Coal slime water treatment process based on dimethyl diallyl ammonium chloride and polyacrylamide

A technology of dimethyl diallyl ammonium chloride and polyacrylamide, which is applied in the field of coal slime water treatment, can solve problems such as low efficiency and different adsorption characteristics, and achieve the goals of increasing pores, improving microstructure, and improving settlement efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

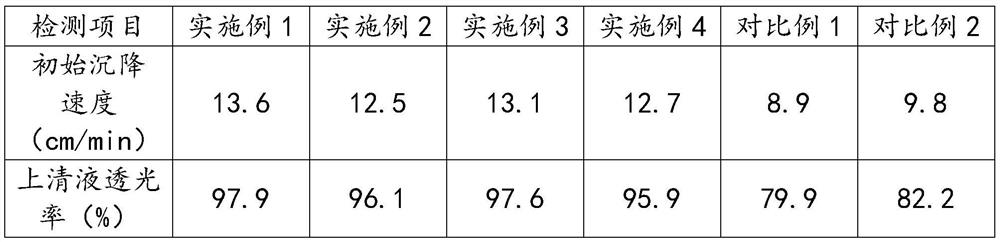

Examples

Embodiment 1

[0032] The present embodiment is based on dimethyl diallyl ammonium chloride and polyacrylamide coal slime water treatment process, and the treatment process of this coal slime water comprises the following steps:

[0033] S1: Determination of the main mineral components contained in the slime water by ray diffraction method, and the determination and analysis of the interface properties of different mineral particles in the slime water;

[0034] S2: Using density functional theory to simulate and calculate the adsorption characteristics of the mineral particle surface, build and optimize the interface model of the main mineral particles in the slime water, and conduct simulation calculation analysis for the adsorption characteristics of different agents on the surface of different mineral particles;

[0035] S3: Determine the dosage of the added medicament according to the simulation calculation results;

[0036] S4: Add agents to the slime water in sequence according to the ...

Embodiment 2

[0044] The difference between this example and Example 1 is that the modified nano filter aid is prepared by the following steps:

[0045] S31: Wash the corn or wheat straw, dry it in a constant temperature drying oven, and pulverize it with a pulverizer, grind and sieve it, and place it in KMnO 4 Stir and soak for 24-36 hours, filter with suction, wash with distilled water until neutral, and then dry in a dryer at 60-70°C to obtain modified fibers;

[0046] S32: Add chitosan to deionized water, heat in a water bath at 45-55°C, stir at 3000-4000r / min until completely dissolved, then add FeS0 under nitrogen protection 4 ·7H 2 0 and FeCl 3 ·6H 2 0, heat up to 80-90°C, stir for 10-30min, add NH3·H 2 0 to pH 9-10, continue heating and stirring for 30-40min, add modified fiber, stir for 60-120min, wash with distilled water until neutral, collect with magnetic separation equipment, and dry in a vacuum oven at 60-70°C 12-24h, to obtain nano-intermediate A;

[0047] S33: Wash, d...

Embodiment 3

[0051] The difference between this example and Example 1 is that the modified nano filter aid is prepared by the following steps:

[0052] S31: Wash the corn or wheat straw, dry it in a constant temperature drying oven, and pulverize it with a pulverizer, grind and sieve it, and place it in KMnO 4 Stir and soak for 24-36 hours, filter with suction, wash with distilled water until neutral, and then dry in a dryer at 60-70°C to obtain modified fibers;

[0053] S32: Add chitosan to deionized water, heat in a water bath at 45-55°C, stir at 3000-4000r / min until completely dissolved, then add FeS0 under nitrogen protection 4 ·7H 2 0 and FeCl 3 ·6H 2 0, heat up to 80-90°C, stir for 10-30min, add NH3·H 2 0 to pH 9-10, continue heating and stirring for 30-40min, add modified fiber, stir for 60-120min, wash with distilled water until neutral, collect with magnetic separation equipment, and dry in a vacuum oven at 60-70°C 12-24h, to obtain nano-intermediate A;

[0054] S33: Wash, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com