Patents

Literature

41 results about "Iopromide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

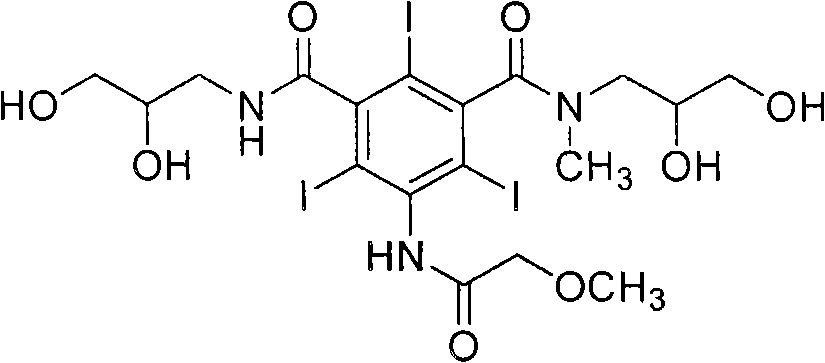

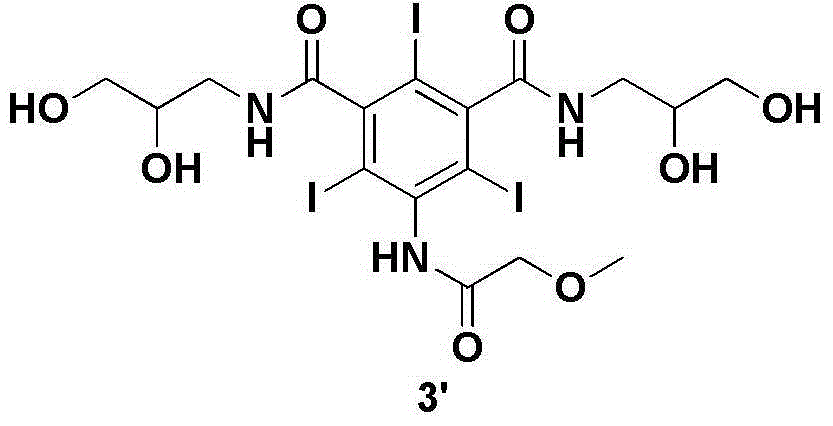

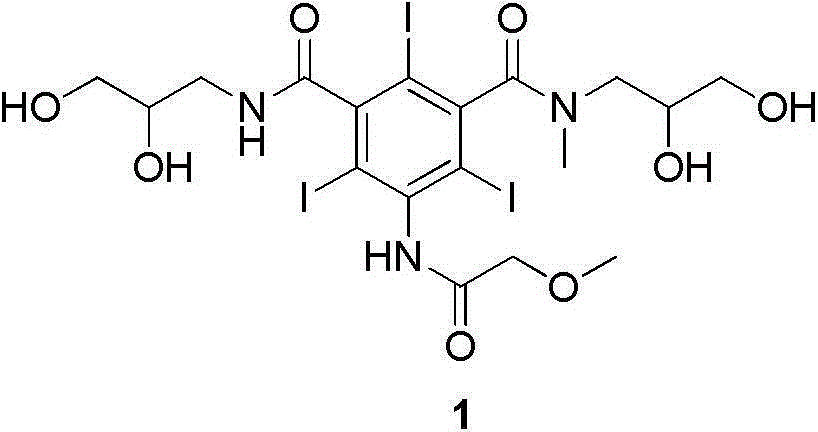

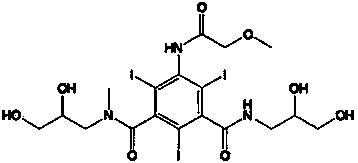

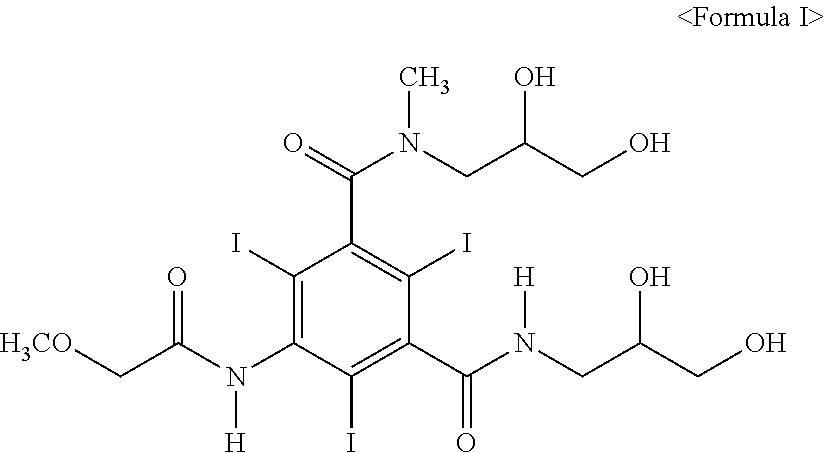

Iopromide is a molecule used as a contrast medium. It is marketed under the name Ultravist which is produced by Bayer Healthcare. It is a low osmolar, non-ionic contrast agent for intravascular use. It is commonly used in radiographic studies such as intravenous urograms, brain computer tomography (CT) and CT pulmonary angiograms (CTPAs).

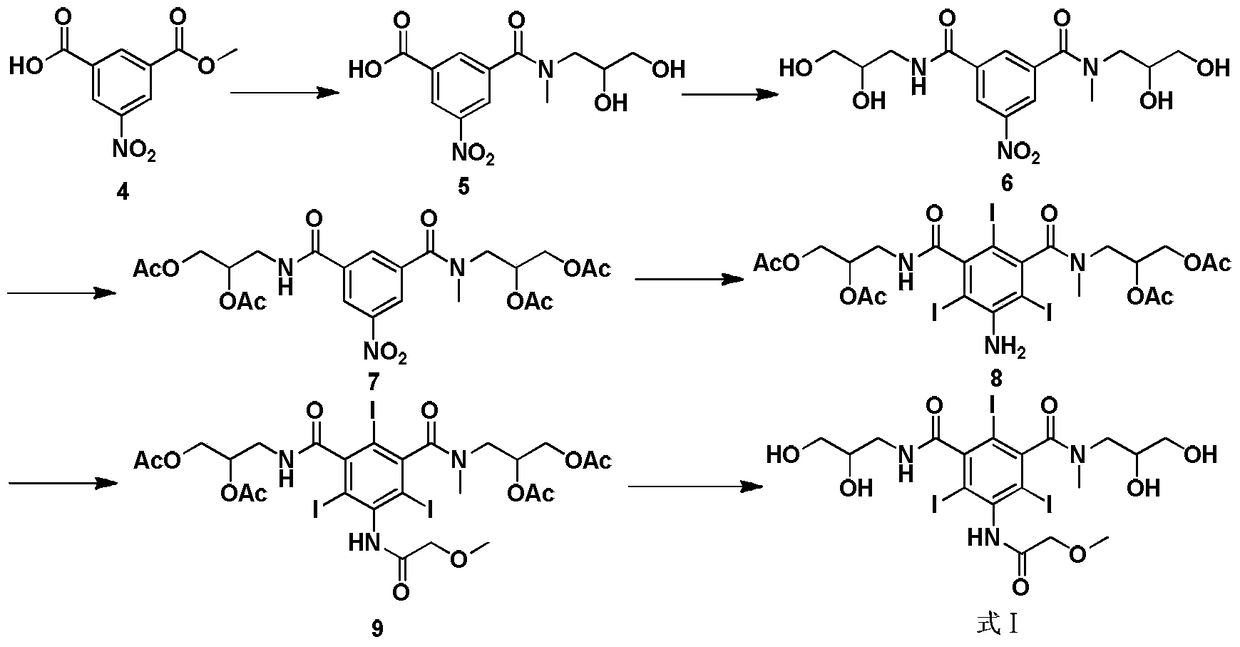

Preparation method of high-purity iopromide

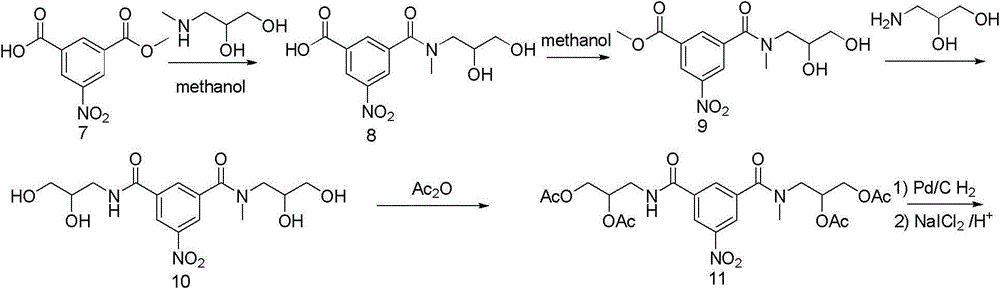

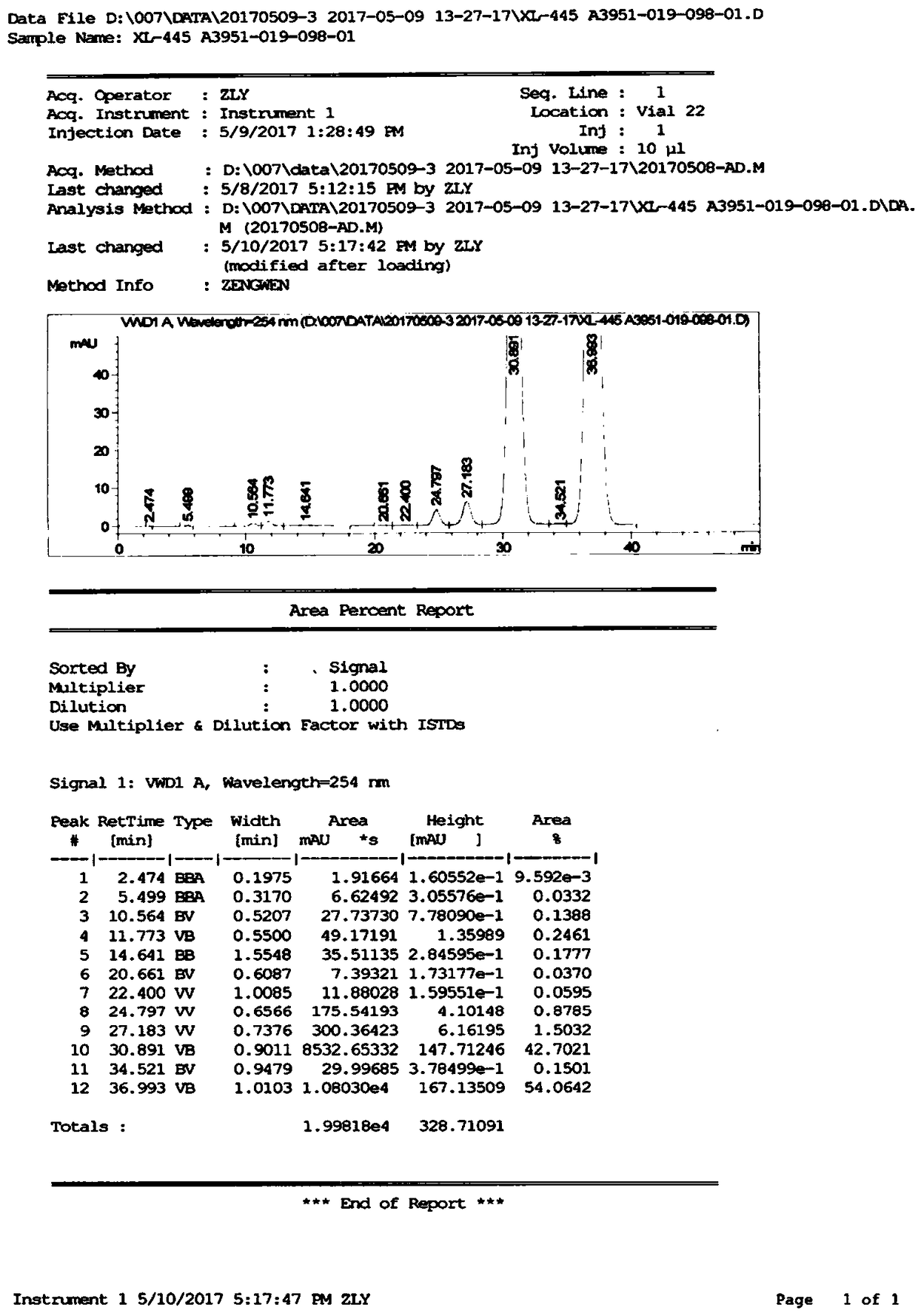

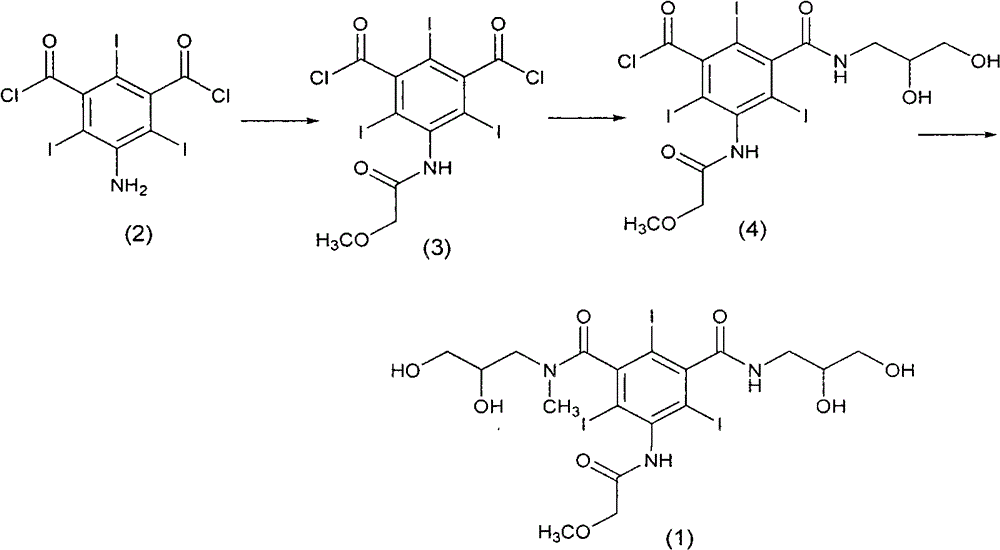

ActiveCN103570580AHigh yieldHigh purityOrganic compound preparationCarboxylic acid amides preparationIopromideMedicinal chemistry

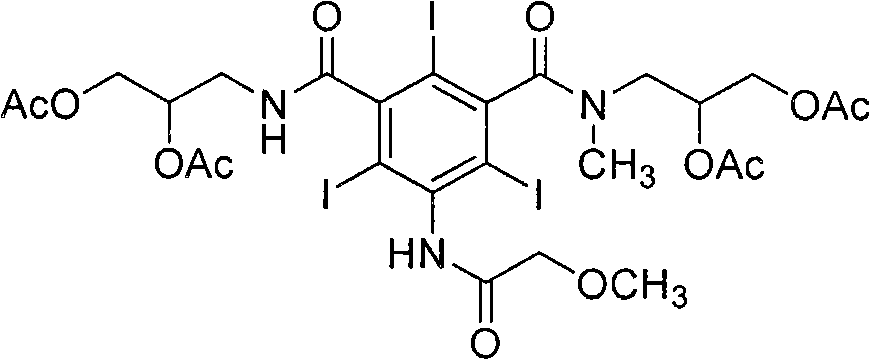

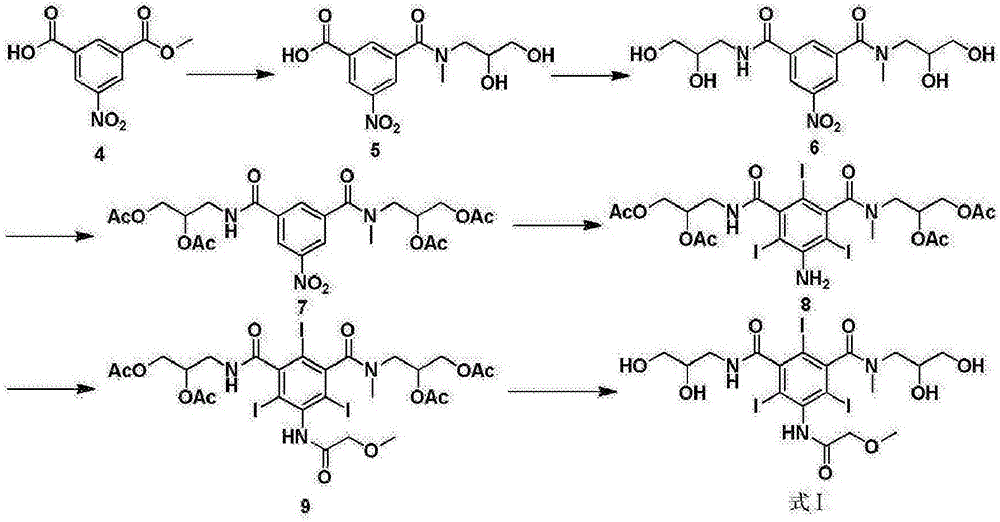

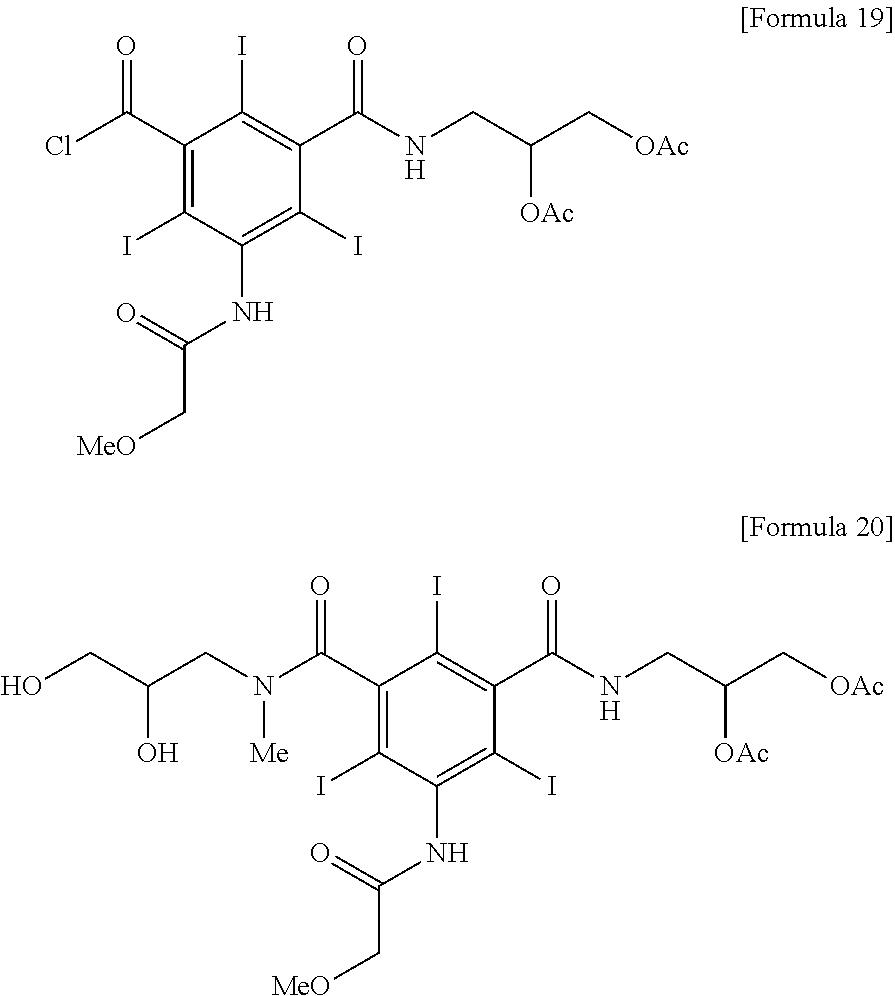

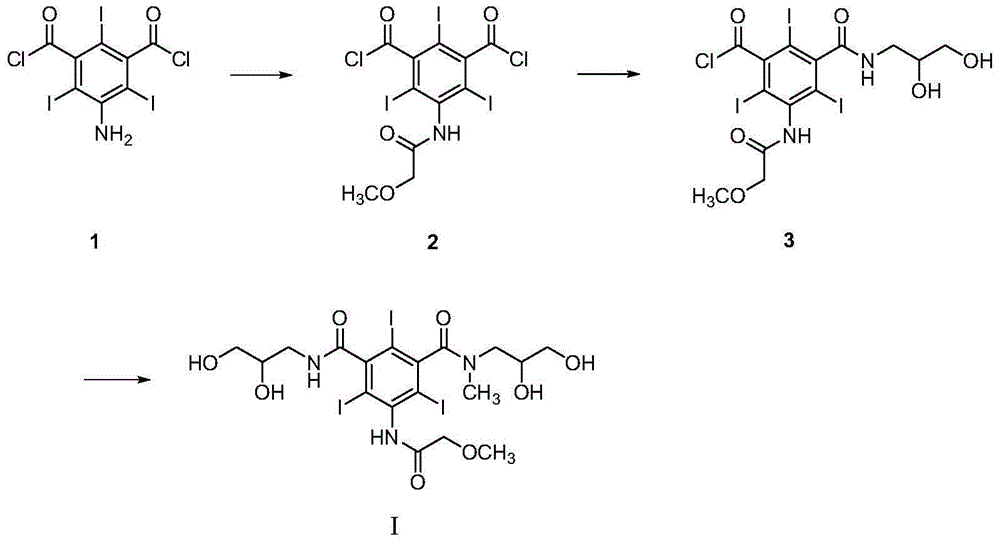

The invention relates to a preparation method of a high-purity contrast medium raw material iopromide, wherein byproducts generated in the preparation process can be removed by introducing a compound shown in a formula (19): 5-methoxyl acetamido-2, 4, 6-triiodo isophthalic acid [(2, 3-diacetoxyl-N-methyl propyl)-(2, 3-diacetoxyl propyl)] diamide serving as an intermediate. The invention provides the preparation method of iopromide with high purity.

Owner:内蒙古白医制药股份有限公司

Method for degrading iopromide-containing wastewater

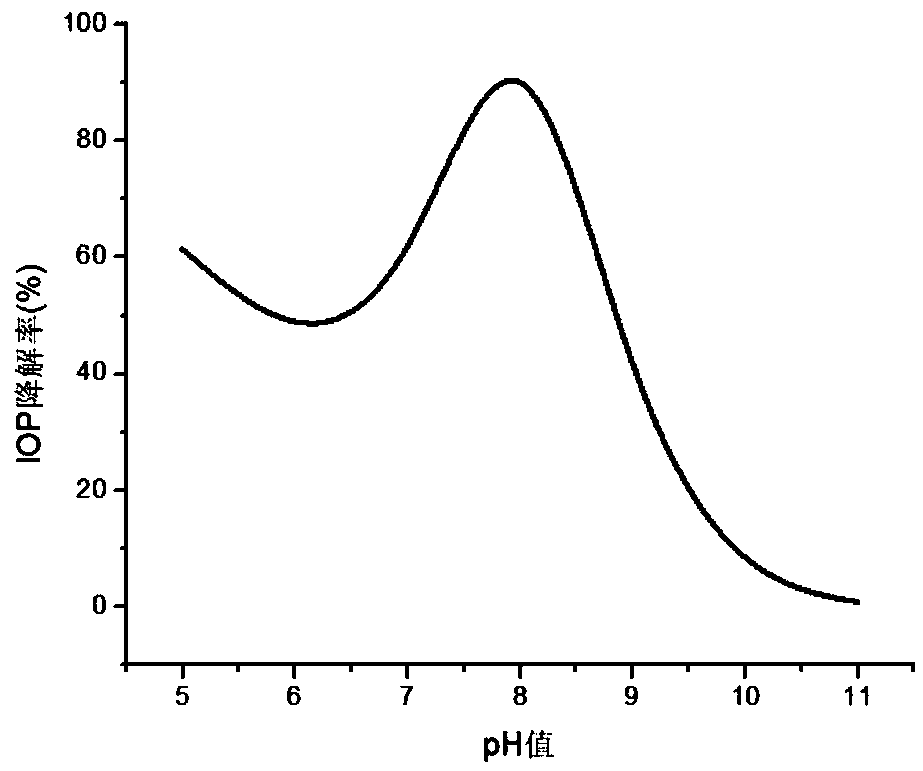

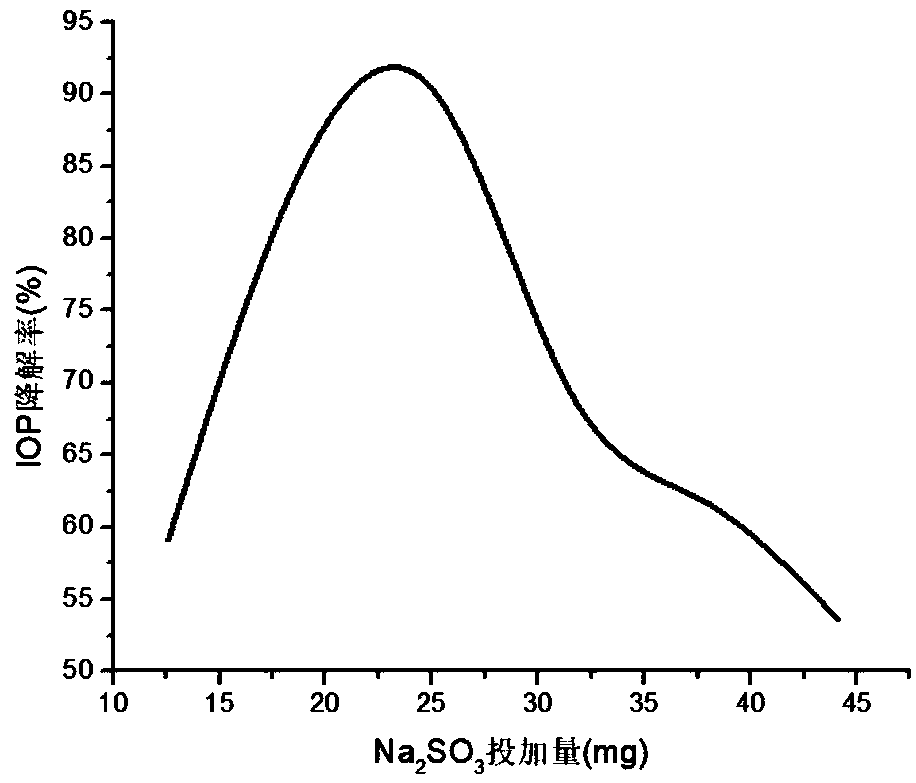

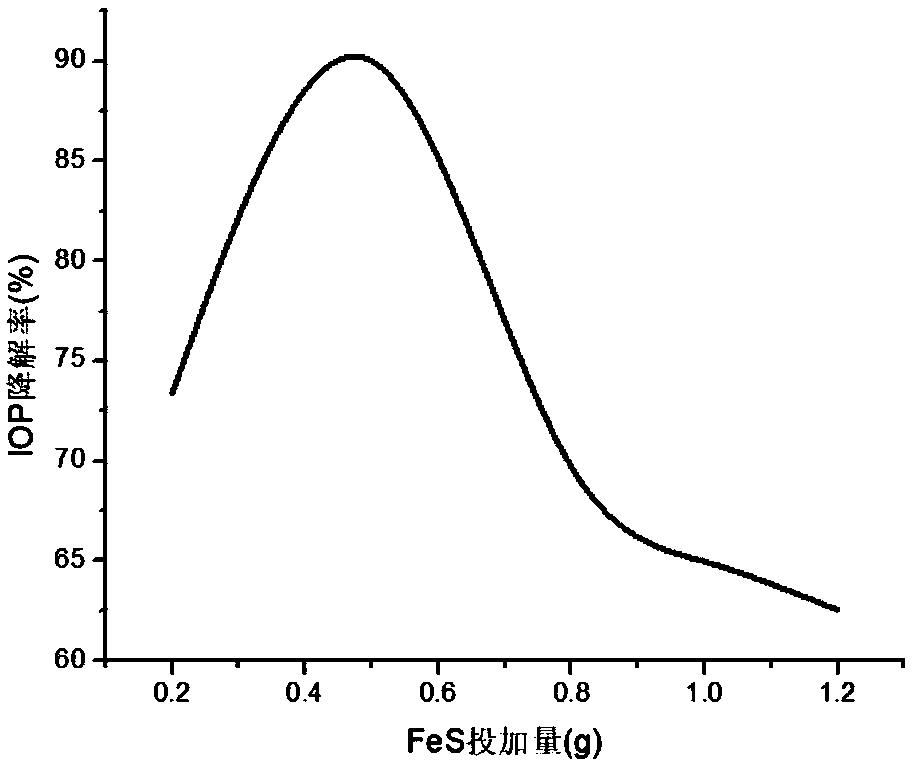

InactiveCN109231565APromote degradationSolve problems such as corrosionWater contaminantsMultistage water/sewage treatmentSulfite saltEconomic benefits

The invention discloses a method for degrading iopromide-containing wastewater, and belongs to the field of treatment of organic wastewater. The method is characterized in that ferrous sulfide is usedas a catalyst, and sodium sulfite is used as an oxidant, so as to effectively degrade the iopromide. The method has the advantages that the organic pollutant, such as iopromide, can be effectively degraded, and the degrading rate can reach 90%; when the iopromide-containing wastewater is treated by the method, the investment of materials is low, the wastewater treatment effect is good, the speedis quick, and the good social and economic benefits are realized.

Owner:LIAONING UNIVERSITY

New method for preparing iopromide

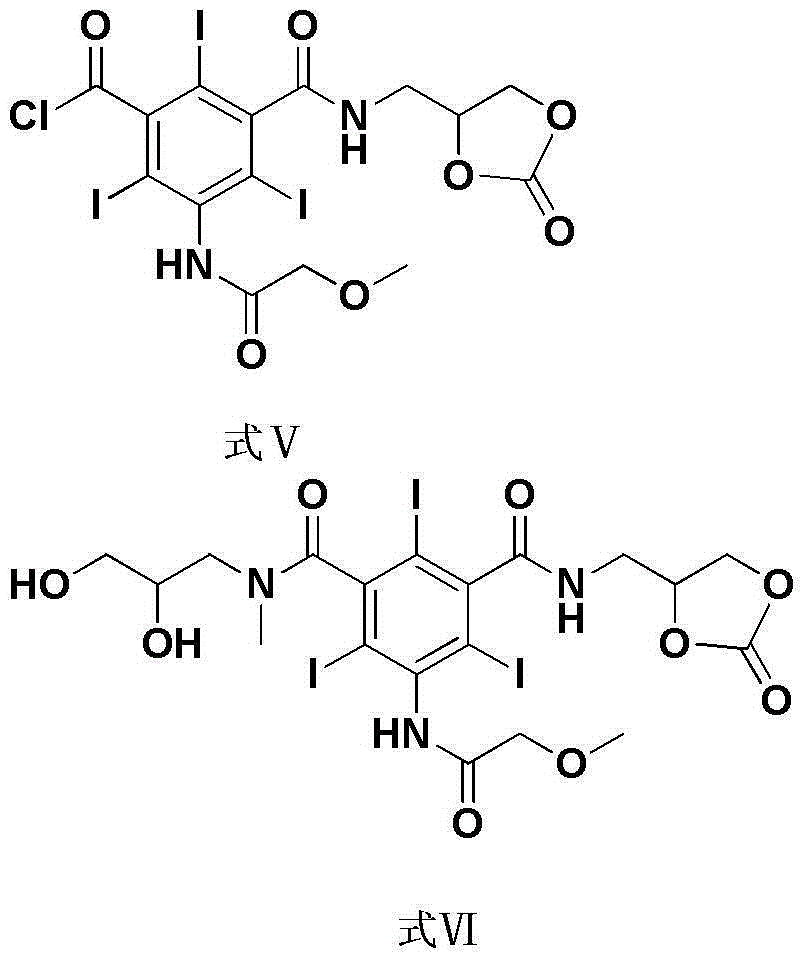

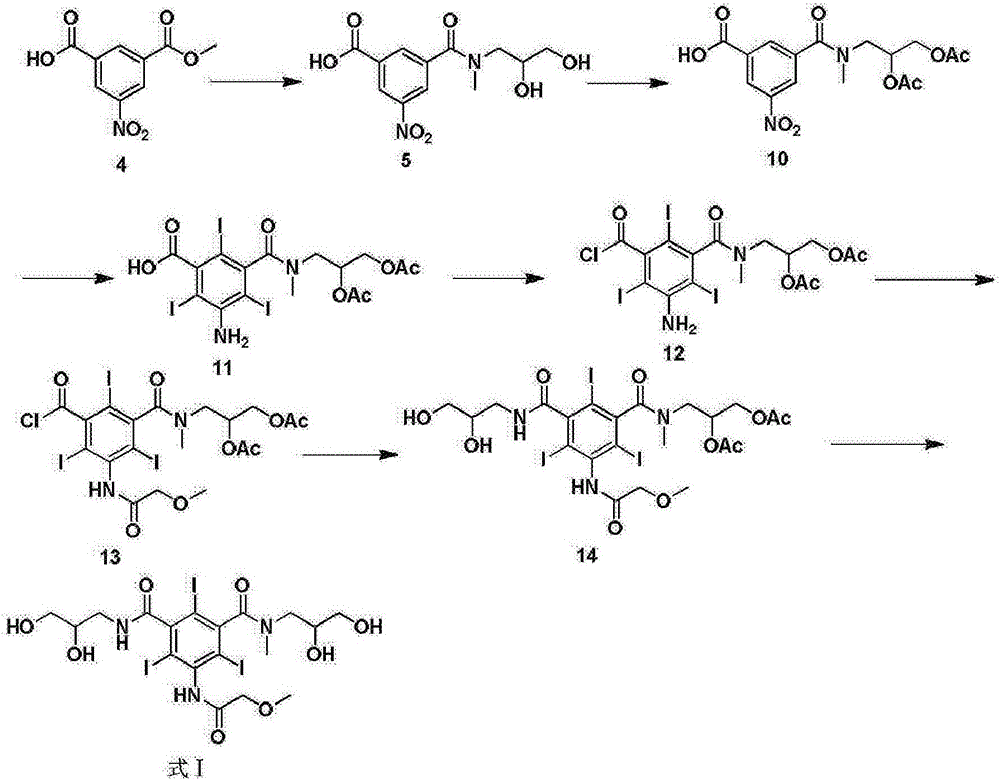

ActiveCN105017062AEasy to removeHigh purityOrganic compound preparationCarboxylic acid amides preparationCombinatorial chemistryIopromide

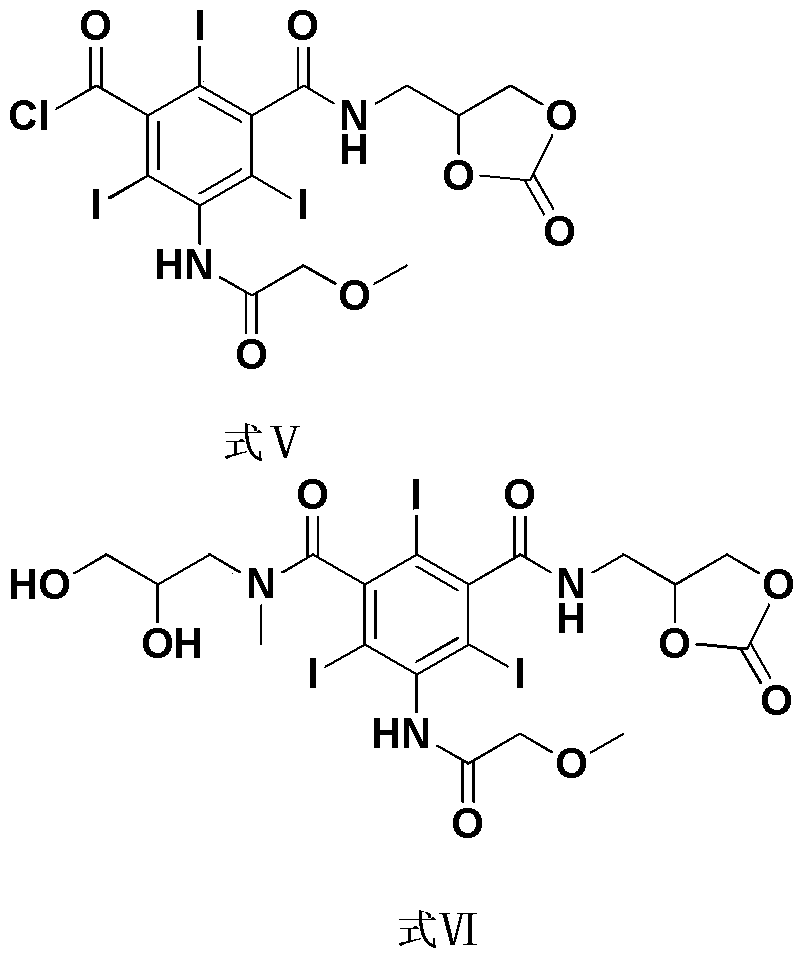

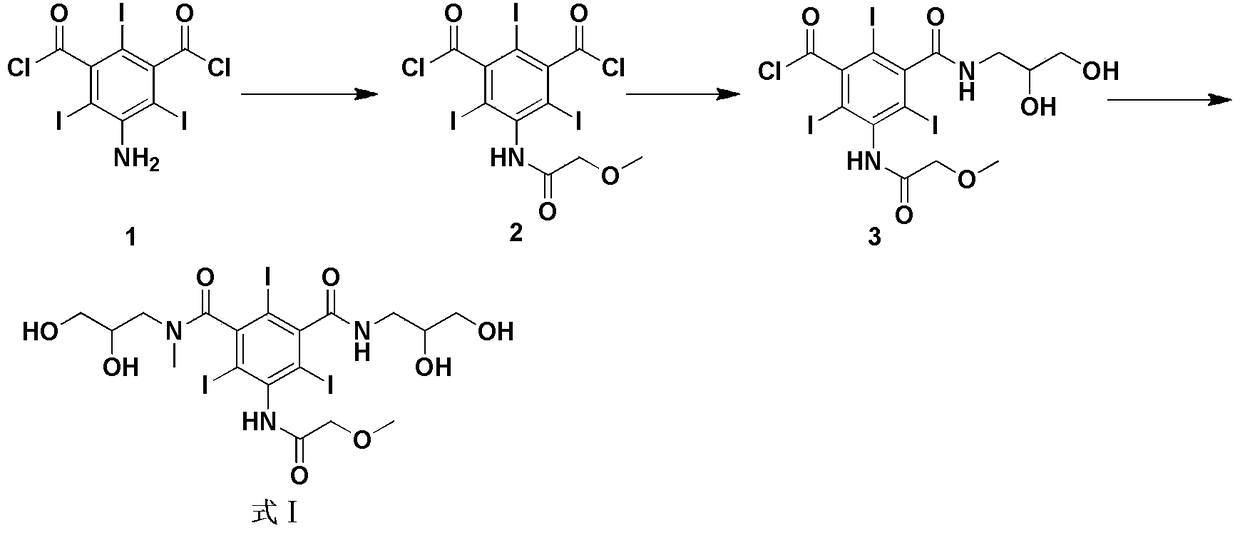

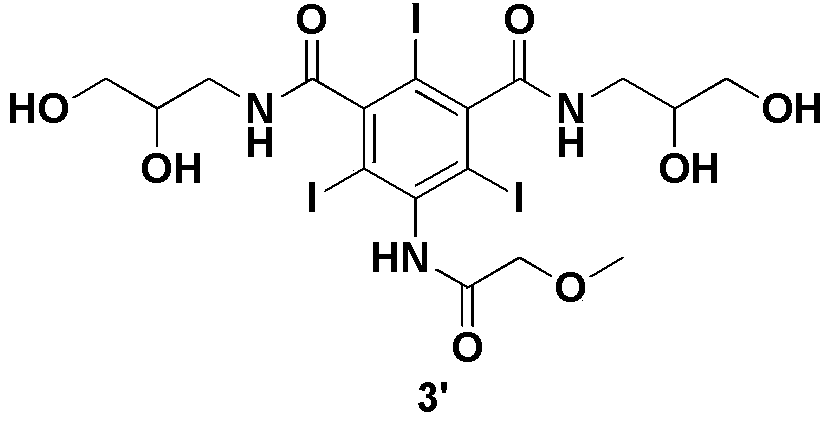

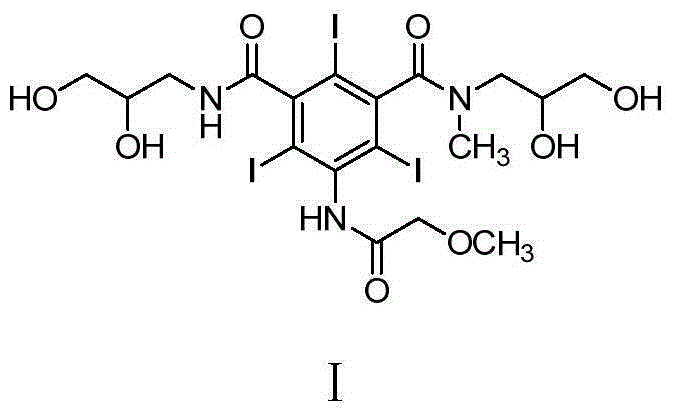

The invention relates to a preparation method of iopromide. 5-methoxylacetamido-2,4,6-triiodo m-phthalic acid[(2-oxo-1,3-dioxolame-4-yl)methyl]amido chloride (Formula V) and 5-methoxylacetamido-2,4,6-triiodo m-phthalic acid{[(2-oxo-1,3-dioxolame-4-yl)methyl]-(2,3-dyhydroxyl-N-methyl propyl)}diamide (Formula VI) are introduced to be used as intermediates. Even if there is no additional purification step, a bismer by-product generated during the reaction also can be removed by introduction of the intermediates and high-purity iopromide can be prepared at high yield.

Owner:白银京宇新药业有限公司

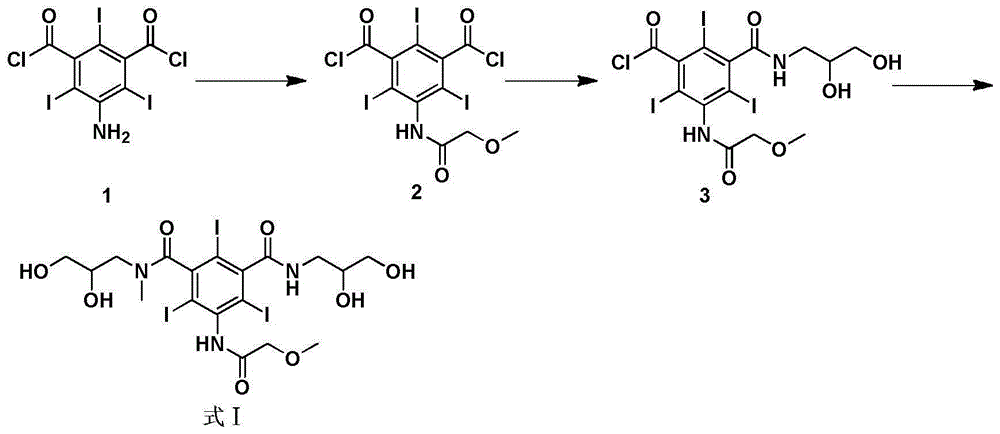

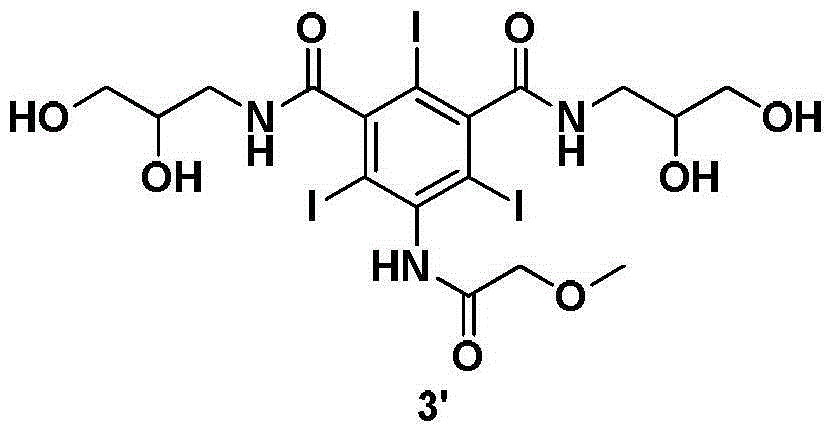

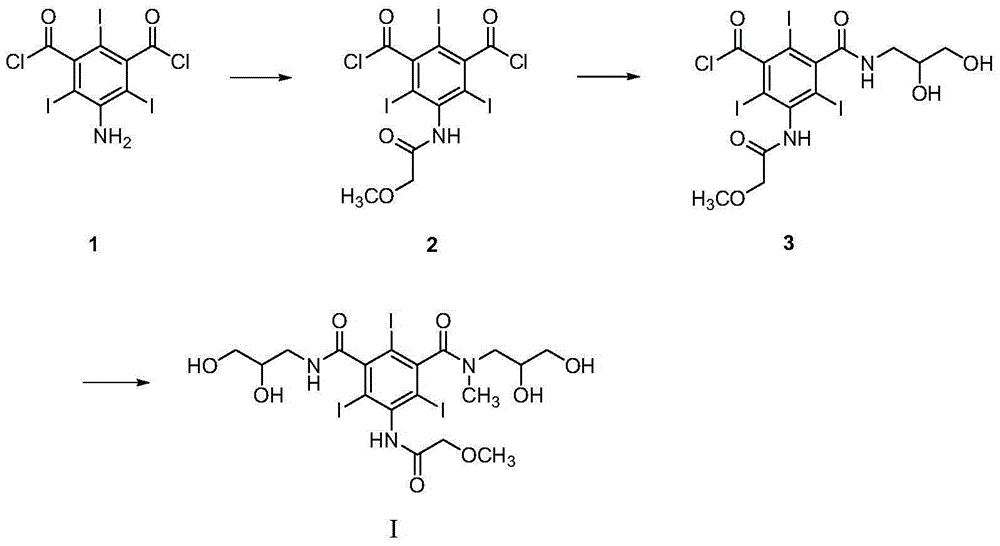

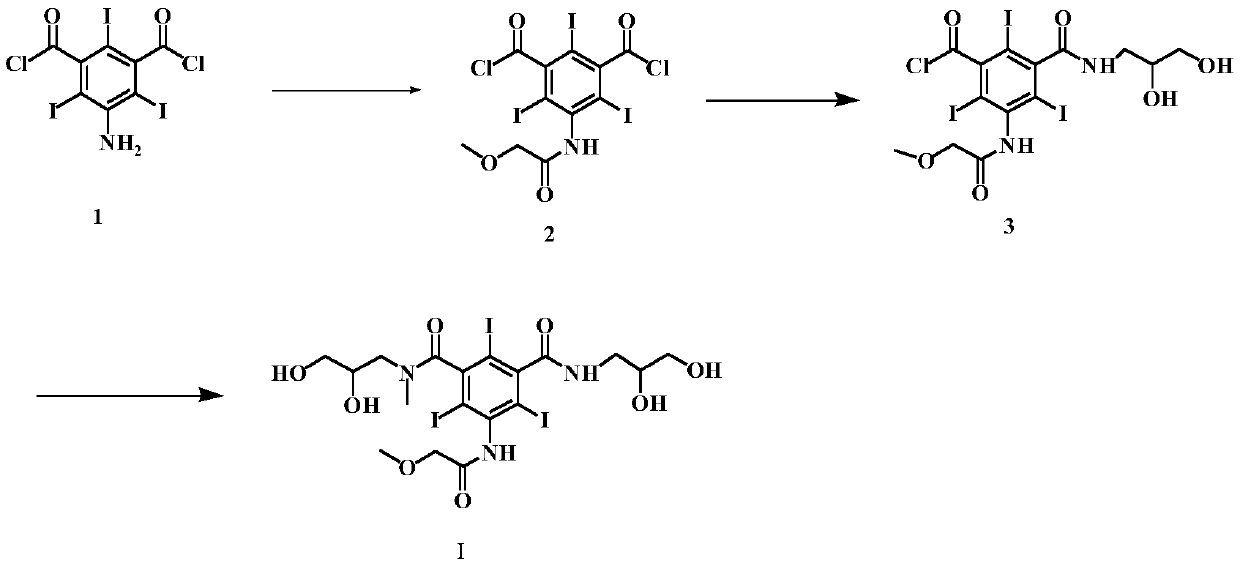

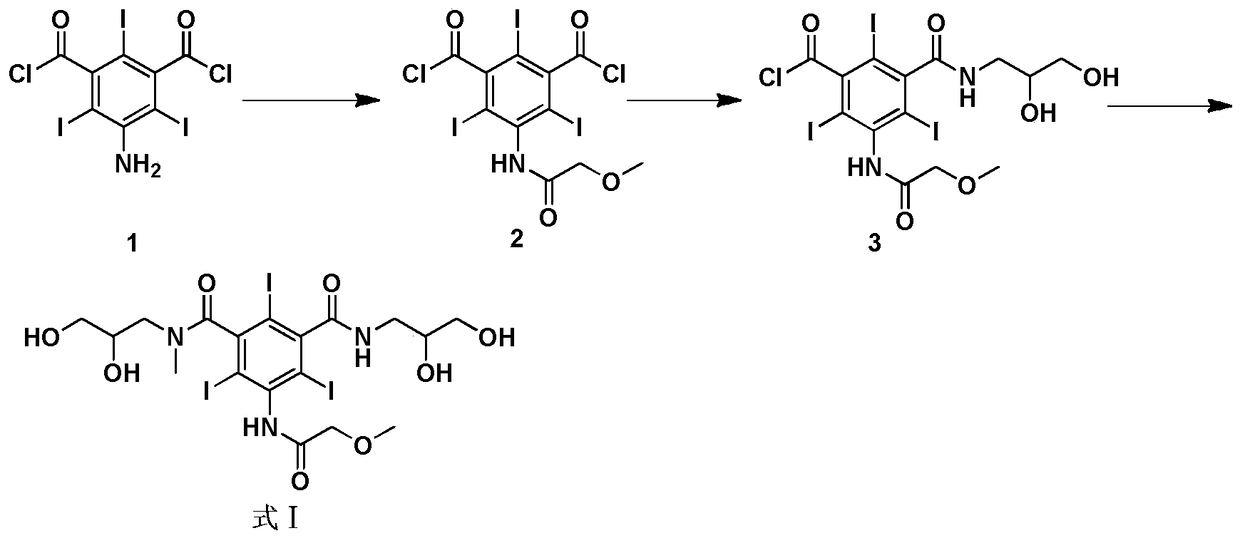

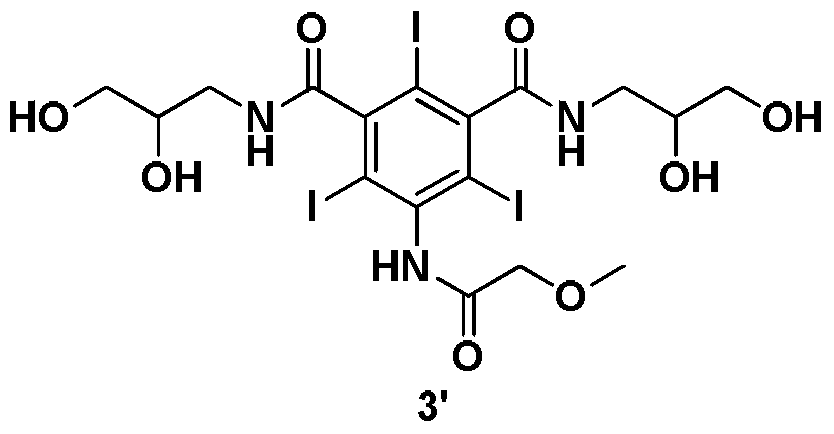

Novel synthesis method for iopromide

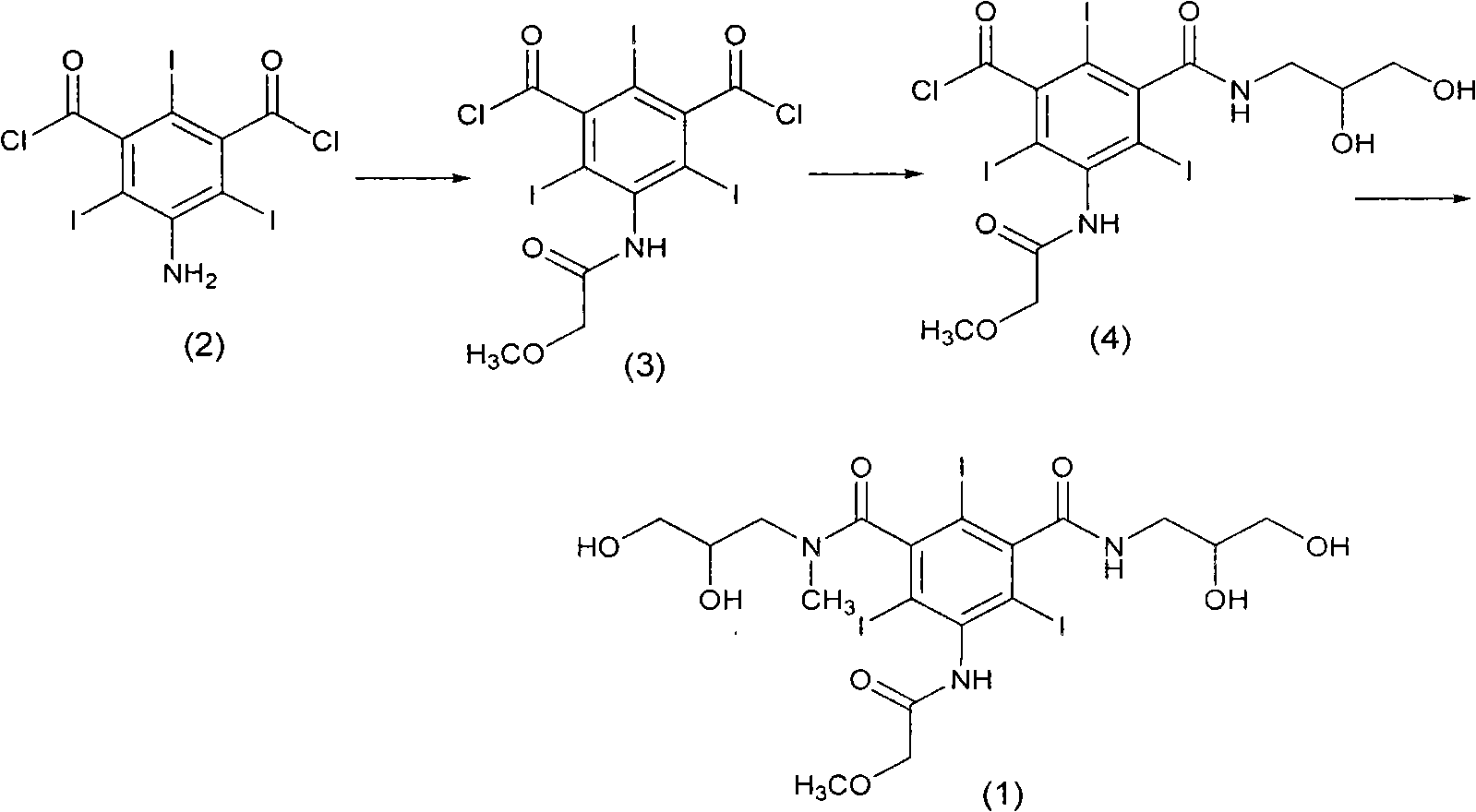

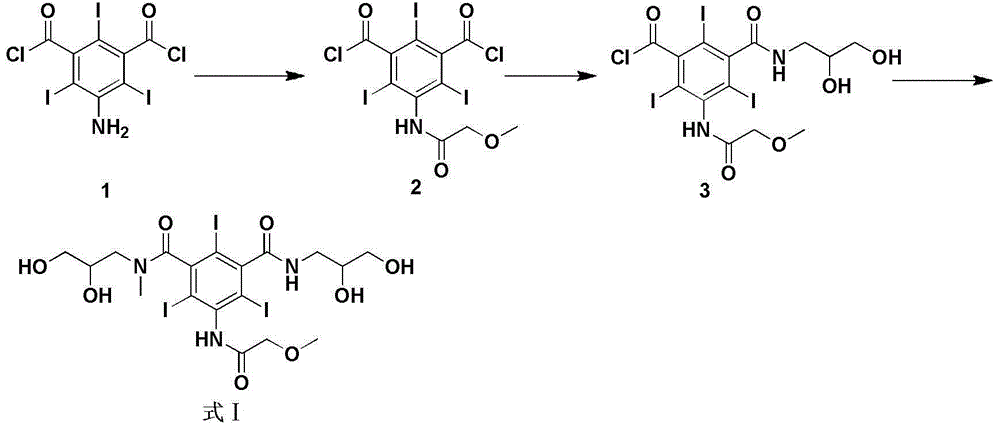

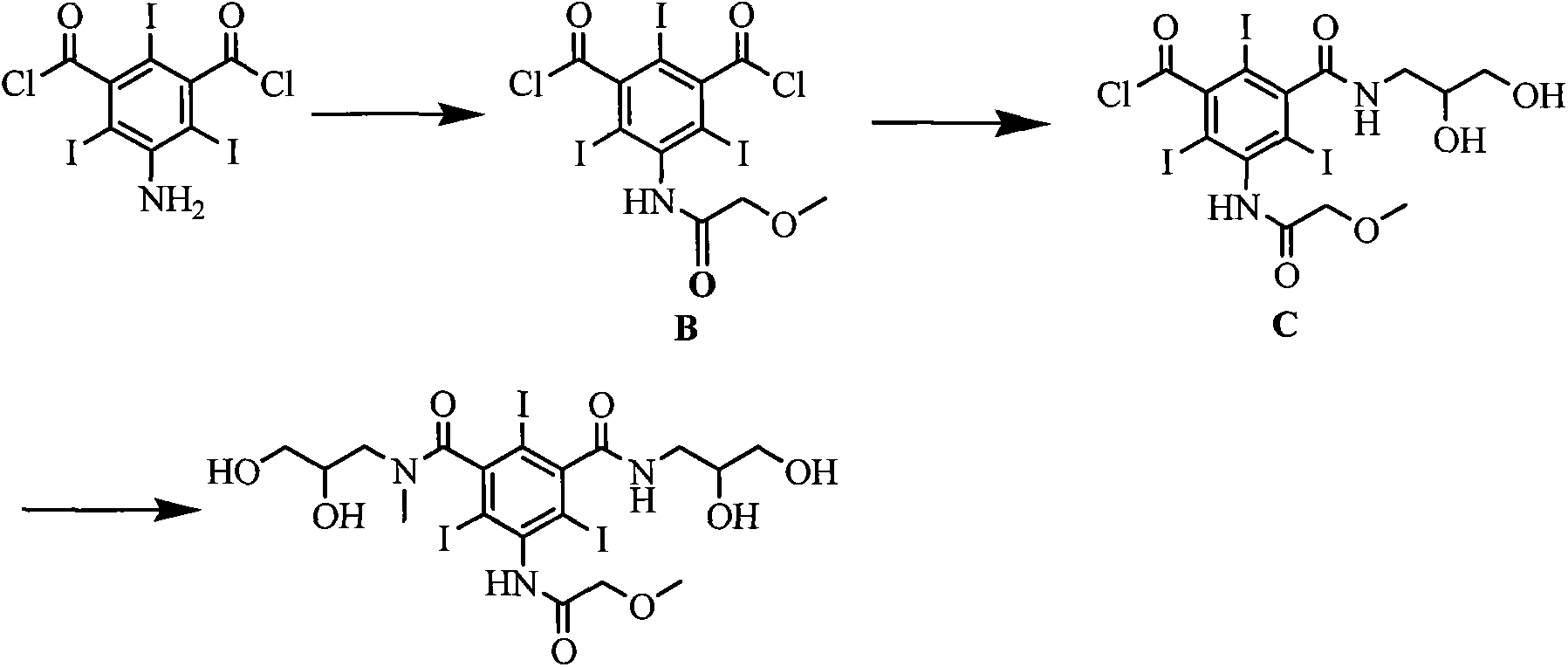

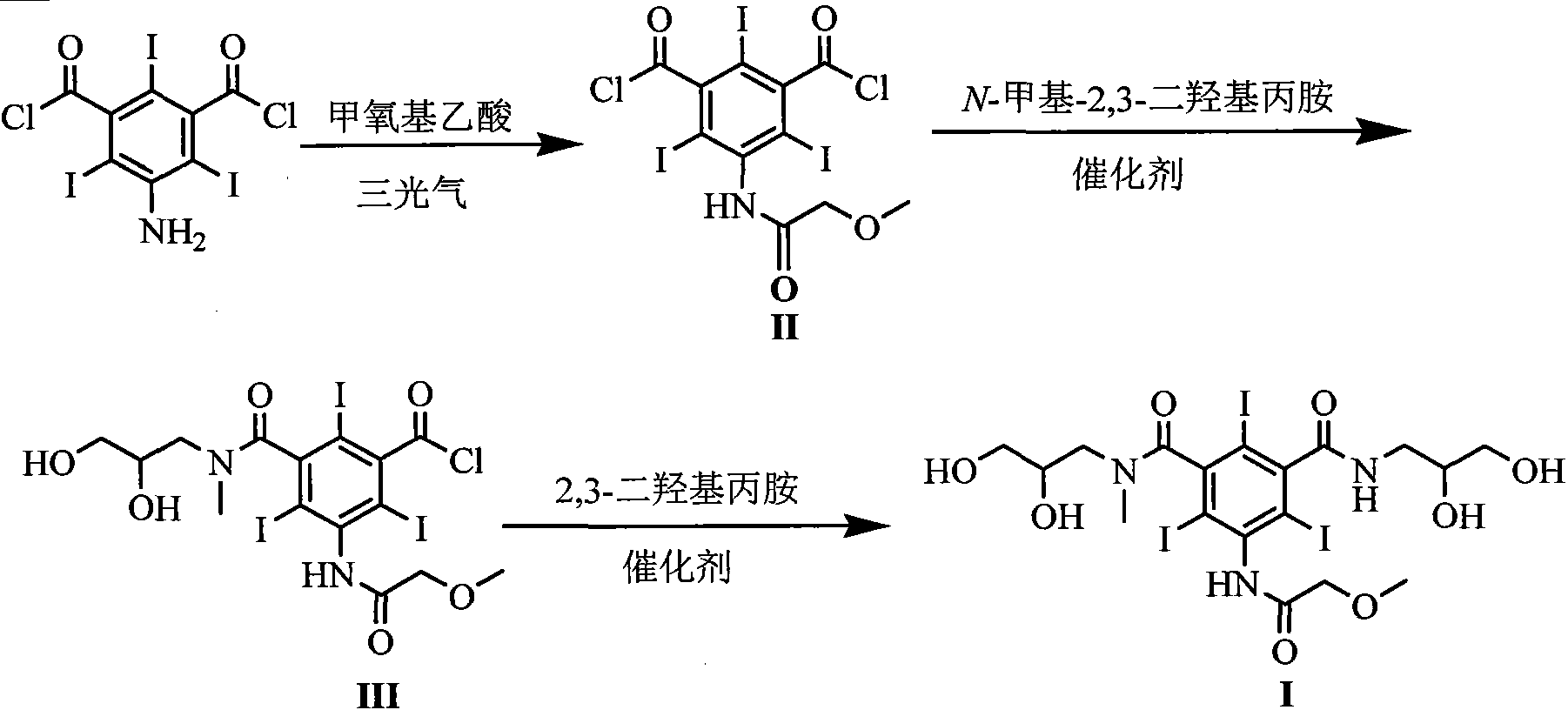

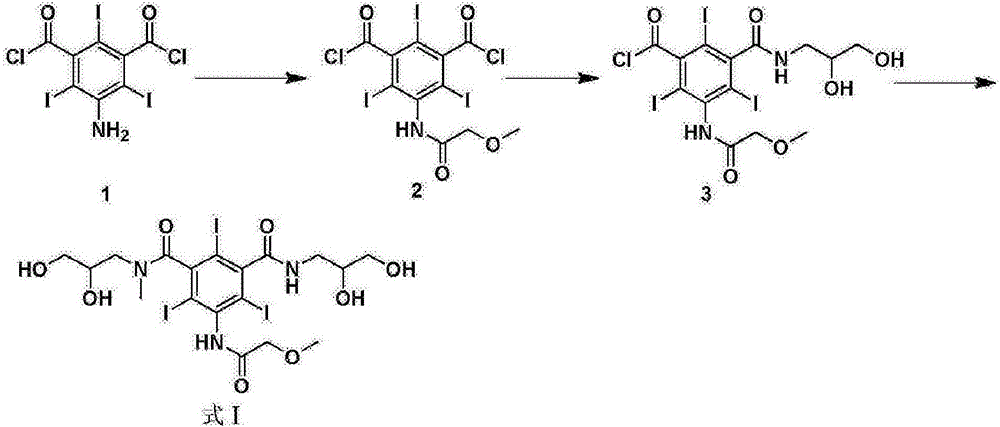

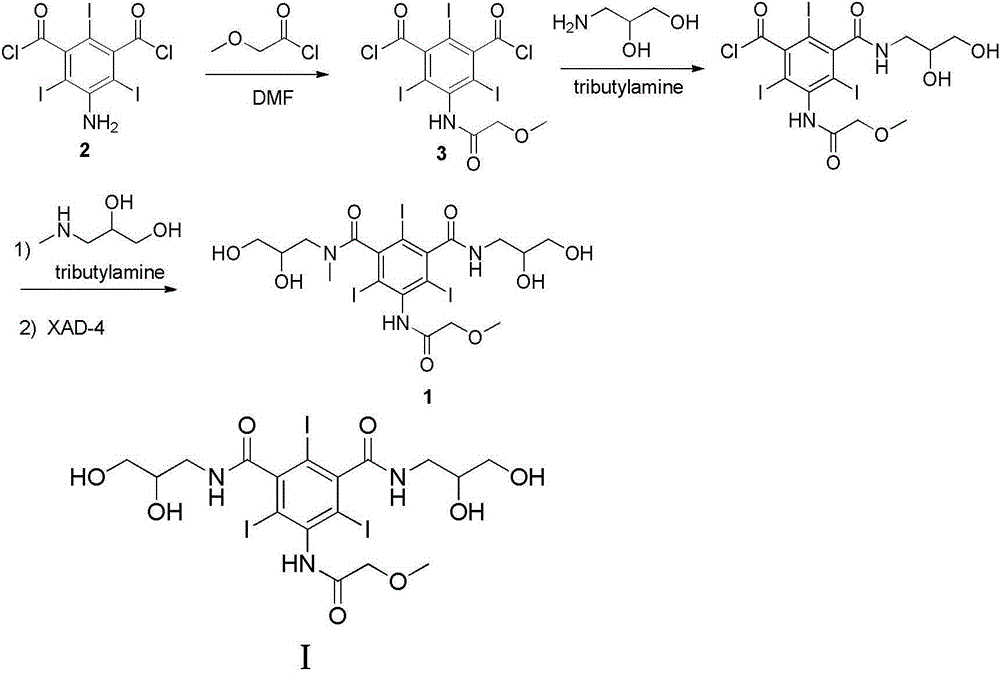

ActiveCN103965074AFew stepsProduct quality is easy to controlOrganic compound preparationCarboxylic acid amides preparationMethoxyacetic acidSynthesis methods

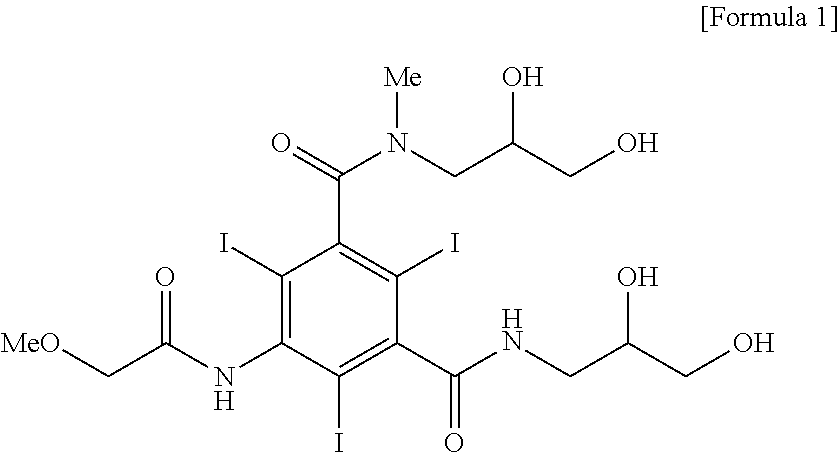

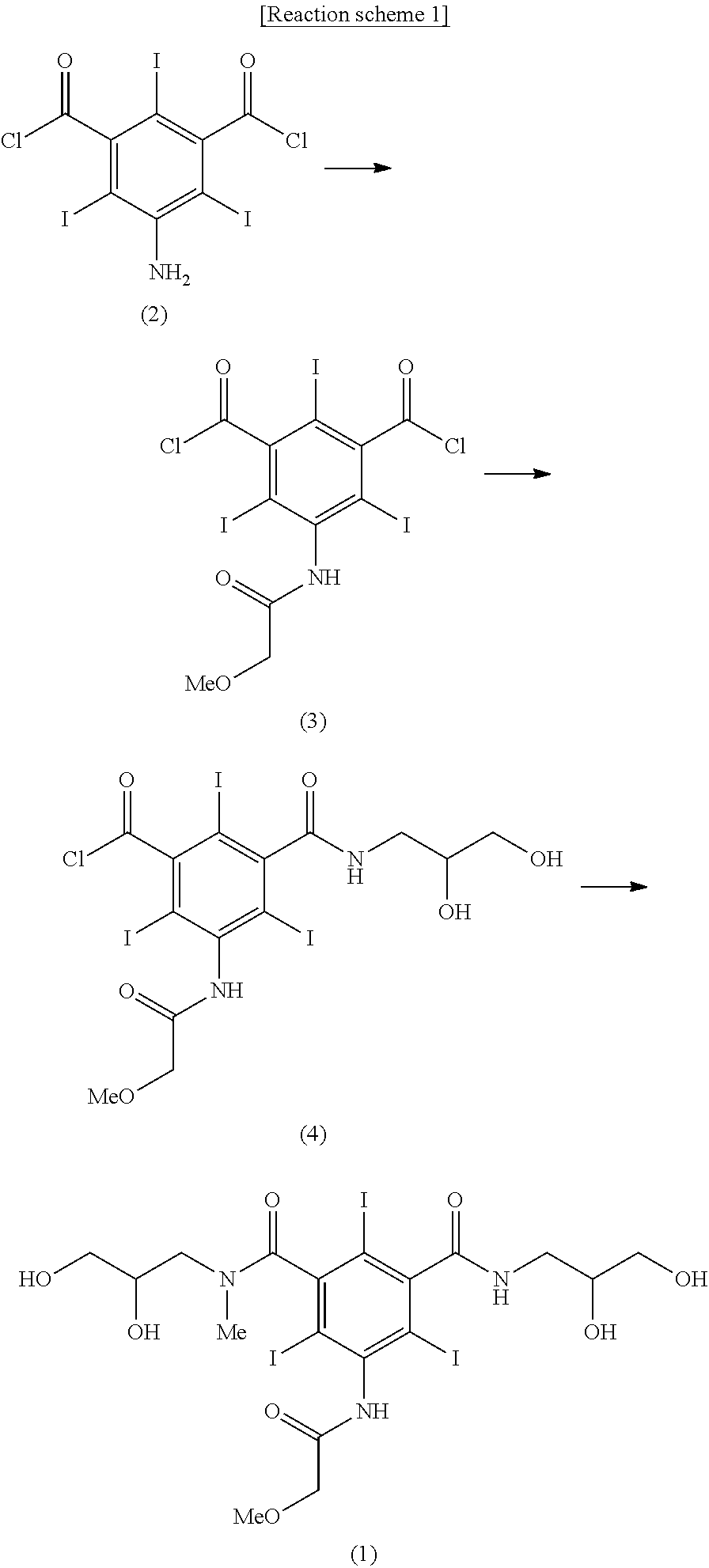

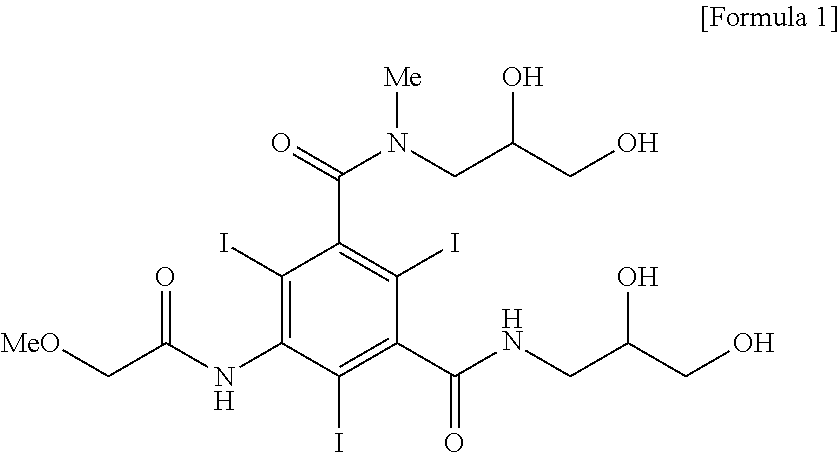

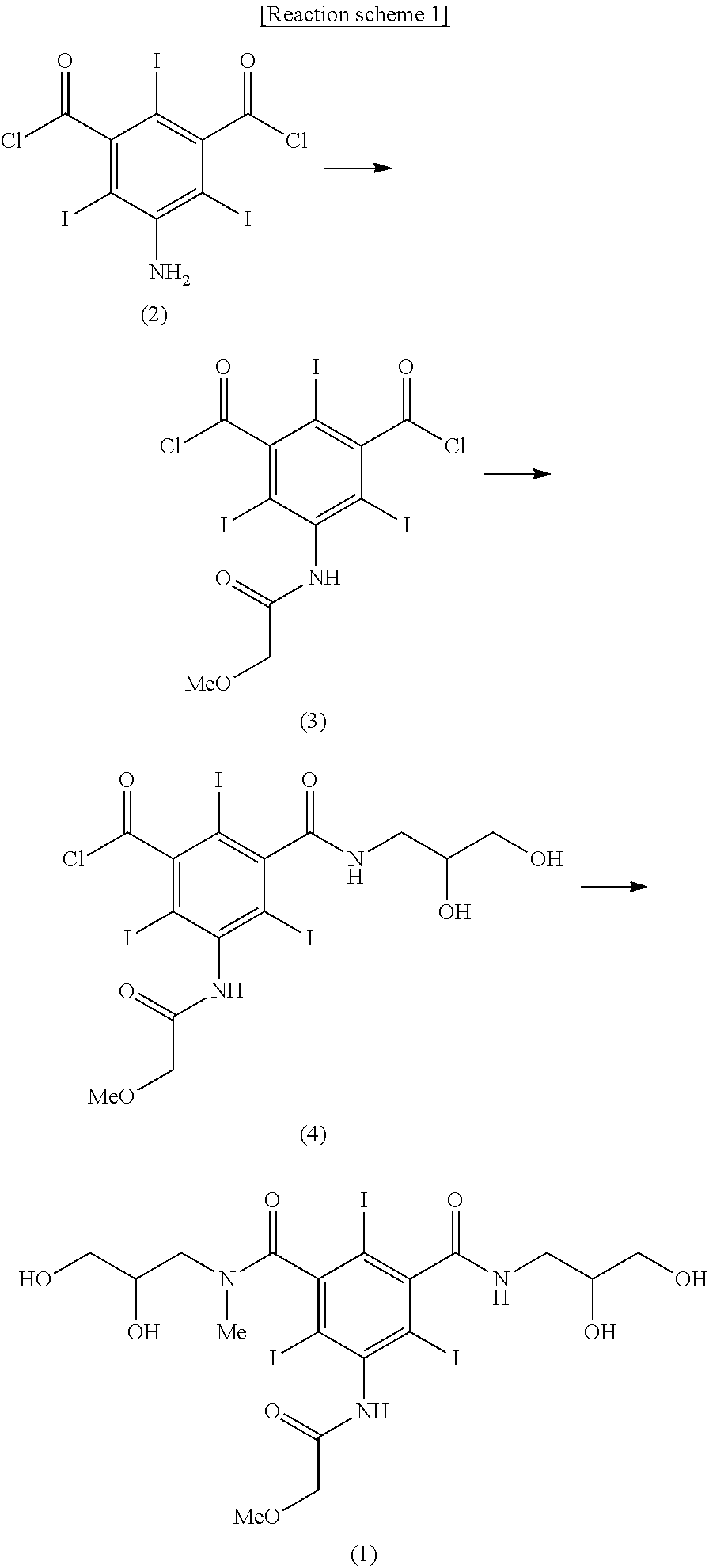

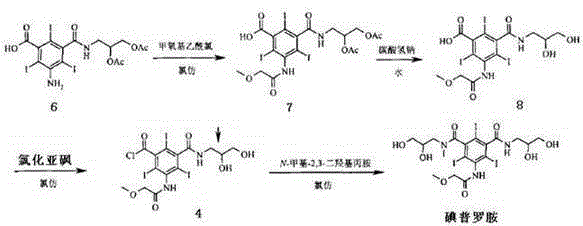

The invention discloses a novel synthesis method for iopromide. The novel synthesis method comprises the following steps of 1, enabling methoxyacetic acid to react with triphosgene to obtain a reaction product, and then, enabling the reaction production to be directly subjected to one-pot reaction with 5-amino-2, 4, 6-triiodo-isophthalicacyl chloride to prepare a compound 5-[(2-methoxyl) acetamido]-2, 4, 6-triiodo-isophthalicacyl chloride as shown in the formula (II); 2, condensing the compound as shown in the formula (II) and N-methyl-2, 3-dihydroxyl propylamine under the action of a solid catalyst ZrO2-Cr2O3 to obtain a compound 5-[(2-methoxyl) acetamido]-3-(2, 3-dihydroxyl-N-methylpropylaminoformoxyl)-2, 4, 6-triiodo-benzoyl chloride as shown in the formula (III); 3, condensing the compound as shown in the formula (III) and 2, 3-dihydroxylpropylamine under the action of a catalyst to prepare a compound iopromide as shown in the formula (I). The synthesis method for iopromide, disclosed by the invention, is few in byproduct, easy to control the product quality, high in product purity, cheap and easily-obtained in used reagent, few in step, simple in operation, relatively high in total yield and suitable for industrial production, and provides a novel approach for preparing iopromide.

Owner:HUAIHAI INST OF TECH

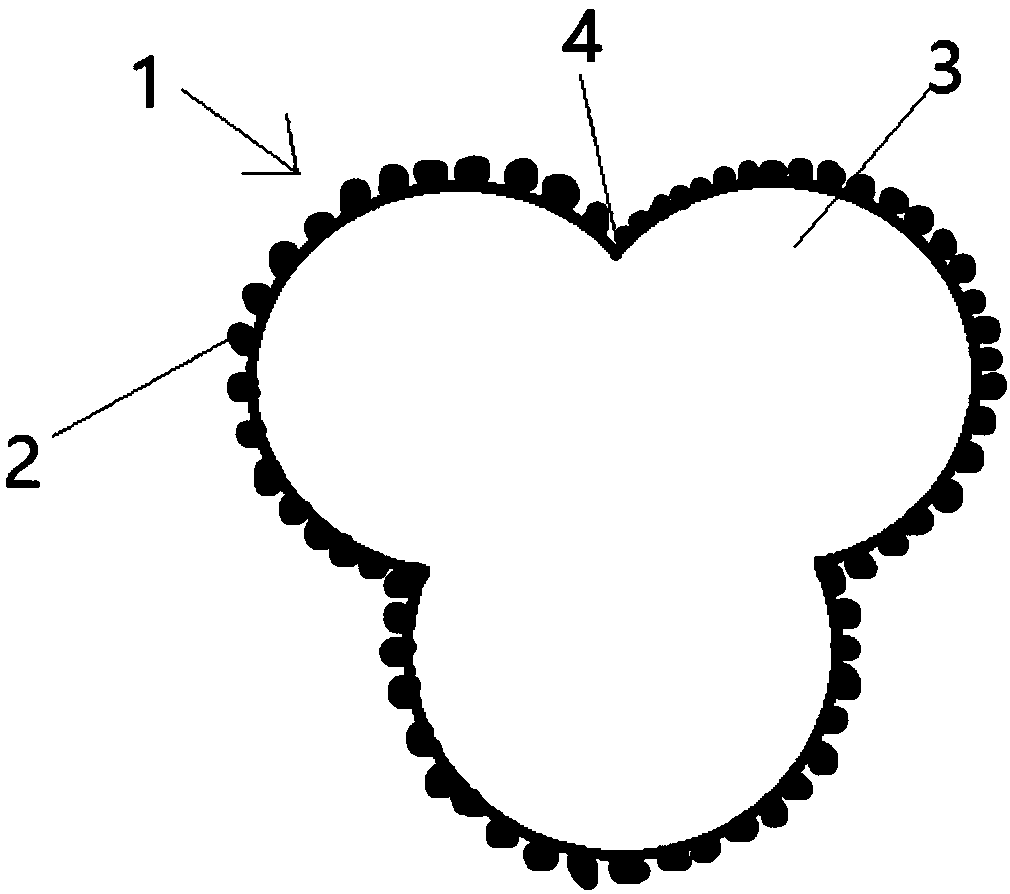

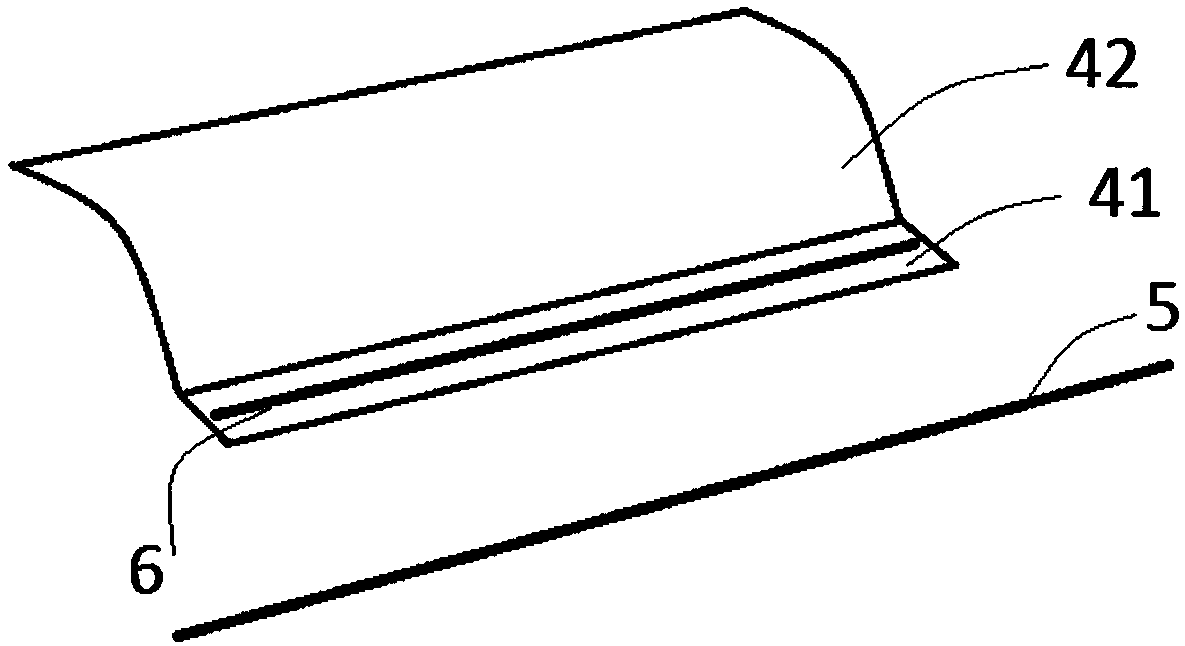

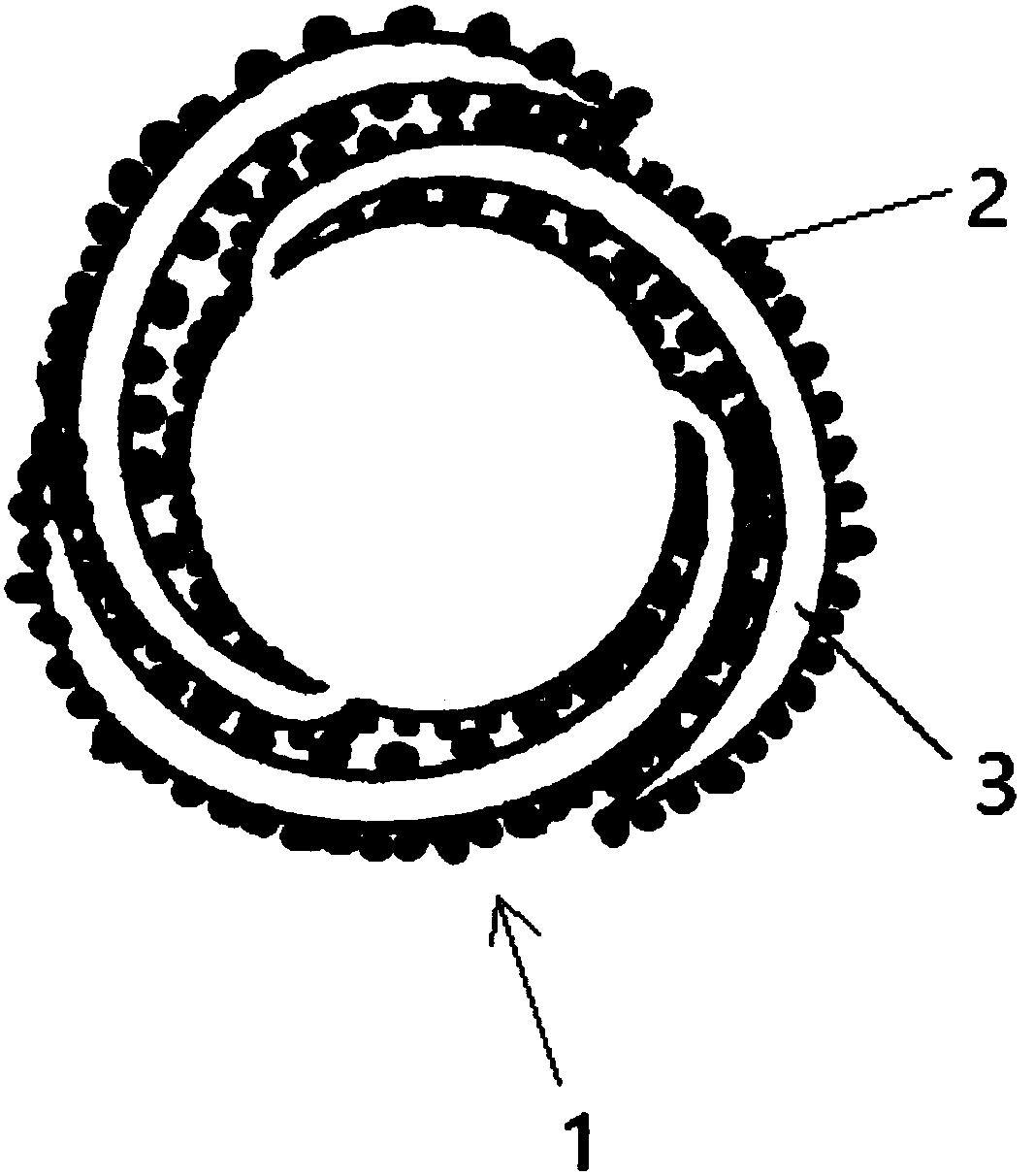

Novel medicine balloon and preparation method thereof

PendingCN107551385AEasy to passImprovement and effectOrganic active ingredientsBalloon catheterTreatment effectIopromide

The invention discloses a novel medicine balloon, which comprises a balloon main body, wherein the balloon main body has a folded state and a full state; and under the full state, a concave structureappears on the balloon main body, so that blood can pass through the balloon main body through the concave structure. The invention also discloses a making method of the novel medicine balloon, and relates to an approach of covering the balloon main body with medicines through iopromide in a digestion and / or ultrasonic spraying modes / mode. According to the novel medicine balloon provided by the invention, the smoothness of the blood is guaranteed by virtue of the concave structure, so that a working time is prolonged and a better therapeutic effect is guaranteed.

Owner:SHANGHAI XINZHI MEDICAL TECH CO LTD

Preparation method of iopromide

ActiveCN106699594AAvoid concurrentAvoid reactionOrganic compound preparationCarboxylic acid amides preparationChemical synthesisSide chain

The invention belongs to the technical field of chemical synthesis, and particularly relates to a preparation method of iopromide. The method comprises the steps that 5-amino-2,4,6-triiodo isophthalic acid is adopted as a raw material to obtain diester to react with methoxyacetyl chloride, and the product is subjected to an ester ammonolysis reaction with side-chain 3-amino propylene glycol and 3-methylamino propylene glycol respectively to obtain iopromide. The preparation method of the iopromide, a catalyst and a by-product methyl alcohol can be removed only through solvent crystallization, green production can be achieved, no industrial wastewater or waste gases or residues exist, and the preparation method is particularly suitable for preparing iopromide in industrial mass production.

Owner:山东诚汇双达药业有限公司

Iopromide preparation method

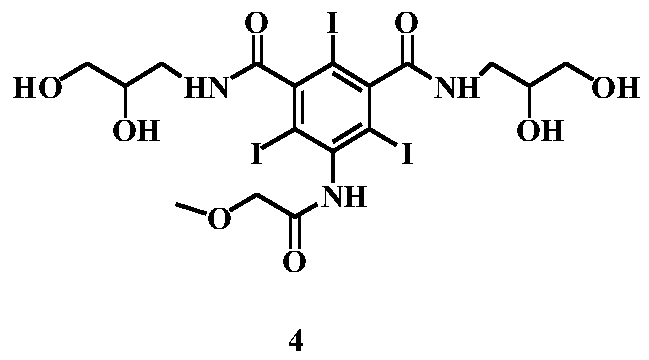

ActiveCN105001113AHigh purityAchieve separationOrganic compound preparationCarboxylic acid amides preparationX-rayIopromide

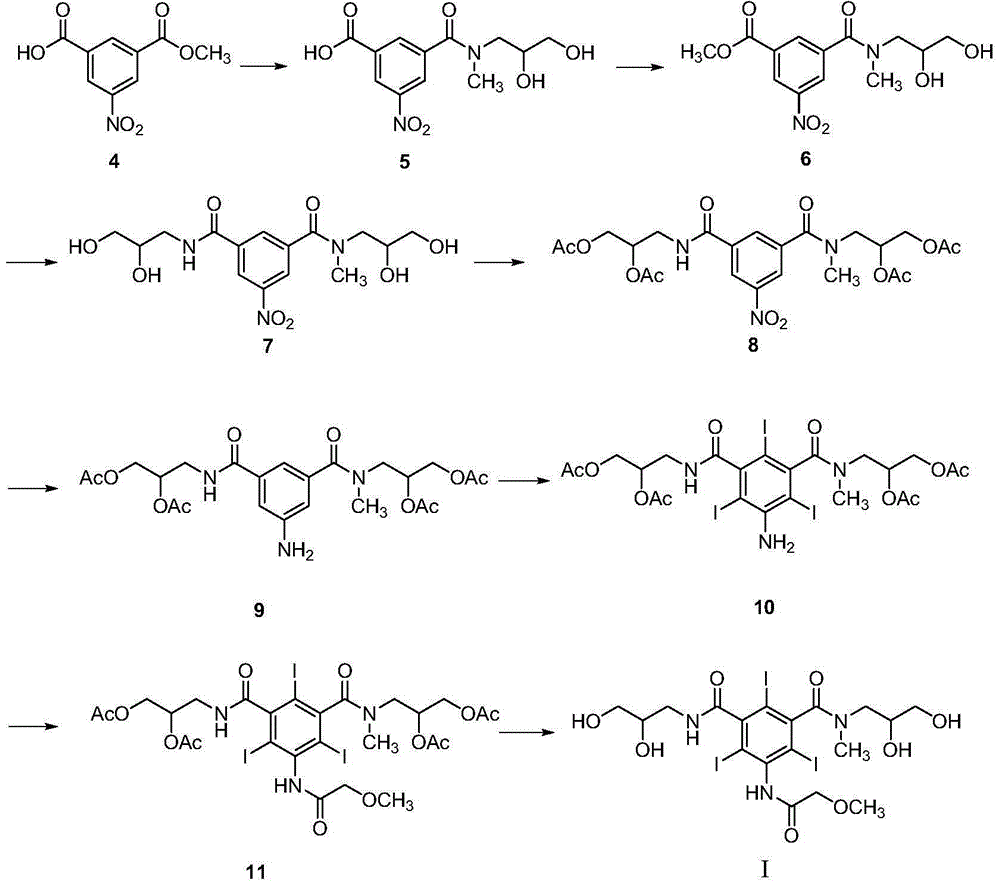

The present invention relates to an X-ray contrast agent iopromide preparation method. According to the method, 3-methoxy acetyl-5-(2,3-dihydroxy-N-methyl-n-propyl-carbamoyl)-2,4,6-triiodobenzoic acid (4) is introduced as an intermediate, the used raw material is cheap and easy to obtain, the experiment operation is relatively simple, the reaction condition is mild, and the product purity is qualified.

Owner:白银京宇新药业有限公司

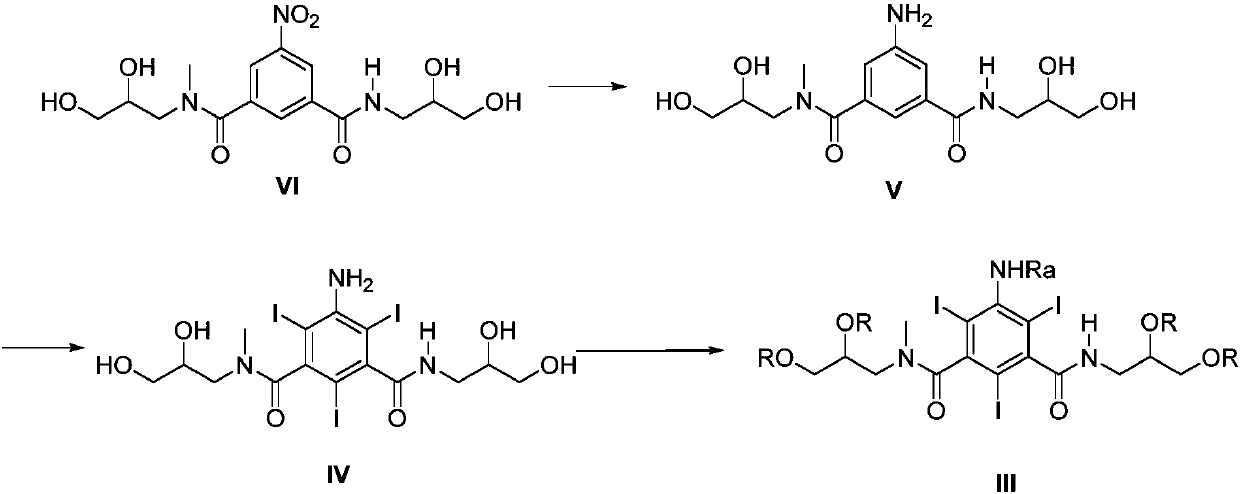

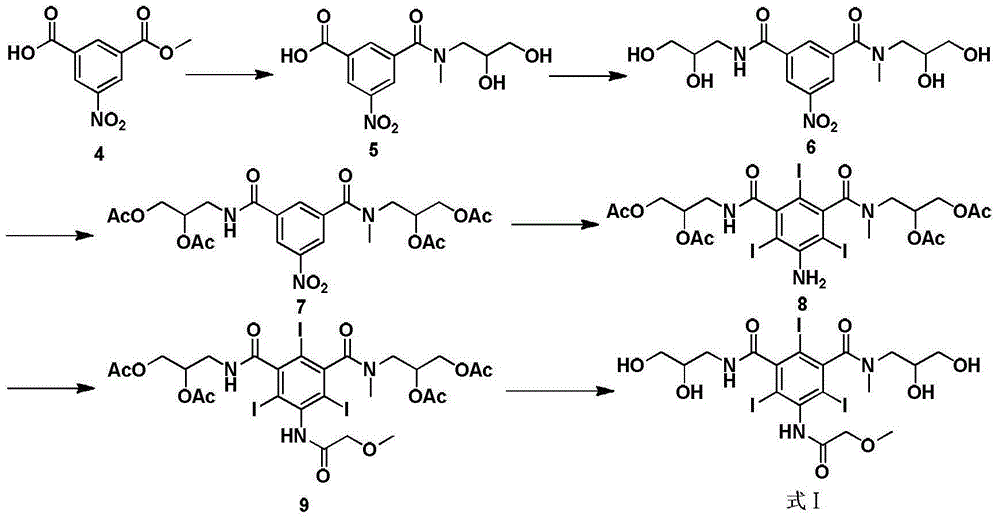

Preparation methods of iopromide and intermediate of iopromide

InactiveCN107778191AAvoid generatingReduce generationOrganic compound preparationCarboxylic acid amides preparationIopromideIodination reaction

The application of the invention relates to preparation methods of iopromide and an intermediate of the iopromide. The method specifically comprises the following steps: conducting a reduction reaction, an iodination reaction and an acylation reaction on a compound shown in the formula VI to prepare a compound shown in the formula III, and further preparing to obtain the iopromide. The method notonly avoids the generation of double acylation byproducts, but also effectively reduces the generation of byproducts in the preparation process, the intermediate is easy to separate and purify, and ahigh-purity product is obtained at a relatively high yield.

Owner:CHIA TAI TIANQING PHARMA GRP CO LTD

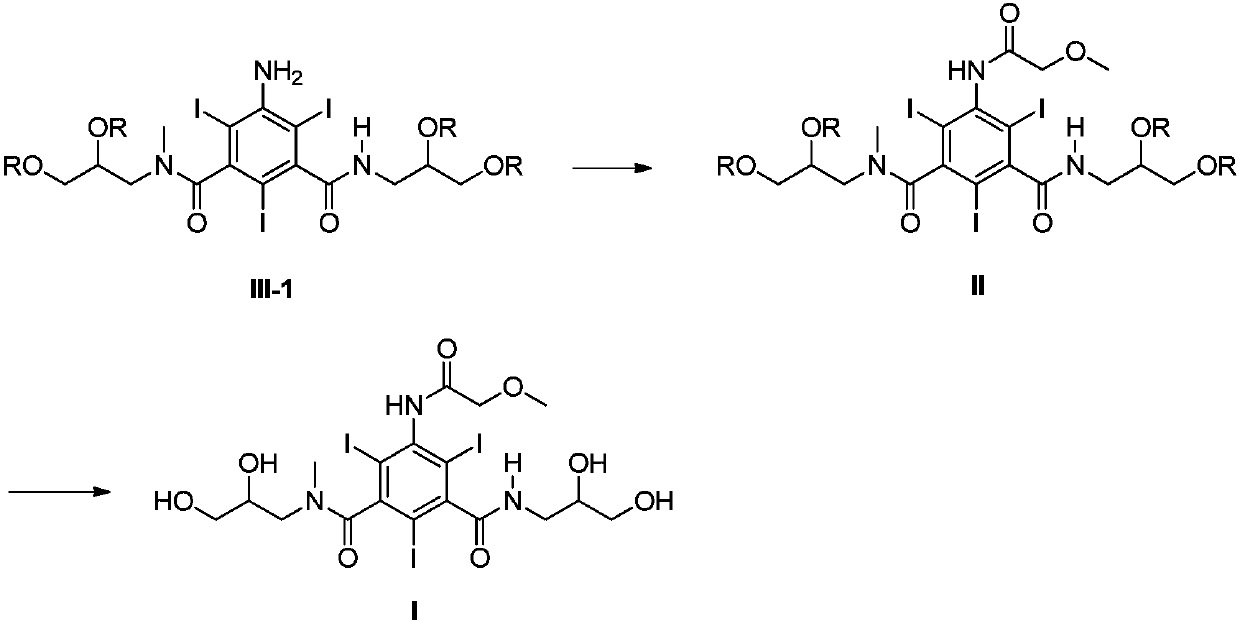

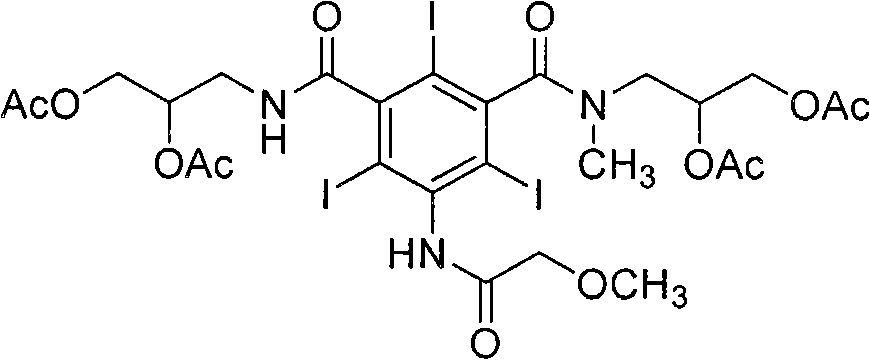

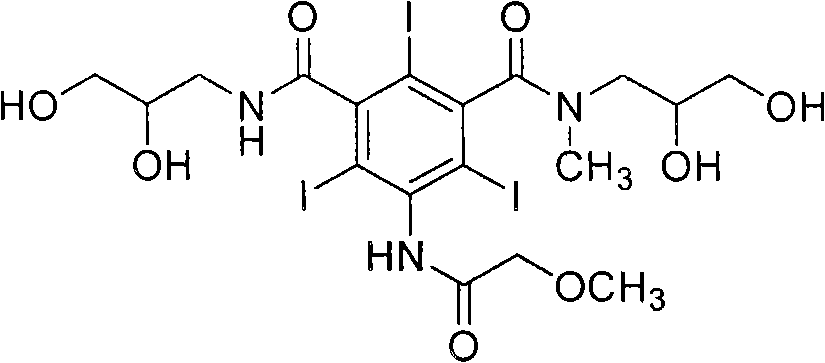

Novel process for preparation of iopromide

InactiveUS20110034730A1Efficient removalHigh purityOrganic compound preparationX-ray constrast preparationsX-rayIopromide

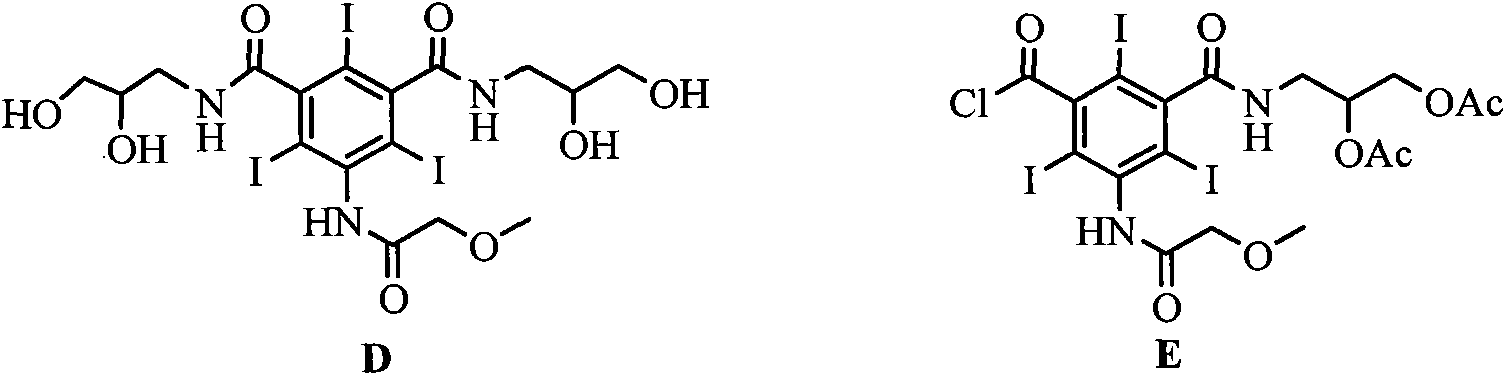

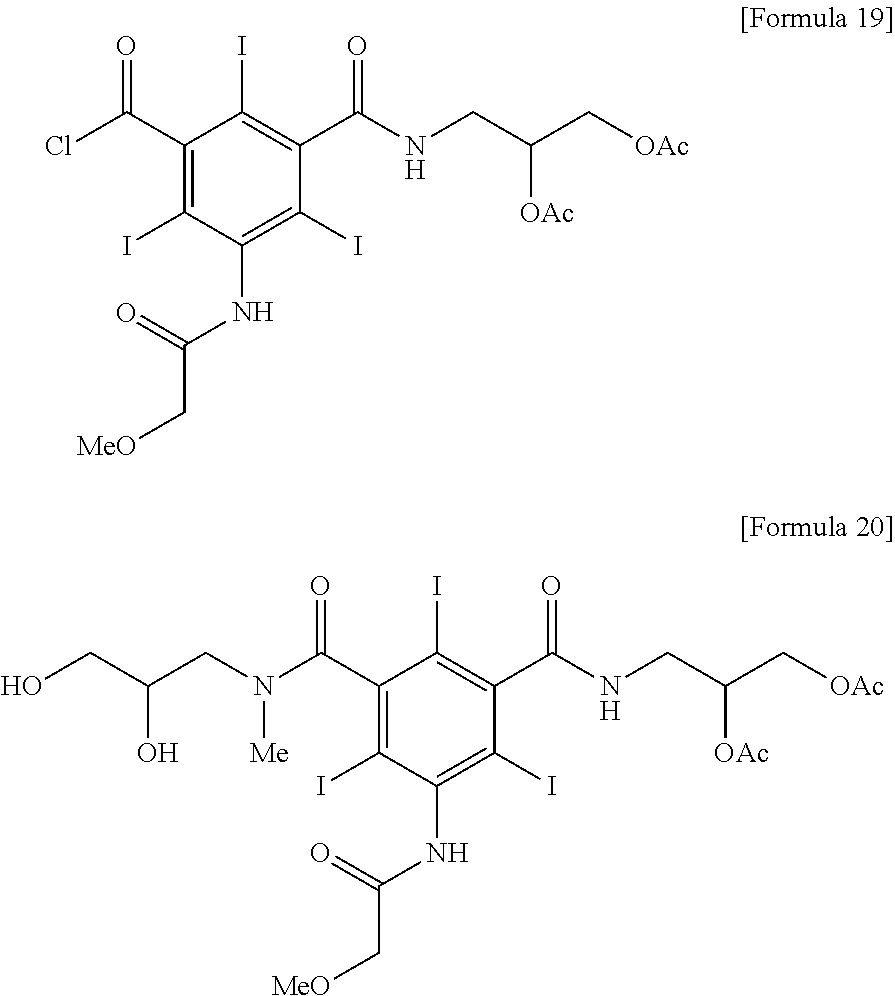

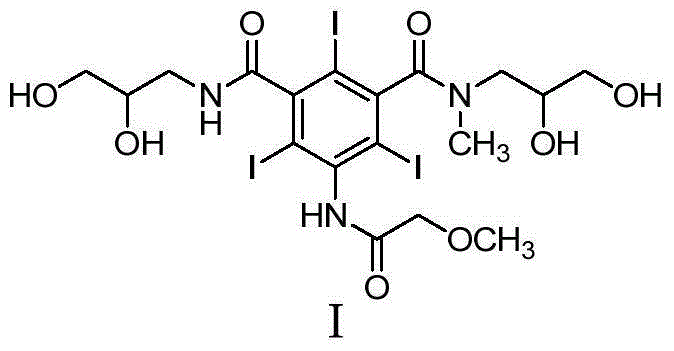

The present invention relates to a novel process for preparing iopromide which is used as a contrast agent for X-ray, wherein 5-methoxyacetylamino-2,4,6-triiodoisophthalic acid (2,3-diacetoxypropyl)amide chloride of formula (19) and 5-methoxyacetylamino-2,4,6-triiodoisophthalic acid [(2,3-dihydroxy-N-methylpropyl)-(2,3-diacetoxypropyl)]diamide of formula (20) are introduced as intermediates, by which a bismer by-product generated during the preparation process can be removed even without an additional removal procedure and thus iopromide with high purity can be prepared in high yield.

Owner:LG LIFE SCI

Efficient contrast agent synthesizing method and application thereof

ActiveCN109134289AIn line with the concept of atomic economicsThere is no special requirement for the order of additionOrganic compound preparationCarboxylic acid amide separation/purificationSynthesis methodsIopromide

The invention discloses an efficient contrast agent synthesizing method. The method includes the following steps of firstly, preparing an intermediate mixture of a compound shown in the formula (II) and a compound shown in the formula (I) and / or (III); secondly, conducting separating to obtain the compound shown in the formula (II) and the compound shown in the formula (I) and / or (III); thirdly, taking the compound shown in the formula (II) to prepare a contrast agent (iopromide); fourthly, taking the compound shown in the formula (III) to prepare a contrast agent (iobitridol), and / or taking the compound shown in the formula (I) to prepare a contrast agent (iohexol, ioversol, iopentol or iodixanol). In the method, the iodic contrast agent is prepared by synthesizing and separating intermediates in the formula (II) and the formula (I) and / or the formula (III) and using the intermediates as the raw materials, the problem that diacylation byproducts need to be removed in an existing method is effectively solved, all the intermediates are effectively used, efficiency is high, and the actual application prospects are good. The formulas (I), (II) and (III) can be seen in the description.

Owner:XILING LAB CO LTD

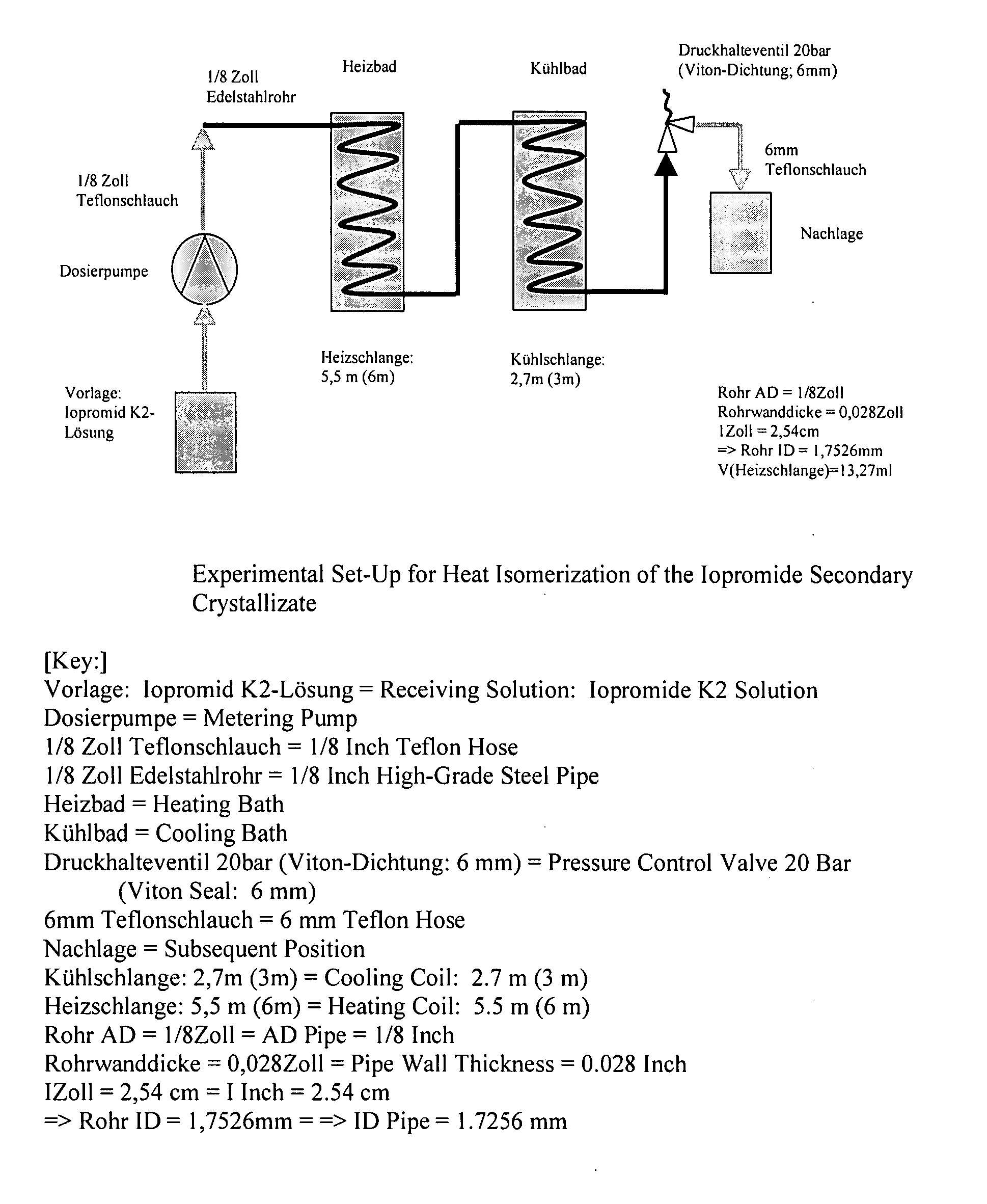

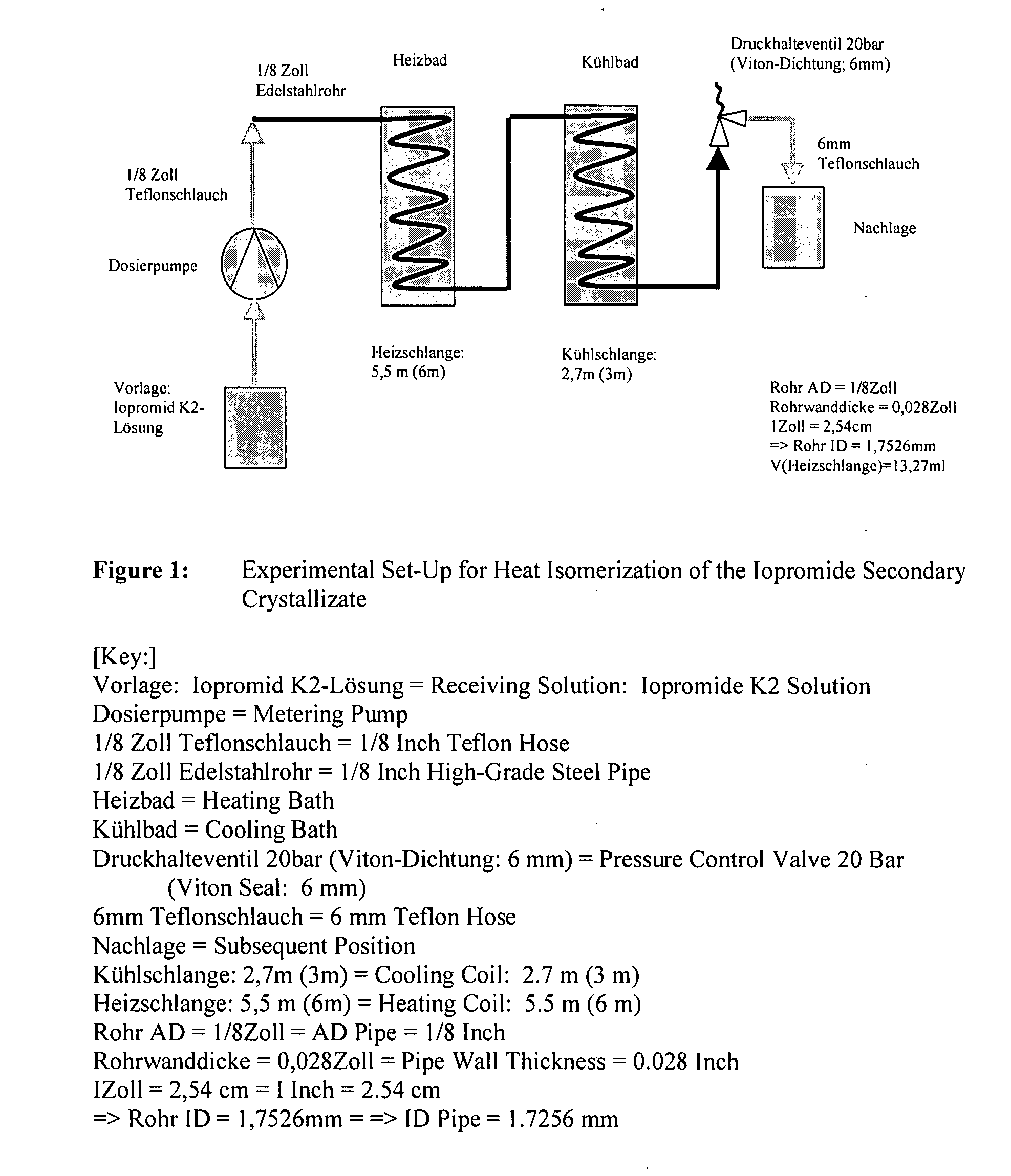

Process for recovery of iopromide, suitable for pharmaceutical purposes, from mother liquors

InactiveUS20070265470A1Increase productionImprove economyCarboxylic acid amide separation/purificationMedicineIopromide

This invention describes a process for recovery of iopromide, suitable for pharmaceutical purposes, by heat treatment of the mother liquors or the secondary crystallizate in a reactor and subsequent crystallization.

Owner:BAYER INTELLECTUAL PROPERTY GMBH

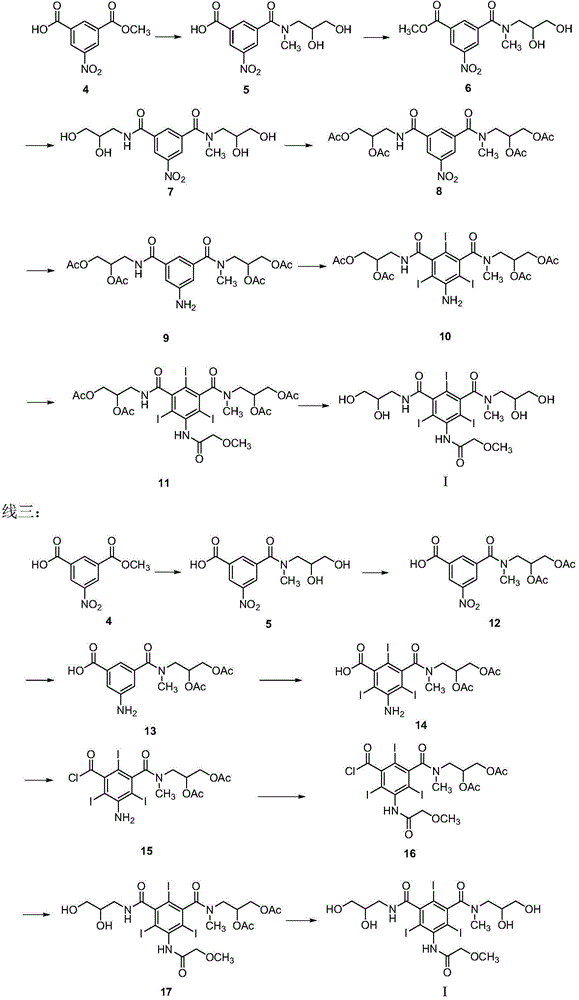

New method for preparing iopromide

InactiveCN105001114AHigh purityHigh yieldOrganic compound preparationCarboxylic acid amides preparationIopromideChloride

The present invention relates to iopromide preparation methods, and provides three new iopromide preparation methods, wherein the method 1 comprises that a compound represented by a formula II is adopted as a starting raw material and reacts with allylamine to obtain a compound represented by a formula III, the compound represented by the formula III reacts with N-methyl allylamine to obtain a compound represented by a formula IV, the compound represented by the formula IV reacts with methoxyacetyl chloride to obtain a compound represented by a formula V, and the compound represented by the formula V is oxidized to obtain the iopromide represented by a formula I, the method 2 comprises that the compound represented by the formula II is adopted as a starting raw material and reacts with allylamine to obtain the compound represented by the formula III, the compound represented by the formula III reacts with methoxyacetyl chloride to obtain a compound represented by a formula IV-1, the compound represented by the formula IV-1 reacts with N-methyl allylamine to obtain the compound represented by the formula V, and the compound represented by the formula V is oxidized to obtain the iopromide represented by the formula I, the method 3 comprises that the compound represented by the formula II is adopted as a starting raw material and reacts with allylamine to obtain the compound represented by the formula III, the compound represented by the formula III reacts with methoxyacetyl chloride to obtain the compound represented by the formula IV-1, the compound represented by the formula IV-1 reacts with 3-methylamino-1,2-propanediol to obtain a compound represented by a formula V-1, and the compound represented by the formula V-1 is oxidized to obtain the iopromide represented by the formula I, and the method 4 comprises that the compound represented by the formula II is adopted as a starting raw material and reacts with methoxyacetyl chloride obtain a compound represented by a formula III-1, the compound represented by the formula III-1 reacts with allylamine to obtain the compound represented by the formula IV-1, the compound represented by the formula IV-1 reacts with N-methyl allylamine to obtain the compound represented by the formula V, and the compound represented by the formula V is oxidized to obtain the iopromide represented by the formula I.

Owner:SHENYANG J & HEALTH PHARMA

Process for preparation of iopromide

InactiveUS8420858B2Efficient removalHigh purityOrganic compound preparationX-ray constrast preparationsX-rayIopromide

The present invention relates to a novel process for preparing iopromide which is used as a contrast agent for X-ray, wherein 5-methoxyacetylamino-2,4,6-triiodoisophthalic acid (2,3-diacetoxypropyl)amide chloride of formula (19) and 5-methoxyacetylamino-2,4,6-triiodoisophthalic acid [(2,3-dihydroxy-N-methylpropyl)-(2,3-diacetoxypropyl)]diamide of formula (20) are introduced as intermediates, by which a bismer by-product generated during the preparation process can be removed even without an additional removal procedure and thus iopromide with high purity can be prepared in high yield.

Owner:LG LIFE SCI LTD

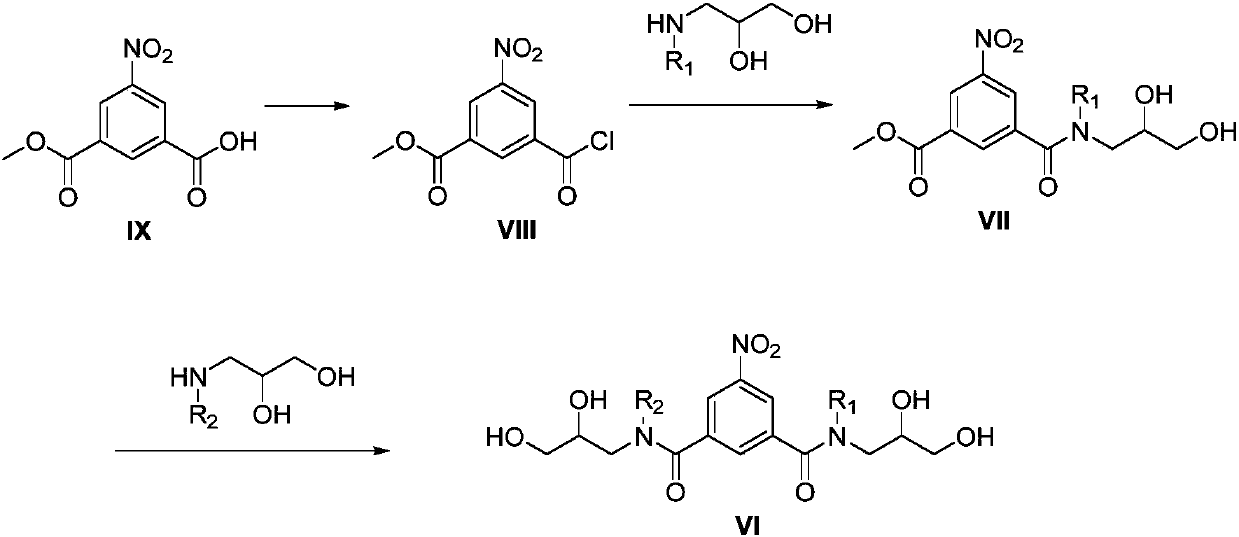

Preparation method and intermediates of iopromide

ActiveCN106366016AEasy to separate and purifyNot easy to open and fall offOrganic compound preparationCarboxylic acid amides preparationIopromideIodination reaction

The present invention relates to a preparation method and intermediates of iopromide. The method specifically comprises: adopting a compound represented by a formula II as a starting raw material, and sequentially carrying out an acylation reaction, a lactonization reaction, a further acylation reaction, a reduction reaction, an iodination reaction, a re-acylation reaction and a final hydrolysis reaction to obtain the iopromide represented by a formula I, wherein a compound represented by a formula VII and a compound represented by a formula V are introduced as the intermediates so as to avoid the generation of the bismer by-product, the lactone ring is not easily subjected to ring opening removing during the iodination reaction process, and the introduced intermediates are easy to separate and purify, such that the high-purity iopromide can be prepared in the high-yield manner.

Owner:LIANYUNGANG RUNZHONG PHARMA CO LTD

Iopromide decoloring and purifying process

InactiveCN104045580AReduce pollutionLarge adsorption capacityCarboxylic acid amide separation/purificationChemical synthesisMicrosphere

The invention relates to an iopromide decoloring and purifying process, mainly solving the technical problems of low yield, waste water environment pollution and the like and belonging to the technical field of chemical synthesis, separation and purification. The iopromide decoloring and purifying process is characterized by comprising the following steps of: weighing an iopromide crude product with the purity of 95%-98%, stirring to dissolve in deionized water until the concentration is 100-250 mg / ml, and filtering to remove impurities; then continuously flowing through a chromatographic column with macroporous polystyrene-divinylbenzene microsphere resin as a chromatographic packing at the flow velocity of 1-4 times of column volume per hour, wherein the ratio of the volume L of the macroporous polystyrene-divinylbenzene microsphere resin and the weight g of a sample is (1:10)-(1:80); eluting by using the deionized water as a mobile phase, collecting eluent with the purity of more than 99%, concentrating by using a nanofiltration membrane, and carrying out spray drying. According to the iopromide decoloring and purifying process, the chromatographic packing has the advantages of large adsorption quantity, good selectivity and the like; an iopromide product with the purity of 99% and the yield more than 90% can be obtained through one-time operation by eluting through the deionized water. The iopromide decoloring and purifying process disclosed by the invention has the advantages of simple process, high efficiency, easiness for industrialized production, less environmental pollution and the like.

Owner:上海华震科技有限公司

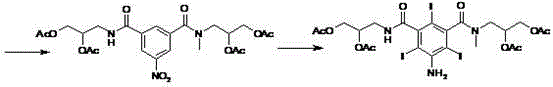

Preparation technology of iopromide intermediate

InactiveCN105254521AGood choiceHigh yieldOrganic compound preparationCarboxylic acid amides preparationAlcoholFiltration

The invention provides an iopromide intermediate. A preparation technology of a compound 3-(2,3-dihydroxypropyl formamyl)-5-nitroisophthalic acid comprises the steps that monomethyl 5-nitroisophthalate is reacted with 3-amino propane-1,2-diol in alcohol solvent at appropriate heating temperature on the condition that strong alkali exists to obtain a product, wherein the reaction equation is shown in the specification. According to the preparation technology of the iopromide intermediate, the synthetic technology is good in selectivity, the synthetic route is simple, the product can be obtained through simple filtration, and the yield is high. Therefore, the technology has the advantages of being efficient, rapid and low in cost.

Owner:ZUNYI MEDICAL UNIVERSITY

New method for preparing iopromide

ActiveCN105017062BEasy to removeHigh purityOrganic compound preparationCarboxylic acid amides preparationCombinatorial chemistryIopromide

The invention relates to a preparation method of iopromide. 5-methoxylacetamido-2,4,6-triiodo m-phthalic acid[(2-oxo-1,3-dioxolame-4-yl)methyl]amido chloride (Formula V) and 5-methoxylacetamido-2,4,6-triiodo m-phthalic acid{[(2-oxo-1,3-dioxolame-4-yl)methyl]-(2,3-dyhydroxyl-N-methyl propyl)}diamide (Formula VI) are introduced to be used as intermediates. Even if there is no additional purification step, a bismer by-product generated during the reaction also can be removed by introduction of the intermediates and high-purity iopromide can be prepared at high yield.

Owner:白银京宇新药业有限公司

Synthesis Method of 3-Methylamino-1, 2-Propanediol

InactiveUS20120277471A1Reduce pressurePromote safe productionOrganic compound preparationAmino compound preparationSynthesis methodsDistillation

A synthesis method of 3-methylamino-1,2-propanediol is disclosed in the invention, and it includes the following steps: (1) adding glycerin chlorohydrin, aqueous monomethylamine solution and an amination catalyst, namely NaOH solution and NaHCO3, into a reactor, mixing the material sufficiently, and allowing amination reaction to proceed in two temperature stages; (2) removing monomethylamine and water from the amination solution after the amination reaction is completed, filtering out the solid resultant, and feeding the filtrate into a still; (3) distilling under reduced pressure to obtain 3-methylamino-1,2-propanediol, wherein the vacuum for distillation under reduced pressure is equal to or greater than 0.099 MPa and the temperature is 130-160° C. The product synthesized according to the invention, a liquid appearing colorless and transparent, has increased purity of over 99.5% (GC) and decreased impurities. Therefore, when this product is used for synthesis of iopromide as a hypo-osmolar nonionic contrast medium, it exactly meets the quality demand.

Owner:WEIFANG XINGXIN TECHN SERVICES

Preparation method and intermediates of iopromide

ActiveCN106366015AHigh purityHigh yieldOrganic compound preparationCarboxylic acid amides preparationIopromideIodination reaction

The present invention relates to a preparation method and intermediates of iopromide. The method specifically comprises: adopting a compound represented by a formula VIII as a starting raw material, and sequentially carrying out an acylation reaction, a further acylation reation, a bislactonization reaction, a reduction reaction, an iodination reaction, a re-acylation reaction and a final hydrolysis reaction to obtain the iopromide represented by a formula I, wherein a compound represented by a formula III and a compound represented by a formula V are introduced as the intermediates so as to avoid the generation of the bismer by-product, the bislactonization of the compound represented by the formula V is complete, the di-lactone ring is not easily subjected to ring opening removing during the iodination reaction process, and the introduced intermediates are easy to separate and purify, such that the high-purity iopromide can be prepared in the high-yield manner.

Owner:CHIA TAI TIANQING PHARMA GRP CO LTD

Preparation method of high-purity iopromide

ActiveCN103570580BOrganic compound preparationCarboxylic acid amides preparationIopromideMedicinal chemistry

The invention relates to a preparation method of a high-purity contrast medium raw material iopromide, wherein byproducts generated in the preparation process can be removed by introducing a compound shown in a formula (19): 5-methoxyl acetamido-2, 4, 6-triiodo isophthalic acid [(2, 3-diacetoxyl-N-methyl propyl)-(2, 3-diacetoxyl propyl)] diamide serving as an intermediate. The invention provides the preparation method of iopromide with high purity.

Owner:内蒙古白医制药股份有限公司

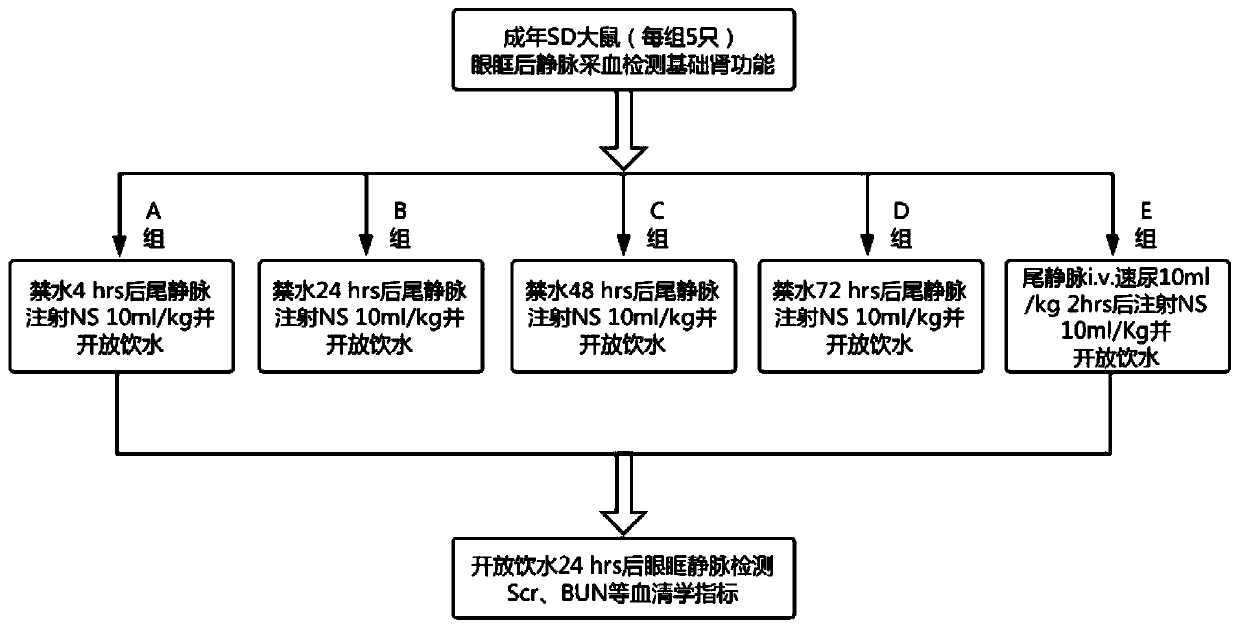

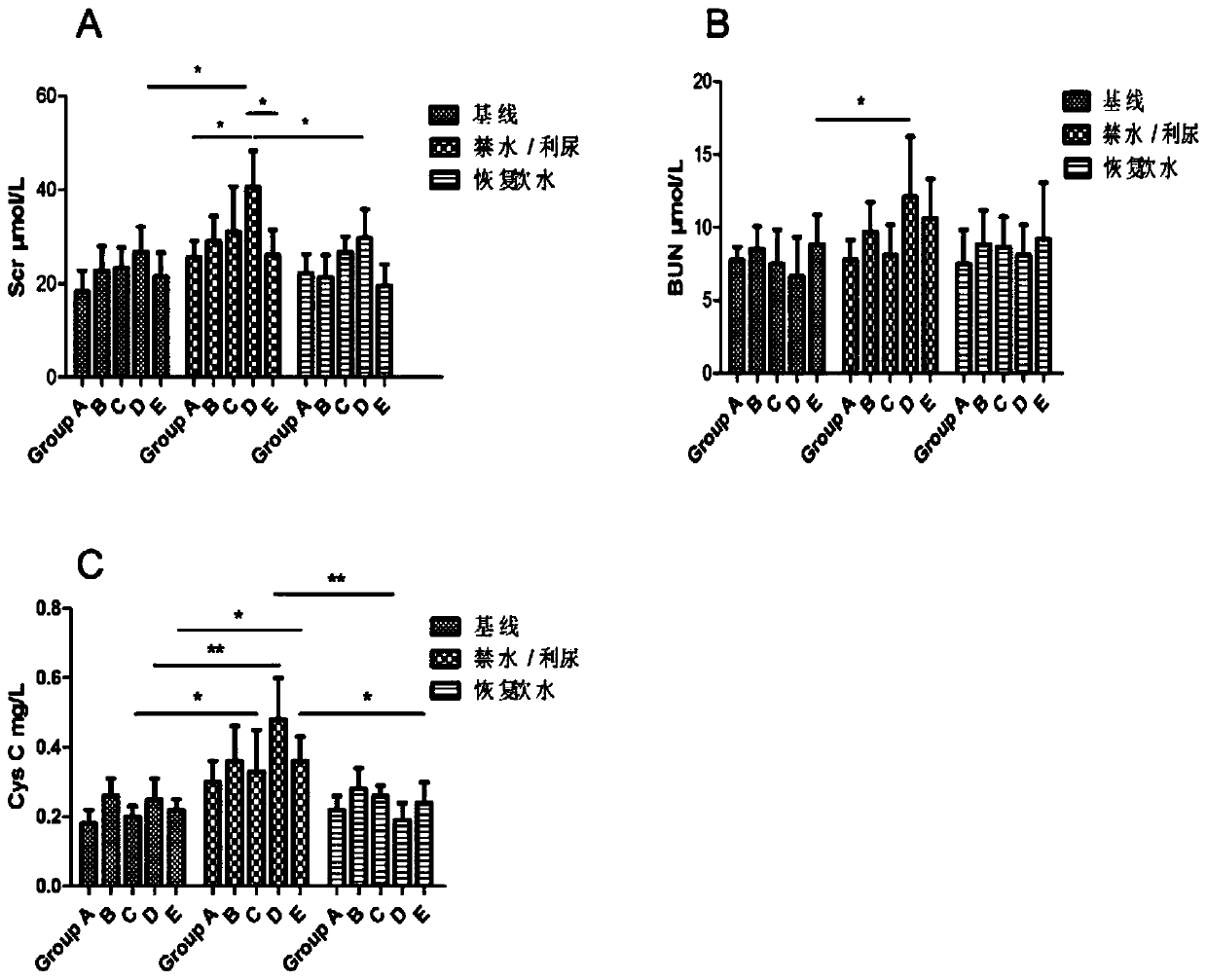

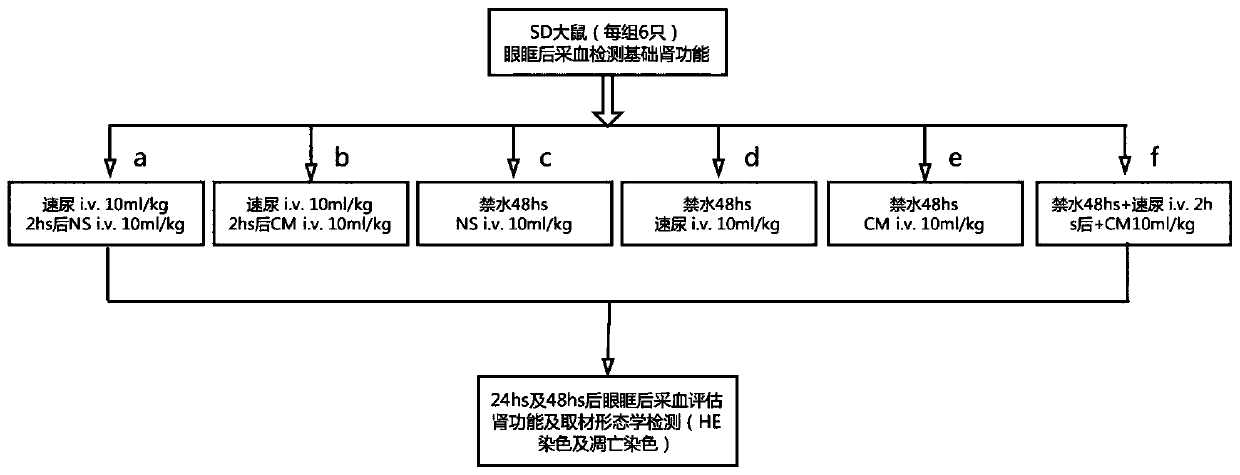

Method for establishing rat contrast-induced nephropathy model

InactiveCN109771403AReduce injection stepsGood vascular conditionOrganic active ingredientsAnimal husbandryCreatinine riseIopromide

The invention discloses a method for establishing a rat contrast-induced nephropathy model. The method includes the following steps that 1, rats do not drink water within 24-55 hours; 2, iopromide isapplied to the rats who do not drink water within 24-55 hours to obtain the contrast-induced nephropathy model. After detecting renal damage markers such as serum creatinine after different water-forbidden time in the test, it comes to a conclusion through discussion that occurrence of CIN is promoted under suitable water-forbidden conditions, and there are no irreversible renal damage changes caused by water-forbidden operation factors. The operation steps in the modeling process are optimized, caudal vein furosemide injection operation is reduced, good vascular conditions are kept for injection of contrast agent, unnecessary intervention factors are reduced, the success rate of tail vein injection of the contrast agent and the success rate of model construction are increased, and the simplified and repeatable modeling process can be completed with fewer and effective steps.

Owner:THE FIRST AFFILIATED HOSPITAL OF GUANGZHOU MEDICAL UNIV (GUANGZHOU RESPIRATORY CENT)

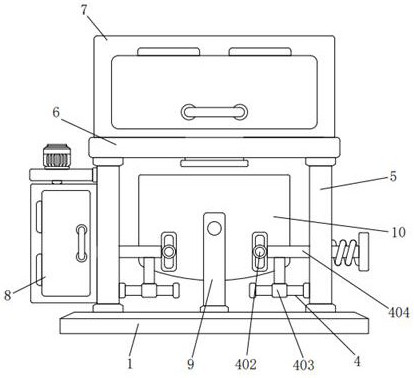

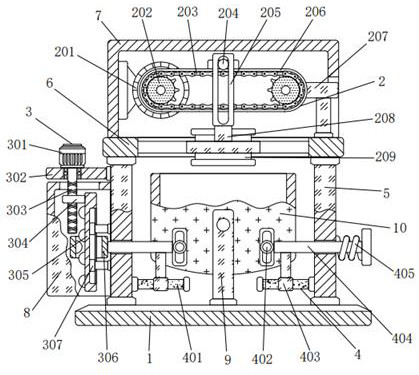

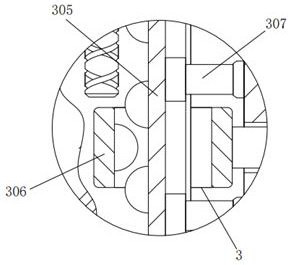

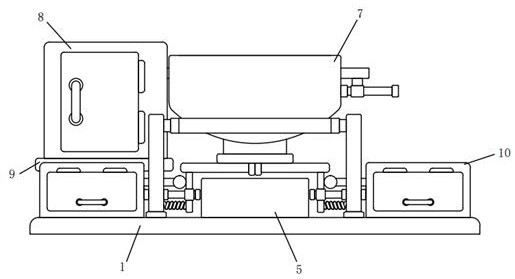

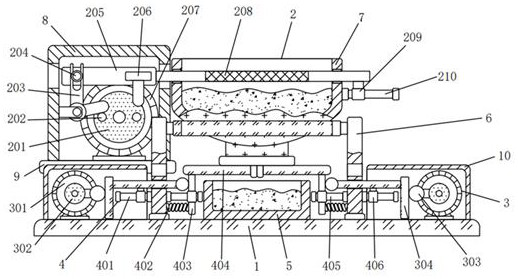

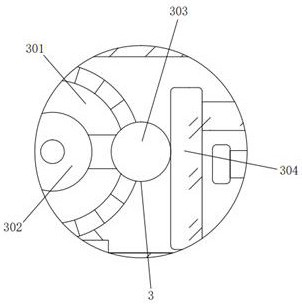

Drying machine for iopromide processing

InactiveCN113280589AUniform drying effectImprove drying effectDrying chambers/containersDrying solid materialsGear wheelElectric machinery

The invention discloses a drying machine for iopromide processing, which comprises a vertical plate, the upper portion of the front end face of the vertical plate is rotatably connected with the front end face of a box body through a pin shaft, a transverse plate is arranged above the box body, a drying structure is arranged above the transverse plate, and the drying structure comprises a motor I, gears, a chain, a straight block, an annular plate, a belt, a bent plate, a sliding block I and a drying machine. According to the drying machine for the iopromide processing provided by the invention, through cooperation of a bottom plate, a straight plate, a transverse plate, a shell II, a first shell, the vertical plate, the box body and the drying structure, the motor I drives the gears on one side to rotate, the chain enables the two gears to rotate at the same time, then the chain rotates, the chain drives the belt to rotate, the belt drives the straight block to rotate, the straight block drives the annular plate to move left and right, the annular plate drives the sliding block I to move left and right, the sliding block I drives the drying machine to move left and right, then the drying machine moves left and right, the drying effect of iopromide is more uniform, and the drying effect is improved.

Owner:东莞市丰泽精密模具有限公司

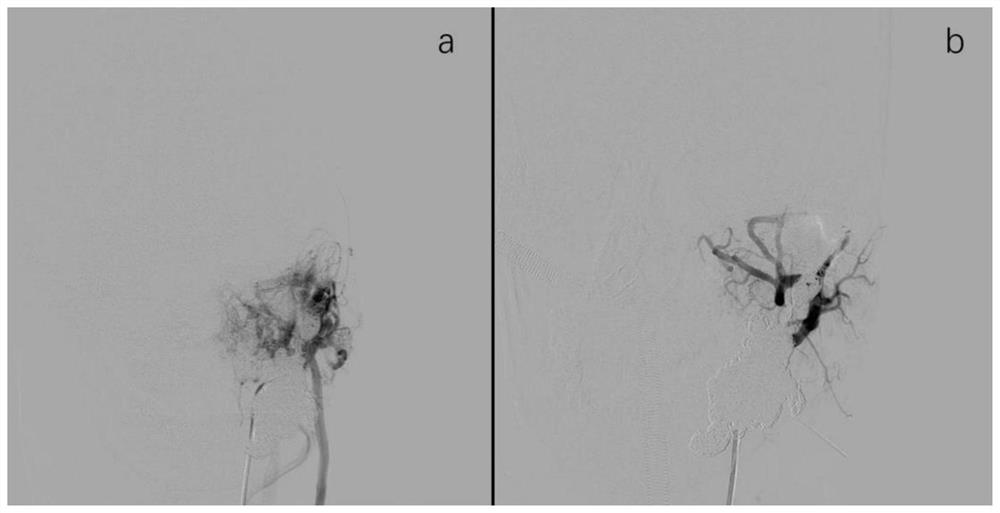

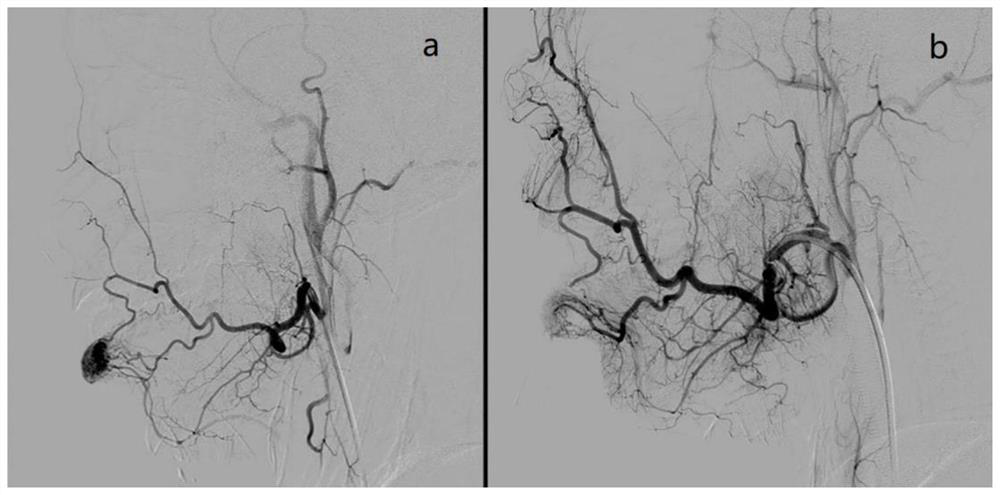

Visual absolute ethyl alcohol-iopromide composite hardening injection as well as preparation method and application thereof

PendingCN113694020AGuaranteed embolization abilityDoes not change physical and chemical propertiesHydroxy compound active ingredientsX-ray constrast preparationsAlcohol ethylPhysical chemistry

The invention provides a visual absolute ethyl alcohol-iopromide composite hardening injection. The visual absolute ethyl alcohol-iopromide composite hardening injection comprises absolute ethyl alcohol and iopromide, and the volume fraction of ethyl alcohol in the composite hardening injection is 99.5% at the temperature of 15 DEG C. The invention also provides a preparation method of the visual absolute ethyl alcohol-iopromide composite hardening injection. The method comprises the following steps: mixing iopromide powder with a proper amount of absolute ethyl alcohol, and stirring to uniformly disperse to obtain an iopromide-absolute ethyl alcohol suspension; and adding absolute ethyl alcohol to fix the volume, so that the volume fraction of the ethyl alcohol of the prepared composite hardening injection at 15 DEG C is 99.5%. According to the composite hardening injection, the flow direction of the absolute ethyl alcohol is dynamically monitored in the embolism hardening process, accurate and visual treatment is achieved, the treatment risk and complications are reduced, and the X-ray radiation resistance of the composite preparation can be adjusted by adjusting the content of iopromide added into the absolute ethyl alcohol according to specific treatment requirements.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

Positioning technique used under X ray

InactiveCN105999306AHigh iodine contentExcellent developabilityX-ray constrast preparationsSoft x rayX-ray

The invention discloses a positioning technique used under X ray. The positioning technique comprises the steps of S1, weighing a certain amount of iohexol and tromethamine, and grinding iohexol and tromethamine in a grinder into 200-500-mesh powder; S2, placing tromethamine in step 1 into a stirrer, then weighing a certain amount of hydrochloric acid, sodium calcium edentate and iopromide, placing hydrochloric acid, sodium calcium edentate and iopromide into the stirrer, adding a certain amount of methanol solution of 75-85% to the stirrer, starting the stirrer, maintaining temperature at 30-45 DEG C, and conducting stirring for 1-3 h; S3, placing iohexol powder in step 1 in the stirrer in step 2. The positioning technique is used for medical operation or examination and positioning, can well achieve recognition on skin, can achieve development during X-ray fluoroscopy and accurate positioning, and can not cause damage to human body.

Owner:万承兴

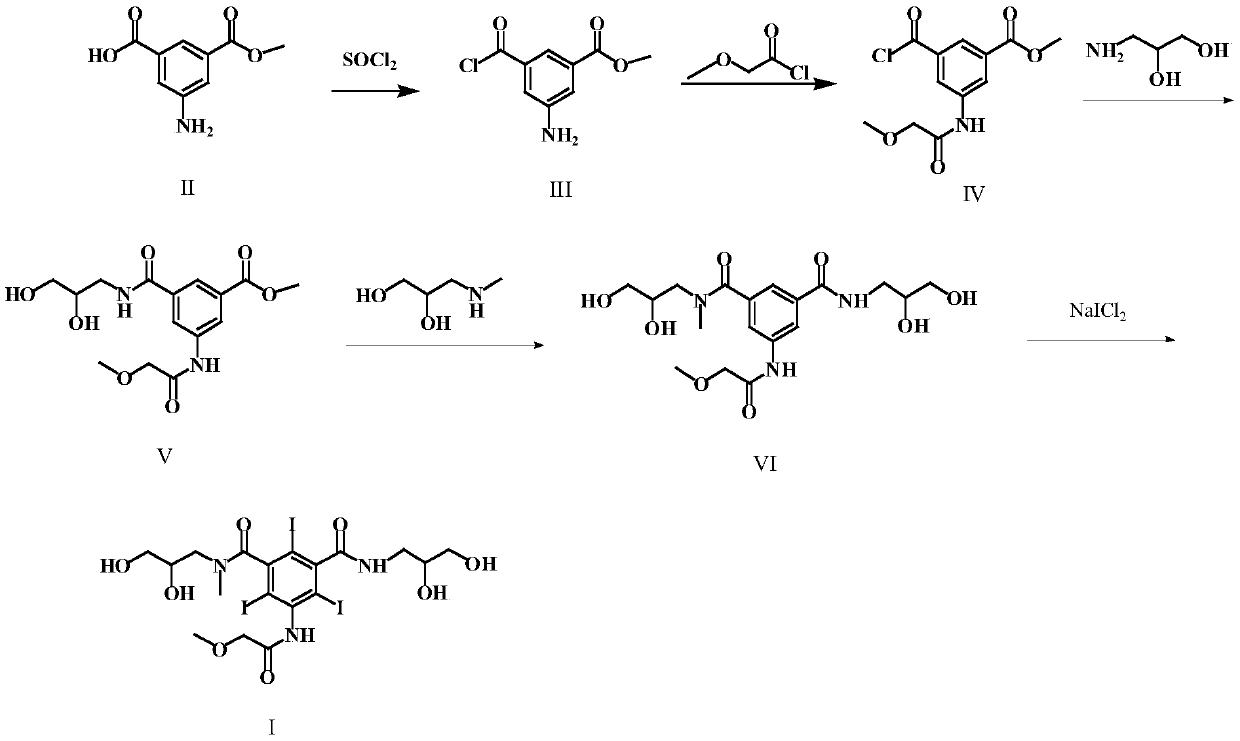

Preparation method of iopromide

ActiveCN110028419ASave the protection stepHigh selectivityOrganic compound preparationCarboxylic acid amides preparationChemical synthesisChloride

The invention belongs to the technical field of chemical synthesis, and particularly relates to a preparation method of iopromide. The method comprises the following steps: (1) chloridizing 5-methylaminoisophthalic acid monomethyl ester as shown in a formula II and used as a raw material to obtain 3-amino-5-chloroformylbenzoate as shown in a formula III; (2) enabling reaction between the compoundas shown in the formula III and methoxyacetyl chloride to obtain 3-chloroformyl 5-[methoxyacetyl)amino)]-methyl benzoate as shown in a formula IV; (3) enabling reaction between the compound as shown in the formula IV and 3-aminopropanediol to obtain 3-[(2,3-dihydroxypropylaminoformyl)-5-[(methoxyacetyl)amino]-methyl benzoate as shown in a formula V; (4) enabling reaction between the compound as shown in the formula V and 3-methylamino propanediol to obtain N,N'-di(2,3-dihydroxyl)-5-[(methoxyacetyl)amino)]-N-methyl-1,3-phthalamide as shown in a formula VI; and (5) enabling reaction between thecompound as shown in the formula VI and NaICl2 to obtain the iopromide. The preparation method of the iopromide provided by the invention is low in production cost, high in reproducibility and high inyield.

Owner:TAIZHOU UNIV

Novel preparation method of iopromide

ActiveCN102964269BOrganic compound preparationCarboxylic acid amides preparationIopromidePropylene glycol

The invention relates to a preparation method of iopromide. The preparation method comprises the following steps of: on the basis of using 5-amino-3-(2,3-dyhydroxy propylamino formyl)-2,4,6-triiodo isophthalic acid shown in a formula II or 5-methoxyl acetamido-3-(2,3-dyhydroxy propylamino formyl)-2,4,6-triiodo isophthalic acid shown in a formula II-1 as a starting material, protecting amino in a position 5 of the formula II and two hydroxyls in (2,3-dyhydroxy propylamino formyl) in a position 3 or two hydroxyls in (2,3-dyhydroxy propylamino formyl) in a position 3 of the formula II-1 by using methoxyl acetyl, so as to generate a compound shown in a formula III; chloridizing by utilizing a chloridizing agent, so as to prepare a corresponding acyl chloride compound shown in a formula IV; then reacting with methylamino propylene glycol to generate a compound shown in a formula V; and hydrolyzing and purifying so as to prepare high-purity iopromide.

Owner:浙江海昌药业股份有限公司

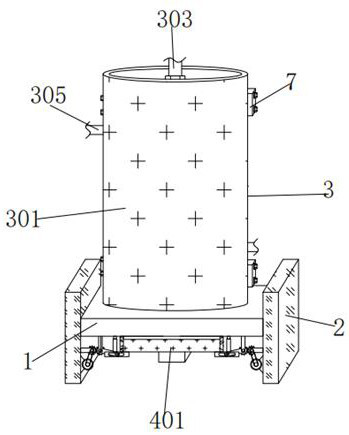

Filter for iopromide processing

InactiveCN113332777AIncrease filtration rateImprove work efficiencyMoving filtering element filtersElectric machineryIopromide

Owner:东莞市盈通环保科技有限公司

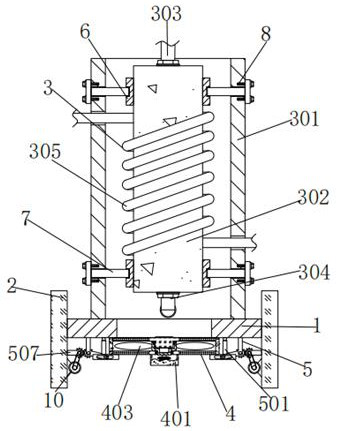

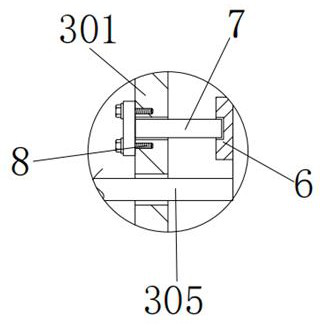

Condenser used for iopromide processing

InactiveCN113375383AImprove cooling efficiencyLighting and heating apparatusCooling fluid circulationElectric machineryEngineering

The invention discloses a condenser used for iopromide processing. The condenser used for iopromide processing comprises a base and supporting legs, wherein the supporting legs are welded to two ends of the base, a through hole is formed in a center of the base through machining, and a cooling device is installed above the base. According to the condenser used for iopromide processing, through mutual cooperation of a first shell, a box body, a liquid inlet pipe, a liquid outlet pipe, a condensation pipe and other structures, a stock solution which needs to be cooled can be injected into the box body through the liquid inlet pipe, then cooling liquid is injected into a cooling pipeline through external equipment, thus the stock solution in the box body is cooled, through mutual cooperation of a second shell, a rotating rod, fan blades, a first motor and other structures, the first motor can drive the rotating rod to rotate, and thus the rotating rod drives the fan blades to rotate, so that the box body is further cooled, and then the cooling efficiency is improved.

Owner:东莞市泽韵电子有限公司

New method for preparing iopromide

InactiveCN105001114BHigh purityHigh yieldOrganic compound preparationCarboxylic acid amides preparationChlorideIopromide

The present invention relates to iopromide preparation methods, and provides three new iopromide preparation methods, wherein the method 1 comprises that a compound represented by a formula II is adopted as a starting raw material and reacts with allylamine to obtain a compound represented by a formula III, the compound represented by the formula III reacts with N-methyl allylamine to obtain a compound represented by a formula IV, the compound represented by the formula IV reacts with methoxyacetyl chloride to obtain a compound represented by a formula V, and the compound represented by the formula V is oxidized to obtain the iopromide represented by a formula I, the method 2 comprises that the compound represented by the formula II is adopted as a starting raw material and reacts with allylamine to obtain the compound represented by the formula III, the compound represented by the formula III reacts with methoxyacetyl chloride to obtain a compound represented by a formula IV-1, the compound represented by the formula IV-1 reacts with N-methyl allylamine to obtain the compound represented by the formula V, and the compound represented by the formula V is oxidized to obtain the iopromide represented by the formula I, the method 3 comprises that the compound represented by the formula II is adopted as a starting raw material and reacts with allylamine to obtain the compound represented by the formula III, the compound represented by the formula III reacts with methoxyacetyl chloride to obtain the compound represented by the formula IV-1, the compound represented by the formula IV-1 reacts with 3-methylamino-1,2-propanediol to obtain a compound represented by a formula V-1, and the compound represented by the formula V-1 is oxidized to obtain the iopromide represented by the formula I, and the method 4 comprises that the compound represented by the formula II is adopted as a starting raw material and reacts with methoxyacetyl chloride obtain a compound represented by a formula III-1, the compound represented by the formula III-1 reacts with allylamine to obtain the compound represented by the formula IV-1, the compound represented by the formula IV-1 reacts with N-methyl allylamine to obtain the compound represented by the formula V, and the compound represented by the formula V is oxidized to obtain the iopromide represented by the formula I.

Owner:SHENYANG J & HEALTH PHARMA

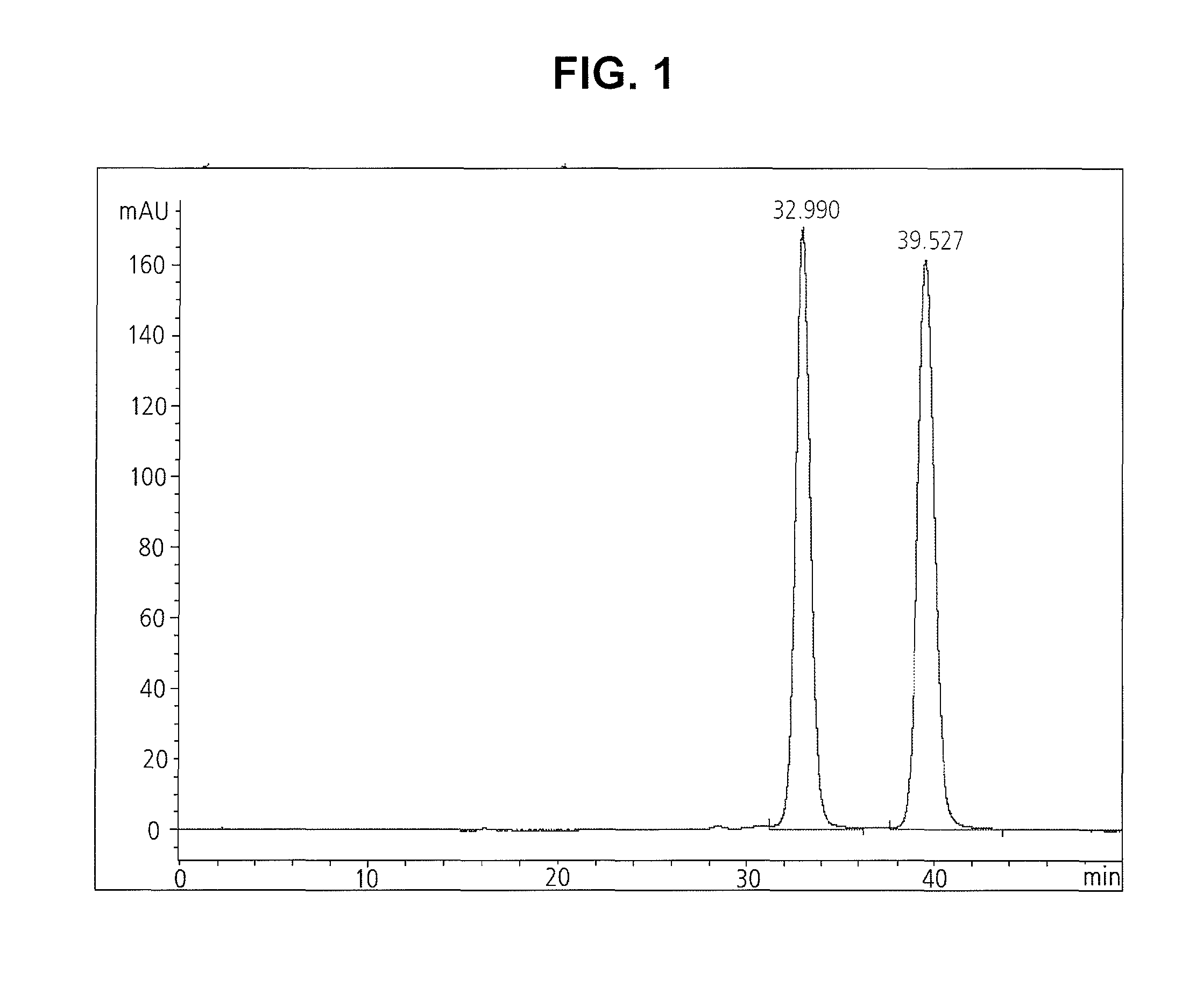

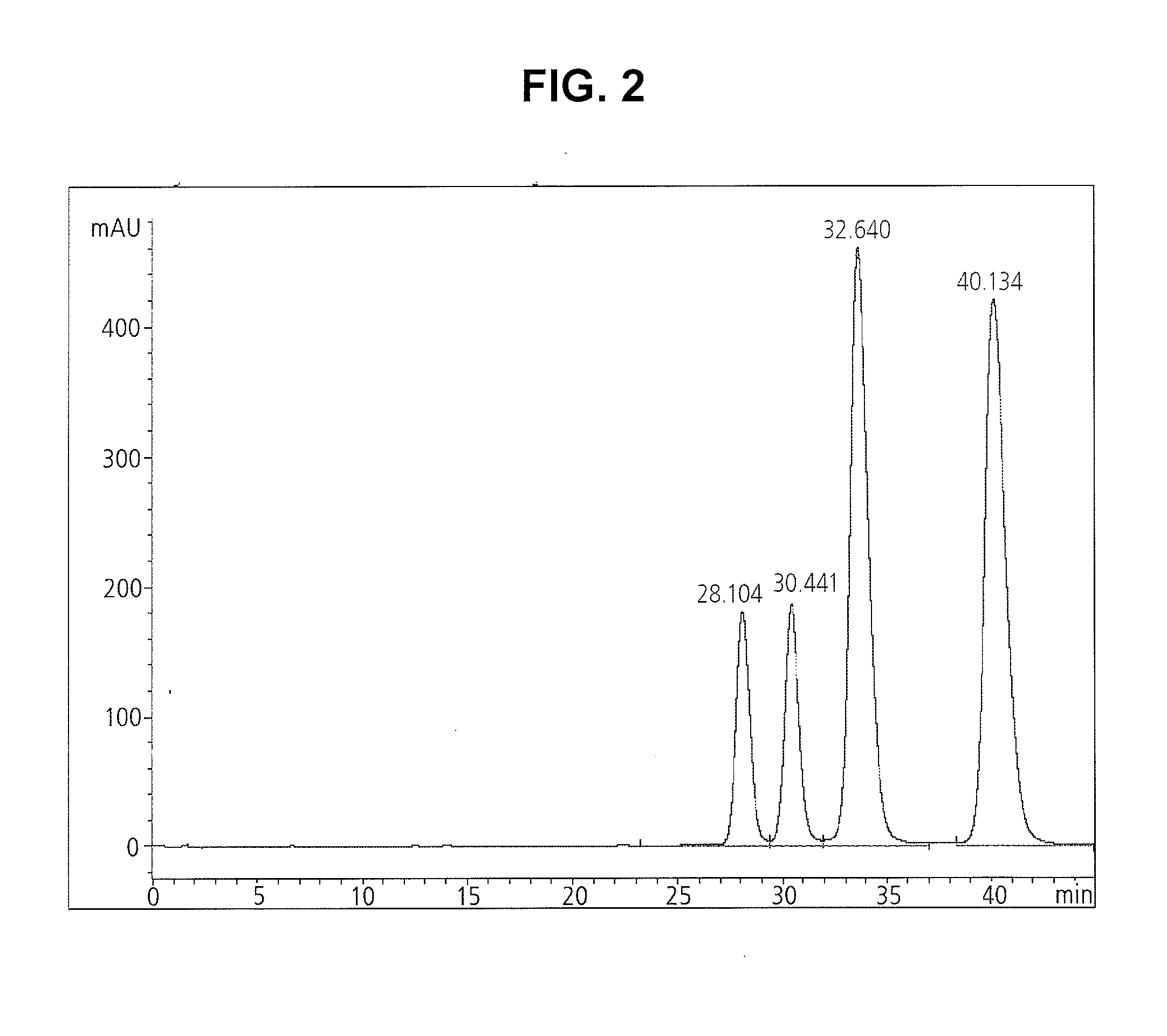

Method for selectively crystallizing a Z isomer of iopromide

The present invention relates to a method for selectively crystallizing Z isomer of iopromide of formula (I) comprising a) dissolving a crude iopromide comprising a mixture of E and Z isomers or a concentrate thereof in an alcohol, and b) heating the resulting alcohol solution to obtain crystalline of Z isomer of iopromide; and a method for preparing a composition comprising the crystalline Z isomer of iopromide.

Owner:DAEWOONG PHARM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com