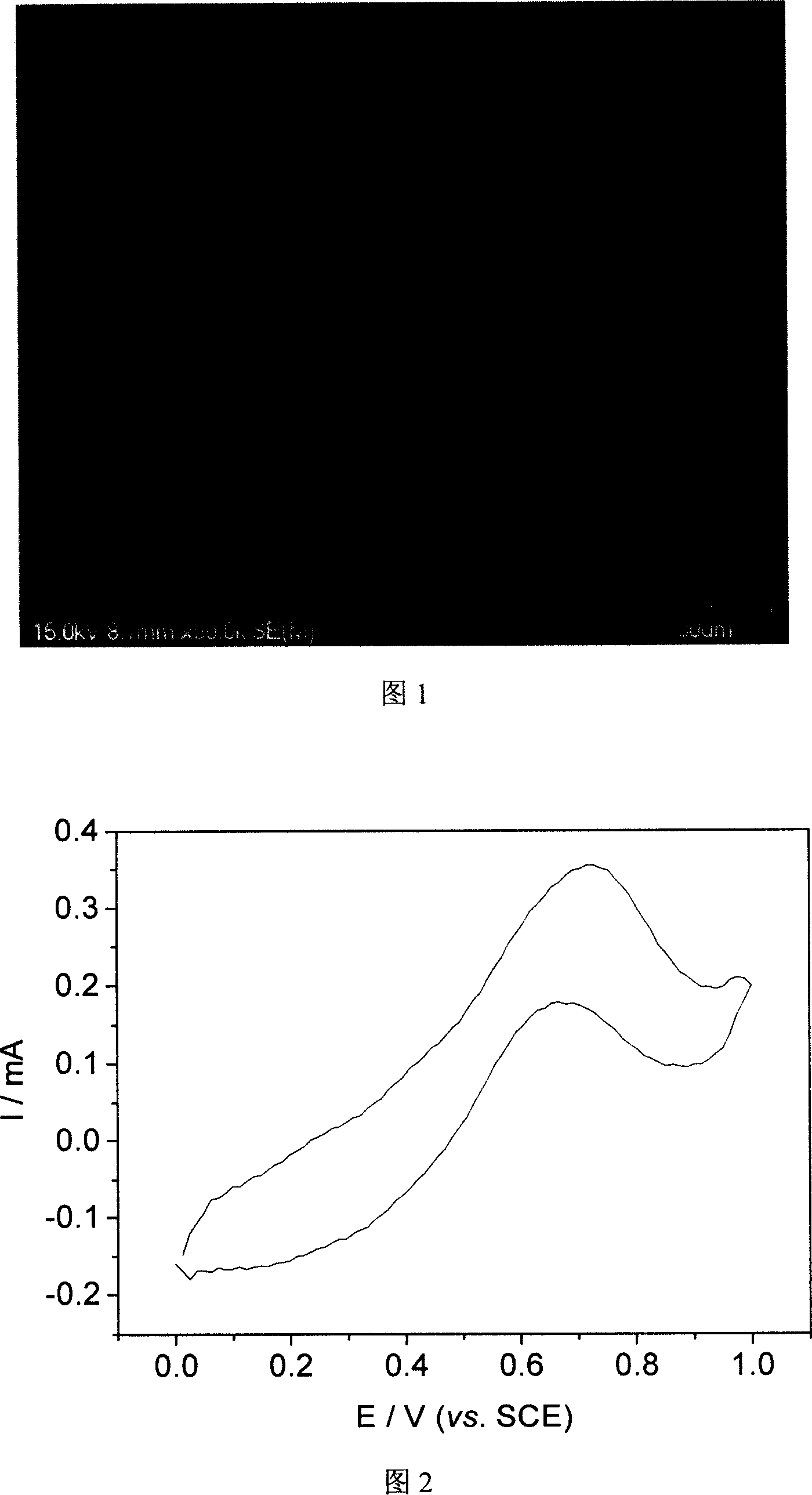

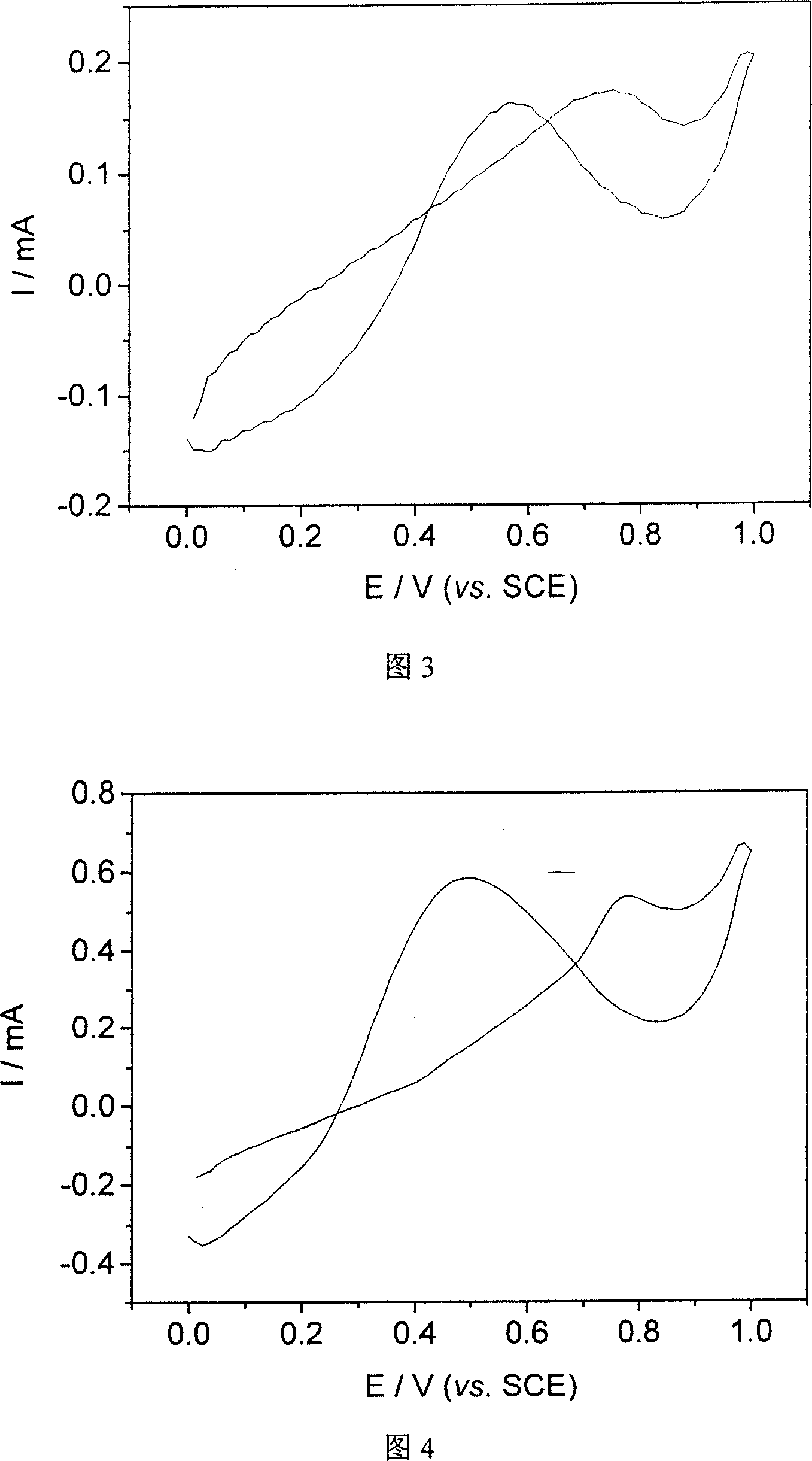

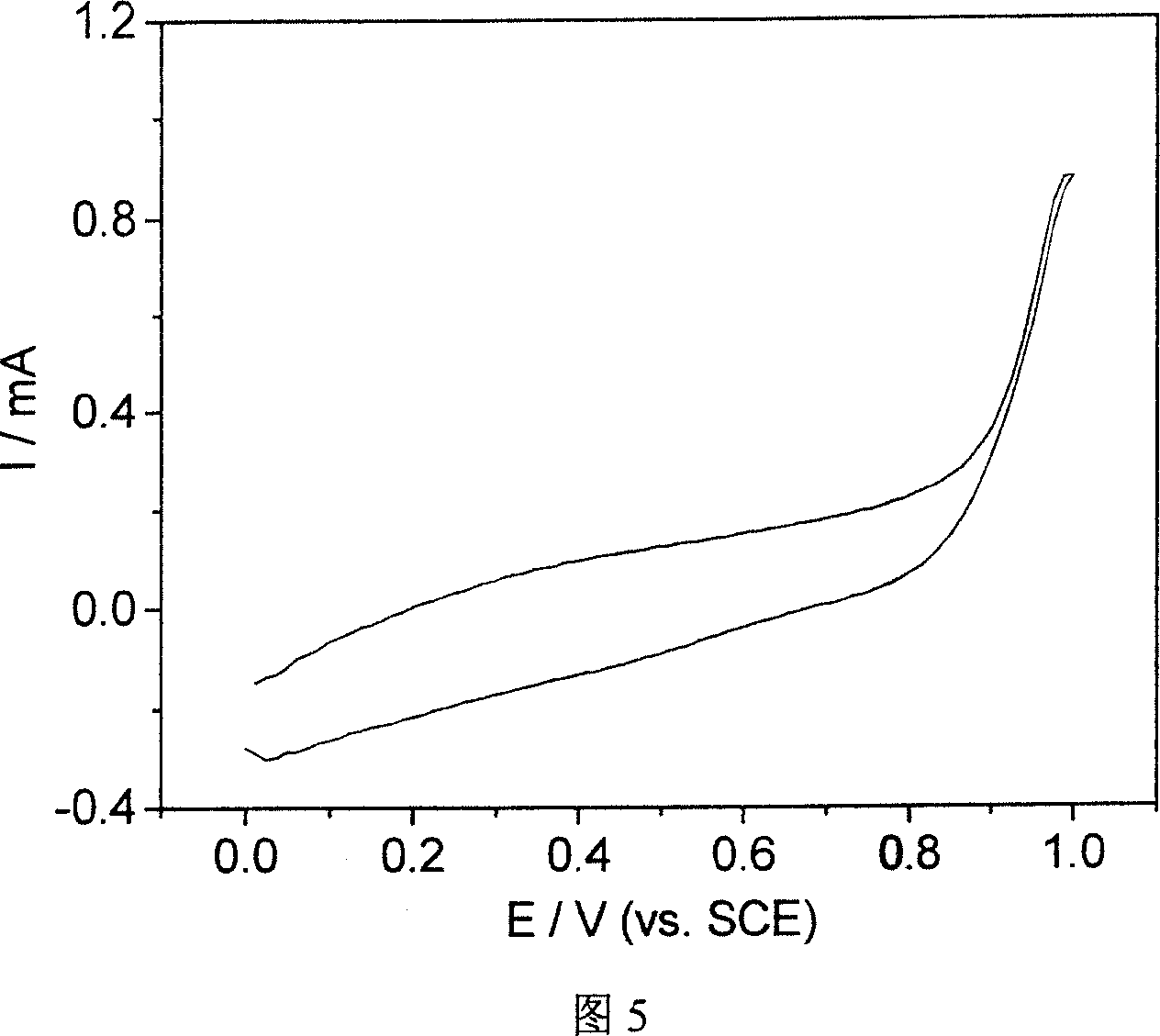

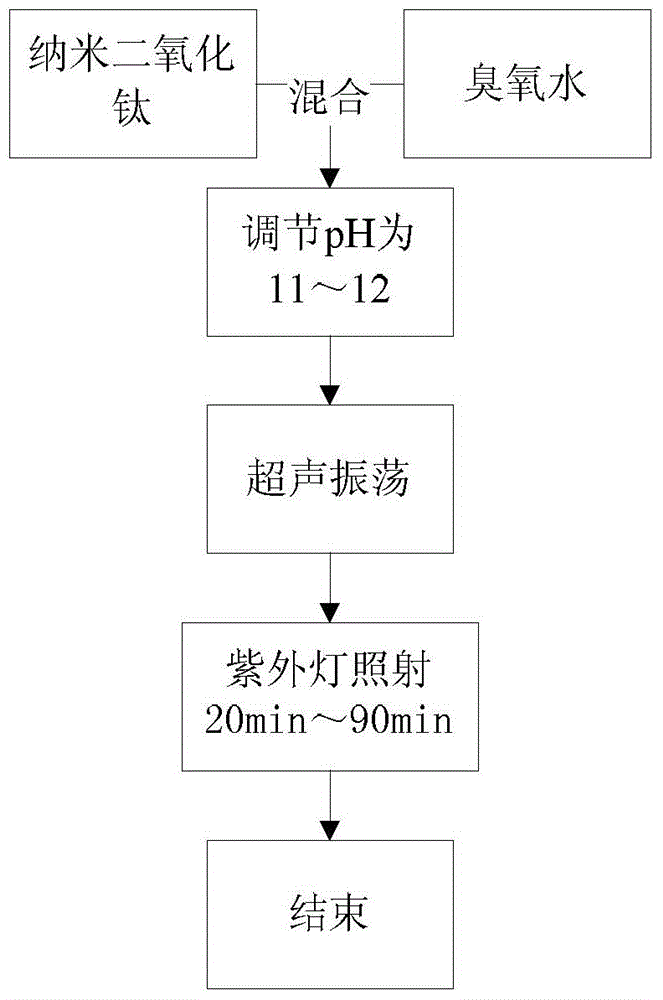

Polypyrrole electrolytic synthesis method

ActiveCN1995462AGood electrocatalytic oxidation propertiesReduce manufacturing costElectrolysis componentsElectrolytic organic productionElectrolysisSynthesis methods

The invention discloses an electrolyzing synthesizing method of polypyrrole, which comprises the following steps: dissolving pyrrole monomer in the Bronsted acid typed ionic liquid; placing in the electrolyser with working electrode, auxiliary electrode and reference electrode; selecting working electrode from stainless steel electrode or platinum electrode or nickel electrode or glass-carbon electrode; selecting the auxiliary electrode from platinum electrode or graphite electrode with large area; selecting reference electrode from Ag / AgCl electrode or saturated calomel electrode or large area of platinum electrode or standard hydrogen electrode.

Owner:ZHEJIANG UNIV OF TECH

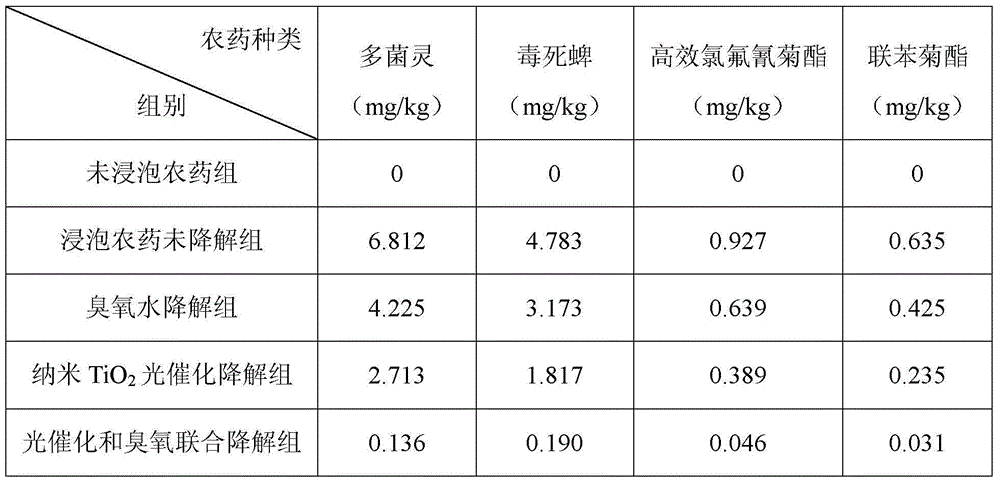

Method for degrading pesticide residues on fruit and vegetables

InactiveCN104055198APromote degradationImprove efficiencyFood treatmentPesticide residueUltraviolet lights

The invention provides a method for degrading pesticide residues on fruit and vegetables. The method comprises the steps of mixing, adjusting pH, performing ultrasonic oscillation and UV (ultraviolet light)-irradiation. The steps are specifically as follows: mixing nanometer TiO2 with ozone water and adjusting pH to 11-12 with a pH modifier; performing ultrasonic oscillation, thereby acquiring a mixed solution; putting the fruit and vegetables into the mixed solution, introducing air into the mixed solution and irradiating for 20min-90min with a UV lamp, thereby finishing the degrading of the pesticide on the fruit and vegetables. According to the invention, after photocatalysis and ozone combined degradation, the pesticide residues on the fruit and vegetables are quickly degraded. The method has the advantages of high efficiency, low cost, safety, environmental protection, and the like.

Owner:HUNAN AGRI PRODS PROCESSING INST

Method for catalytic alcoholysis of PLA (Polylactic Acid) by CaO/MCF (Mesocellular silica Foam) mesoporous basic molecular sieve

ActiveCN107382718ALarge hole volumeLarge and adjustable apertureMolecular sieve catalystsPreparation by ester-hydroxy reactionMolecular sieveDistillation

The invention discloses a method for the catalytic alcoholysis of (Polylactic Acid PLA) by a CaO / MCF (Mesocellular silica Foam) mesoporous basic molecular sieve, and belongs to the technical field of the high-value conversion of waste resources. The method is a reaction of degrading the PLA by using the CaO / MCF mesoporous basic molecular sieve as a catalyst and methanol as a reactant; after the reaction is finished, a methyl lactate product is recovered through operations of filtration, distillation and the like; the alcoholysis rate of the PLA can reach 98 percent or above; the selectivity of the product methyl lactate can reach 90 percent or above. According to the method, CaO / MCF is used as the catalyst; the methanol is used as a reactive raw material; a reaction condition is mild; a reaction method is simple; the price of the raw material is low; a process of recovering the product is simple; the catalyst can be repeatedly utilized; the degradation efficiency is high; the cost of degrading the PLA can be greatly industrially decreased; the method is actually an economical and effective way, and is worth popularizing.

Owner:QINGDAO UNIV OF SCI & TECH

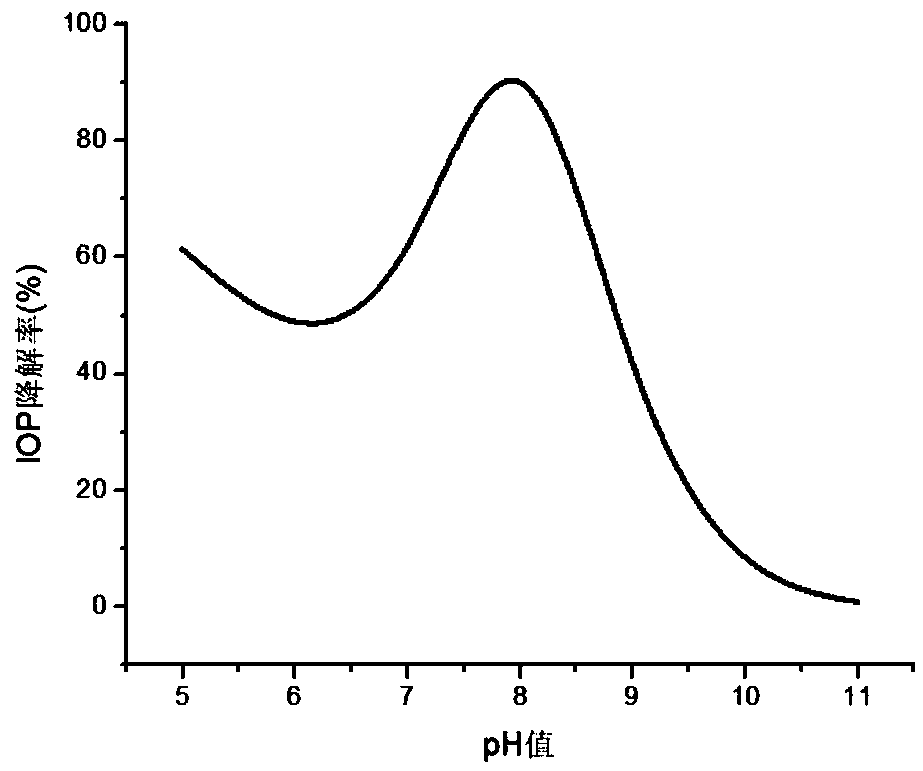

Method for degrading iopromide-containing wastewater

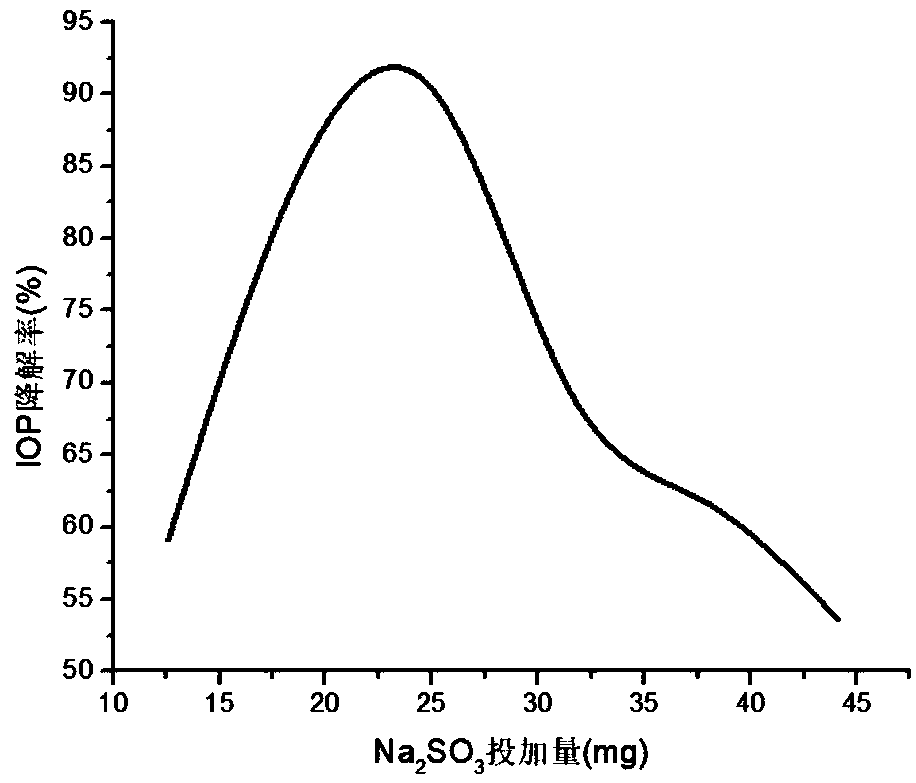

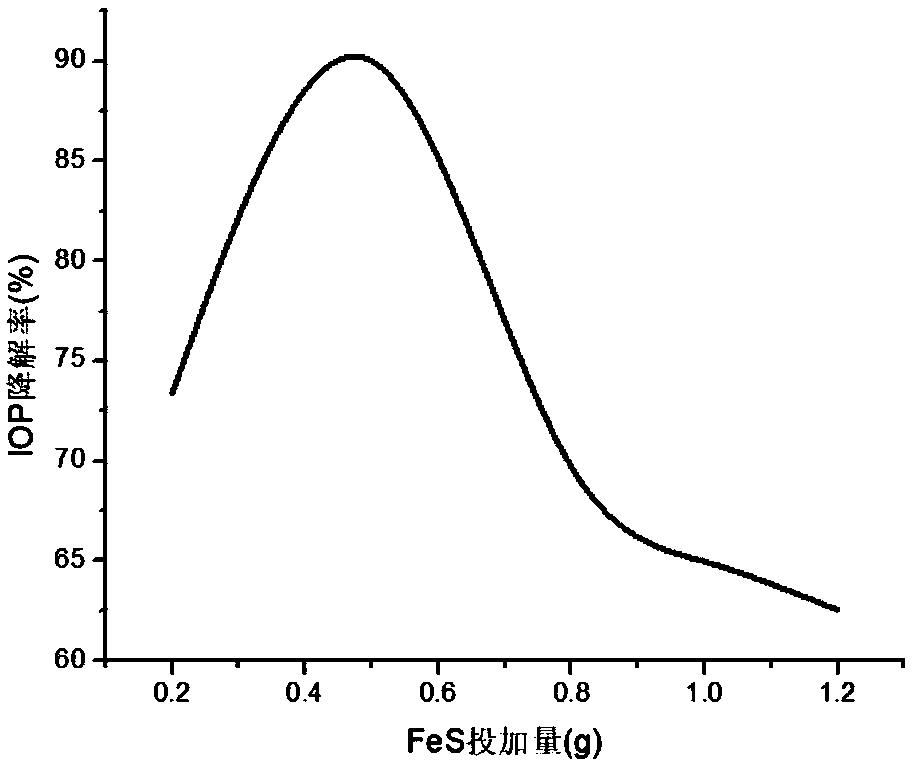

InactiveCN109231565APromote degradationSolve problems such as corrosionWater contaminantsMultistage water/sewage treatmentSulfite saltEconomic benefits

The invention discloses a method for degrading iopromide-containing wastewater, and belongs to the field of treatment of organic wastewater. The method is characterized in that ferrous sulfide is usedas a catalyst, and sodium sulfite is used as an oxidant, so as to effectively degrade the iopromide. The method has the advantages that the organic pollutant, such as iopromide, can be effectively degraded, and the degrading rate can reach 90%; when the iopromide-containing wastewater is treated by the method, the investment of materials is low, the wastewater treatment effect is good, the speedis quick, and the good social and economic benefits are realized.

Owner:LIAONING UNIVERSITY

Co/sepiolite catalyst and preparation method and application thereof

InactiveCN108043407AWide variety of sourcesLow costOrganic compound preparationCatalyst activation/preparationMicrowaveActive component

The invention discloses a Co / sepiolite catalyst and a preparation method and application thereof. The Co / sepiolite catalyst includes sepiolite serving as a carrier and Co serving as an active component and loaded on the surface of the sepiolite. According to the Co / sepiolite catalyst, sepiolite serving as a raw material is wide in source and low in cost, the degradation cost can be effectively reduced, and the Co / sepiolite catalyst is suitable for large-scale industrial application. Moreover, the Co / sepiolite catalyst is cooperated with a microwave field, the conversion rate of degraded ligninis very high, the conversion rate of lignin can reach 85% or above, the selectivity of a phenolic compound exceeds 55%, and the selectivity of guaiacol exceeds 20%.

Owner:ANHUI UNIV OF SCI & TECH

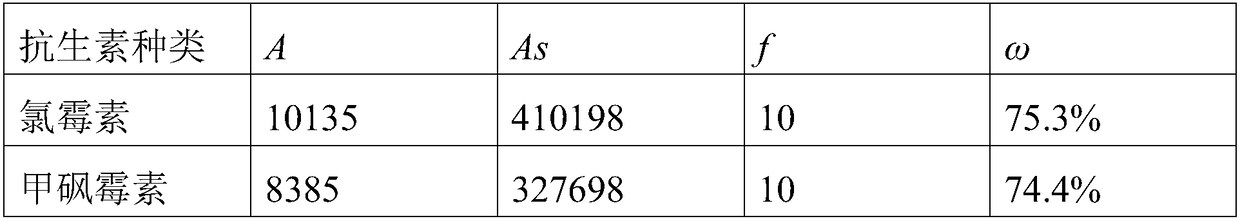

Formula for degrading antibiotic fungi residues by microbe mixing solid fermentation method and technology thereof

The invention discloses a formula for degrading antibiotic fungi residues by a microbe mixing solid fermentation method. The formula comprises a functional bacteria phase is mixed by two bacteria, a microzyme, two aspergillus, and two or three trichoderma species; and a fermentation matrix phase which is a mixture of fungi residues with water content of 50-75% or dried fungi residues and an auxiliary material. The method also comprises a technology for degrading antibiotic by the microbe mixing solid fermentation method. The technology comprises the following steps: 1) preparing the functional bacteria phase and preparing the mixing bacterial strain; 2) preparing the fermentation matrix phase; 3) placing the functional bacteria phase and the fermentation matrix phase obtained in the step 1) and 2) into a fermentation body for primary fermentation; and 4) performing secondary fermentation when the antibiotic residual quantity is higher than 10%. A scheme of the present invention is characterized in that an aerobic solid state fermentation mode is employed, metabolism movement of functional microbe is used, the antibiotic residual quantity in the fungi residues is degraded, risk is reduced or eliminated, and quantitative reduction is simultaneously realized.

Owner:刘仰化

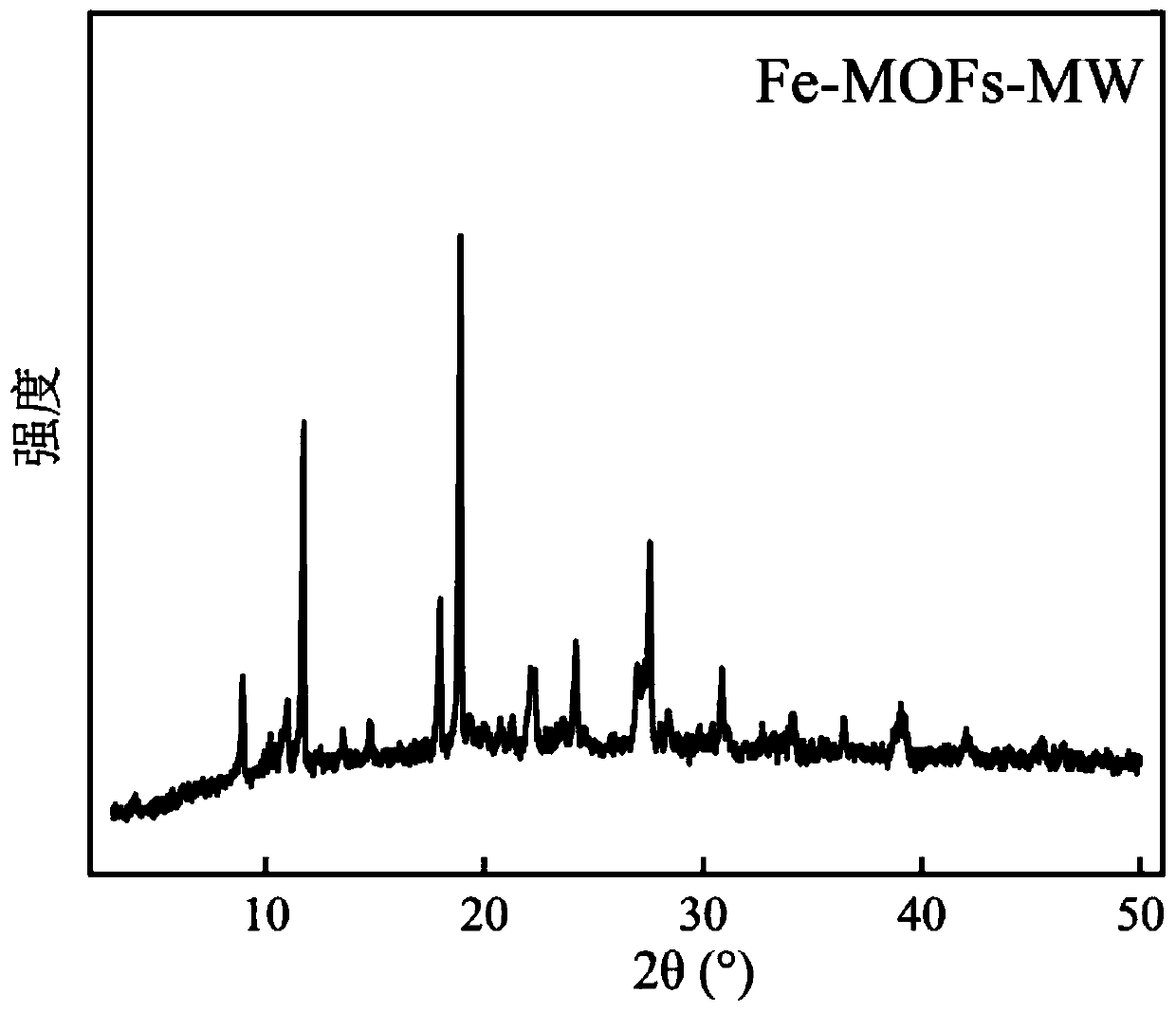

Iron oxide doped iron metal organic framework and green macro preparation method and application thereof

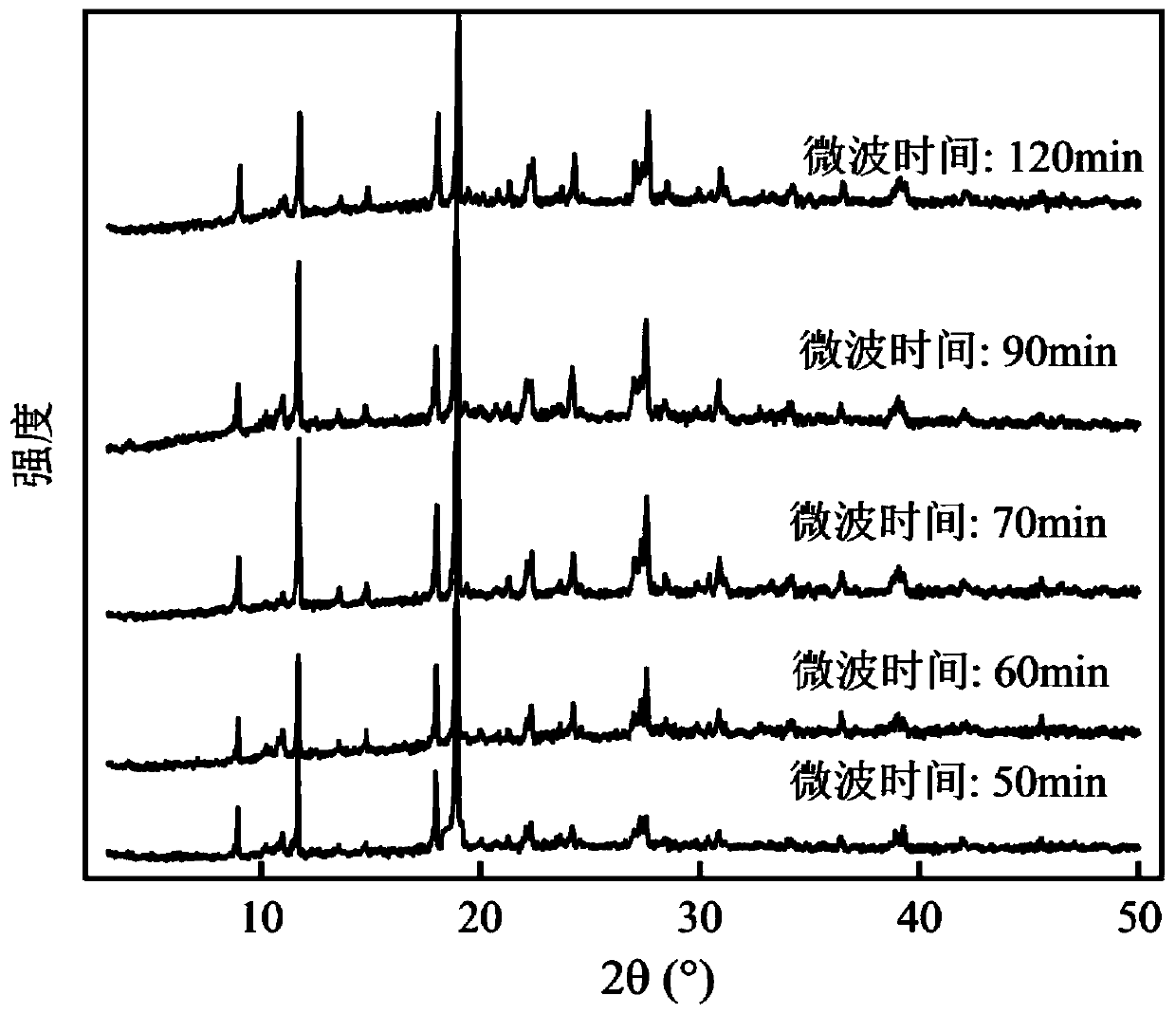

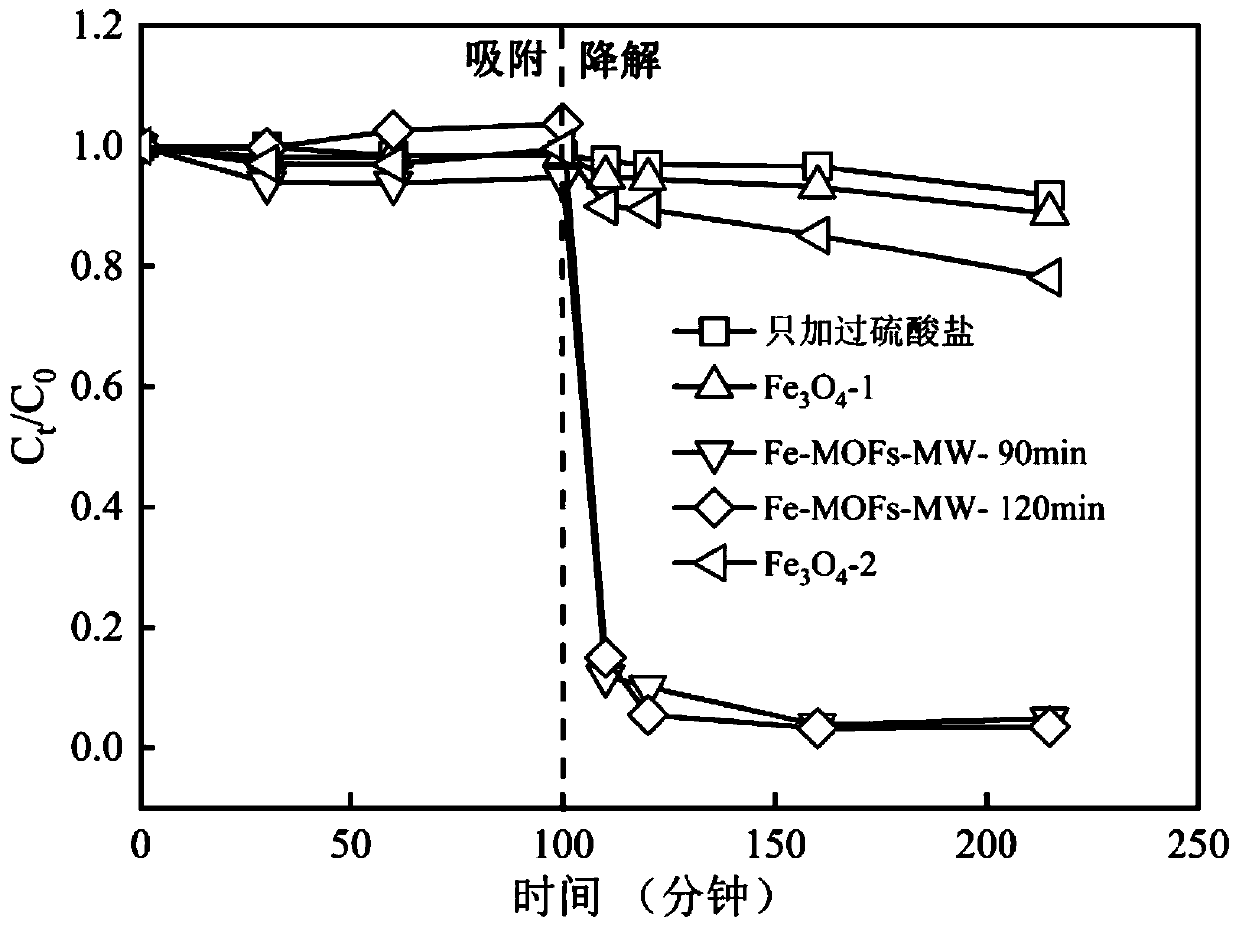

ActiveCN110548544ATo avoidImprove environmental qualityOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsMetal-organic frameworkVacuum drying

The invention discloses an iron oxide doped iron metal organic framework material and a green macro preparation method and an application thereof. The preparation method comprises the following steps:(1) grinding and mixing ferrous sulfate heptahydrate and trimesic acid evenly, adding a sodium hydroxide solution, transferring to a micro wave reaction kettle, carrying out ultrasonic treatment, heating, and cooling to room temperature to obtain a mixed liquid; and (2) washing the mixed liquid obtained in the step (1), centrifuging to obtain a solid, washing the obtained solid, and drying in vacuum to obtain the iron oxide doped iron metal organic framework material. A heterogeneous catalyst is synthesized by a microwave solid-phase co-crystallization method, the synthesis cycle is greatly shortened, the synthesis process is green, environmentally friendly and efficient, and the synthesized iron oxide doped iron metal organic framework material can make full use of an unsaturated metal site to efficiently activate persulfate to degrade organic pollutants, avoid the generation of iron mud, reduce the cost of synthesis of the heterogeneous catalyst material and the cost of degradationof organic pollutants, and improve water environment quality.

Owner:SOUTH CHINA UNIV OF TECH

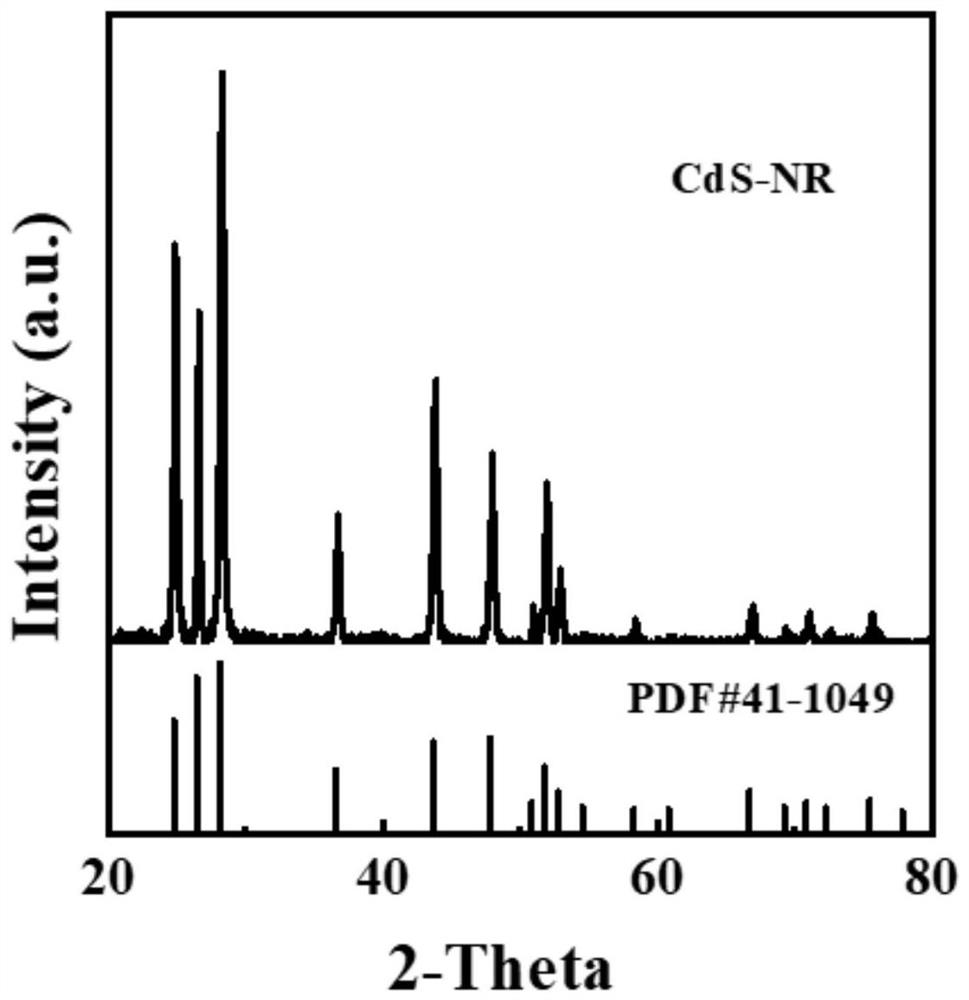

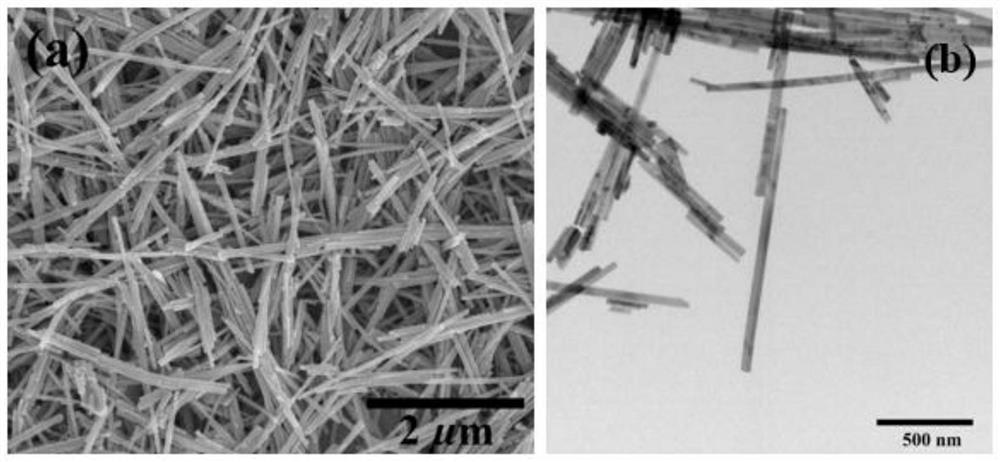

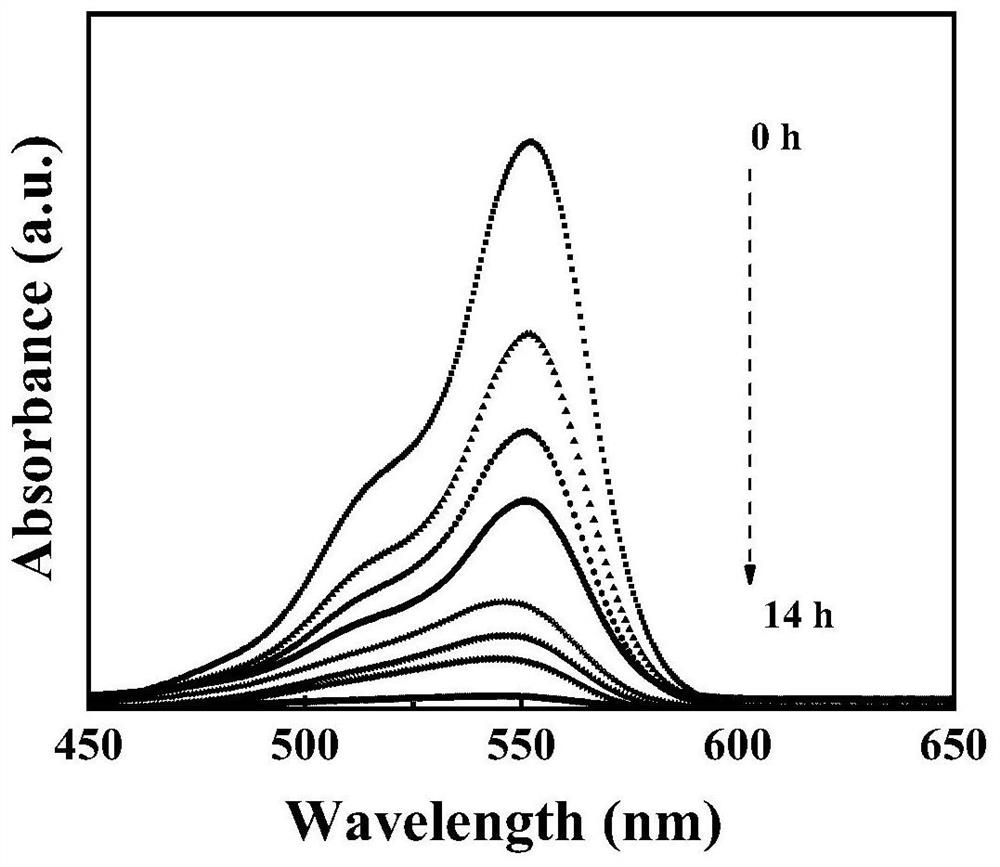

Cadmium sulfide nanorod and method for friction catalytic degradation of organic pollutants

InactiveCN111847498AEfficient enrichmentOvercoming the problem of low response efficiencyMaterial nanotechnologyPhysical/chemical process catalystsWurtzite crystal structureLight response

The invention particularly relates to a cadmium sulfide nanorod and a method for friction catalytic degradation of organic pollutants. The cadmium sulfide nanorod is of a hexagonal wurtzite crystal structure, belongs to a non-centrosymmetric point group, and has a specific diameter of 40-50 nm and a length-diameter ratio of 8: 1 to 100: 1. According to the cadmium sulfide nanorod and the method for friction catalytic degradation of organic pollutants in the invention, operation is simple; the piezoelectric property of cadmium sulfide with a specific structure is utilized, so mechanical energyin an environment can be enriched more effectively; organic matter degradation can be achieved only through magnetic stirring under a dark condition, so the problem that a conventional photocatalysisexperiment is low in visible light response efficiency is solved; and meanwhile, the demand for equipment capable of generating sound waves in piezoelectric catalysis is avoided, sewage degradation efficiency is greatly improved, sewage treatment cost is reduced, and the method is suitable for application and popularization.

Owner:QILU UNIV OF TECH

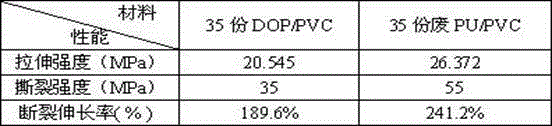

Polyurethane polymer capable of being quickly degraded as well as preparation method and application thereof

ActiveCN104788641AImprove mechanical propertiesEasy to processOrganic compound preparationPreparation by ester-hydroxy reactionState of artAcetic acid

The invention relates to the technical field of modified polymer materials, and especially relates to a polyurethane polymer capable of rapidly decomposing, a preparation method and applications thereof. The polyurethane polymer comprises hard sections and soft sections, wherein the hard sections comprise analogous glycolic acid structures. Degradable analogous glycolic acid structures are introduced into the polyurethane hard sections of the polyurethane polymer, and the structures are easy to degrade in natural environment; furthermore the polymer has a good mechanical performance and processing property, and can be applied to fields of food package, ground film, synthesis leather, and shoe materials.

Owner:SHANGHAI HUAFENG MATERIAL TECH RES INST LLP +1

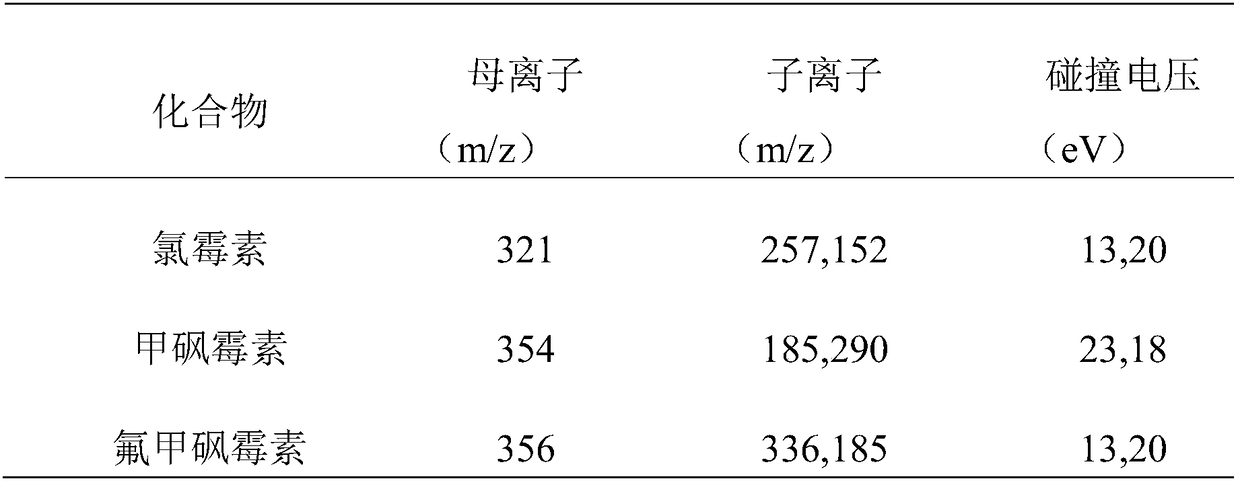

Method for degrading chloramphenicol antibiotics in soil or clay

ActiveCN108188165ALow costEasy to operateComponent separationContaminated soil reclamationAntibiotic YCHLORAMPHENICOL TOXICITY

The invention discloses a method for degrading chloramphenicol antibiotics in soil or clay. According to the method, ferrous ions or peroxysulphate is used for degrading chloramphenicol compounds in the soil or clay. The method is simple in operation, low in cost, free of pollution and high in speed, pollution to by-products is avoided, and the removal rate on the chloramphenicol antibiotics in the soil is high.

Owner:SHANGHAI ACAD OF AGRI SCI

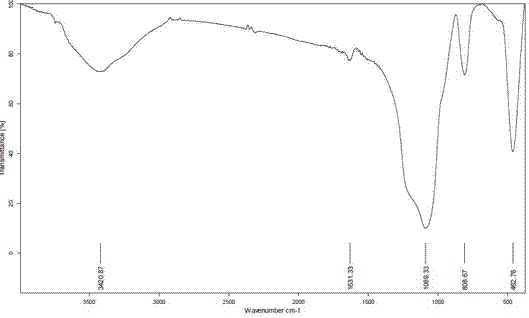

Magnetic composite photocatalyst as well as preparation method and application thereof

InactiveCN105879890ASimple and convenient separabilityEasy and convenient to reusePhysical/chemical process catalystsWater/sewage treatment by irradiationPhoto catalysisAntibiotic drug

The invention discloses a magnetic composite photocatalyst as well as a preparation method and an application thereof. The magnetic composite photocatalyst adopts a Fe3O4 nanoparticle as a core, the surface of the Fe3O4 nanoparticle is coated with a SiO2 inert layer, Ag3PO4 is enriched on the surface of the SiO2 inert layer, and the surface of Ag3PO4 is modified with AgCl. The preparation method of the magnetic composite photocatalyst comprises steps as follows: preparing Fe3O4-SiO2 carriers, preparing Fe3O4-SiO2@Ag3PO4 and preparing Fe3O4-SiO2@Ag3PO4 / AgCl. The magnetic composite photocatalyst can be applied to treatment of antibiotic wastewater and has the advantages of high visible light utilization rate, convenient recycling, stable photocatalytic performance and high antibiotic degradation efficiency.

Owner:CHANGSHA UNIVERSITY

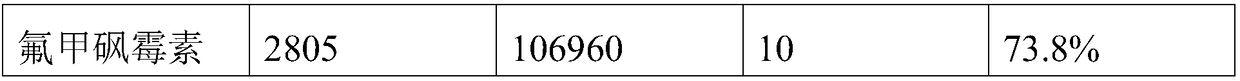

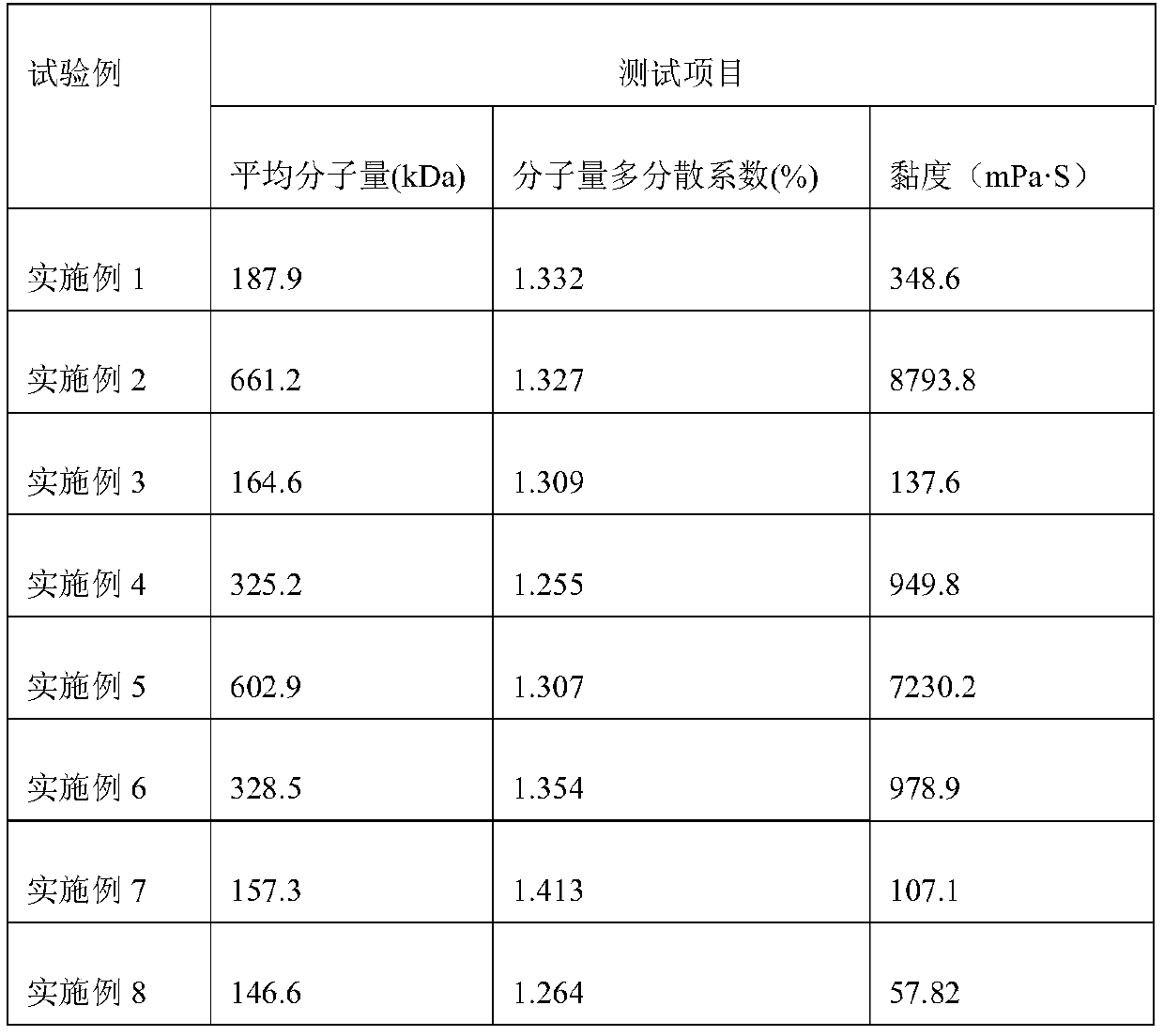

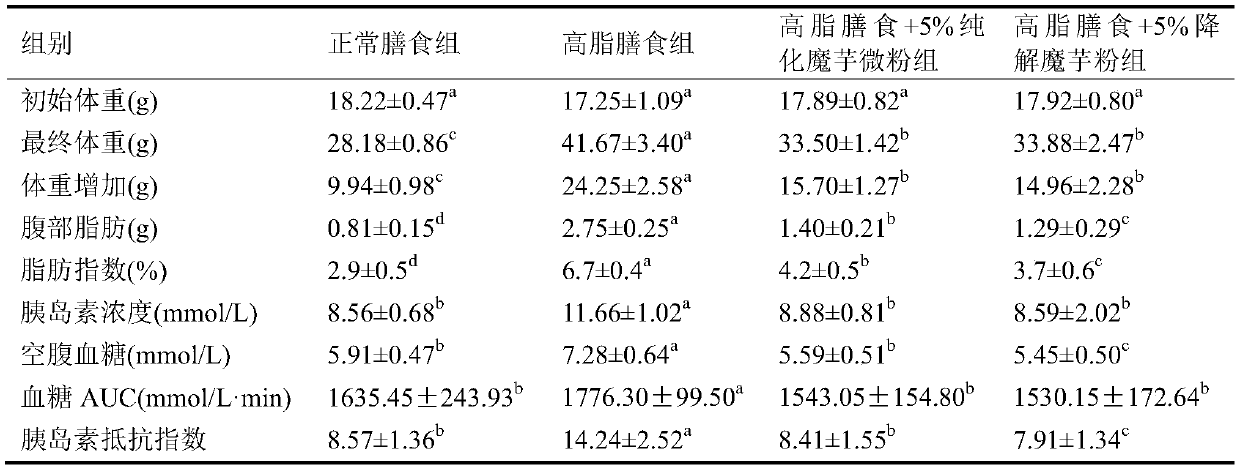

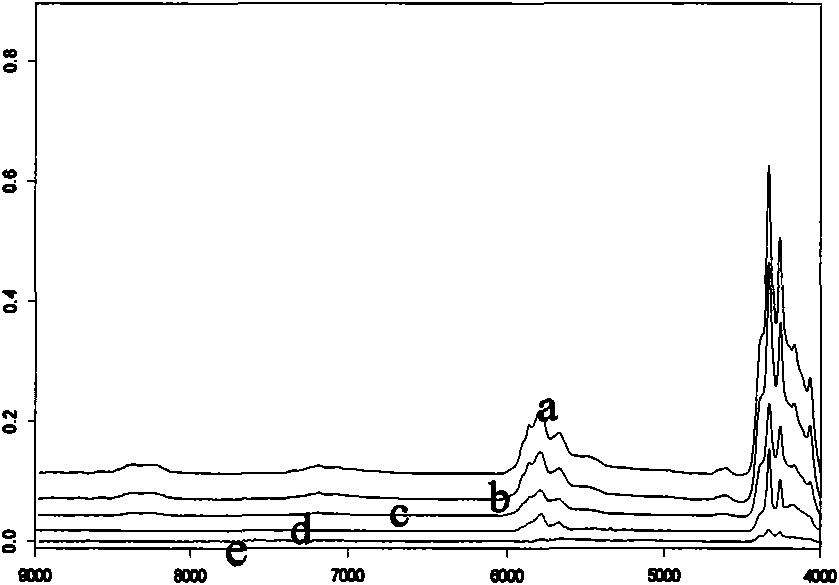

Degradation method of konjac glucomannan

The invention relates to a degradation method of konjac glucomannan, which comprises the following steps: preparing a water-containing konjac flour mixture of which the water content is 5-60%; and carrying out heterogeneous damp-heat degradation on the water-containing konjaku flour mixture to obtain a low-molecular-weight konjaku polysaccharide degradation product. According to the degradation method, a heterogeneous system is adopted for degradation reaction; time-consuming and energy-consuming dehydration operation after degradation of the konjac glucomannan homogeneous phase (prepared intosol) can be avoided; meanwhile, organic solvents such as ethyl alcohol used for limiting swelling of konjac polysaccharide in other heterogeneous degradation methods can be avoided, operation steps are simple, time is saved, efficiency is high, the molecular weight distribution range of degradation products can be adjusted by controlling reaction conditions, and large-scale production is facilitated.

Owner:HUAZHONG AGRI UNIV

Method for degrading crude oil with bacillus

InactiveCN101607120APromote degradationEasy to operateWater contaminantsMicroorganism based processesSingle typeNutrient solution

The invention discloses a method for degrading crude oil with bacillus. Degradation solution is prepared according to the ratio of 80 to 150 ml of crude oil culture solution to 0.8 to 1.5 ml of bacillus solution, the degradation solution is degraded for 10 to 30 days with the temperature being 30 to 37 DEG C and the shaking condition being 150 to 200 r / min, the concentration of the bacillus solution is 10 to 10 bacilli / ml, and the mass concentration of the crude oil culture solution is 0.5 to 5 percent; the method adopts single type of bacillus, the trouble that the prior degradation bacillus solution is mainly prepared by two or more cultures is avoided, the operation is more convenient, additional nutrient solution is not required to be prepared, additional surface active agent is not required to be prepared either, the degradation cost can be lower, the effect of the method on crude oil degradation is good, and crude oil can be totally degraded in about 20 days. The invention is a method for degrading crude oil with bacillus, with the advantages of convenient operation, lower cost and better degradation effect.

Owner:NINGBO UNIV

Method for degrading antibiotics in livestock farm wastewater by aid of ultraviolet irradiation processes

InactiveCN109354302AFast degradationWide variety of sourcesWater/sewage treatment by irradiationWater treatment compoundsPersulfateSlurry

The invention discloses a method for degrading antibiotics in livestock farm wastewater by the aid of ultraviolet irradiation processes. The method includes regulating a pH (potential of hydrogen) value of the livestock farm wastewater by acid and alkali solution; adding Providencia rettgeri solution and bacillus subtilis solution and preliminarily degrading the antibiotics; adding persulfate andferrous sulfate, forming advanced oxidation systems and then starting ultraviolet irradiation; carrying out oxidation / light degradation and continuing to degrade the antibiotics in biogas slurry; adding Tris-HCl solution and recycling the advanced oxidation systems; carrying out secondary oxidation / light degradation and degrading the antibiotics. The method has the advantages that the antibioticsin the wastewater can be degraded by the aid of technologies, and the method is high in degradation speed and degradation efficiency; good degradation effects can be realized, the antibiotics can be degraded into small-molecular substances, materials used in degradation procedures are low in cost and can come from extensive sources, and the antibiotics in the wastewater can be effectively degraded.

Owner:陈先锐

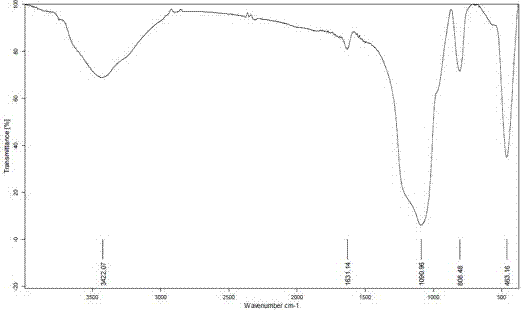

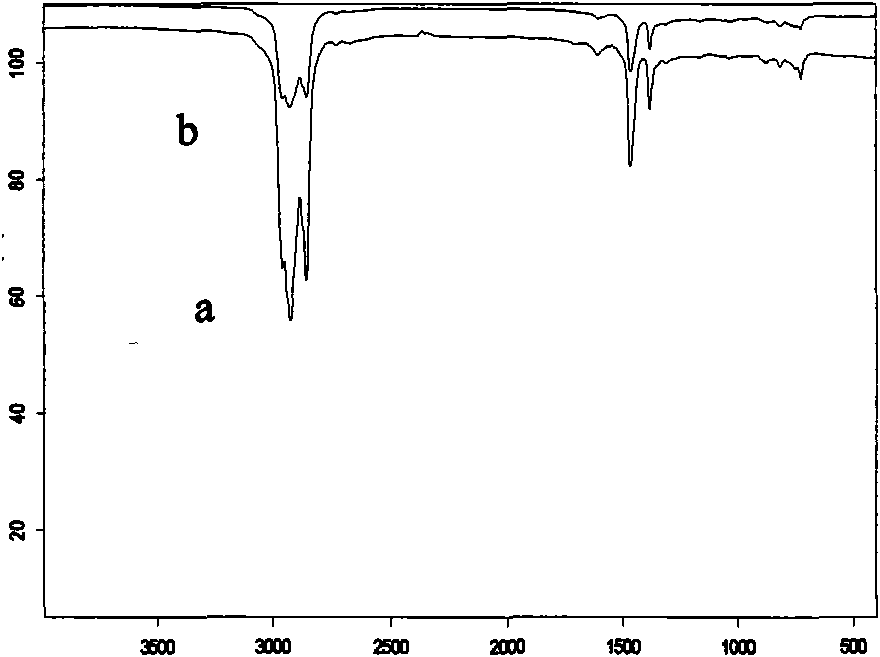

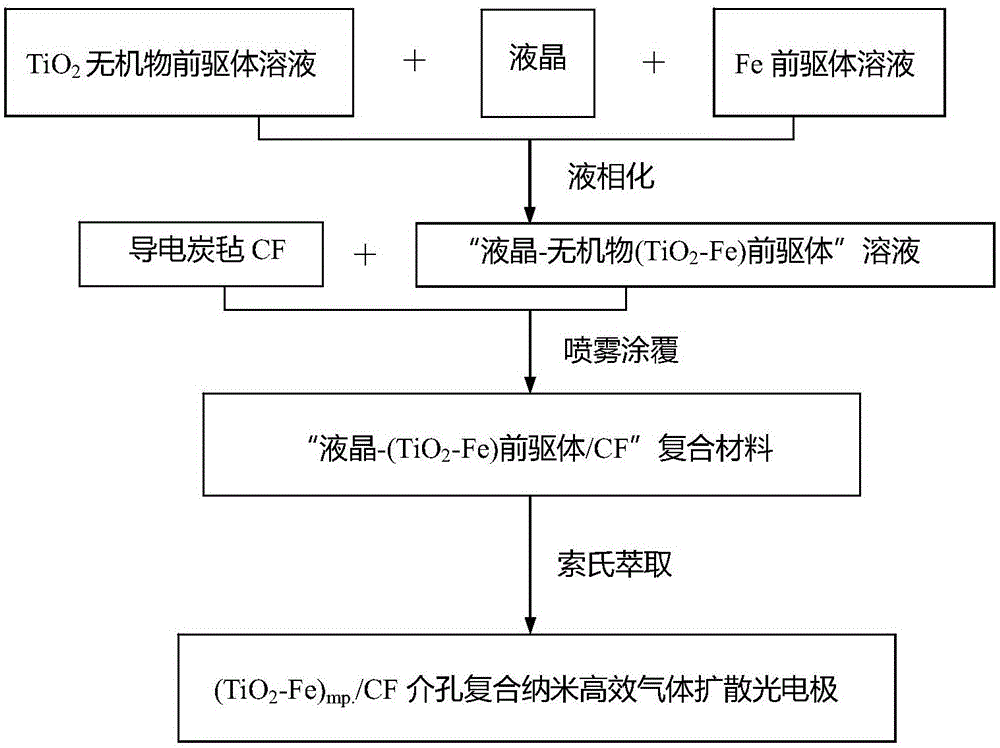

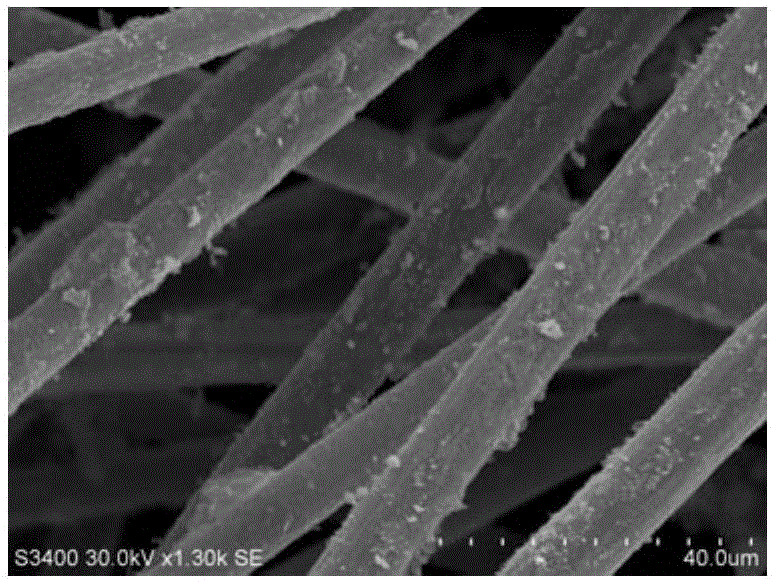

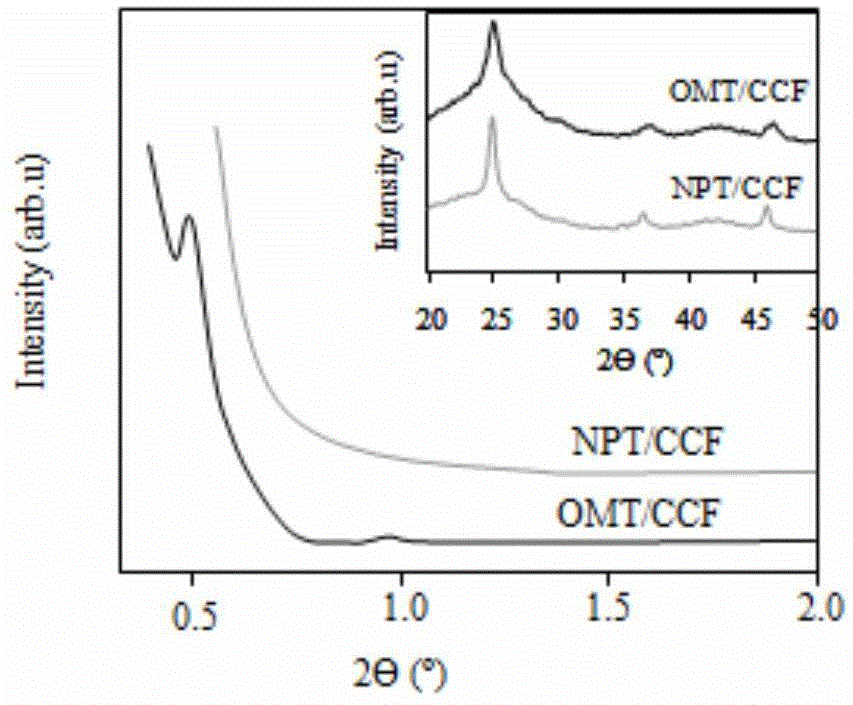

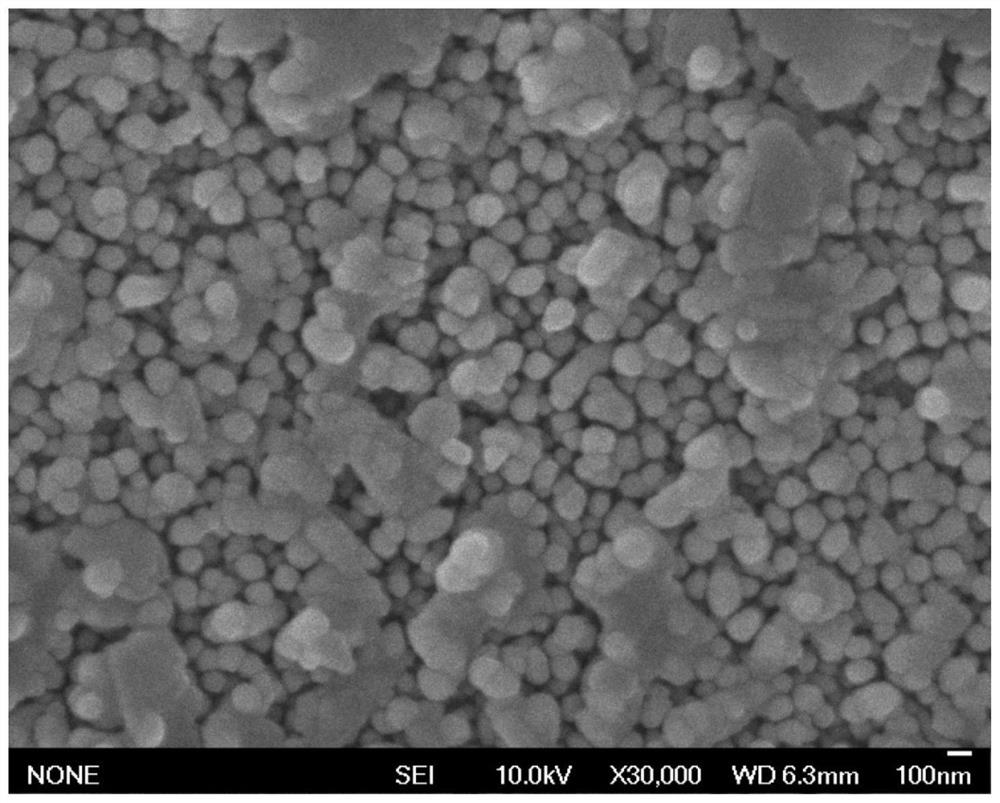

Conductive carbon felt loaded ferric ferric-doped mesoporous titanium oxide gas diffuse photoelectrode and preparation method therefor

ActiveCN105080546AReduce degradation costReduce stickingOther chemical processesDispersed particle separationPore distributionSpray coating

The invention relates to a conductive carbon felt loaded ferric ferric-doped mesoporous titanium oxide gas diffuse photoelectrode and a preparation method therefore. An efficient gas diffusion photoelectrode (TiO2-Fe)mp. / CF mesoporous loaded composite nano material is prepared by adopting a liquid crystal template method and a spray coating technology. The method has the remarkable characteristics that the conductive carbon felt loaded mesoporous (TiO2-Fe) composite nano material with a special structure and the efficient gas diffusion photoelectrode is prepared by applying the spray coating technology and the liquid crystal template method, thereby providing a novel path for application and research of a porous material loaded mesoporous doped TiO2 photocatalytic material. The conductive carbon felt loaded ferric ferric-doped mesoporous titanium oxide gas diffuse photoelectrode is simple in process and easy for industrial production. The prepared efficient gas diffusion photoelectrode mesoporous loaded composite material is good in conductivity, large in specific surface area and uniform in pore distribution.

Owner:JISHOU UNIVERSITY

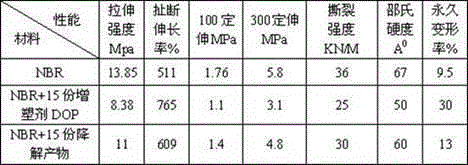

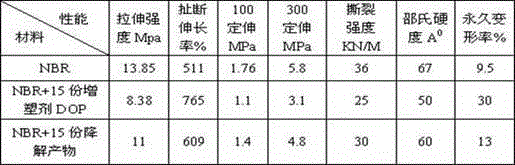

Method for preparing novel plasticizer by using waste polyurethane

InactiveCN104151602AContinuous automated productionHigh recycling efficiencyPlastic recyclingPolymer scienceOligomer

The invention provides a method for preparing novel plasticizer by using waste polyurethane. The method comprises the following orders and steps: (1) the waste polyurethane is crushed and put in a degradation reaction kettle, and degradation agents and catalysts are added; (2) in a stage of high temperature degradation, a high polymer is turned into an oligomer, mainly, the cross bonds and a part of main chains of the waste polyurethane are controlled to be cracked, so that discharging can be performed, the obtained novel plasticizer is a high molecular weight plasticizer which has the advantages that the novel plasticizer does not volatilize, does not migrate, does not reduce the intensity of plasticized materials basically and has low cost, wastes are converted into useful materials, and new pollution is not generated; (3) a degradation reaction is performed once again without additionally adding the degradation agents, degraded products can be used, and the production cost is reduced.

Owner:青岛三瑞节能环保技术有限公司 +1

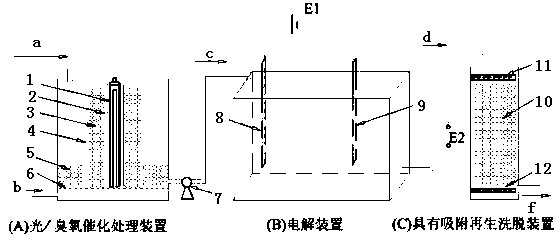

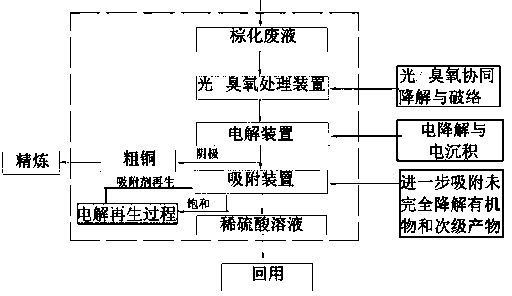

Light/ozone-electricity-adsorption reaction device and method for extracting copper by degrading browning waste liquor

ActiveCN102583840BSimple designEasy to manufacturePhotography auxillary processesMultistage water/sewage treatmentEnvironmental resistanceElectrolysis

The invention relates to a light / ozone-electricity-adsorption reaction device and method for extracting copper by degrading browning waste liquor. The device comprises a light / ozone synergistic decomposing device, an electrolysis device for degrading and recovering metal copper and an adsorption elution device. In the device, a photocatalyst and an oxygen catalyst are loaded on a porous activated carbon carrier with high specific surface area; under the synergistic effect of ultraviolet light and ozone, photo-generated electron pairs are prevented from compounding, long-time catalytic treatment activity is kept, a free radical.OH with strong oxidation activity is generated, organic matters in the browning waste liquor can be oxidized and degraded, and the complexing bond of the complex in the browning waste liquor can be broken; insoluble reticular titanium base material serves as an anode, a copper sheet material serves as a cathode, organic matters in the browning liquor is continuously degraded by electrolysis to generate a second-grade degrading product which is easy to adsorb, and valuable metal copper is recovered on the cathode; and finally, common activated carbon is used for adsorbing to effectively treat the browning waste liquor, so as to realize green and environment-friendly treatment of the browning waste liquor.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD +1

Method for removing algae in water by preparing ferrate activated persulfate

PendingCN114590882AReduce degradation costLow costEnergy based wastewater treatmentWater/sewage treatment by oxidationElectrolytic agentFiltration

The invention discloses a method for removing algae in water by preparing ferrate activated persulfate. The method comprises the following steps: preparing an electrolytic reaction material; carrying out electrolytic reaction to form electrolyte; measuring the concentration of a generated substance in the electrolyte; impurities in the electrolyte are removed; adding a potassium hydroxide solution into the impurity-removed electrolyte to form a second solution; carrying out suction filtration on the second solution; carrying out dehydration treatment on the crystal subjected to suction filtration; performing vacuum drying treatment; and storing the prepared crystal. The method has the beneficial effects that only a small amount of ferrate and persulfate are needed in the method for removing the algae in the water by activating the persulfate with the ferrate, and compared with other chemical methods, a small amount of the ferrate and the persulfate are needed, so that the degradation cost is reduced; compared with a traditional physical and mechanical separation method, algae removal is convenient and fast, manpower consumption and electricity consumption are reduced, and the algae removal cost is greatly saved.

Owner:苏州同达澄澈环境科技有限公司

Alcoholysis method of polylactic acid catalyzed by cao/mcf mesoporous basic molecular sieve

ActiveCN107382718BLarge hole volumeLarge and adjustable apertureMolecular sieve catalystsPreparation by ester-hydroxy reactionMolecular sieveAlcohol

Owner:QINGDAO UNIV OF SCI & TECH

Method for multi-stage degradation and recovery of polyether polyol in polyurethane foam

The invention discloses a method for multi-stage degradation and recovery of polyether polyol in polyurethane foam. The method combines two or more of alcoholysis, acidolysis, aminolysis and hydrolysis for cooperative treatment, and adopts primary and secondary gradient degradation. According to the method, the problems that oligomers in a polyurethane foam degradation product are difficult to degrade and excessive residues exist are solved, the degradation process is mild, and meanwhile, the yield of recycled polyether polyol is increased. Through the synergistic effect of a degradation agent, a catalyst and process parameters, the viscosity and the hydroxyl value of the recycled polyether are effectively controlled, and the recycled product does not need to be purified and can be directly used for polyurethane foaming.

Owner:ZHEJIANG UNIV OF TECH

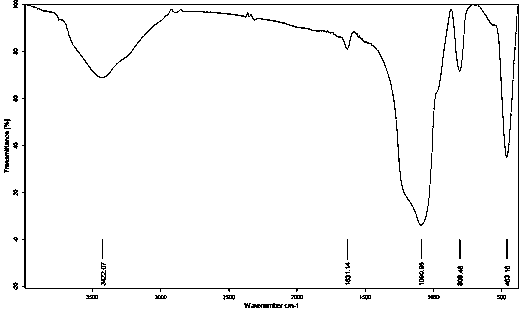

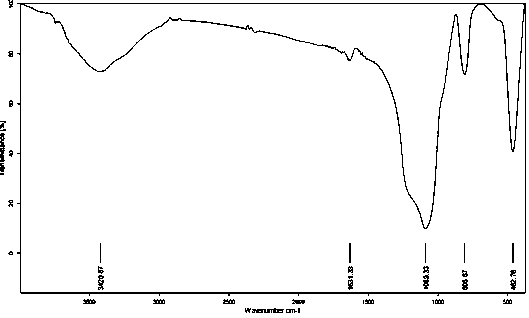

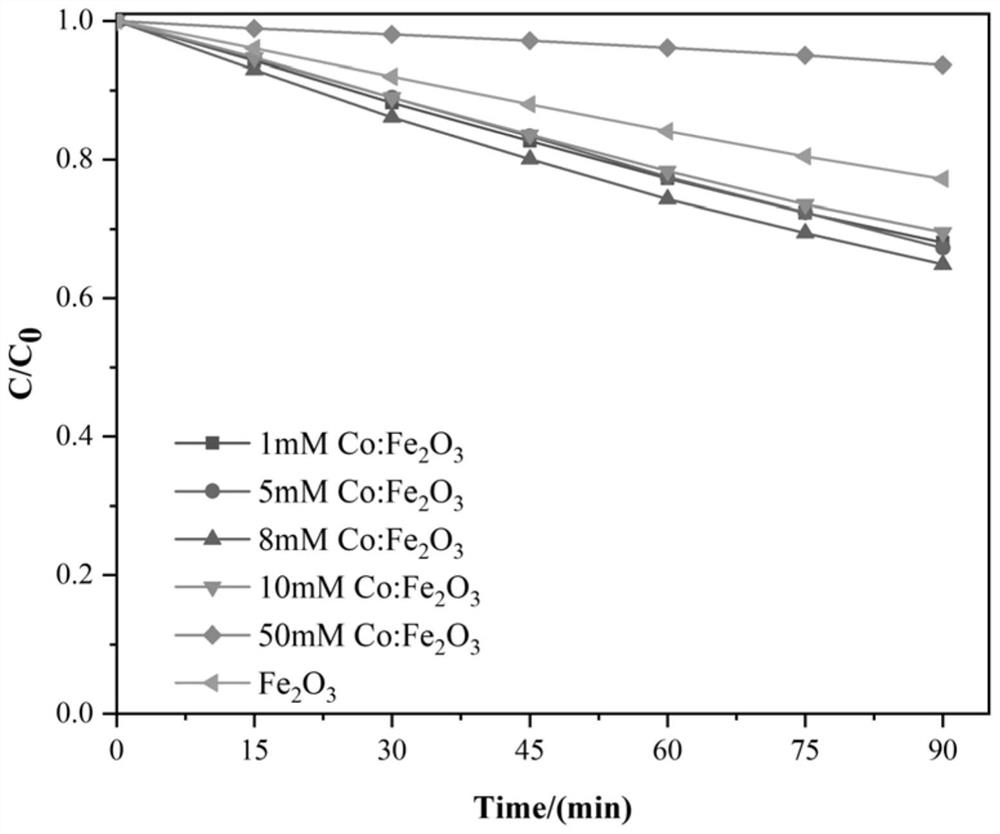

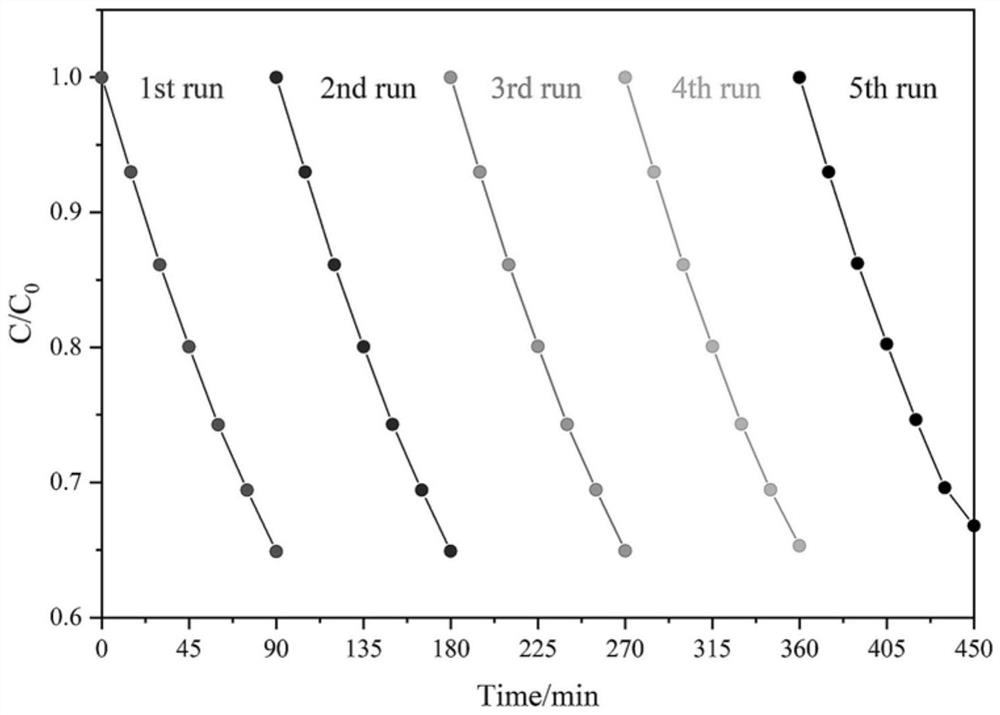

Anode material applied to photoelectric degradation of tetracycline and preparation method of anode material

ActiveCN114044559AAchieve recyclingAchieve degradationWater/sewage treatment by irradiationWater treatment compoundsSodium nitrateMaterials science

The invention relates to the field of materials for degrading tetracycline substances, and in particular, relates to an anode material applied to photoelectric degradation of tetracycline, wherein the anode material comprises ferric chloride hexahydrate, sodium nitrate, a cobalt chloride hexahydrate mixed solution and fluorine-doped SnO2 electrically conductive glass. The invention provides the anode material applied to the photoelectric degradation of tetracycline, the Co:alpha-Fe2O3 anode material is prepared in a Co doping mode, and the recombination rate of an electron-hole pair of alpha-Fe2O3 is effectively reduced. Under the condition of illumination, the Co:alpha-Fe2O3 anode material can degrade tetracycline hydrochloride at a relatively low voltage, so that the degradation cost is reduced, and the safety of the degradation process is improved. Besides, the Co:alpha-Fe2O3 anode material grows on the FTO, and after the degradation process is completed, the Co:alpha-Fe2O3 anode material can be recycled without filtering operation, so that the difficulty of the subsequent treatment process is reduced, and the burden of the material on the structure of the next unit is reduced.

Owner:DONGGUAN UNIV OF TECH

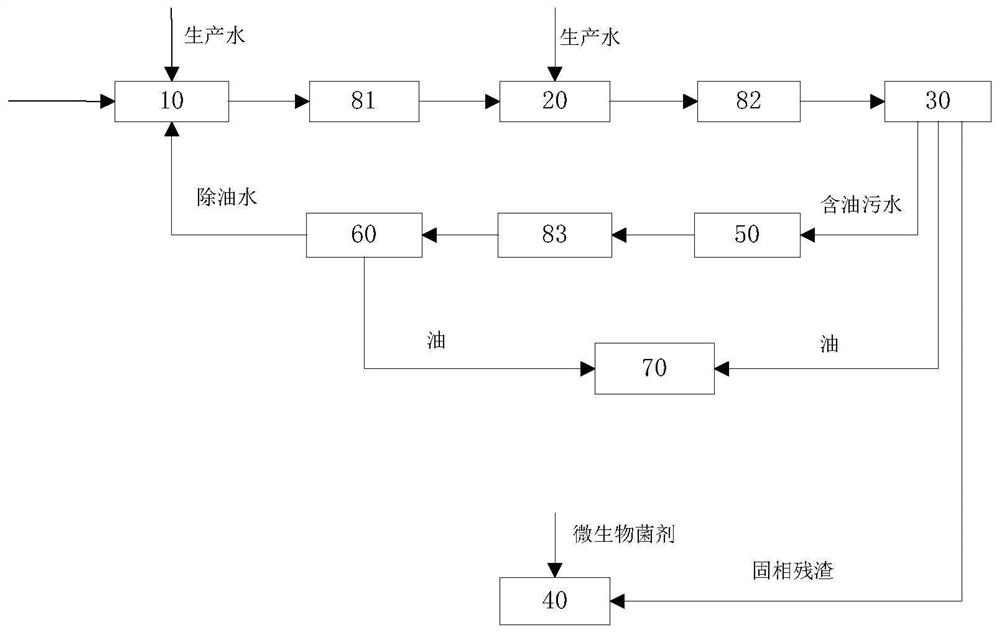

Oil-based drilling cutting treatment device and oil-based drilling cutting treatment method

InactiveCN113118173AReduce oil concentrationQuick washSolid waste disposalTransportation and packagingMicroorganismThermodynamics

The invention provides an oil-based drilling cutting treatment device and an oil-based drilling cutting treatment method. The oil-based drilling cutting treatment device comprises a homogenizing tank, an ultrasonic cleaning tank, a three-phase centrifugal machine and a microbial degradation tank; the homogenizing tank is used for diluting oil-based drilling cuttings; an inlet of the ultrasonic cleaning tank communicates with an outlet of the homogenizing tank, and the ultrasonic cleaning tank is used for cleaning the diluted drilling cuttings; an inlet of the three-phase centrifugal machine communicates with an outlet of the ultrasonic cleaning tank; and the microbial degradation tank is used for carrying out microbial degradation on solid-phase residues centrifuged by the three-phase centrifugal machine. Through the technical scheme, the problem that the requirements of low cost and high efficiency cannot be met in the prior art can be solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

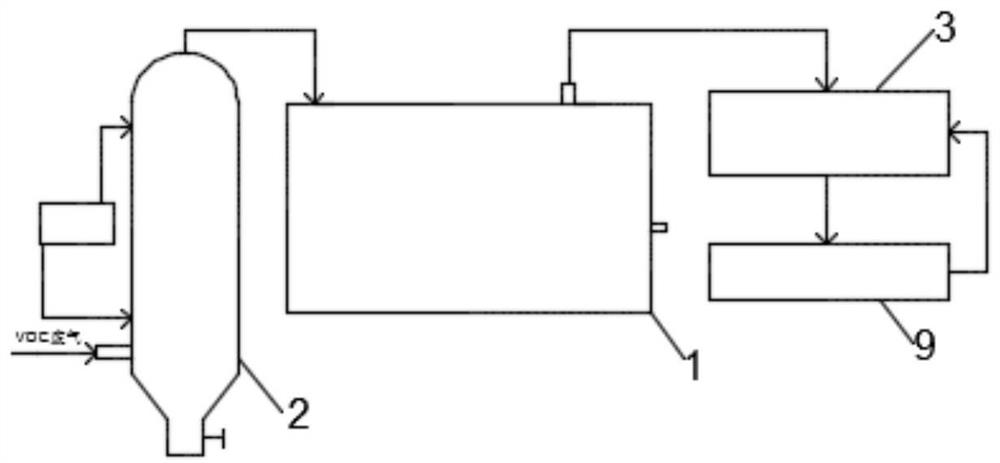

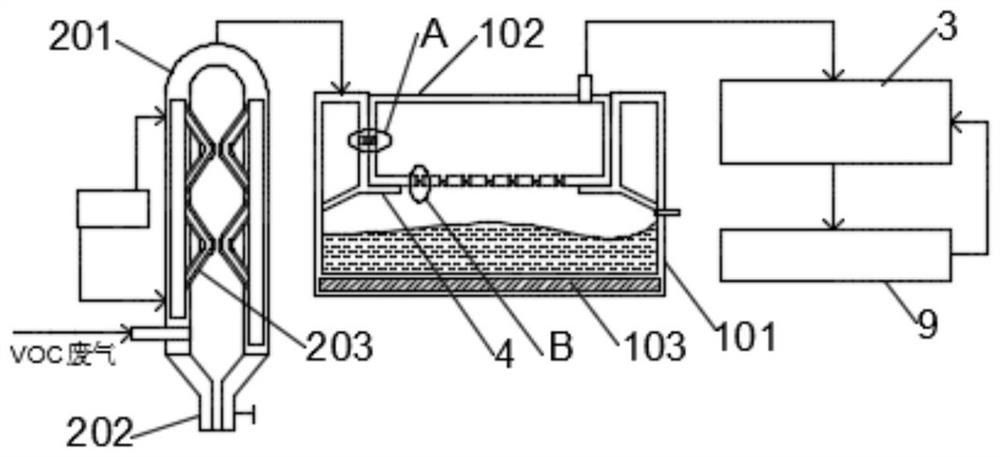

A degradation device in a VOC exhaust gas treatment system for automotive interior processing

ActiveCN112892145BReduce degradation costReduce condensation in liquid formGas treatmentDispersed particle separationWater vaporSteam temperature

The invention discloses a degradation device in a VOC exhaust gas treatment system for automobile interior processing, which works through an electric heating plate to heat and evaporate the hydrogen peroxide solution in the lower liquid storage chamber of the evaporation tank, and the water vapor and The hydrogen peroxide vapor moves up in the lower liquid storage chamber of the evaporator and enters the mixing chamber through the one-way air inlet. At the same time, the heat in the lower liquid storage chamber of the evaporator is transferred to the upper surrounding chamber of the evaporator. The upper surrounding chamber preheats the VOC exhaust gas to make it similar to the temperature of the steam in the mixing chamber. After the upper surrounding chamber of the evaporation tank preheats the VOC exhaust gas, it enters the mixing chamber along the overflow valve to mix with water vapor and hydrogen peroxide vapor. , by setting the evaporation tank and the mixing chamber, the heat of the steam itself can be used to preheat the VOC waste gas in advance, reducing the occurrence of hydrogen oxide vapor condensing into a liquid state, reducing energy consumption, and reducing the cost of VOC waste gas degradation.

Owner:DESIGN INST NO 9 MINISTRY OF MECHINE BUILDING

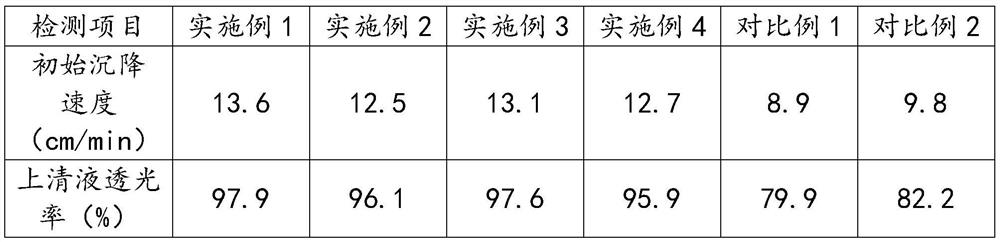

Coal slime water treatment process based on dimethyl diallyl ammonium chloride and polyacrylamide

PendingCN114011589AElimination of steric effectsImprove microstructureDifferential sedimentationFlotationSuspended particlesFiber

The invention discloses a coal slime water treatment process based on dimethyl diallyl ammonium chloride and polyacrylamide, which comprises the following steps: washing corn or wheat straws, conducting drying, conducting grinding, conducting sieving, putting the sieved material into KMnO4, conducting stirring, conducting soaking to obtain modified fibers, and adding chitosan into deionized water. The problem that the sedimentation treatment efficiency is low due to different adsorption characteristics caused by factors such as different components and pH values of the coal slime water is solved. Ferroferric oxide is relatively high in magnetic performance, relatively simple to prepare and very high in inertness, the corn and wheat straw are utilized, the magnetic effect can be improved, waste can be recycled, and in cooperation with the coagulation aiding effect of polyacrylamide, the capacity of removing suspended particles in water can be improved, and the time of sludge precipitation and sludge removal in follow-up process can be shortened. Meanwhile, the volume of a reaction tank is reduced, the land utilization rate is improved, and the degradation cost of agricultural products is reduced, so that the aim of improving the sedimentation and filter pressing efficiency is fulfilled.

Owner:安徽汉华工贸有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com