Patents

Literature

95results about How to "Uniform drying effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

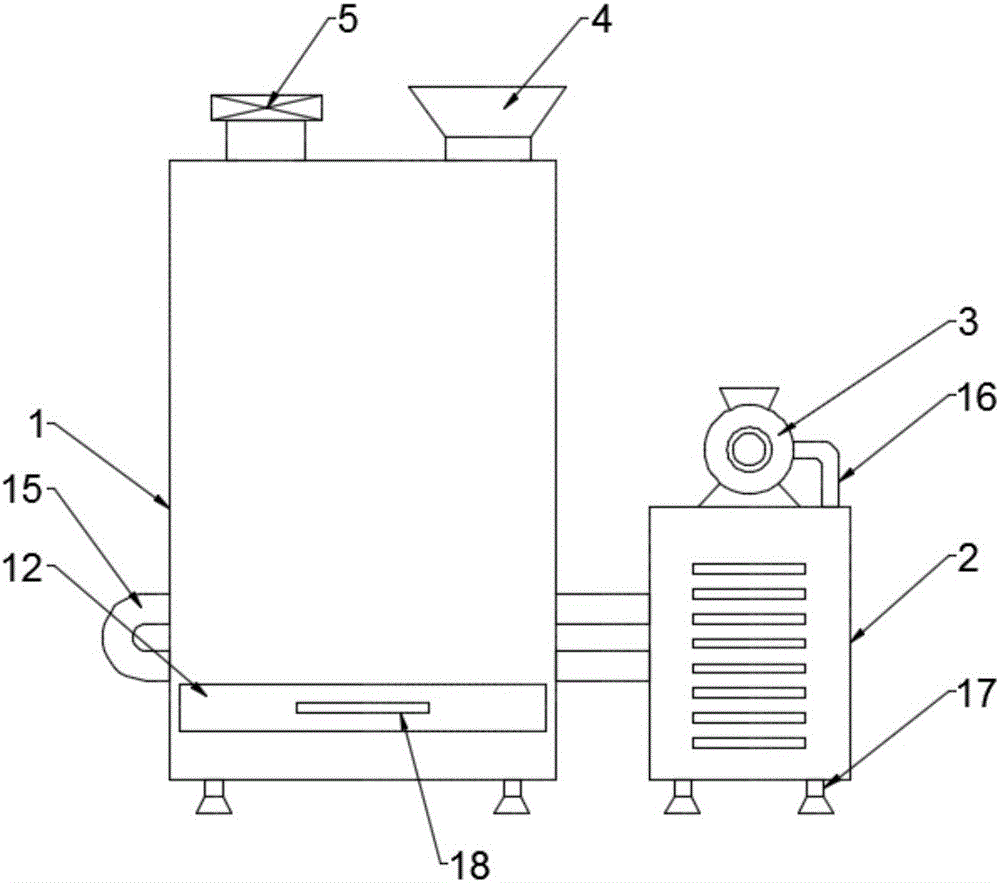

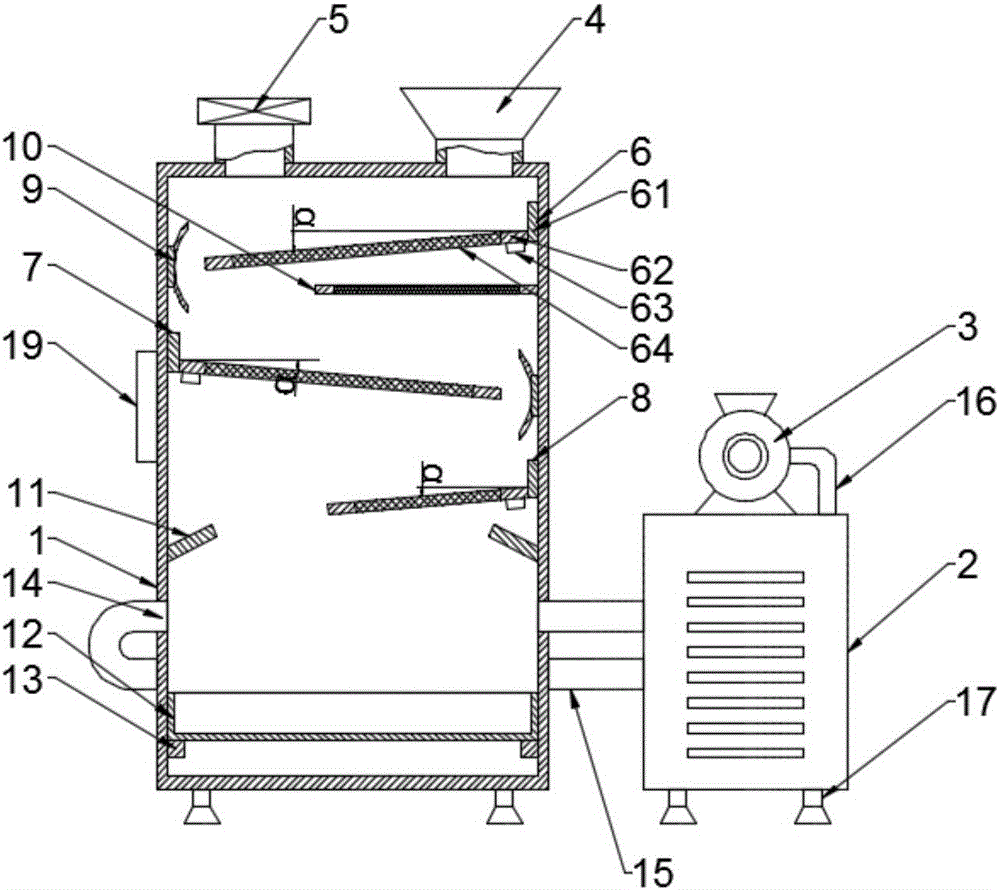

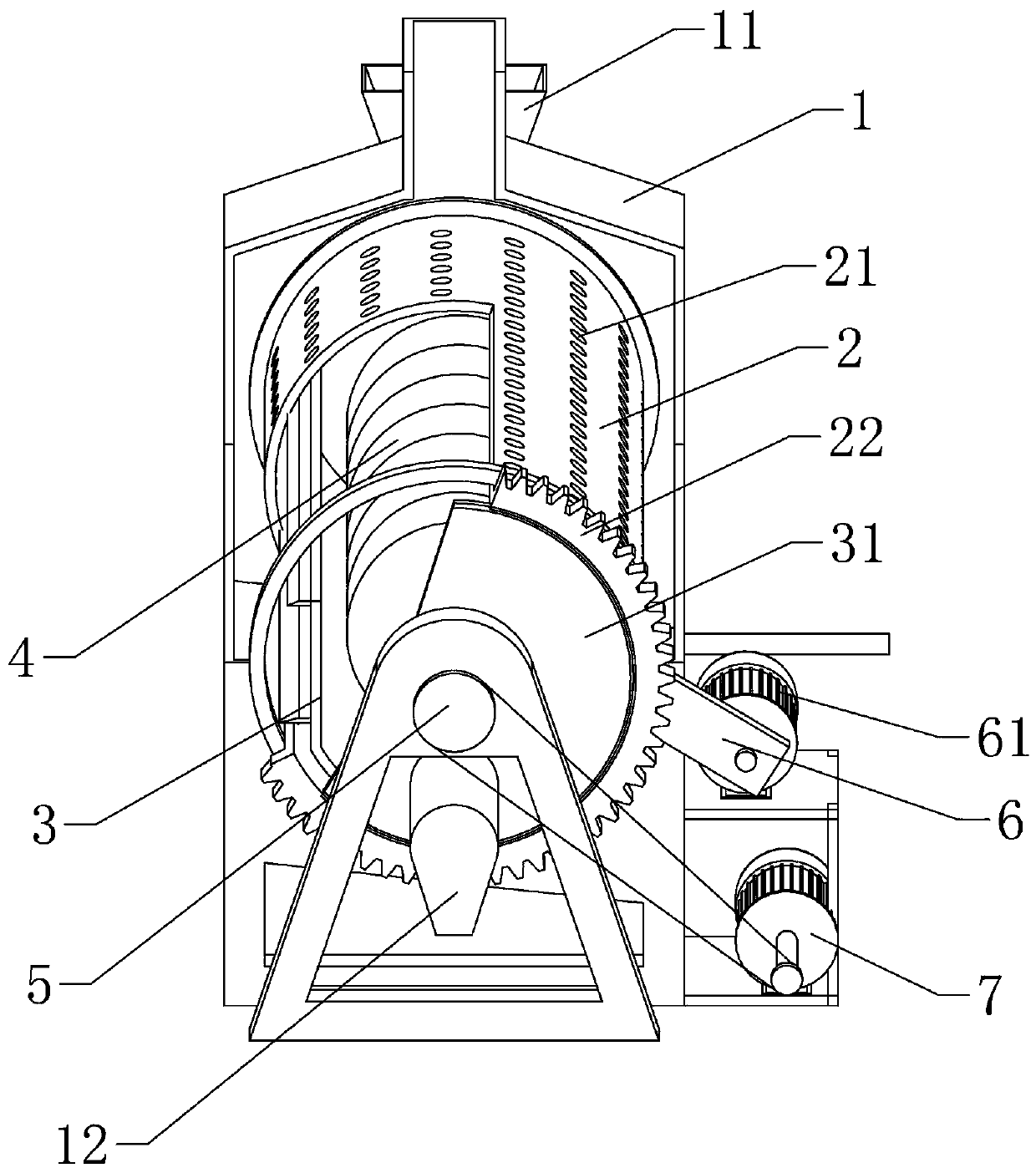

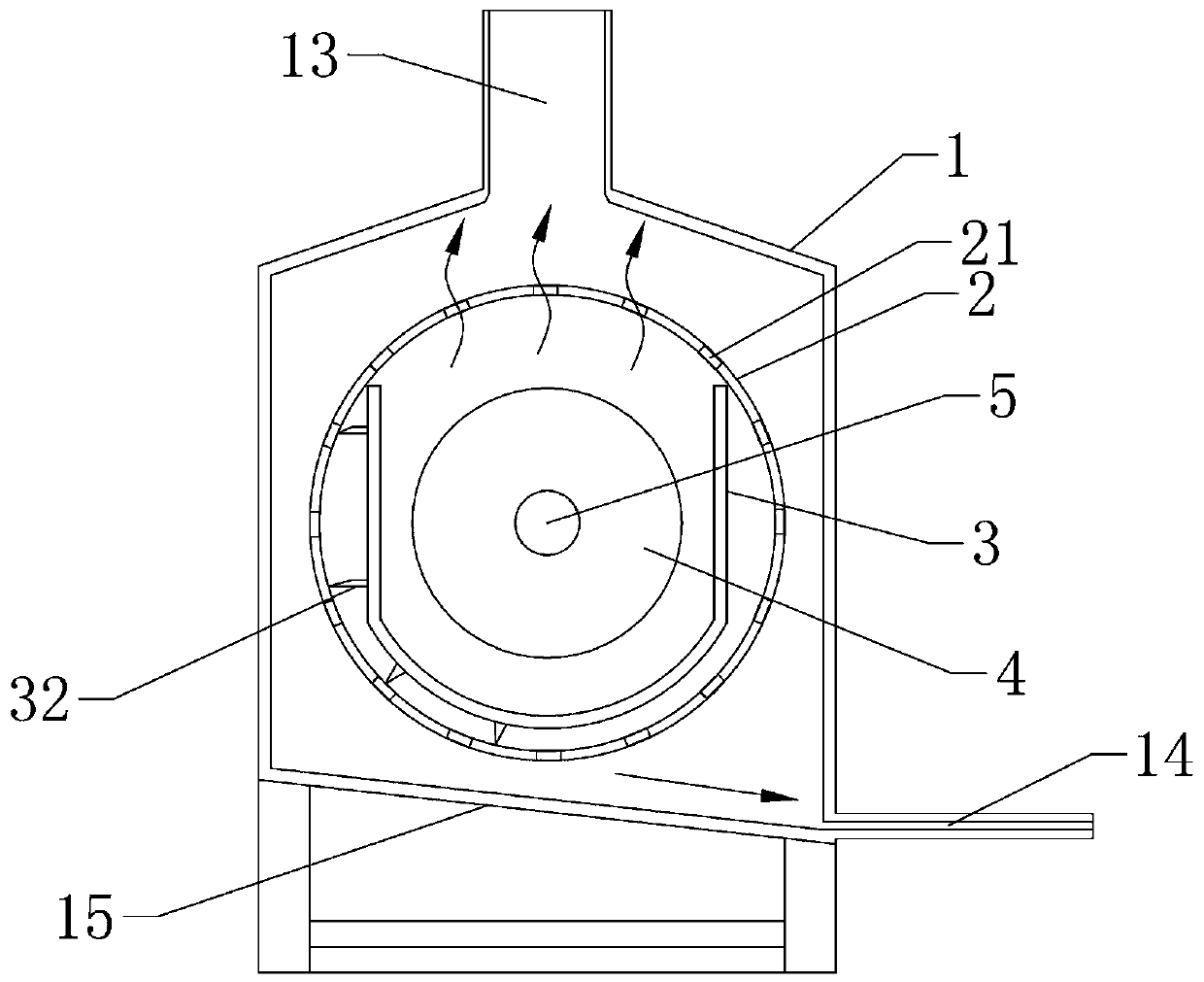

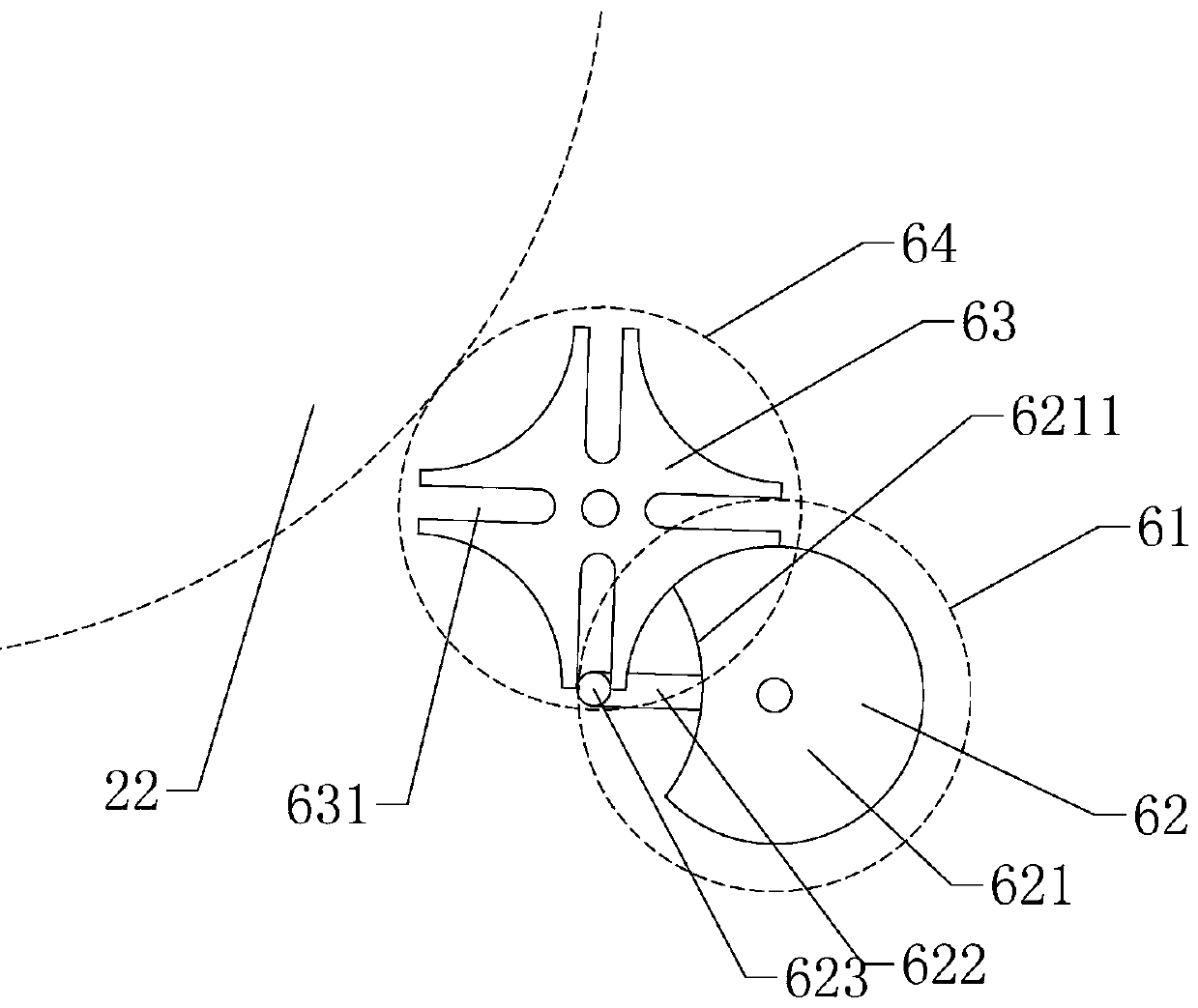

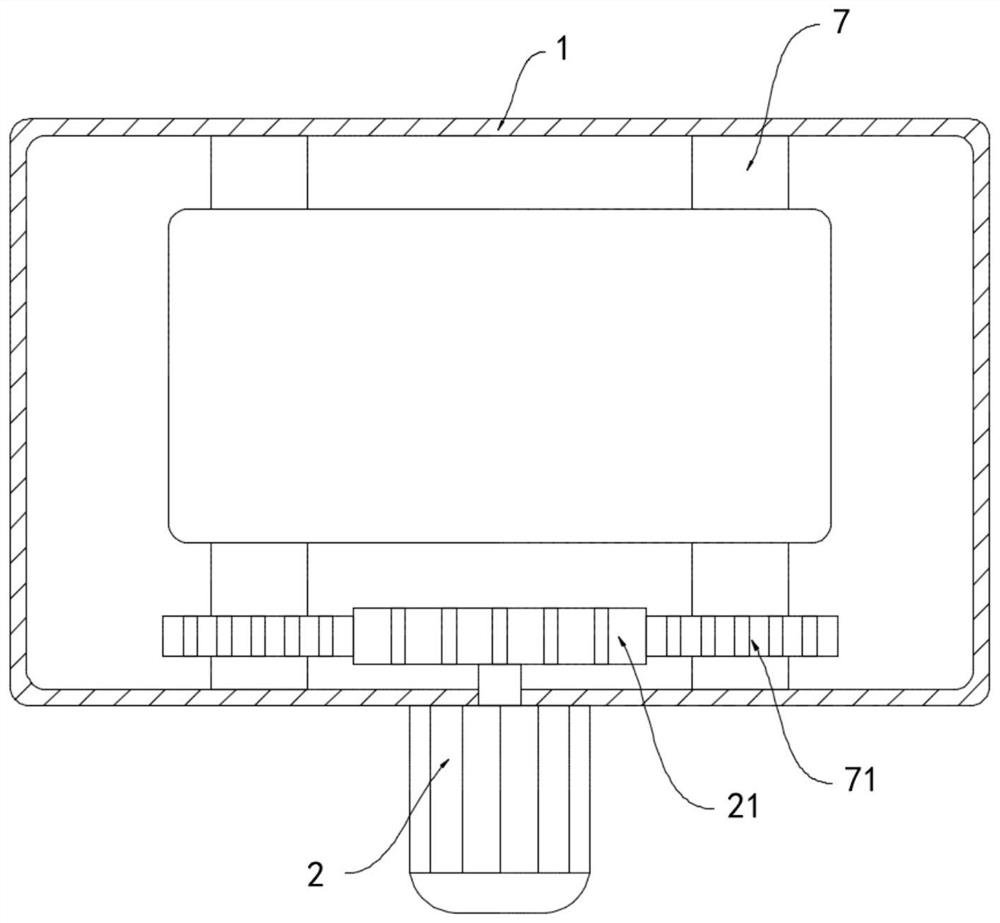

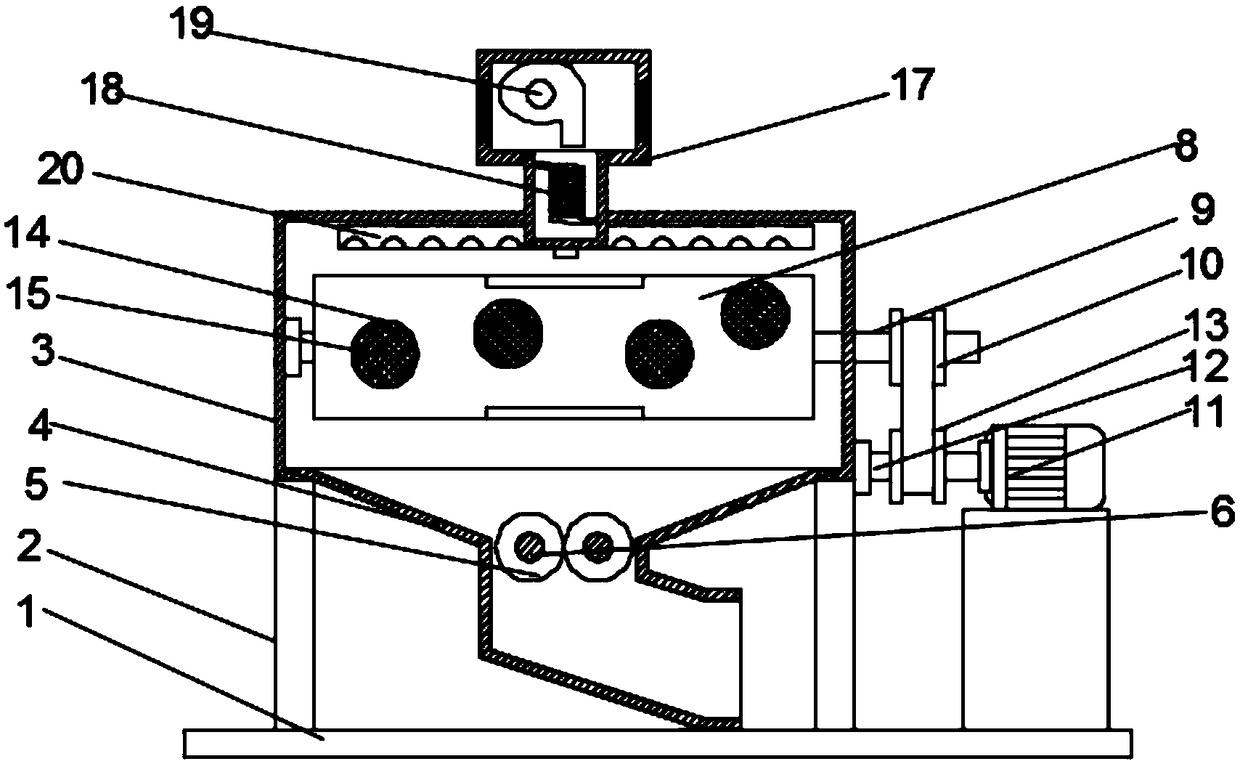

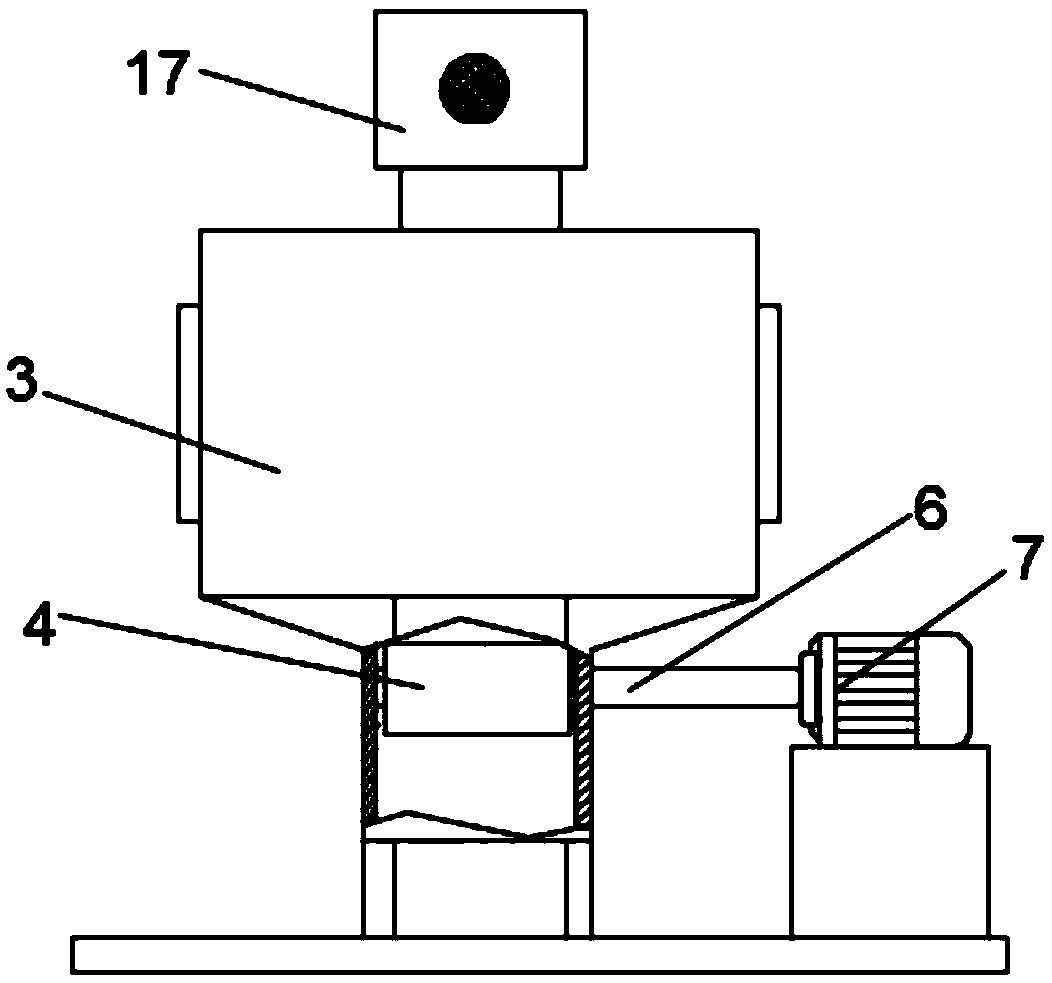

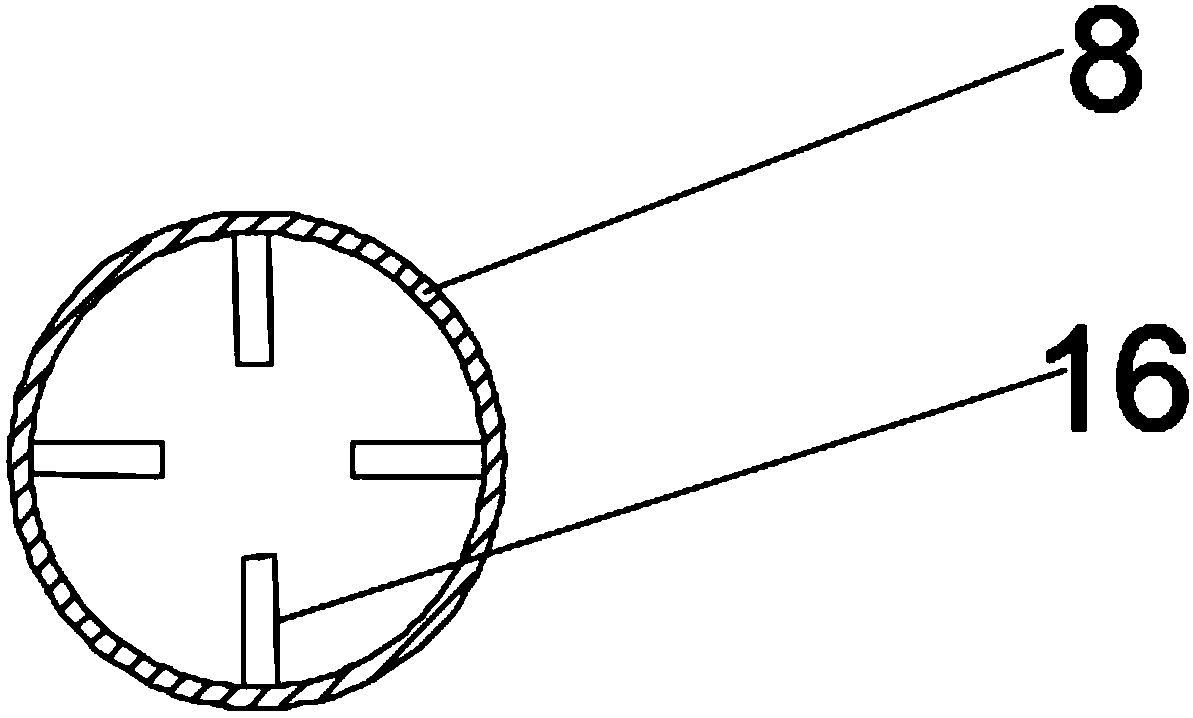

Lumber drying kiln

InactiveCN101144681AHigh thermal efficiencySmooth and even circulationDrying solid materials with heatDrying gas arrangementsEngineeringCombustion

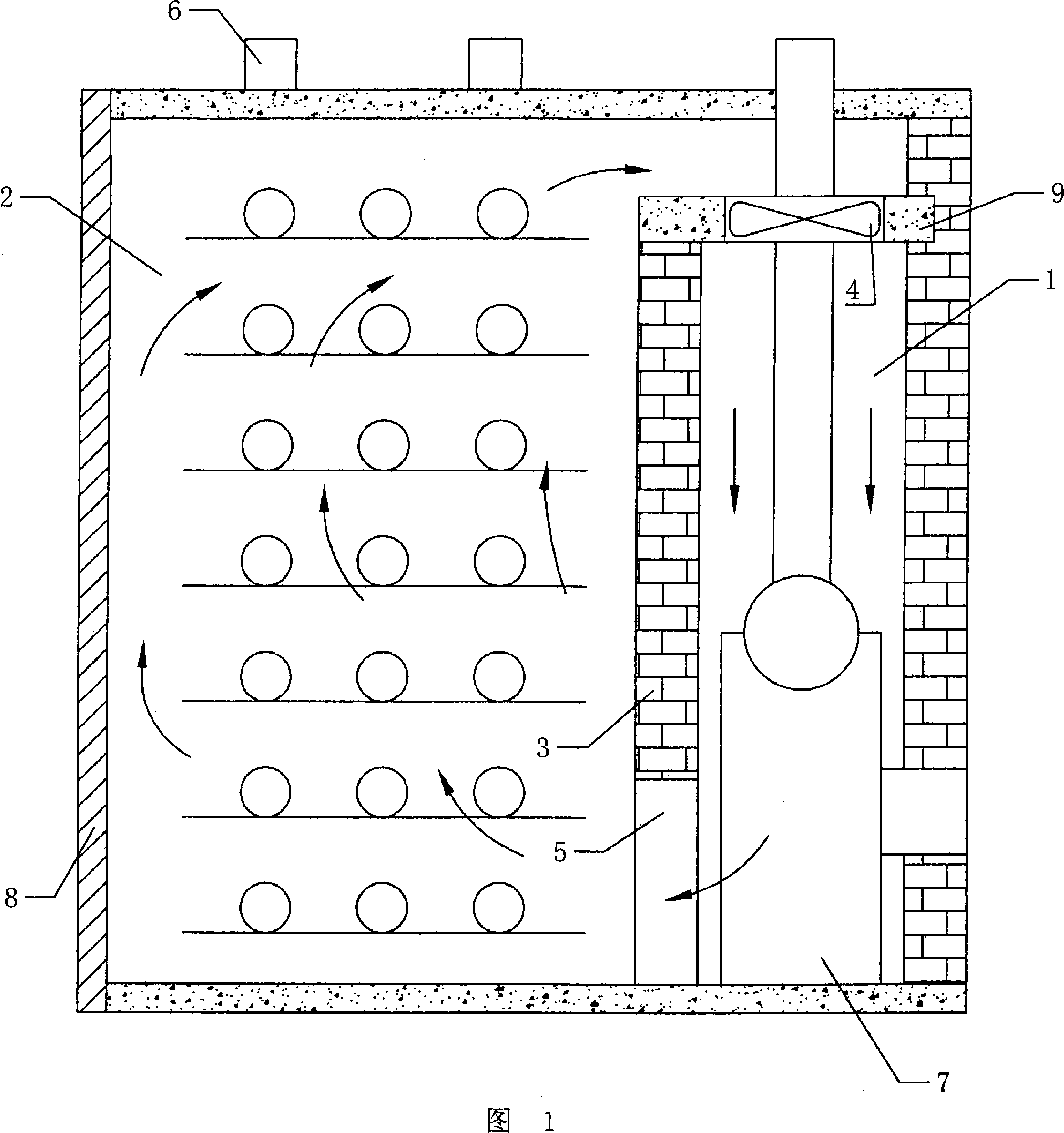

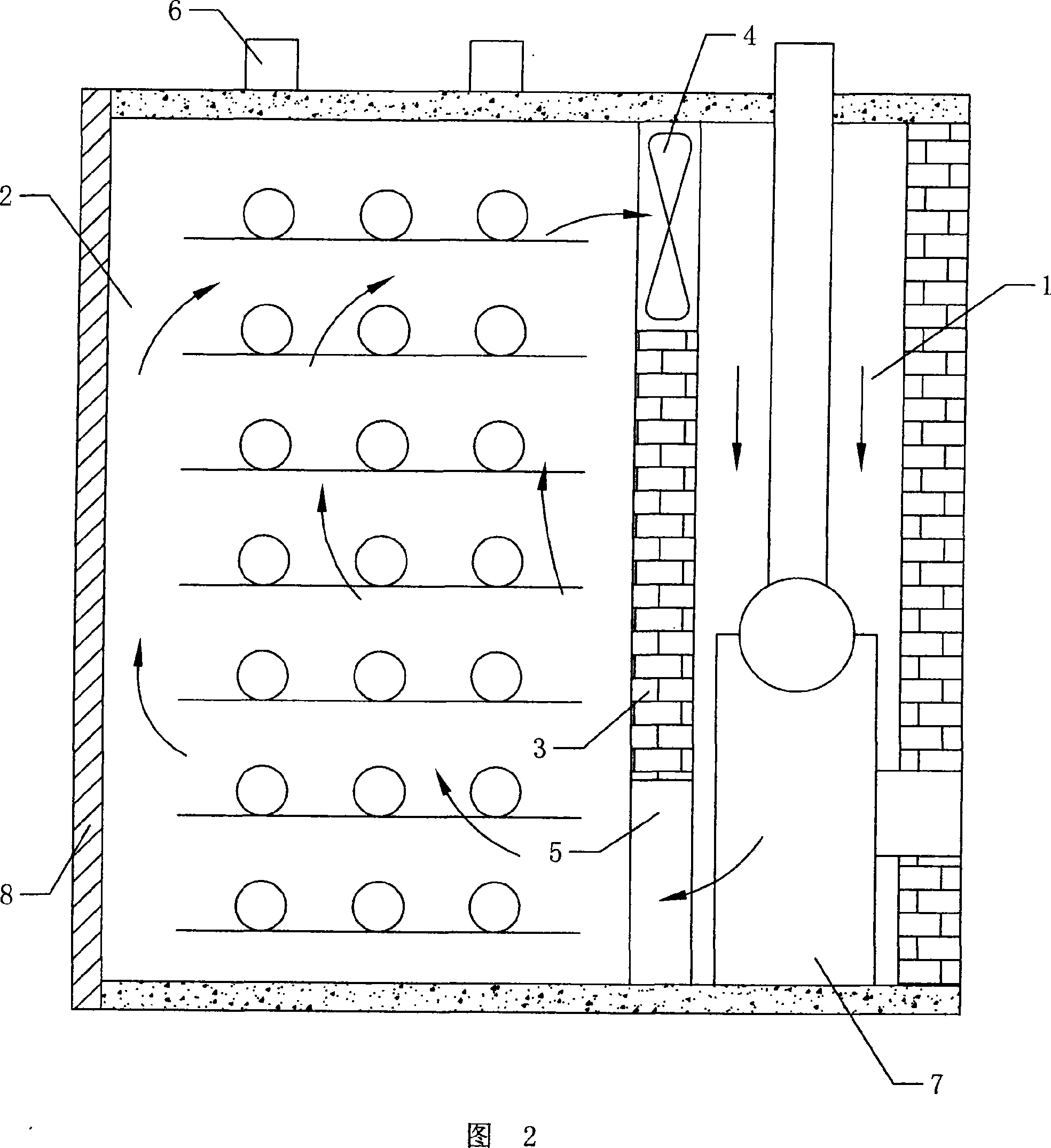

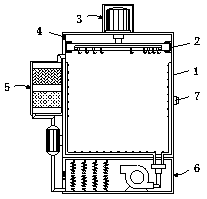

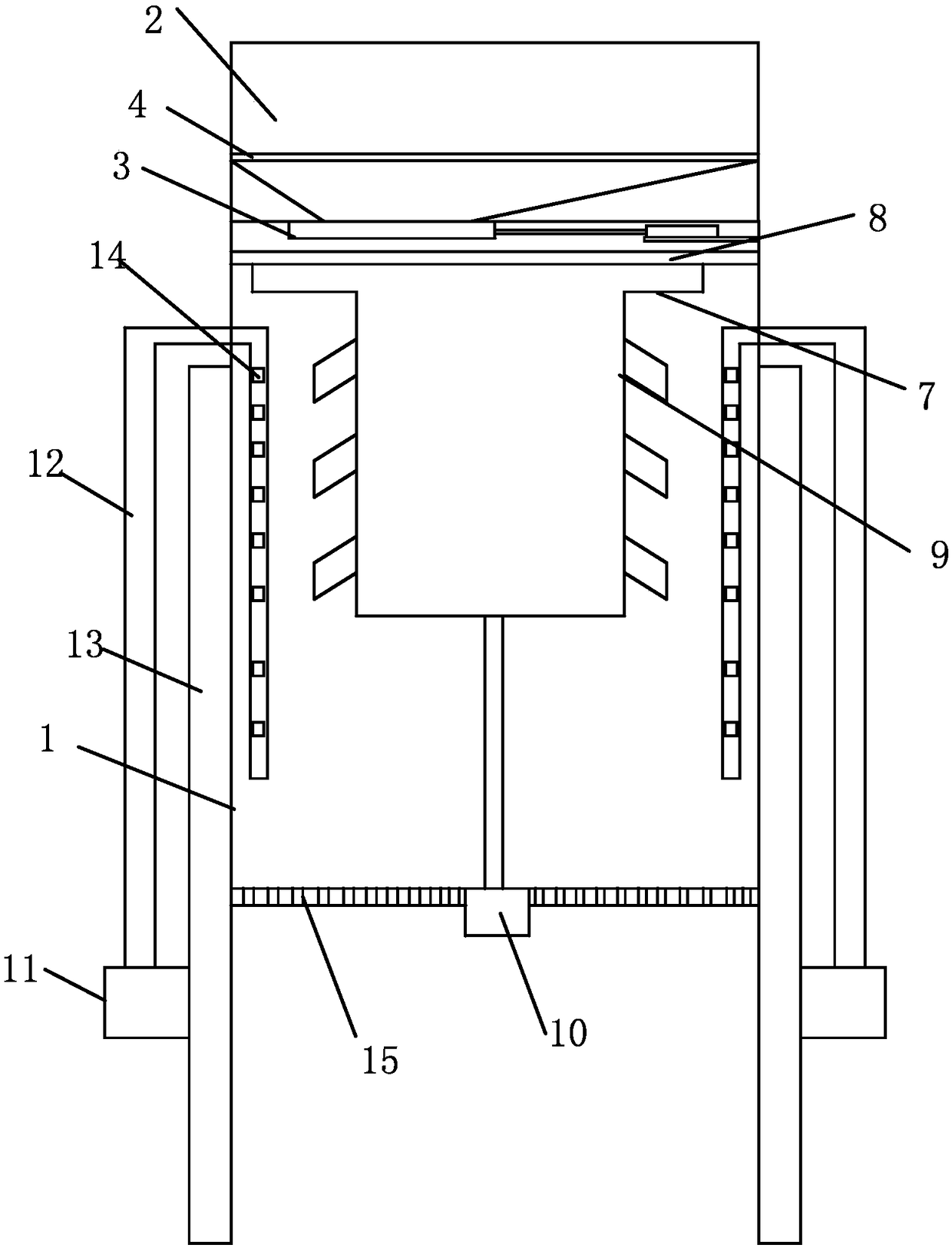

The invention discloses a lumber drying kiln. An isolation wall is arranged between the bottom part and the top part in the drying kiln, the isolation wall divides the space in the kiln into an air heating room used for installing a drying furnace, and a lumber drying room; wherein, an upper ventilation opening is arranged at the upper part of the isolation wall, a lower ventilation opening is arranged at the lower part of the isolation wall, a fan used for blowing air to the air heating room from the lumber drying room is arranged between the air heating room and the lumber drying room; an air exhaust passage is arranged at the top part corresponding to the lumber drying room; because the fan is arranged at the position of the upper ventilation opening, the fan sucks the hot air from the lumber drying room to blow into a lumber heating room, the back flow does not happen, thereby leading the heated air circulation to be smoother, therefore the drying quality to be improved. Because the isolation wall is arranged between the air heating room and the lumber drying room, the charring of the lumber close to a combustion furnace because of over high temperature is avoided, the lumber far away the combustion furnace does not have the drying phenomenon, to lead the drying to be evener.

Owner:李祥文

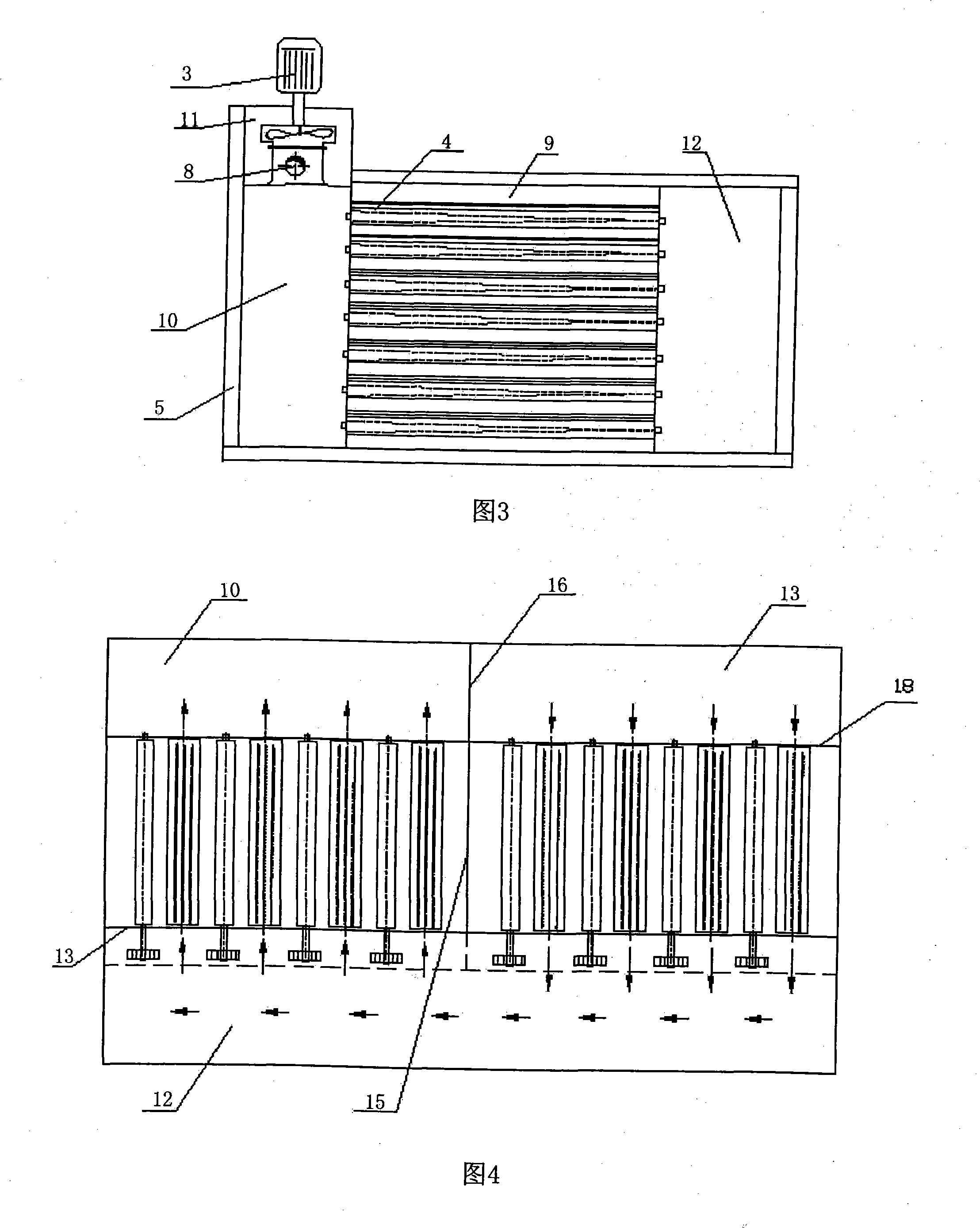

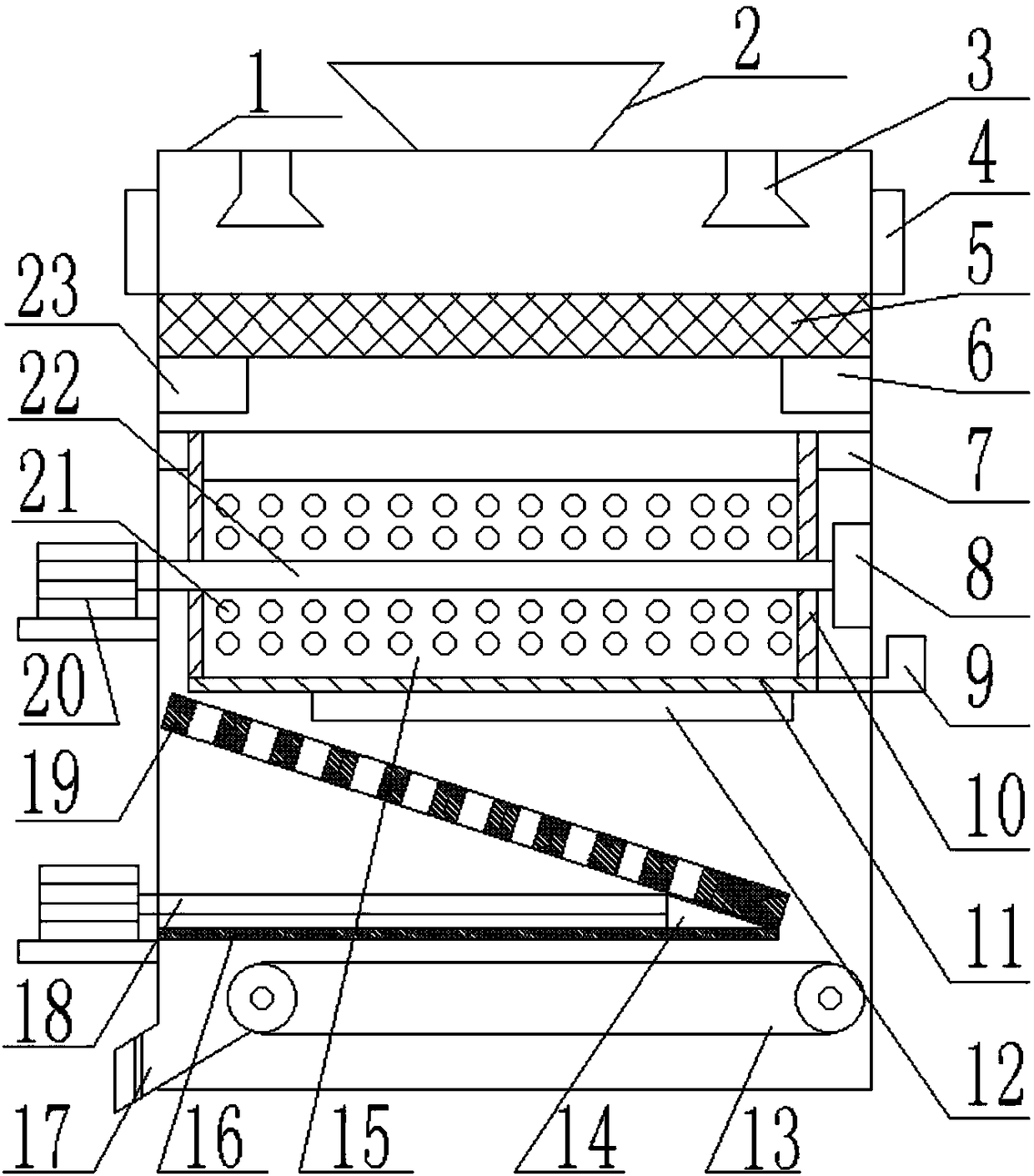

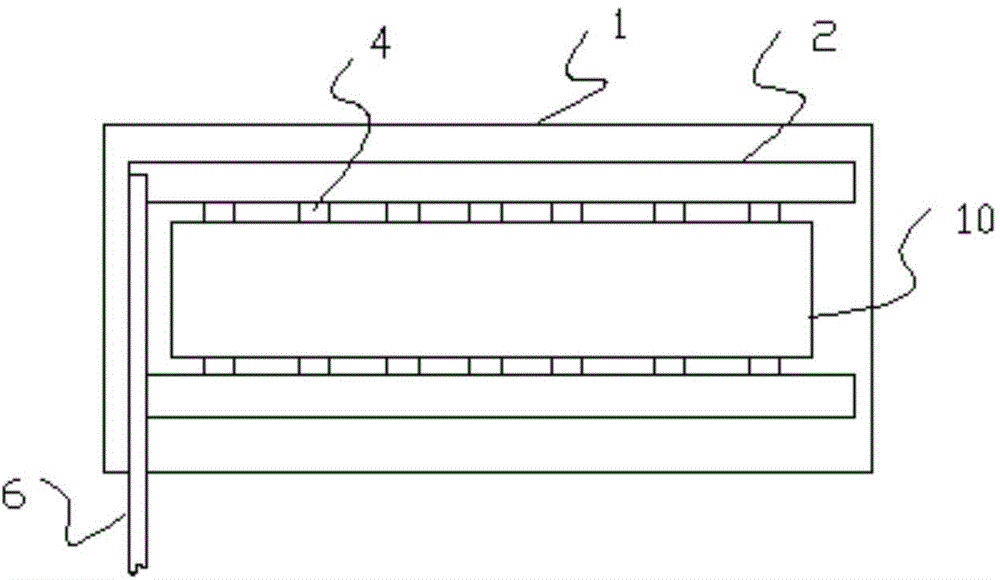

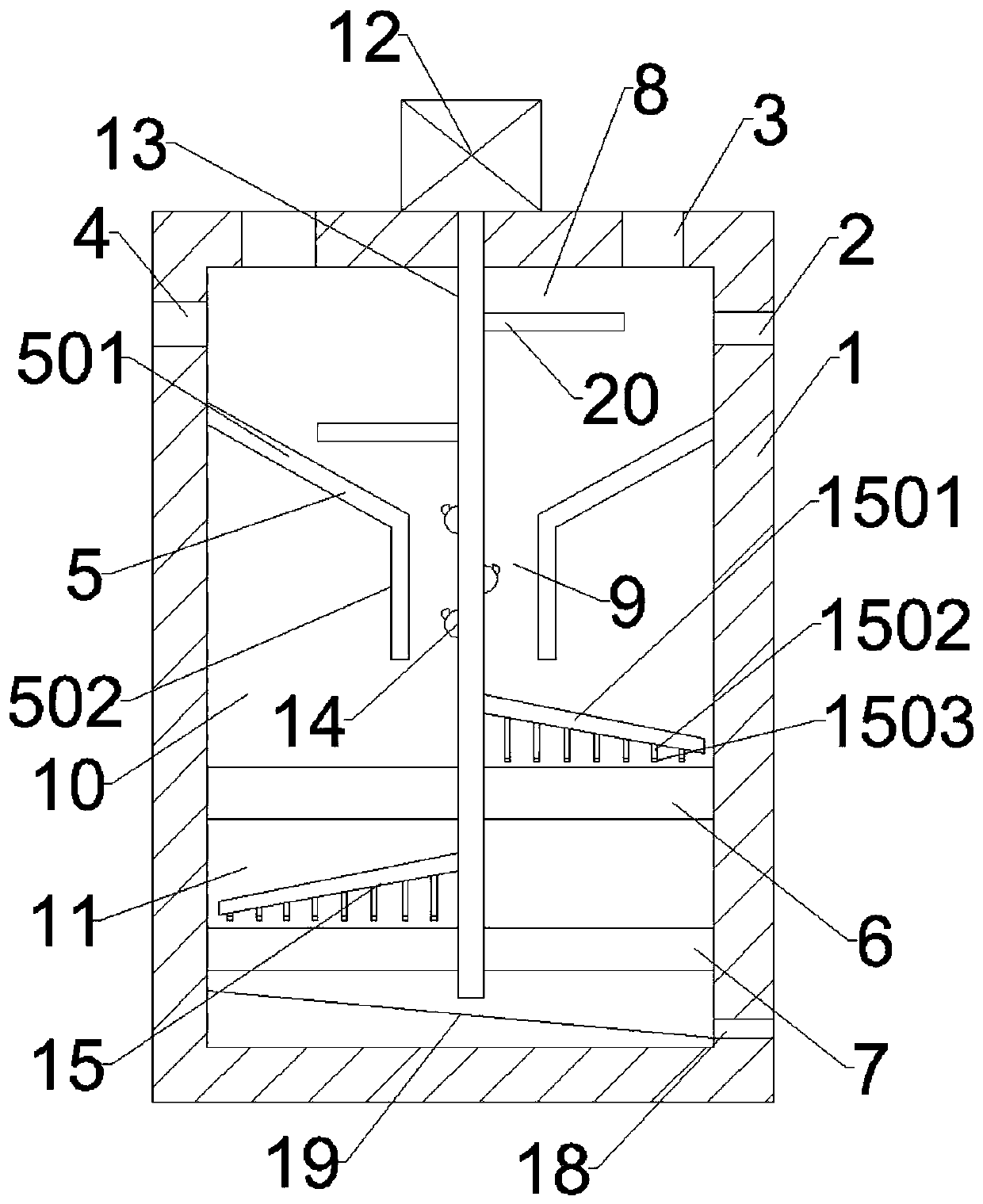

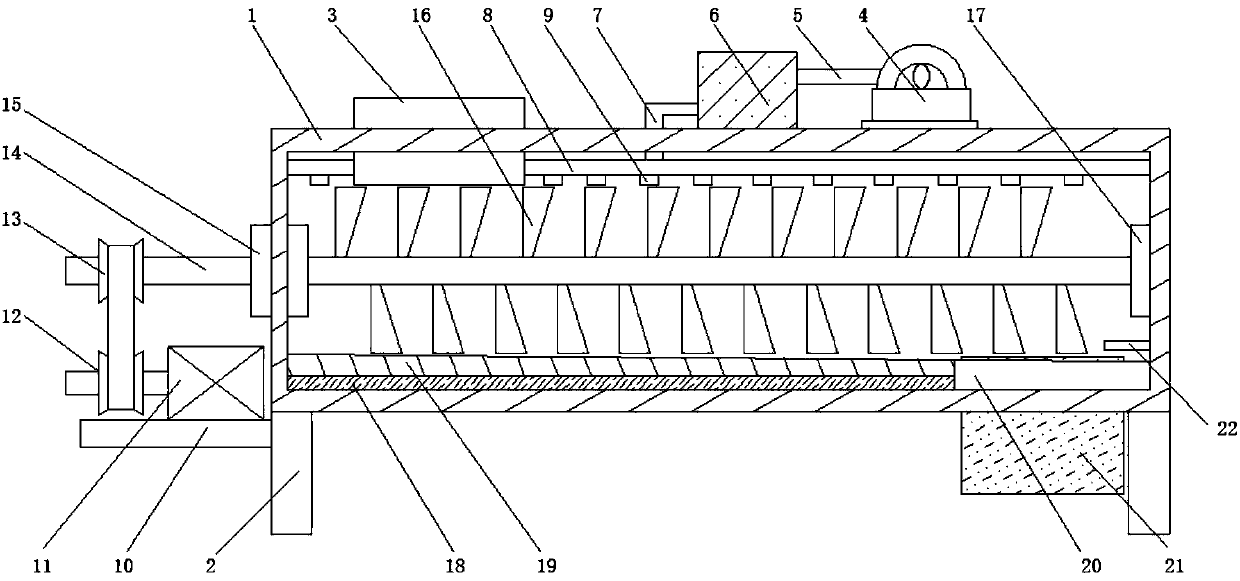

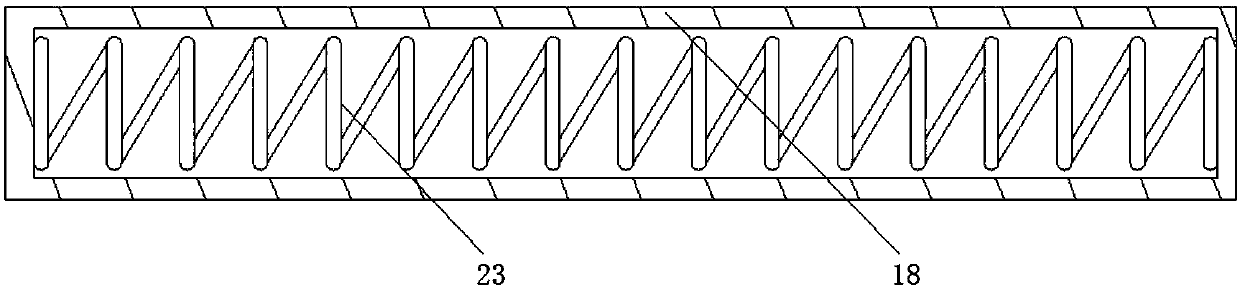

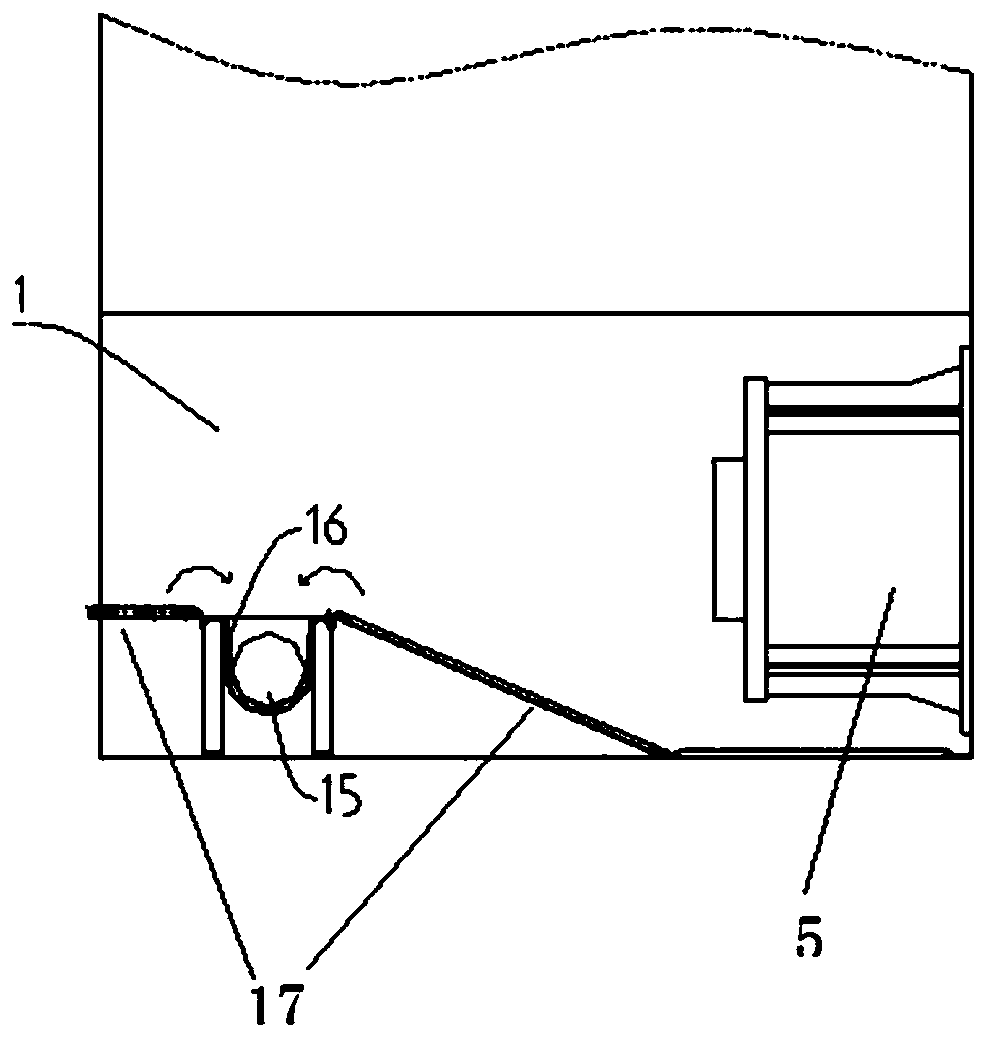

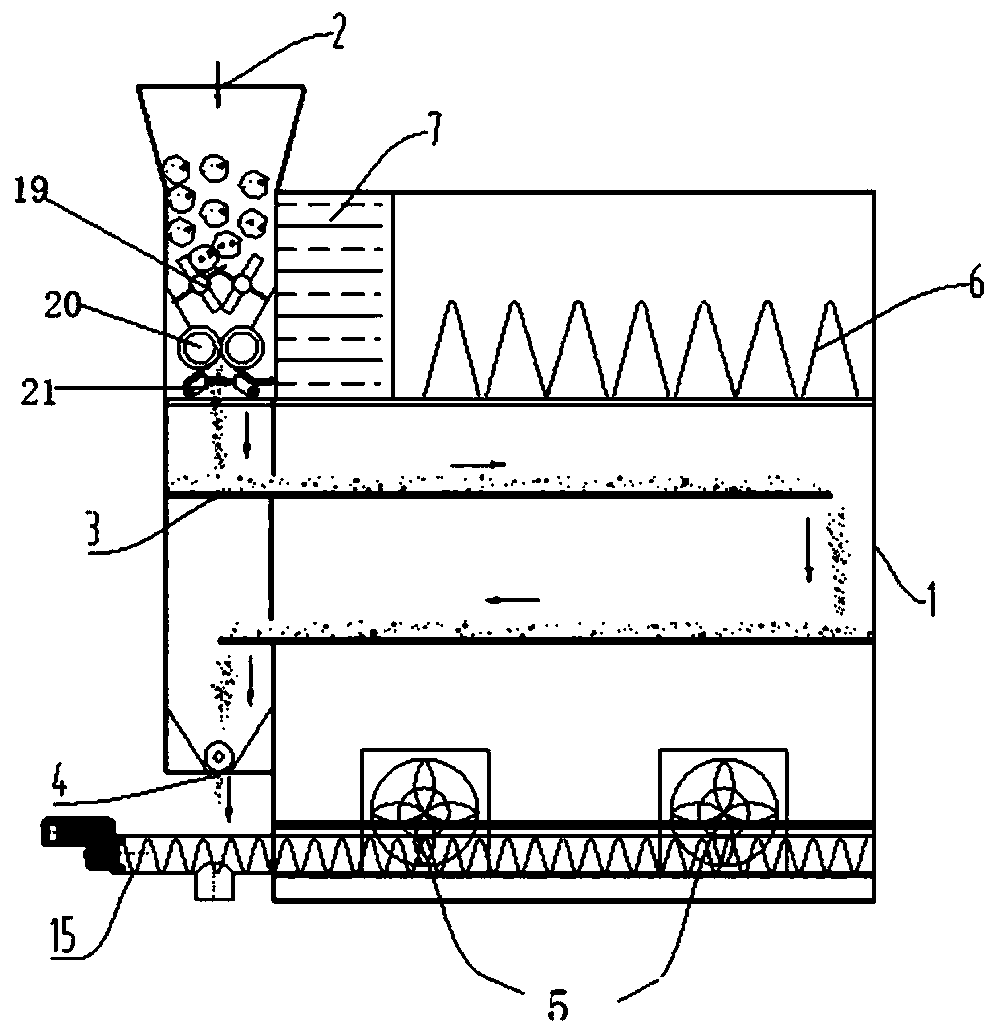

Multi- flow path transverse circulation gypsum board drying apparatus and its drying method

ActiveCN101236047AUniform drying effectEliminate flow resistance lossDrying solid materials with heatDrying gas arrangementsGypsumAirflow

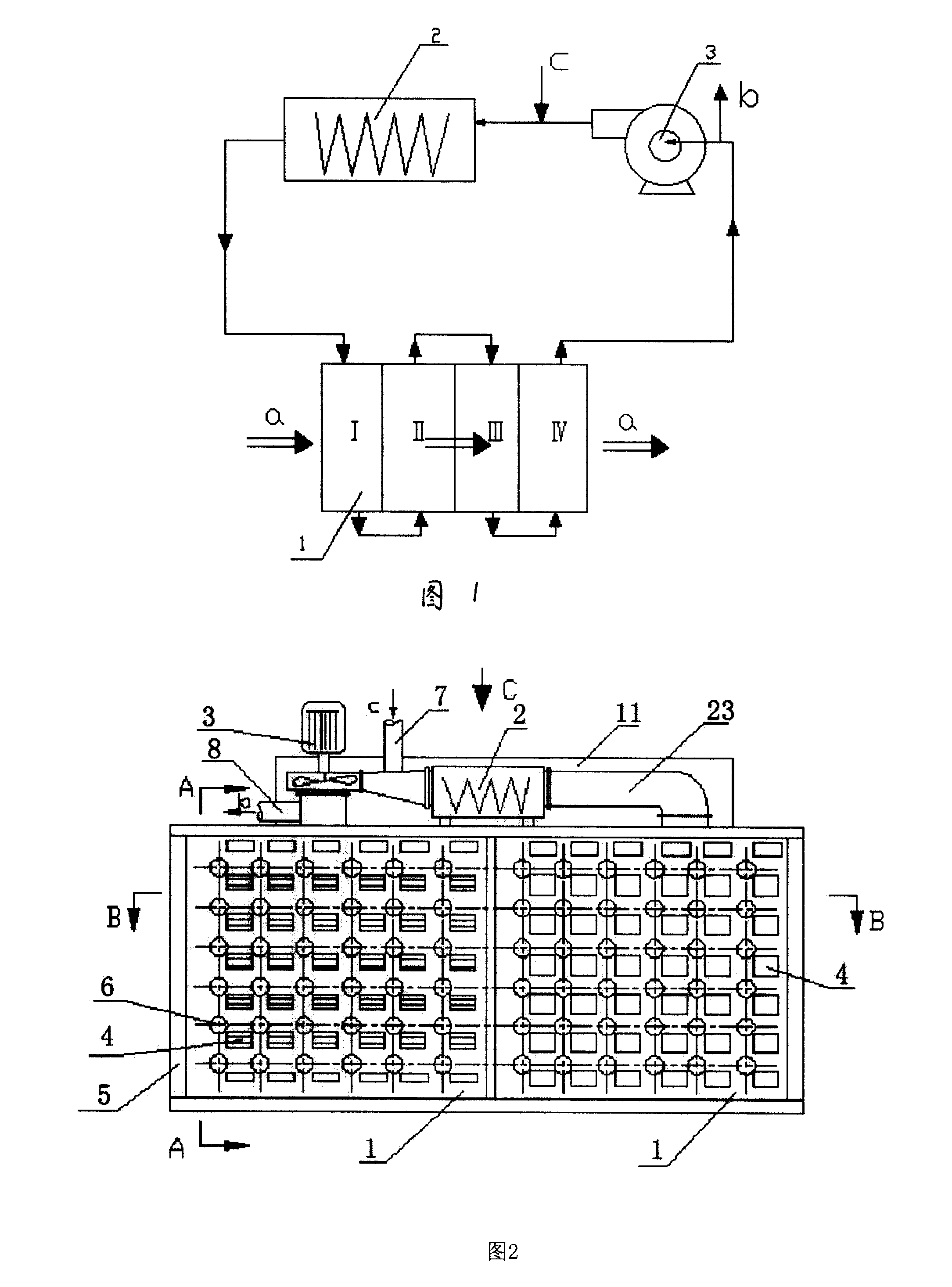

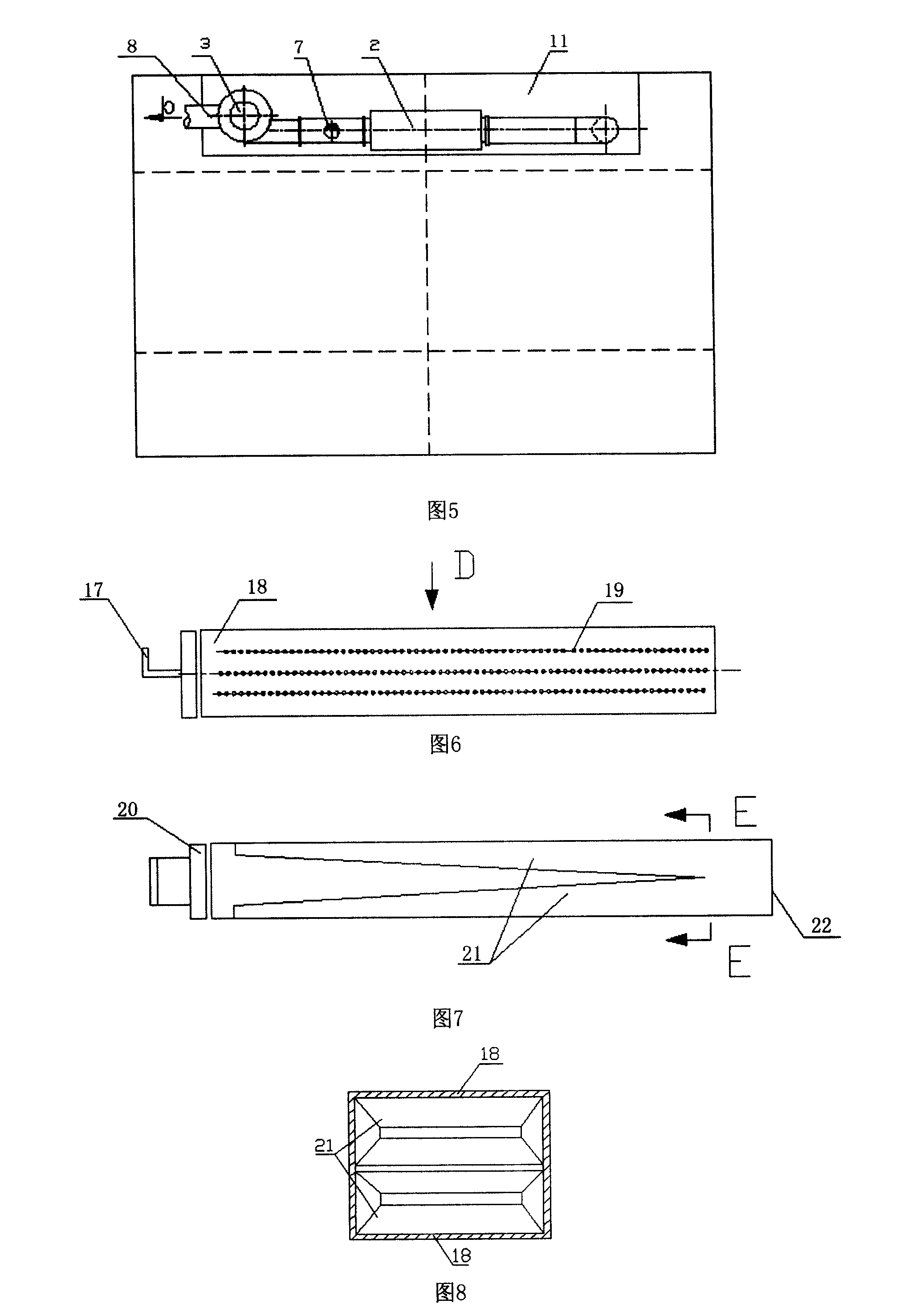

The invention relates to multi-paths horizontal circulation drying device for plasterboards and a drying method thereof, and the drying device is formed by a roller conveyer with the closed inner portion provided with one layer, multi-layers in most cases, and an air circulating device, wherein the roller conveyer is disposed in a main passage, two sides of which are provided with auxiliary passages, the upper portion of the auxiliary passage on one side is provided with an overhead passage, and a circulating fan and a heating device are arranged inside the overhead passage. The drying device is divided into a plurality of areas in the direction of material delivery, each area can be divided into 2-4 segments, each segment is provided with a plurality of air supply blowing pipes, and the main passages of each segment are provide with air flow resistant separators. Hot air as drying medium flows reversely at the first and second segments or the third and the fourth segments via the air supply blowing pipes, and reciprocates and circulates within the plate drying area by horizontal double-paths or multi-paths, thereby forming the intrinsic inherent condition which guarantees moisture on the two sides of the dried plate to be uniformly evaporated, simultaneously the multi-paths horizontal circulation drying device has the advantages of flow resistance consumption reduction, exhaust temperature reduction, increasing energy efficiency and construction cost reduction.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

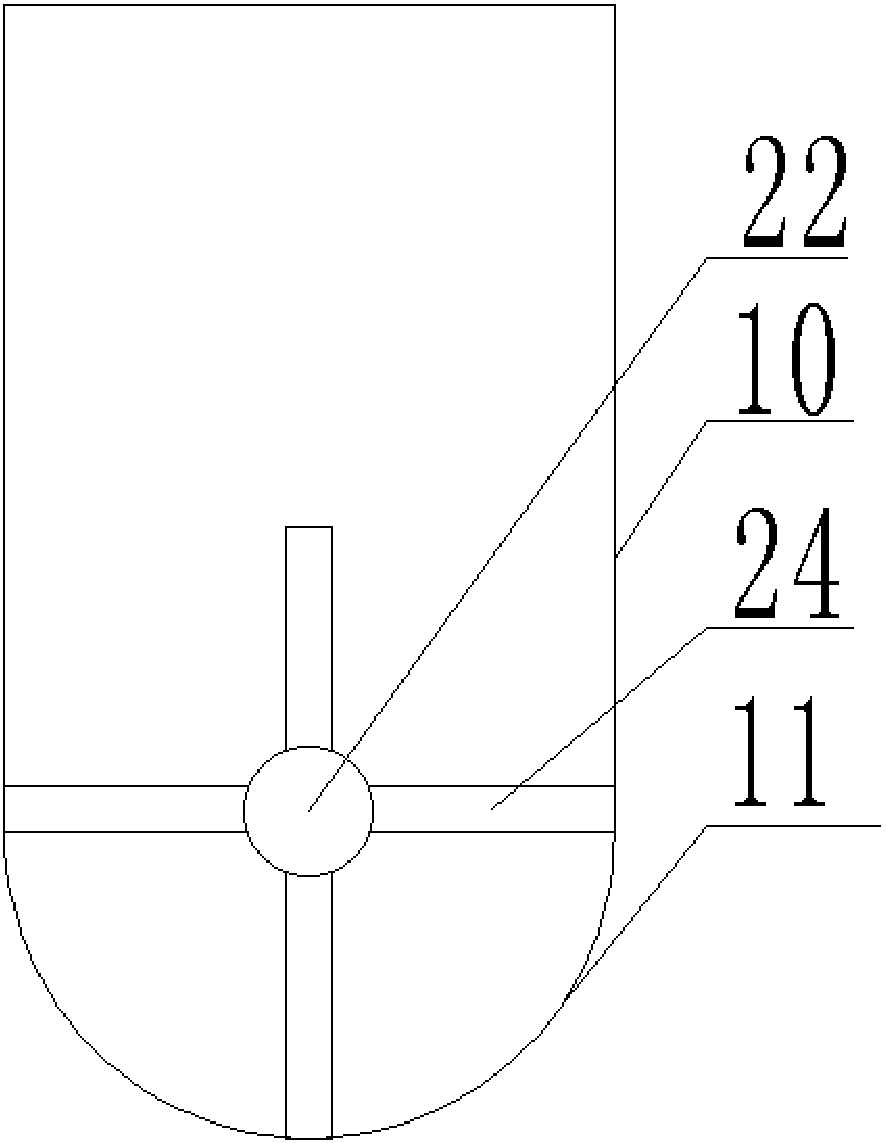

Seed drying box with screening function

InactiveCN108592568AUniform drying effectEasy to removeSievingGas current separationFan bladeBiology

The invention discloses a seed drying box with a screening function, and belongs to the technical field of seed drying. The seed drying box is used for solving the problem that the drying effect cannot be achieved as most of existing seed dryers cannot remove impurities such as pods and aggregates in seeds before drying, and dried seeds are easily re-moisturized in a screening process if screeningis performed after drying. The screen drying box comprises a box body, wherein a charge hole is formed in the top of the box body; a first filter assembly, a drying assembly and a second filter assembly are sequentially arranged in the box body from top to bottom; the drying assembly comprises a drying bin, a heater, an electric motor, a rotary shaft, a bearing base and fan blades; the drying binconsists of side plates and a bottom plate, and an opening is formed in the top of the drying bin; the cross section of the bottom plate is semicircular; the bottom plate is movably connected with the side plates; a heater is arranged on the lower surface of the bottom plate; and the second filter assembly comprises a filter plate, a supporting plate, a cleaning device and a transmission caterpillar band, and a discharge hole is formed in the output end of the transmission caterpillar band.

Owner:ZHENGZHOU QISHUO ELECTRONICS TECH CO LTD

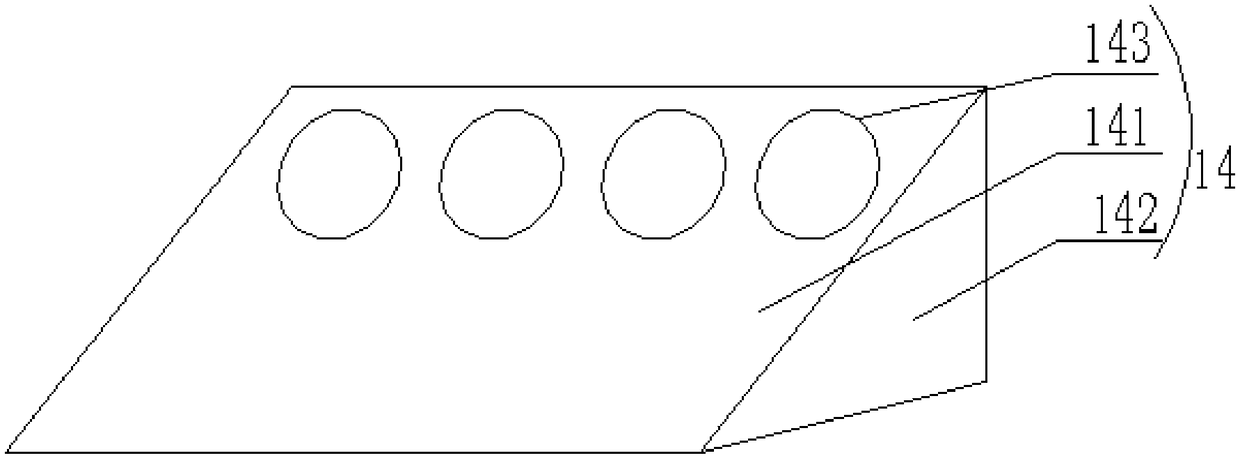

Tuyere special for hot air drying of gravure press and drying oven with same

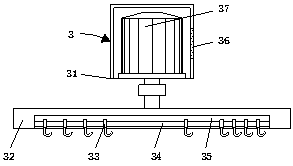

The invention discloses a tuyere special for hot air drying of a gravure press and a drying oven with the tuyere. The tuyere comprises a tuyere box, a tuyere air inlet is formed in the end of the tuyere box, a left flow guide face and a right flow guide face are arranged in the tuyere box, one side of the left flow guide face and one side of the right flow guide face are connected with a left inner wall and a right inner wall of the tuyere box respectively, a left air outlet face and a right air outlet face which are symmetrical are connected with the other side of the left flow guide face and the other side of the right flow guide face respectively, a left platform area and a right platform area which are symmetrical are connected with the free side of the left air outlet face and the free side of the right air outlet face respectively, and a left bevel air guide area and a right bevel air guide area which are symmetrical are connected with the free side of the left platform area and the free side of the right platform area respectively. Because the tuyere of the new structure is adopted and the drying oven is reasonably arranged, the hot air drying time can be prolonged, the utilization efficiency can be improved, the function of optimizing a hot air velocity field, a temperature field, velocity distribution and pressure distribution is achieved, effective running of a whole drying system is guaranteed, and the actual effect of more even drying can be achieved.

Owner:乌兰浩特森辉印务有限公司

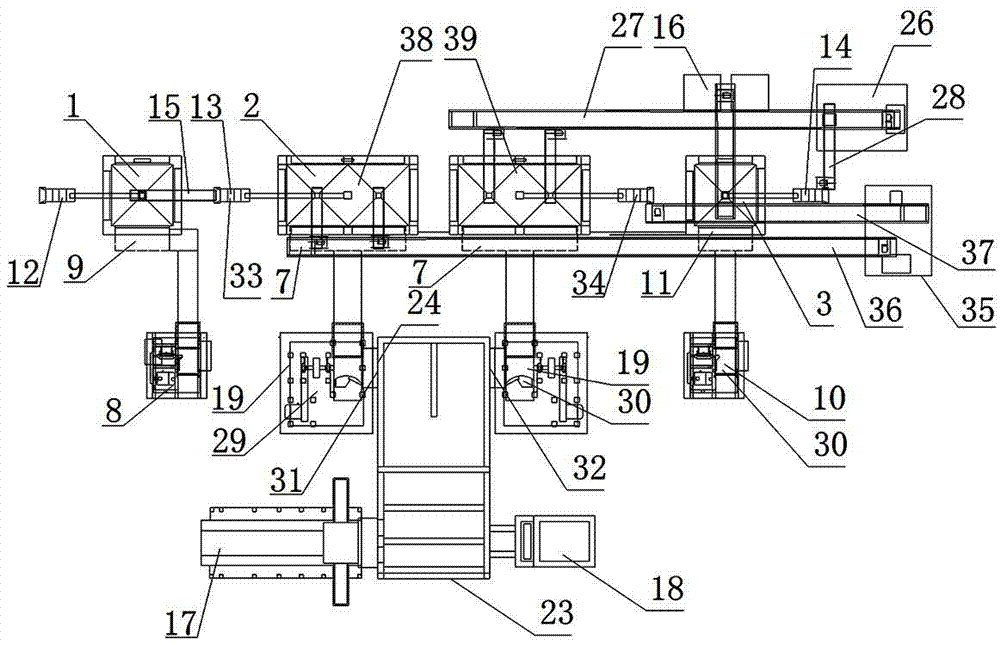

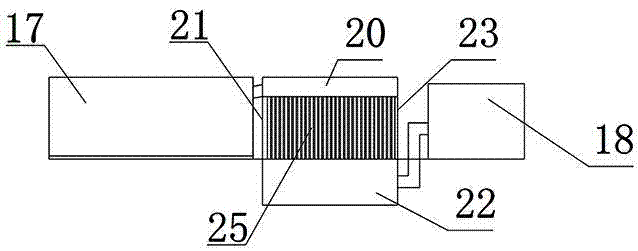

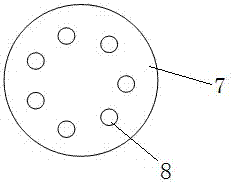

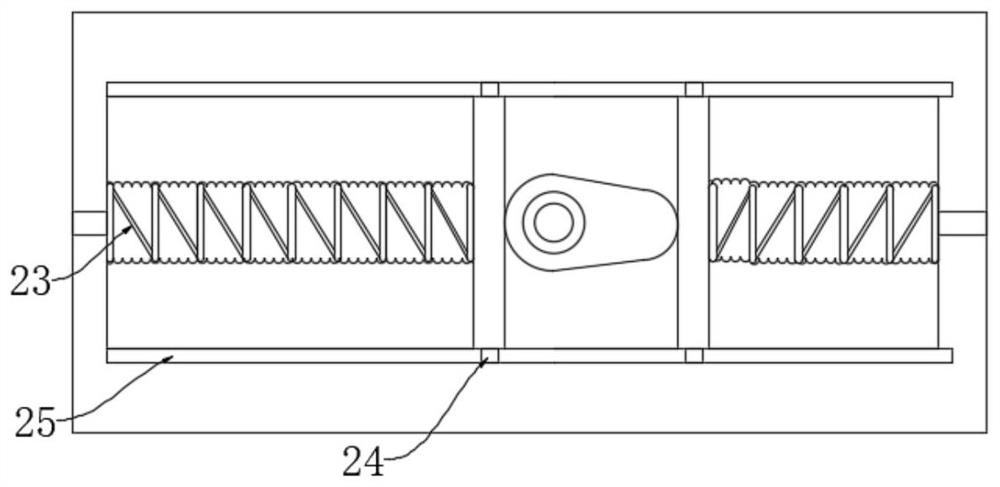

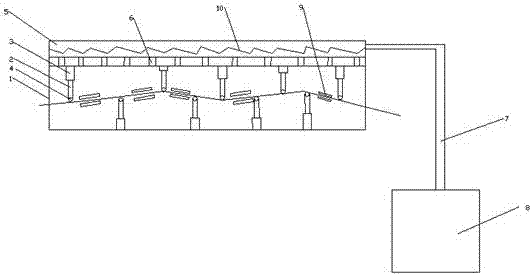

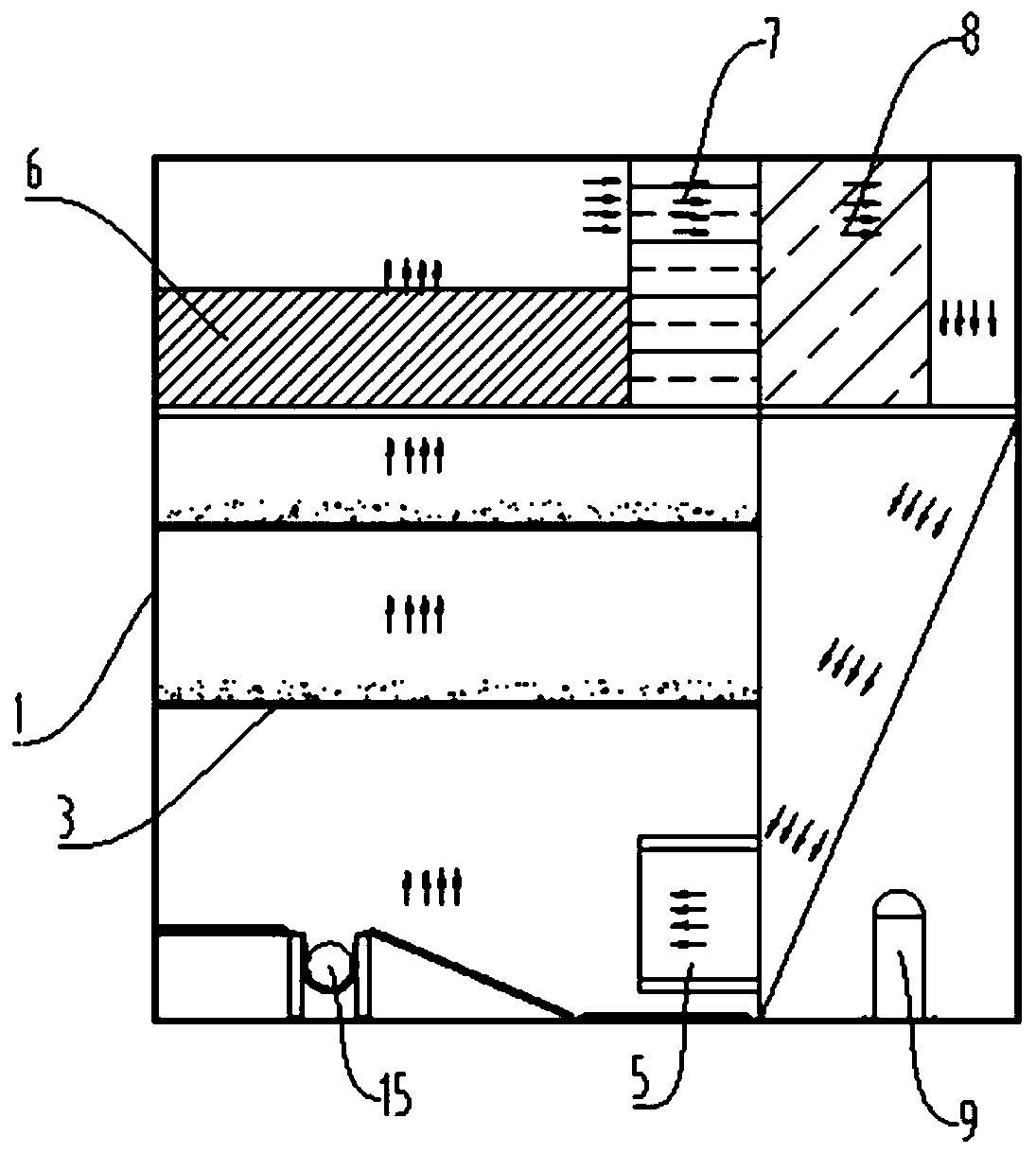

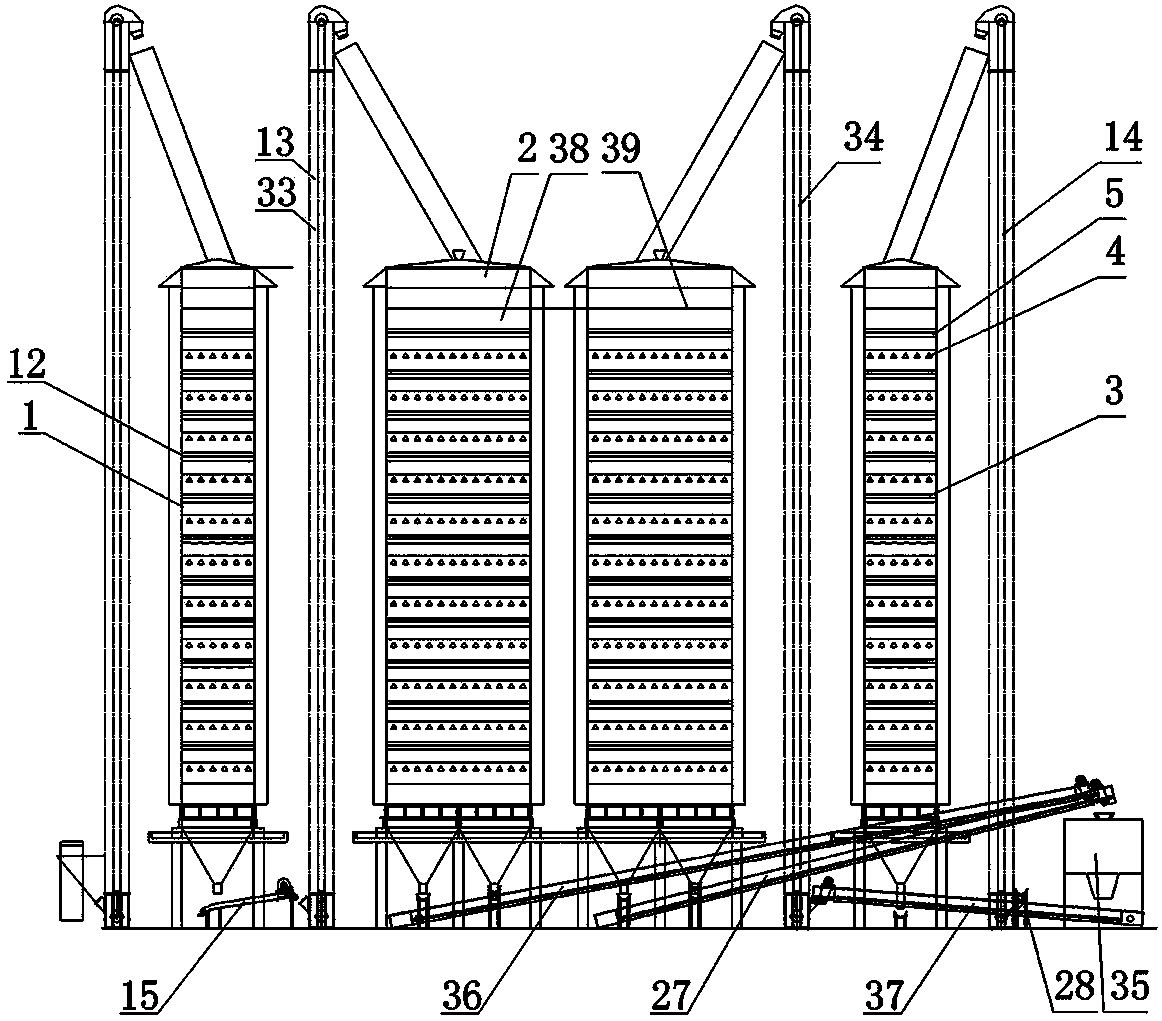

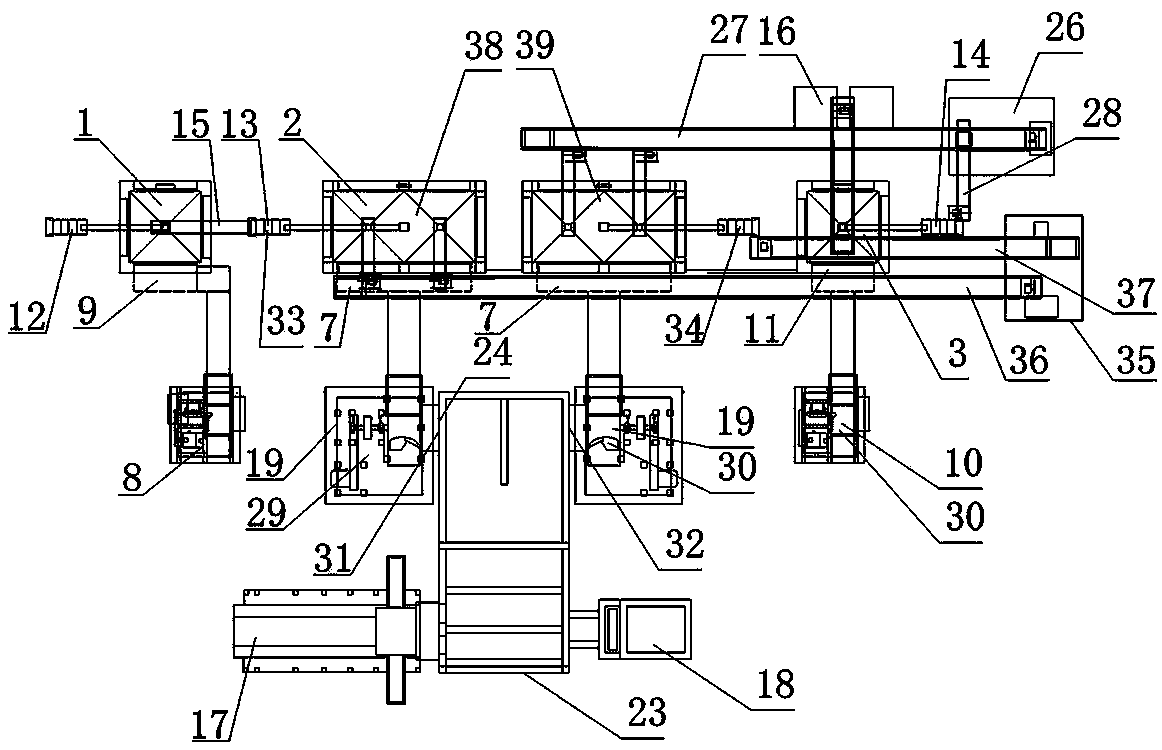

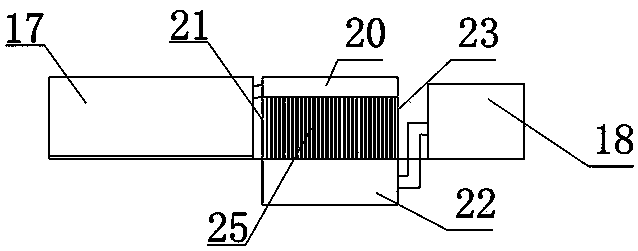

Seed drying system

InactiveCN103168838AMeet the requirements of drying workInhibition of germinationFood processingDrying gas arrangementsCold airAgricultural science

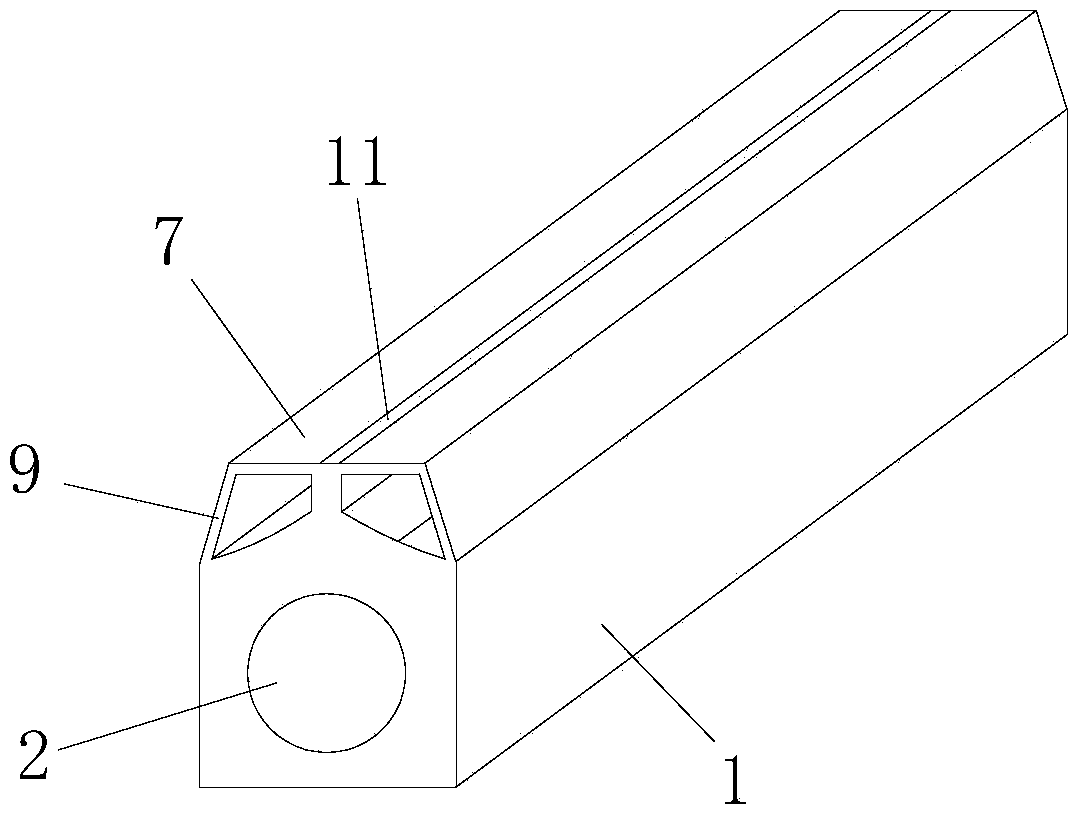

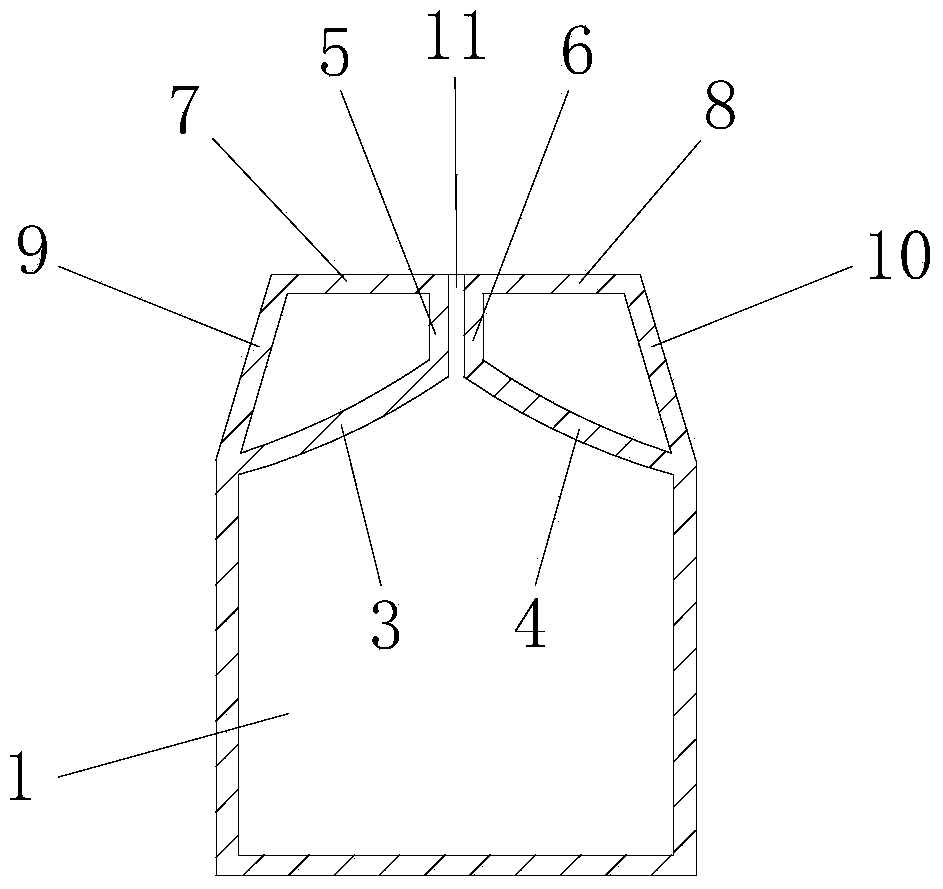

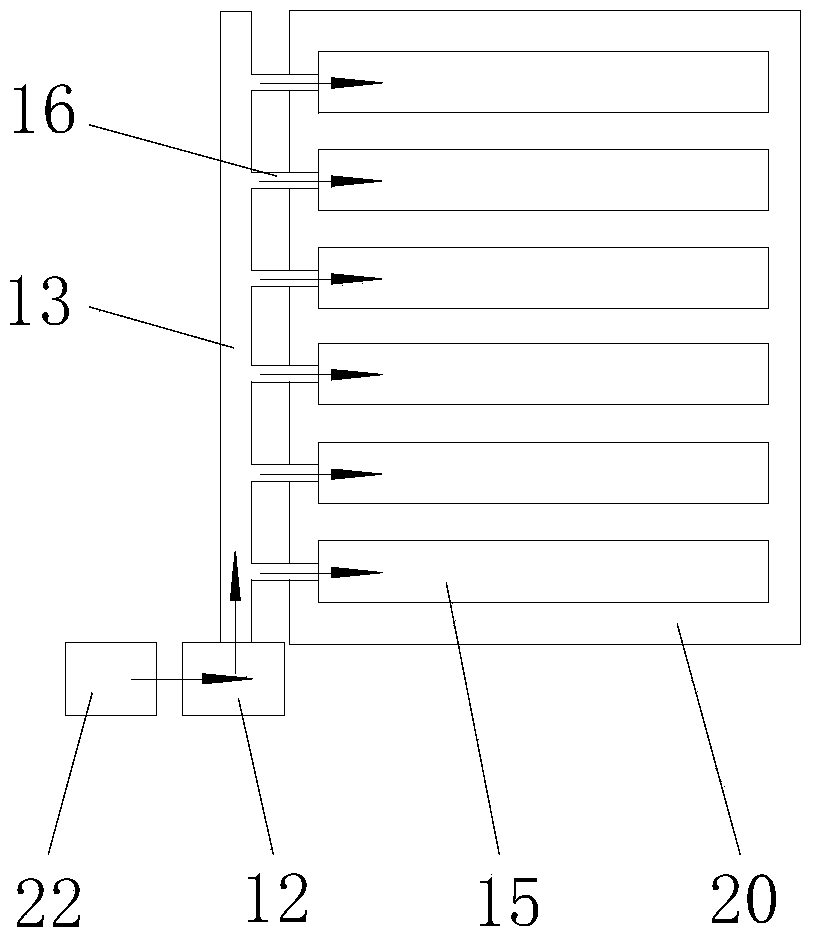

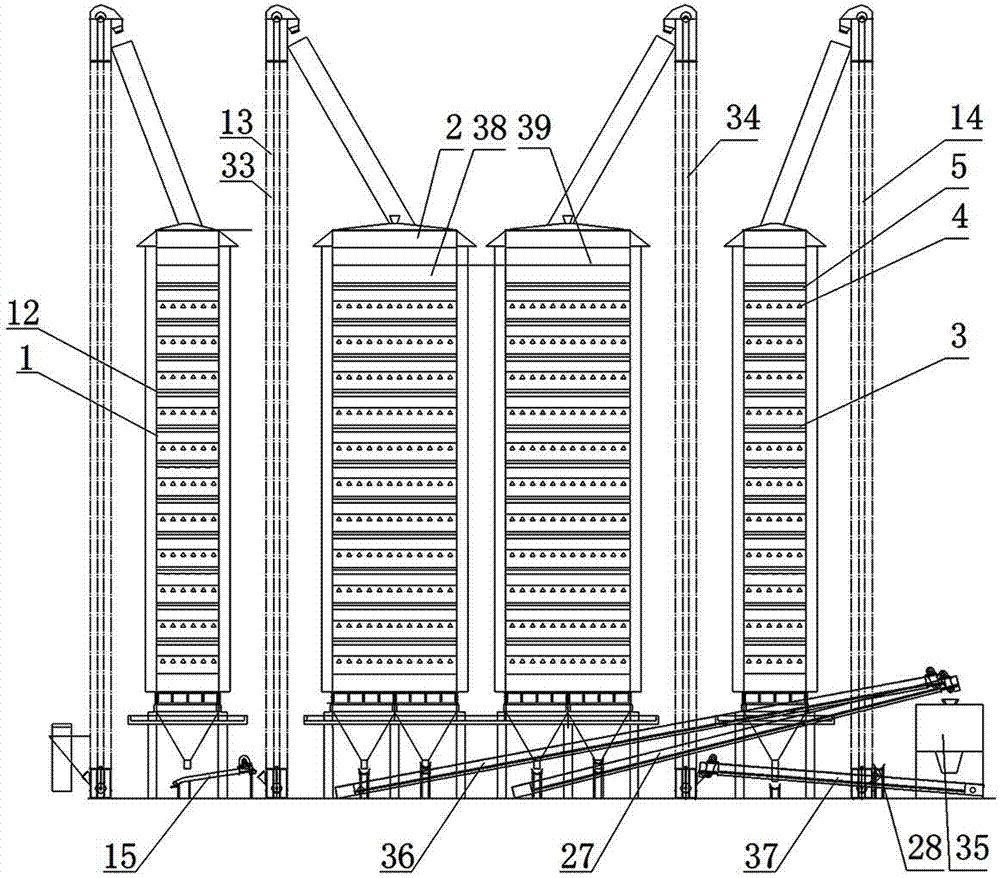

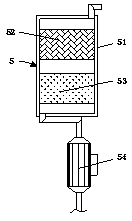

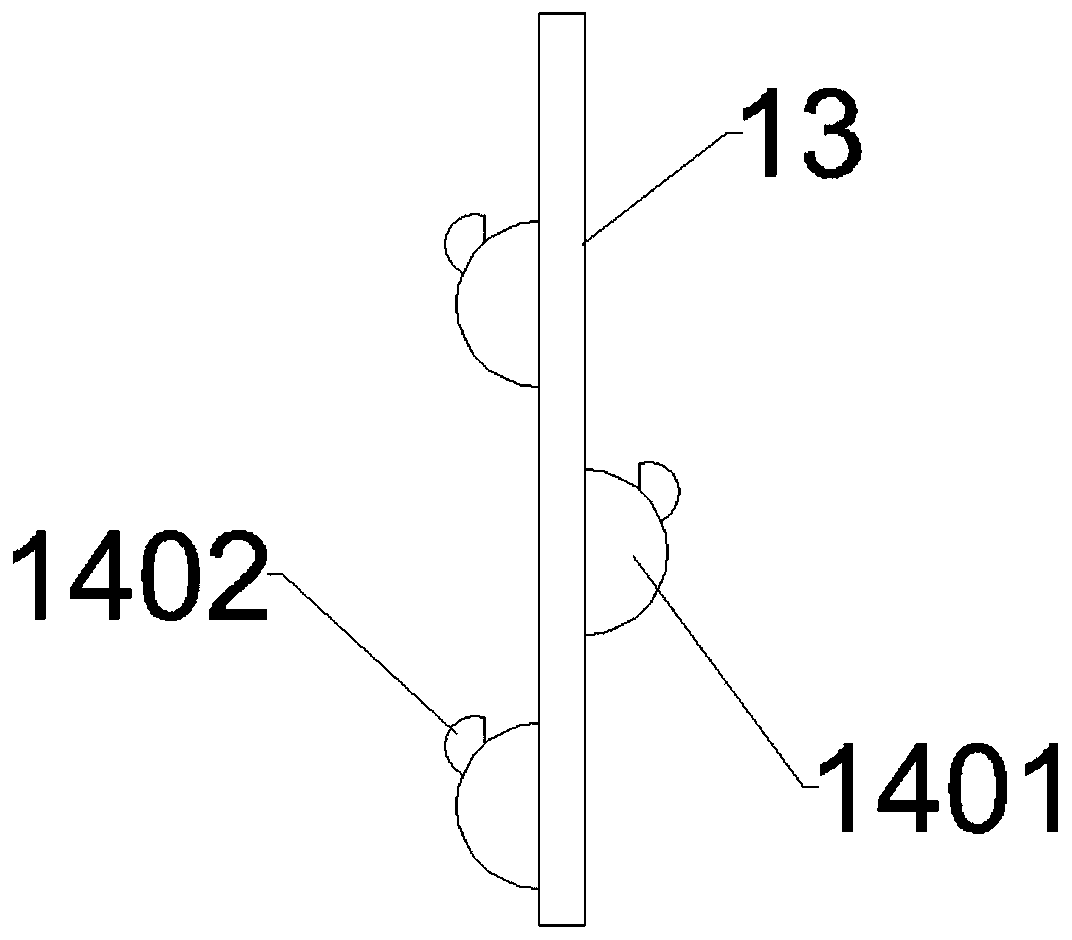

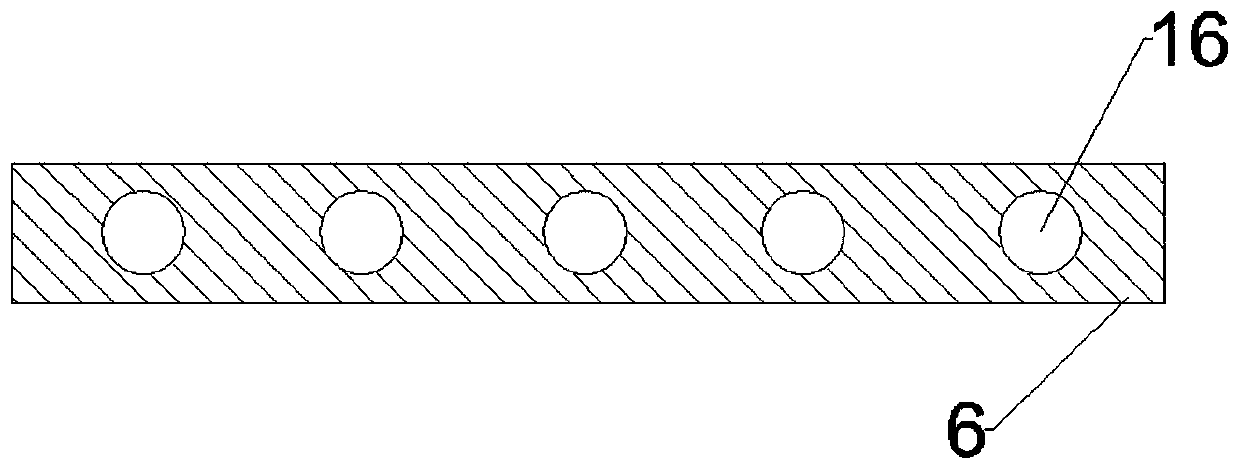

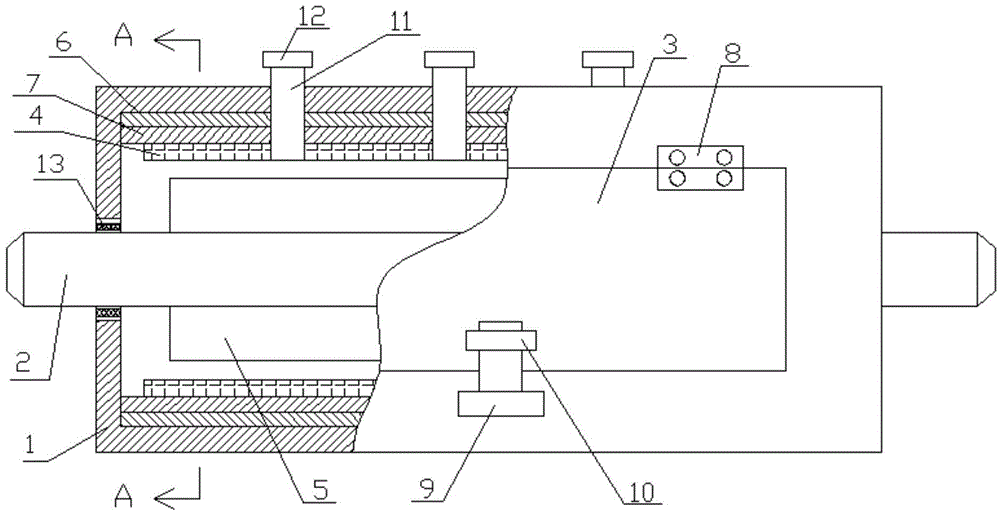

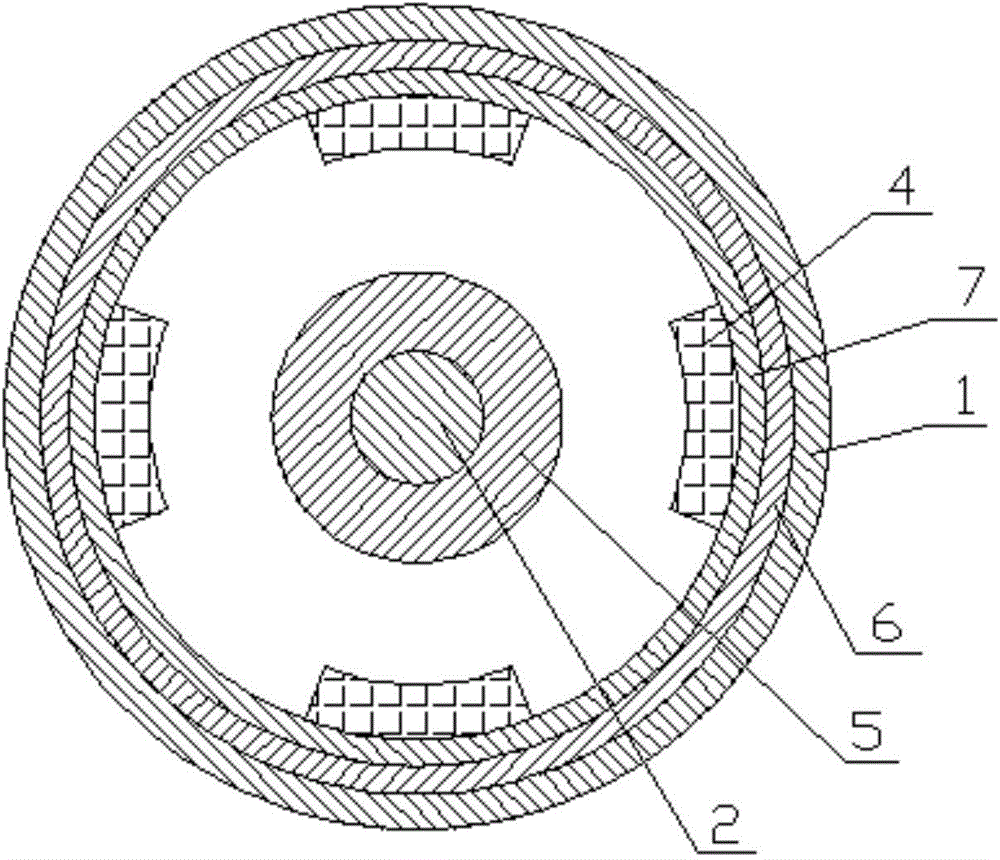

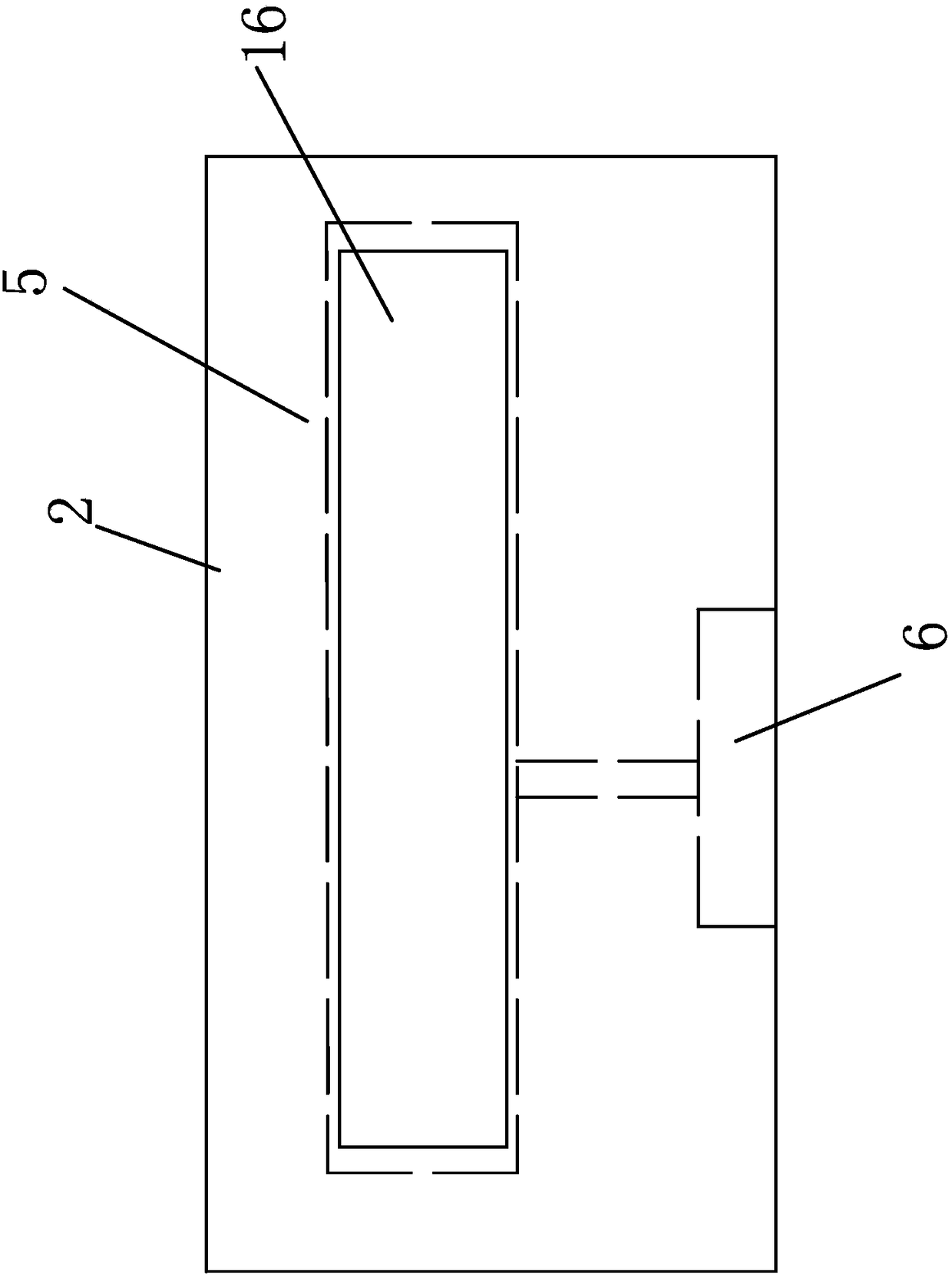

The invention discloses a seed drying system. The seed drying system comprises a pre-storage tower (1), a drying tower (2), a cooling tower (3), a hot air blowing device and two cold air blowers, wherein the pre-storage tower (1), the drying tower (2) and the cooling tower (3) respectively comprise a tower body, a feeding port arranged at the upper part of the tower body, a discharging port arranged at the lower part of the tower body, an air inlet cavity arranged outside the tower body, as well as an air inlet pipe (4) and an air outlet pipe (5) arranged inside the tower body, the lower surfaces of the air inlet pipe (4) and the air outlet pipe (5) have vent holes (6), one end of the air inlet pipe (4) is communicated with the air inlet cavity, the other end of the air inlet pipe (4) is sealed, and two ends of the air outlet pipe (5) are communicated with air outside the tower body. The seed drying system has the beneficial effects of satisfying the requirements on the drying operation of a large number of seeds which needs to be completed in a short period of time during a seed harvesting period, and being high in degree of automation, simple and convenient to operate, small in occupied area, uniform in drying effect and high in heat exchange efficiency.

Owner:CHENGDU JINZHUO AGRI

Gradient tea drying equipment

InactiveCN106524732AUniform drying effectImprove qualityDrying solid materials with heatPre-extraction tea treatmentSwitch boxAgricultural engineering

The invention discloses gradient tea drying equipment. The gradient tea drying equipment comprises a drying box, a heating device and a sucking fan; the top end of the heating device is fixedly connected with the sucking fan; the top end of the drying box is communicated with a feed port and a dehumidifying dust remover; a first drying device, a far infrared heating plate, a second drying device, a third drying device, an airflow cover and a receiving suction box are arranged on one side in an inner cavity of the drying box from top to bottom; multiple intake holes are uniformly formed in the bottom of the side wall of the drying box; the first drying device and the third drying device are the same with the second drying device in structure; the first drying device includes a fixed block, a guide frame, a vibrator and a ventilation net; the ventilation net is embedded in a frame hole of the guide frame; and a switch box is arranged at one side end of the drying box. The first drying device, the second drying device and the third drying device divide the inner cavity of the box body into drying channels, so that tea leaves roll along the channels for flowing; and meanwhile, the tea leaves are heated and dried by hot air currents, so that the tea leaf drying effect is more uniform.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

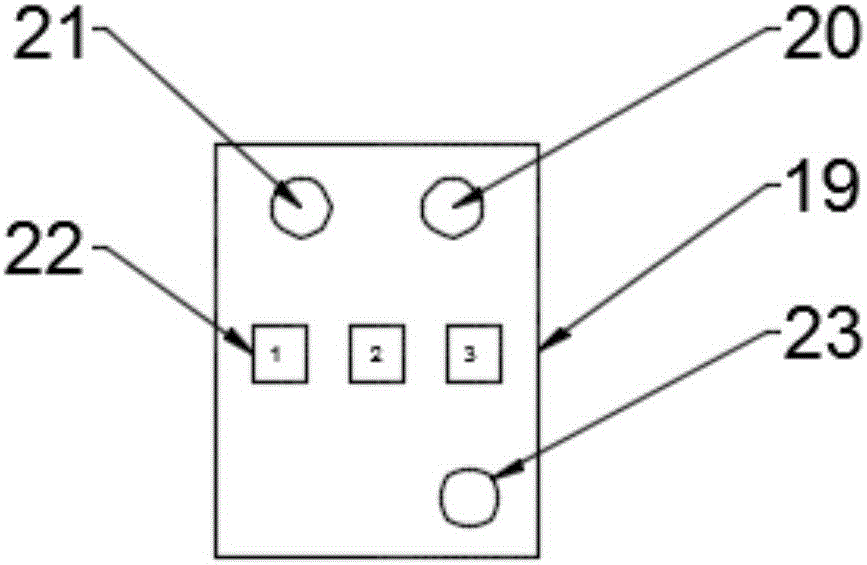

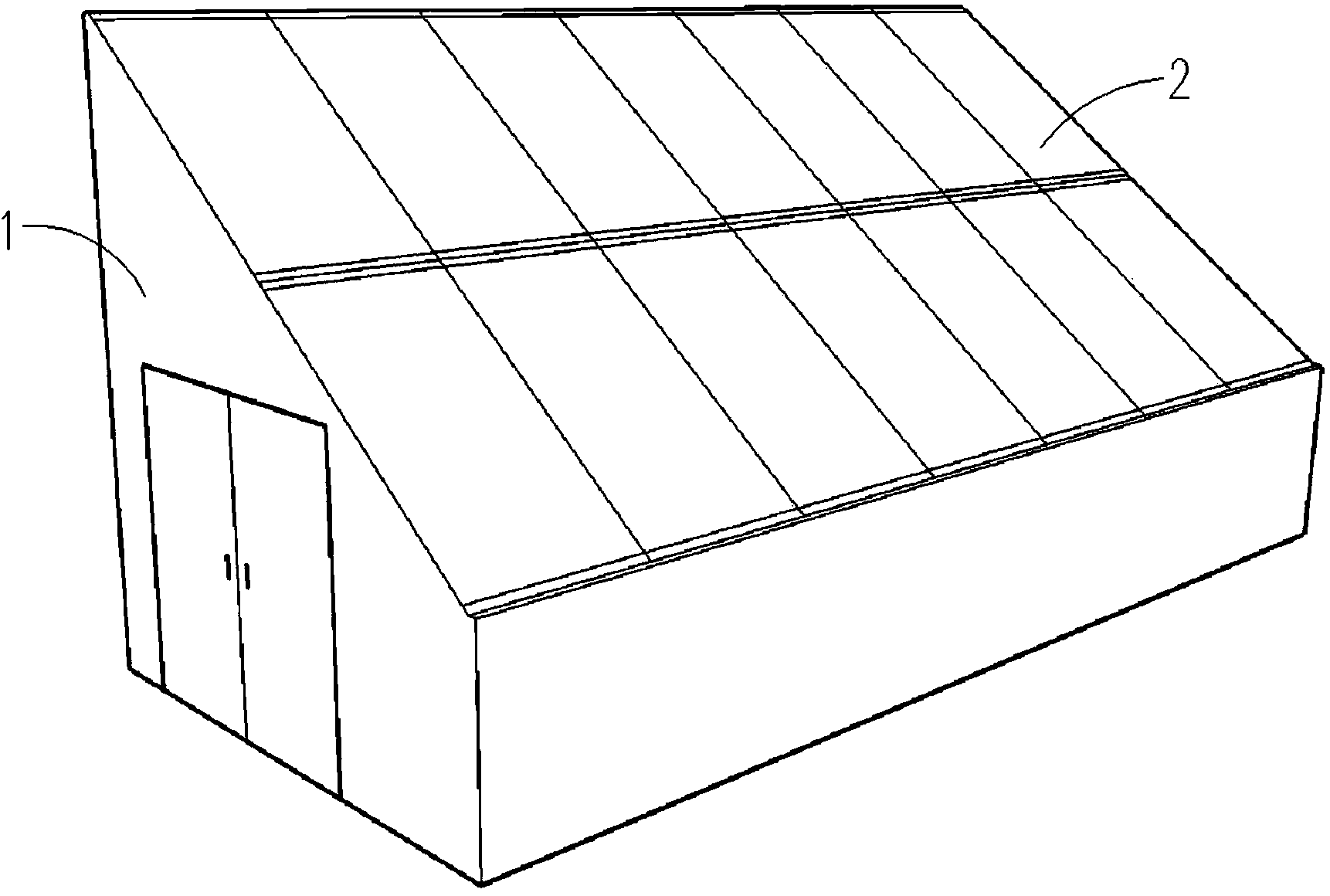

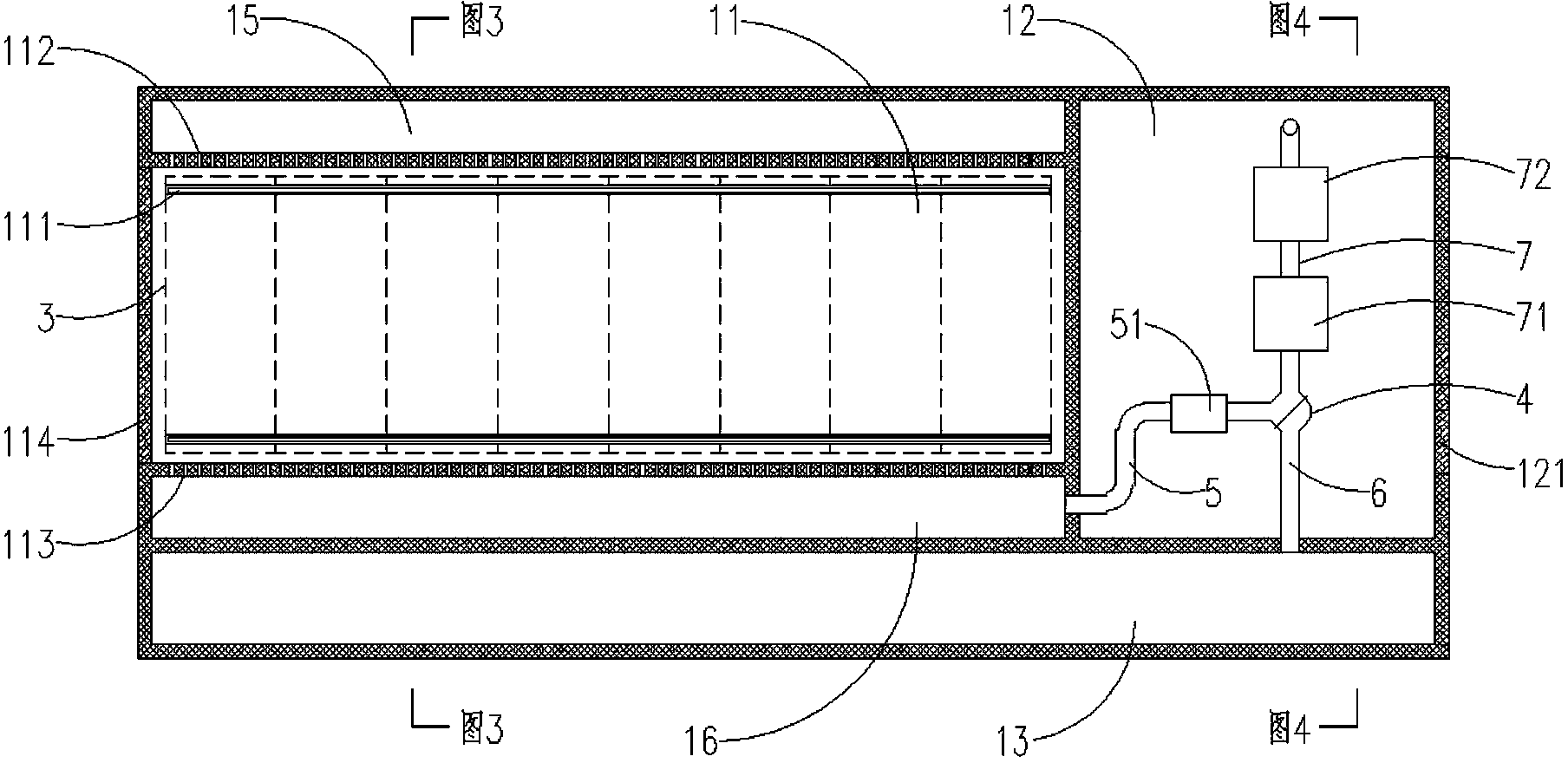

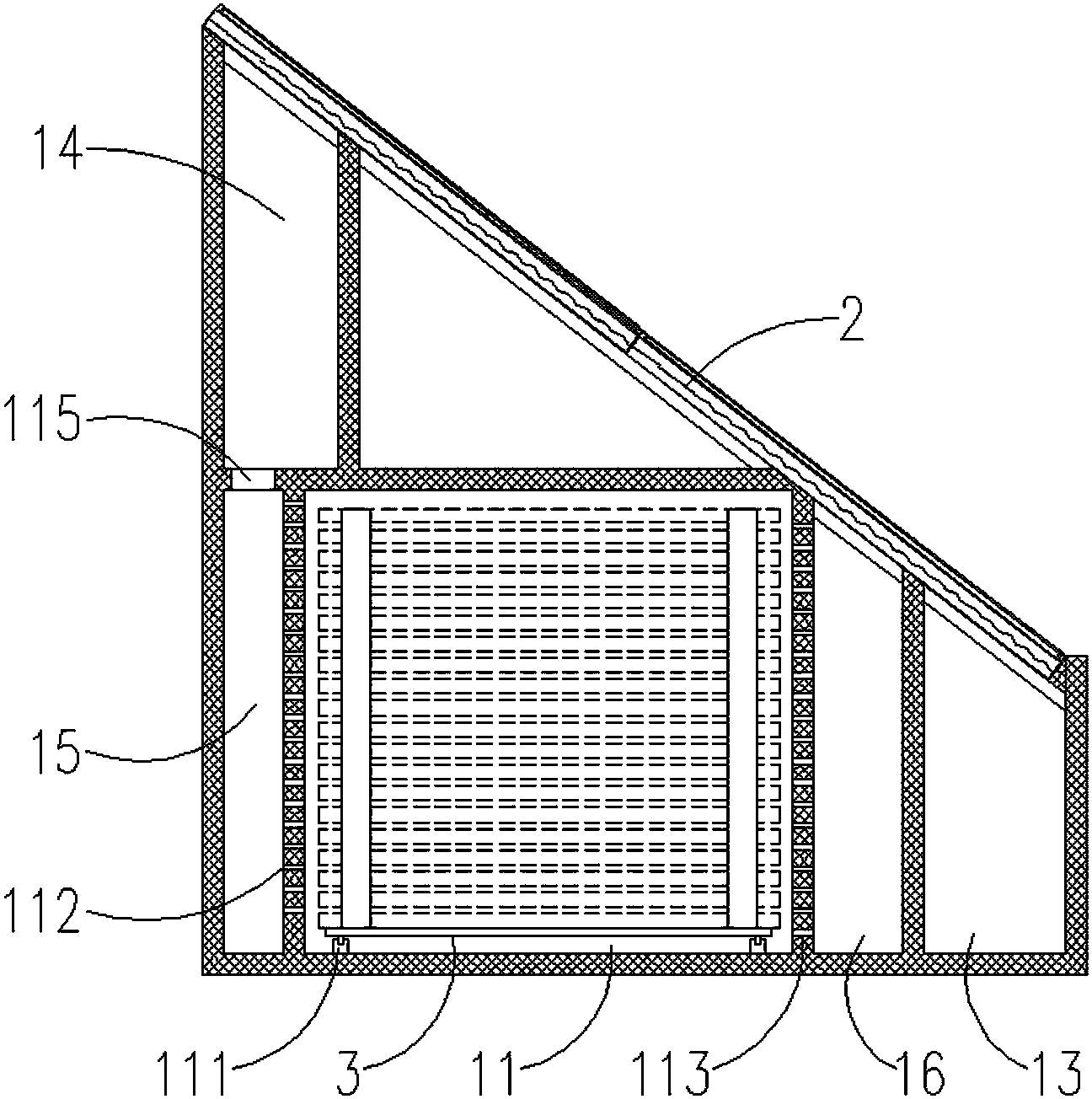

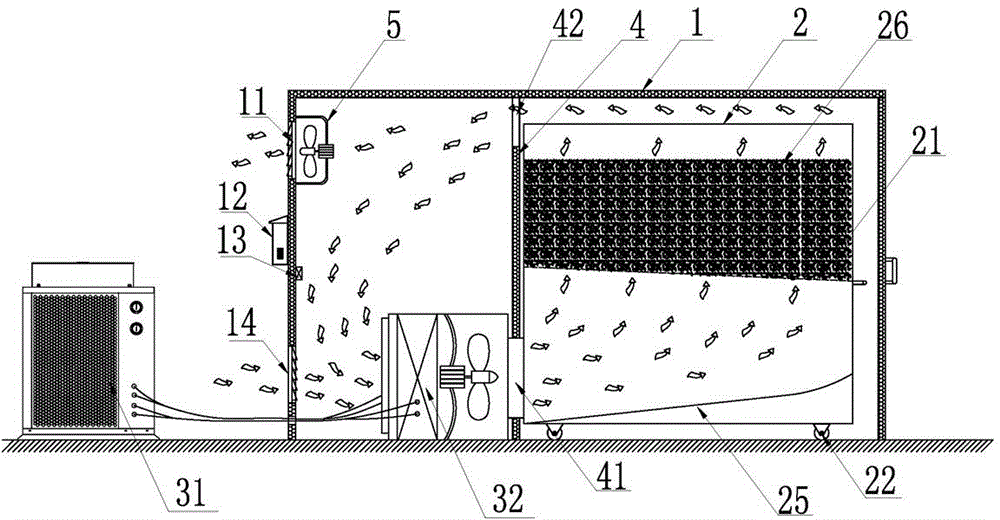

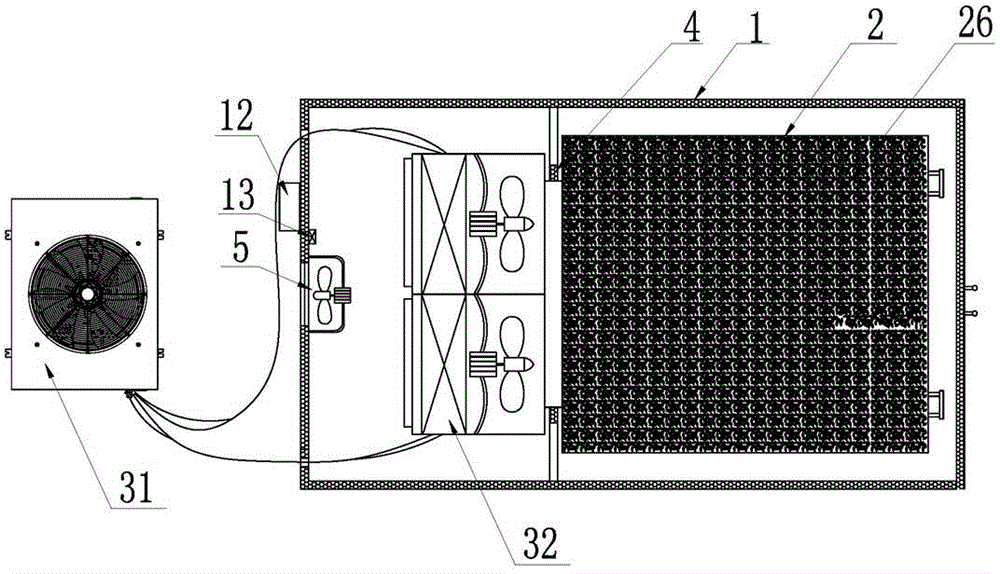

Monolithic moveable energy-saving drying room

ActiveCN104013072AUniform air supply dryingReduce energy consumptionFood processingClimate change adaptationThermal insulationEngineering

The present invention belongs to the technical field of solar energy utilizing, and particularly relates to a solar air collector which can utilize solar energy to heat air. The technical scheme of the present invention is as follows: utilizing thermal insulation materials to produce a closed drying room structure, and circulatingly heating the air in the drying room by a combination of a solar air collector and an active heating equipment. The integrated moveable energy-saving drying room has advantages of that: the enclosed insulation structure has low energy consumption; solar energy hybrid heating is green and energy-saving; inner micropores uniformly provide air so as to achieve a uniform drying effect; and monolithic structure is easy to move.

Owner:宁夏塞上阳光新能源科技有限公司

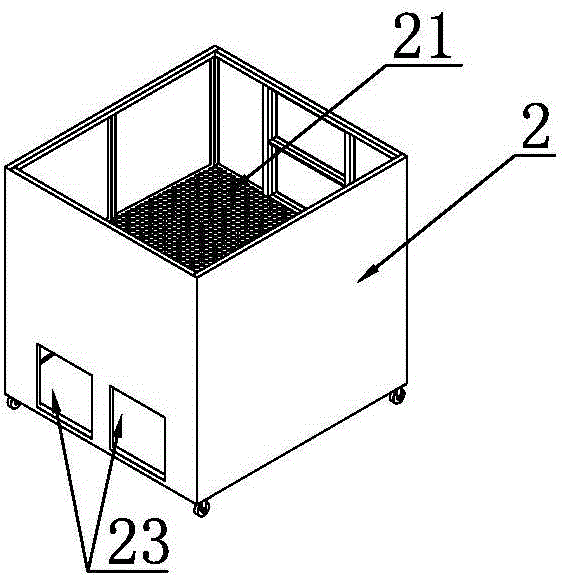

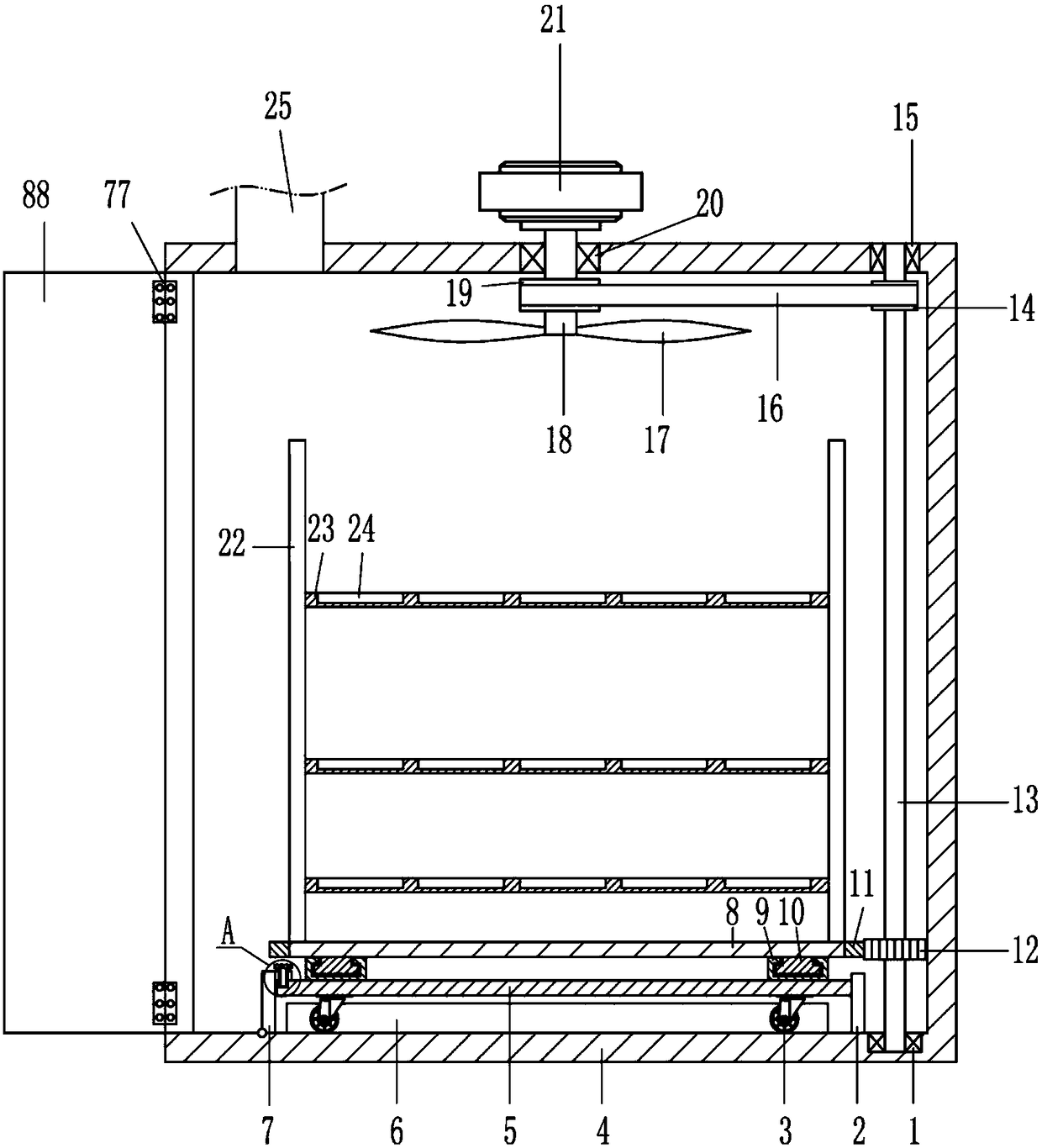

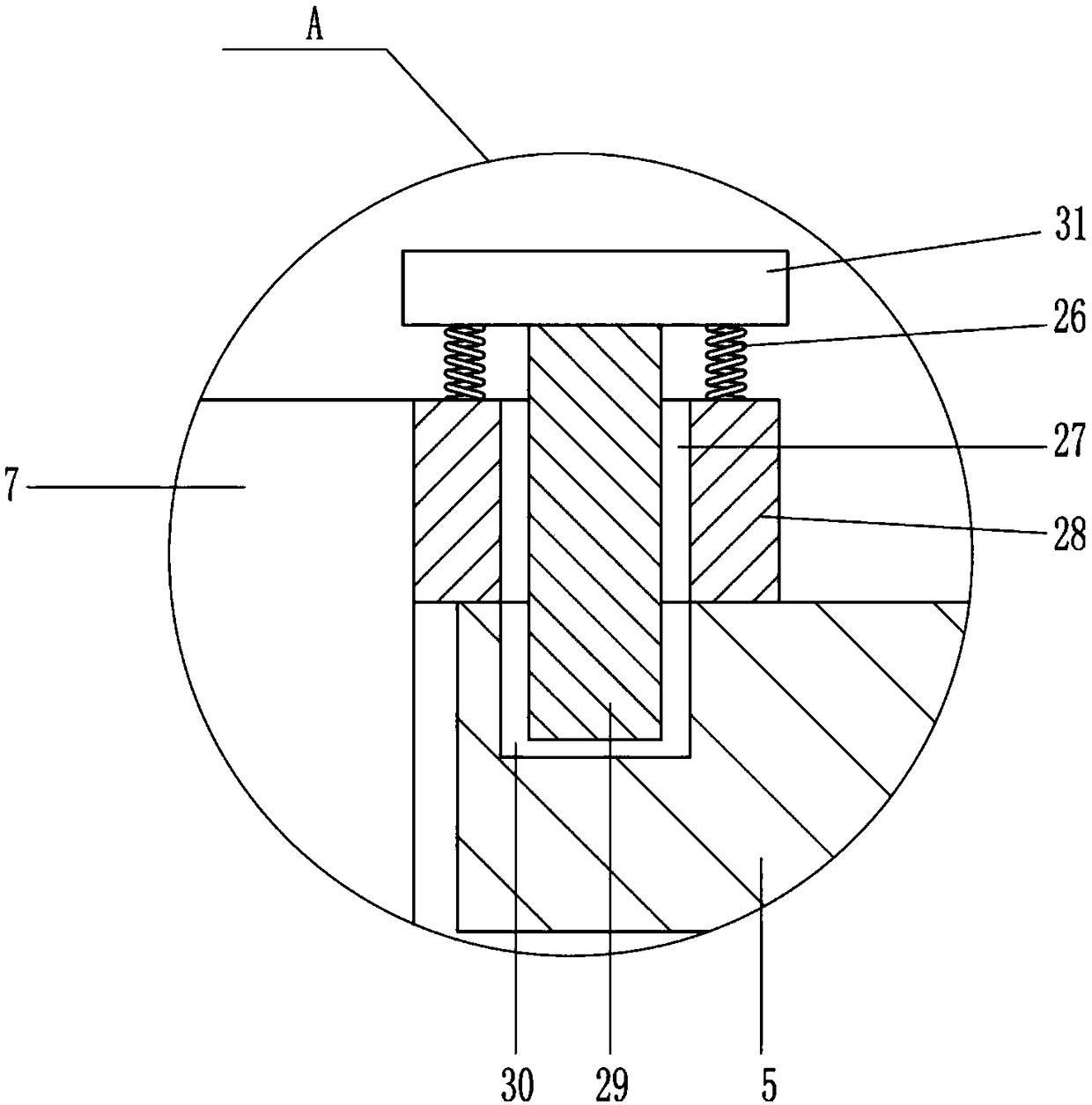

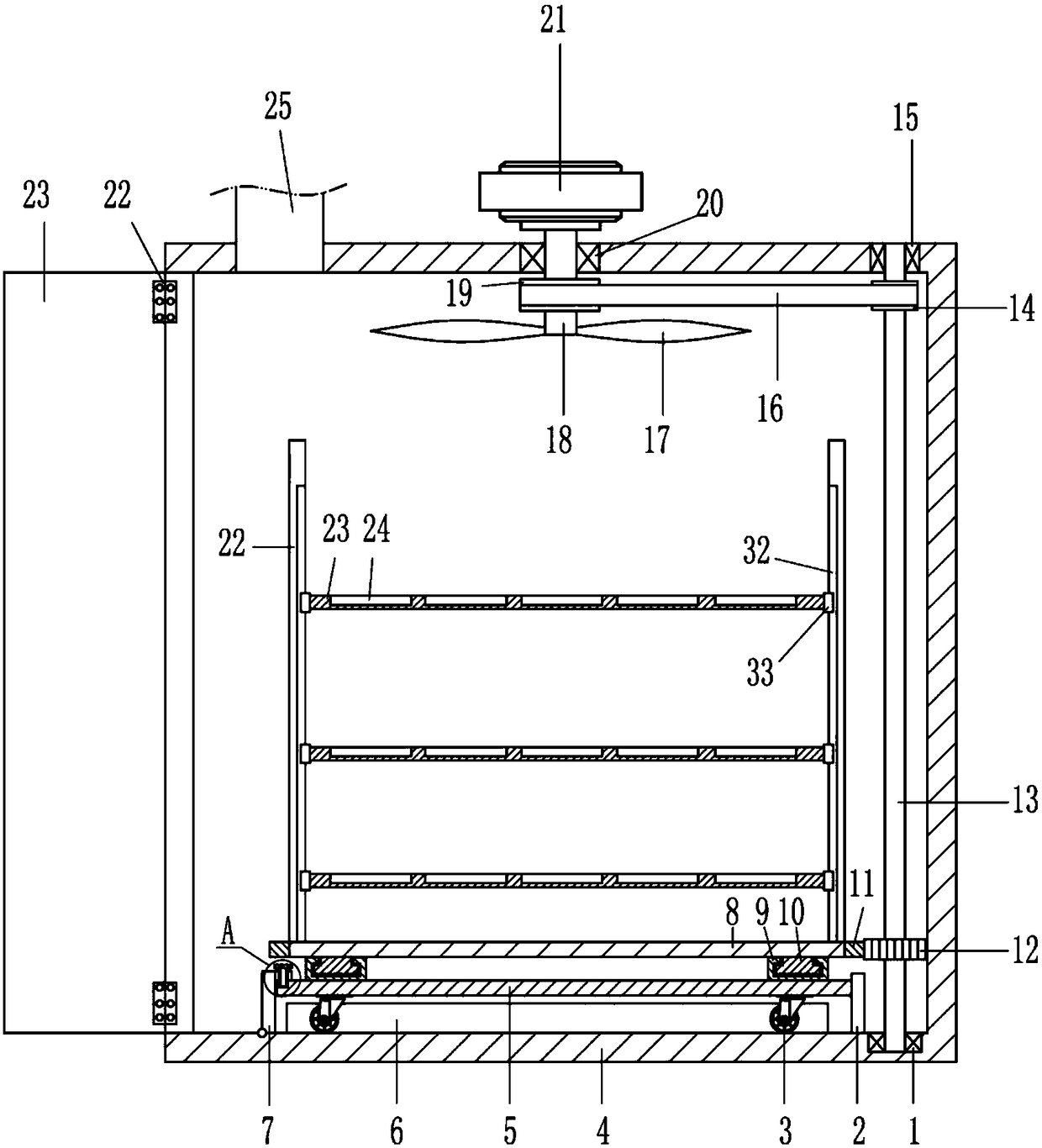

Wardrobe with drying function

InactiveCN109610140AUniform drying effectImprove drying efficiencyWardrobesTextiles and paperPulp and paper industry

The invention discloses a wardrobe with a drying function. The wardrobe comprises a wardrobe body, a clamping seat, a rotating mechanism, an air outlet, a filtering mechanism and a drying mechanism, wherein the drying mechanism is fixedly connected to the bottom of the wardrobe body; the filtering mechanism is fixedly connected to the left side of the wardrobe body; the air outlet is formed in theupper end on the left side of the wardrobe body; the clamping seat is fixedly connected to the upper end of an inner cavity of the wardrobe body; the rotating mechanism is arranged at the top of thewardrobe body; the drying mechanism comprises a drying oven; an air inlet is formed in the middle on the left side of the drying oven; a metal filtering screen cover is fixedly connected to each of the inner surfaces of the air outlet and the air inlet respectively; 3-5 groups of heating wires are fixedly connected to the left end of the inner cavity of the drying oven; the quantity of heating wires in each group is 3-5. According to the wardrobe, clothes can be dried by arranging the drying mechanism; in addition, a uniform drying effect on the clothes can be achieved due to the match of therotating mechanism, so that the drying efficiency of the clothes is improved.

Owner:白雪

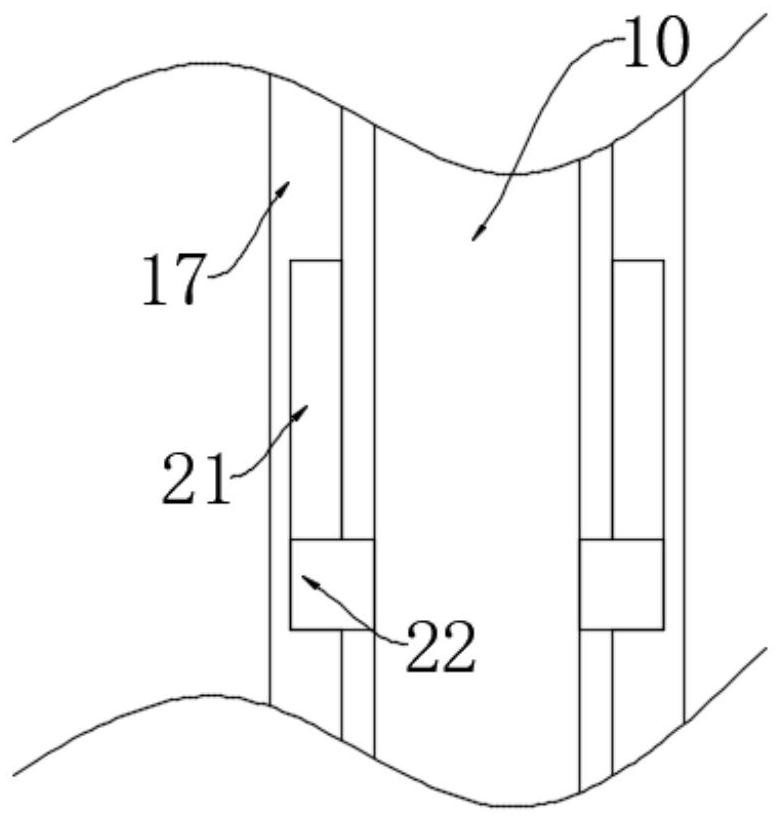

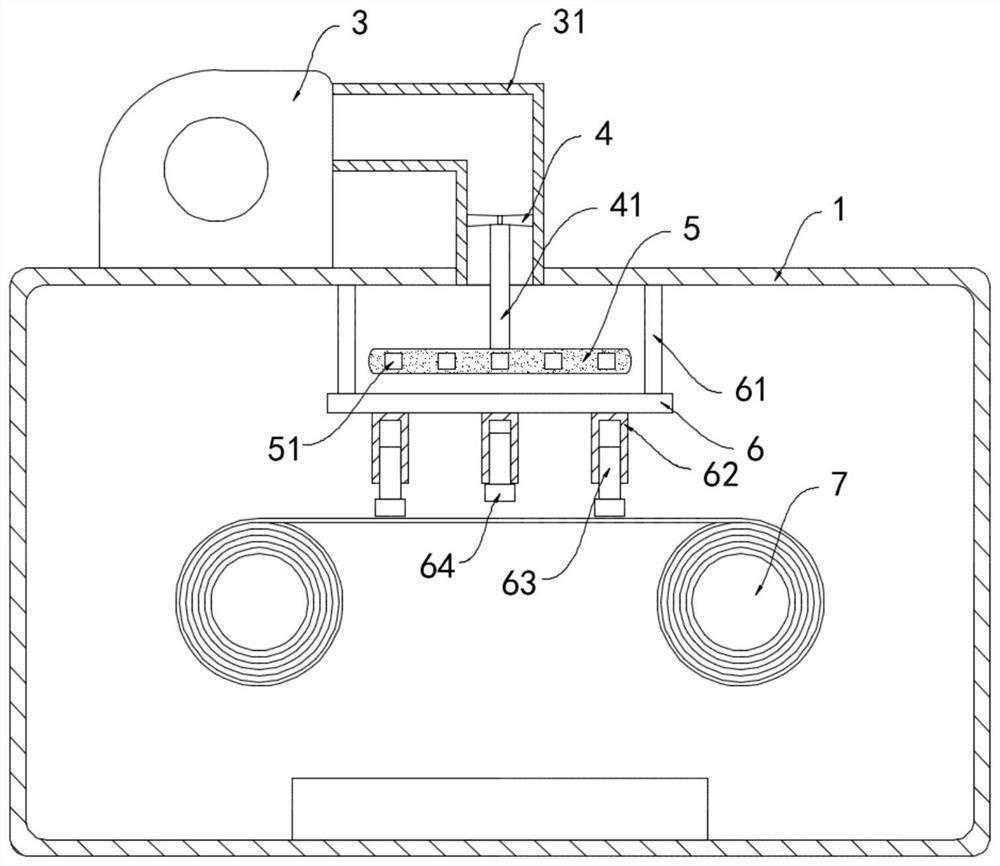

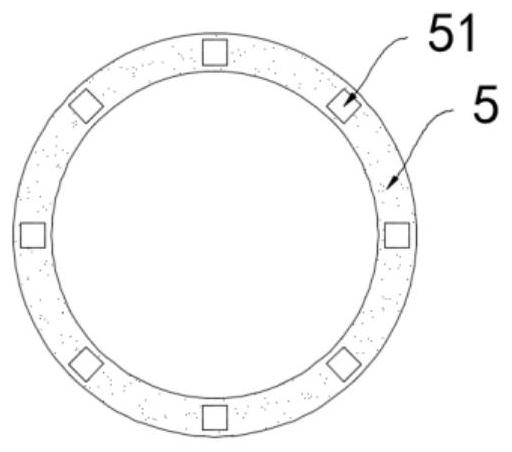

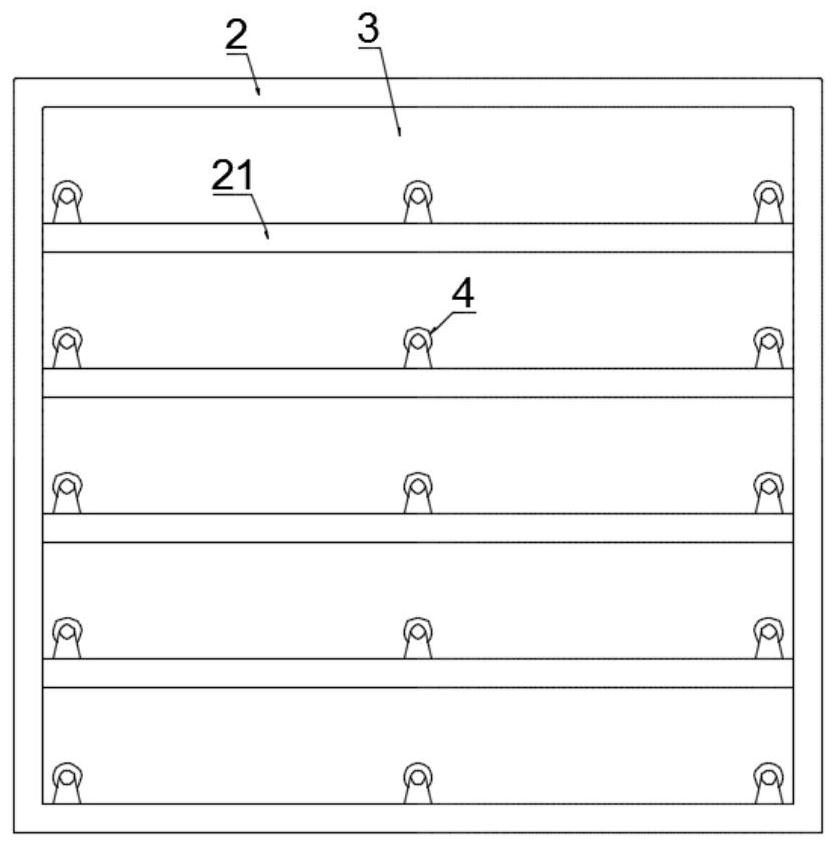

Spool drying device

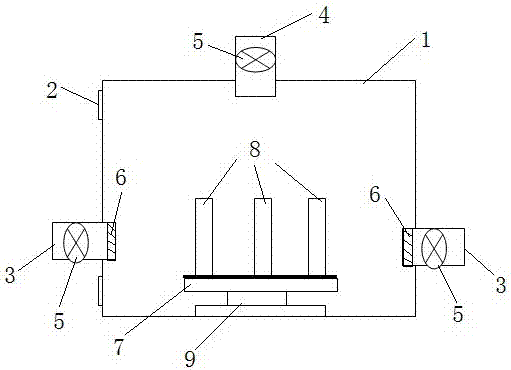

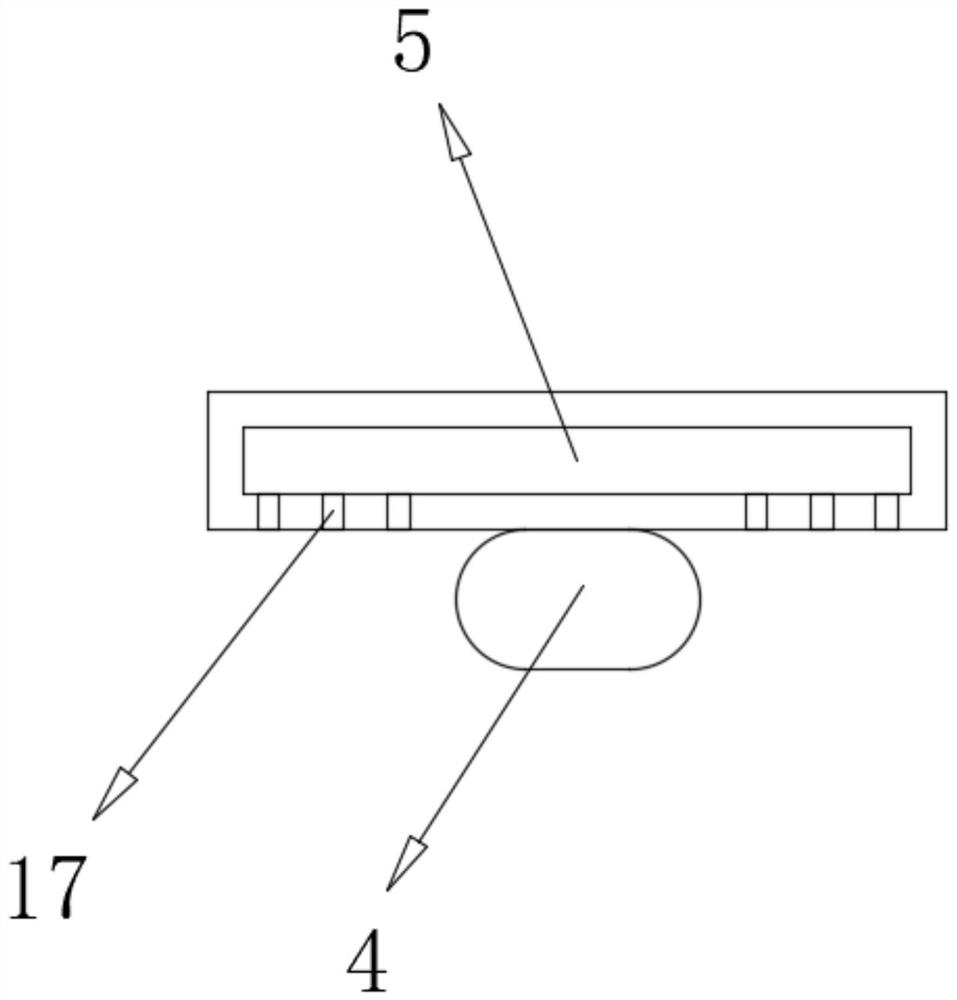

InactiveCN107504785AImprove drying efficiencyUniform drying effectDrying gas arrangementsDrying chambers/containersYarnChassis

The invention discloses a yarn bobbin drying device, which comprises a box body. A door is arranged on the front side of the box body. The door is hingedly connected with the box body and can be opened and closed; the box body is also provided with an air inlet and a A heater is installed at the air outlet, and a rotatable feeding rack is arranged in the box, and the feeding rack includes a chassis and several bobbin shafts arranged on the chassis. The yarn bobbin drying device provided by the invention is provided with two hot air ports, and the material tray and the bobbin shaft rotate simultaneously, so that the yarn on the bobbin shaft is evenly heated, the drying efficiency is high, and the drying effect is uniform.

Owner:JURONG JIAYUN TEXTILE CO LTD

Cloth drying device for spinning

InactiveCN112344706AImprove drying efficiencyEven contactDrying gas arrangementsDrying chambers/containersThermodynamicsSpinning

The invention discloses a cloth drying device for spinning, and belongs to the field of spinning drying. The cloth drying device comprises a working box, wherein an inlet is formed in the left side ofthe working box, cloth stretches into the working box from the inlet, one end of the cloth is in lap joint to a driven roller and a driving roller through the position between two sets of rollers, and then the cloth reaches a winding mechanism from an outlet; when the cloth passes through the position between the two sets of rollers, the two sets of rollers extrude each other so as to remove water in the cloth, and the drying efficiency is improved; water drops slide into a collecting mechanism, a first motor is started to rotate the driving roller to drive the cloth to move, an exhaust fan sucks air into a drying box from the outside, the air enters the drying box to be heated by an electric heating wire net, and the heated air passes through an air outlet to uniformly dry the moving cloth; and the cloth moves at a constant speed all the time, the cloth can be uniformly dried, an electric fan on a moving mechanism is started to blow away hot air in the working box, the situation thatthe air volume is excessively concentrated in a certain area is avoided, and the drying efficiency is better.

Owner:绍兴韵足针纺织有限公司

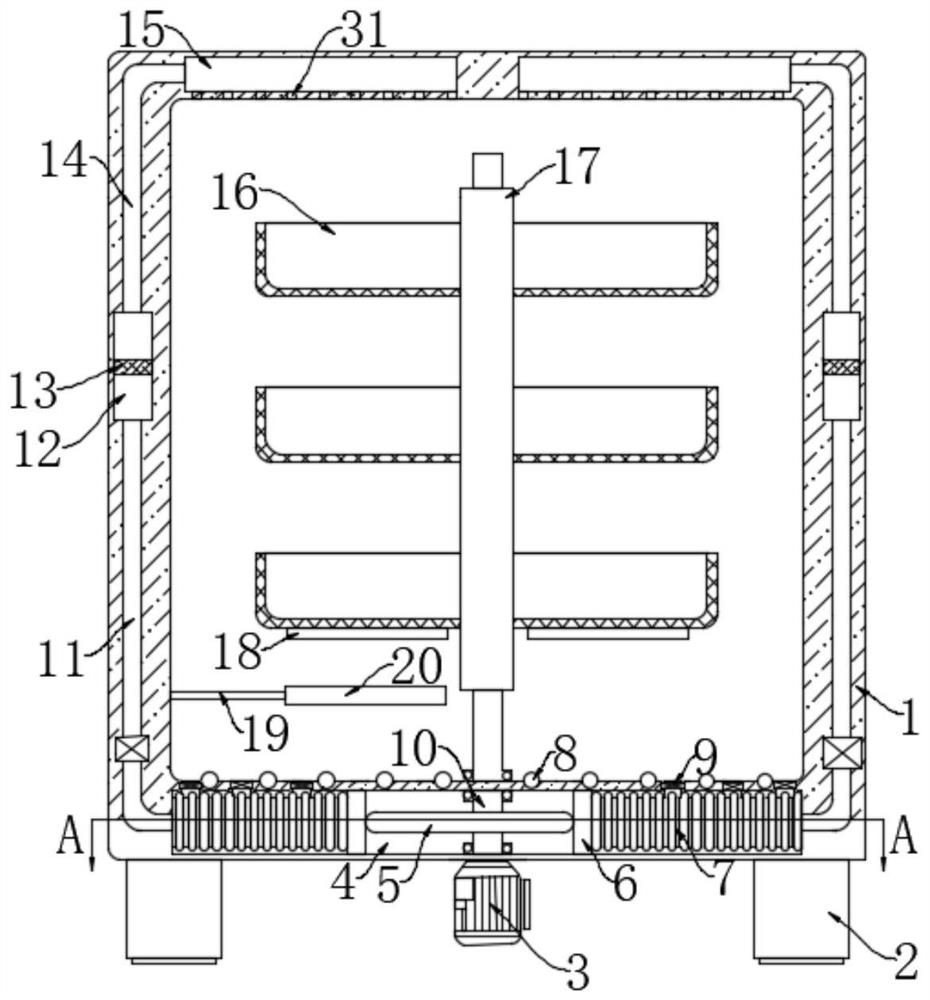

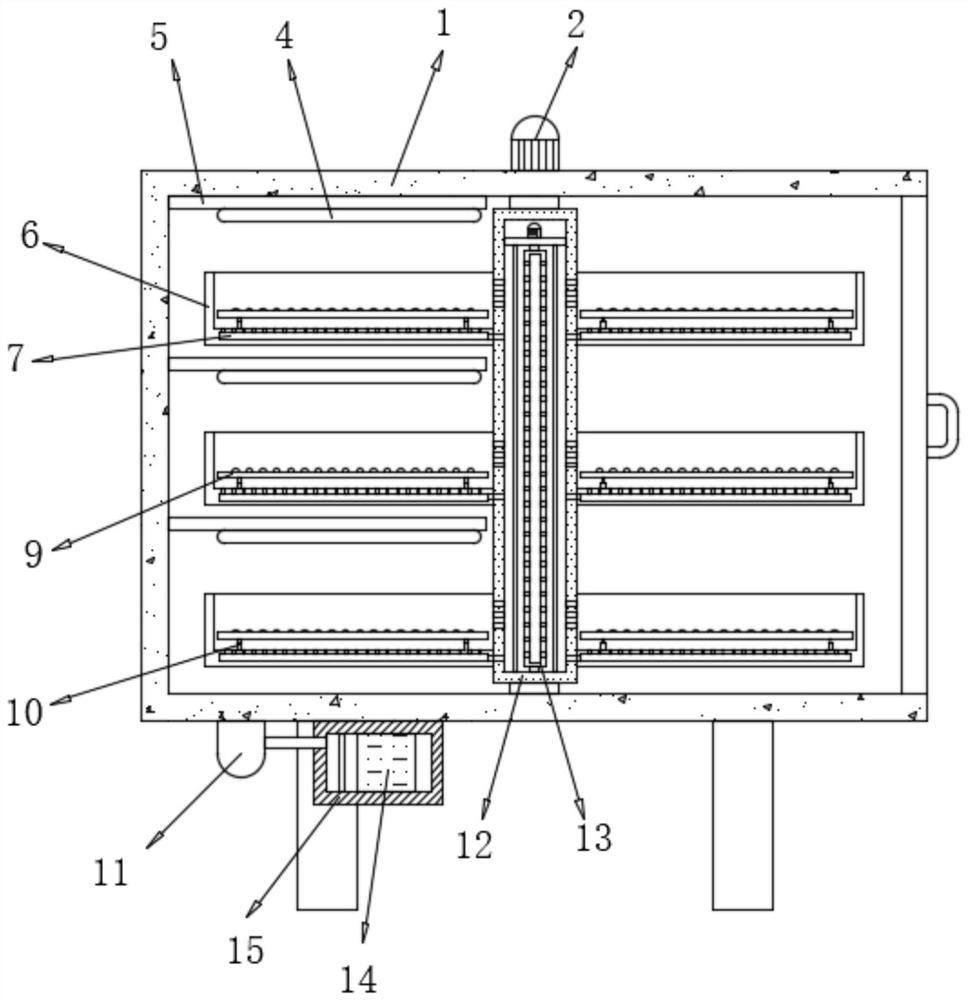

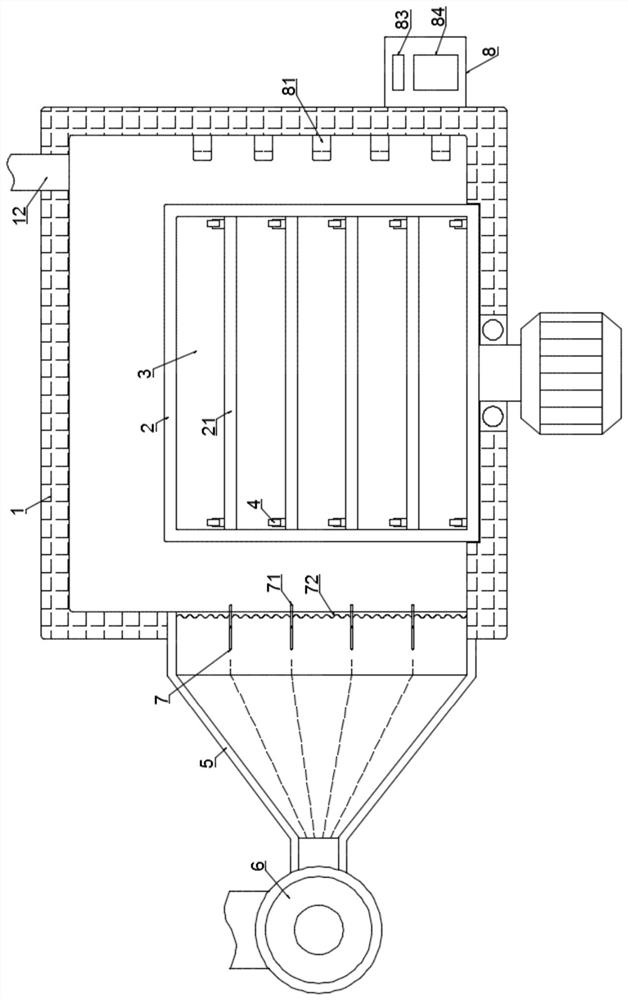

Edible mushroom dewatering and drying device

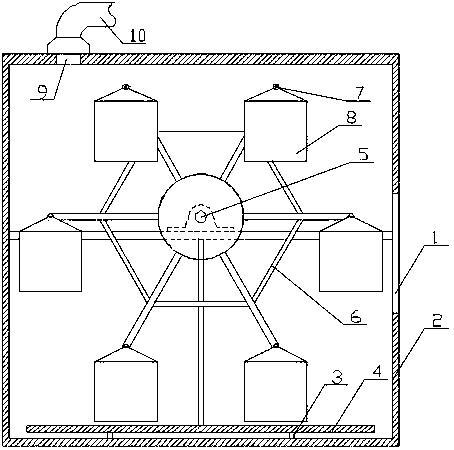

InactiveCN109303345AHeating evenlyUniform drying effectFood treatmentTemperature controlHanging basket

The invention discloses an edible mushroom dewatering and drying device. The edible mushroom dewatering and drying device comprises a box with a taking door, and a heating device, a material rotatingdevice, an exhaust device and a temperature control device are arranged in the box. The heating device is arranged at the bottom of the box, and the heating device is provided with a temperature control valve. The material rotating device comprises a rotary shaft arranged in the middle of the box, the rotary shaft is in transmission connection with the power driving device, radicalized cantileversare arranged on the two sides of the position, in the box, of the rotary shaft, connecting shafts are arranged at the ends of the cantilevers, the connecting shafts are movably connected with a hanging basket, and a tray is placed in the hanging basket. The exhaust device is arranged at the top of the box. The temperature control device is arranged outside the box and is in guide wire connectionwith an air pump and the temperature control valve. According to the edible mushroom dewatering and drying device, multilayer vegetables, fruits and edible mushrooms can be effectively dried, the drying effect is even, the quality is stable, and the heat efficiency is high.

Owner:随州市三龙食用菌机械有限公司

Special steel drainage agent and preparation method thereof

ActiveCN109202055AAppropriate refractorinessImprove liquidityMelt-holding vesselsGranularityNuclear power

The invention provides a special steel drainage agent and a preparation method thereof and belongs to the technical field of metallurgical fireproof materials. The special steel drainage agent is prepared by following raw materials of, by weight, 22-75 parts of natural zircon sand with granularity of 0.1-0.5mm, 8-40 parts of chrome ore with granularity of 0.1-0.5mm, 15-35 parts of desert sand withgranularity of 0.3-0.6mm and 1-3 parts of liquid graphite. According to the invention, the pouring rate of a product can be effectively improved; compared with the existing drainage agent, the automatic pouring rate can be improved by 10% or over and the basic automatic pouring rate can reach 100%; requirements are met that there are many types of special steel currently, the difference of components is big and long-time smelting is required; and the drainage agent and better drainage effects for steel types in war industry, nuclear power and special high-quality products are achieved.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

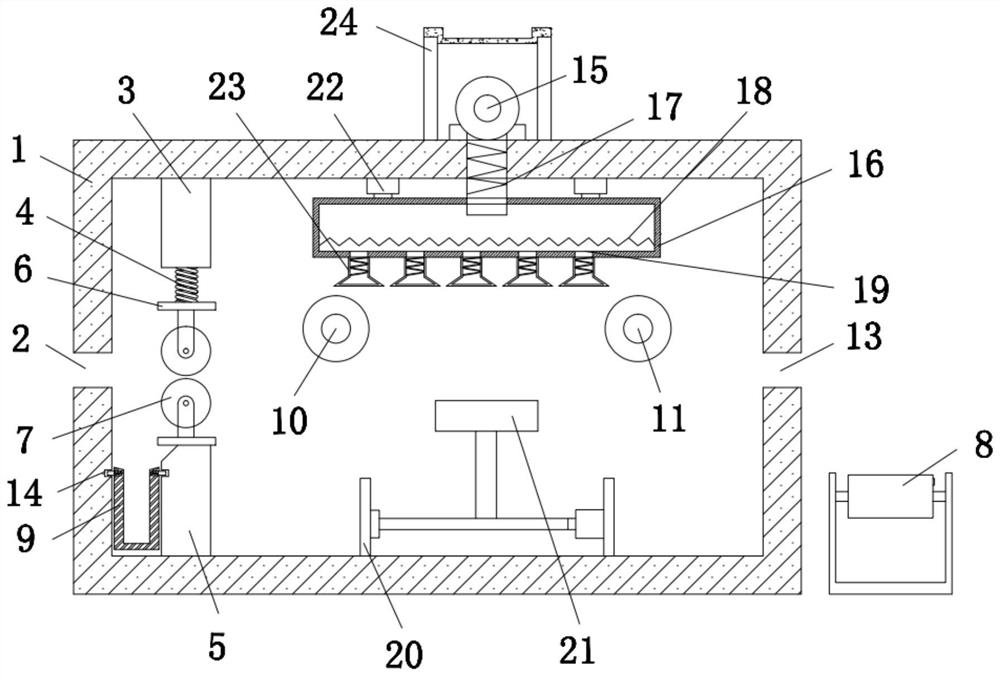

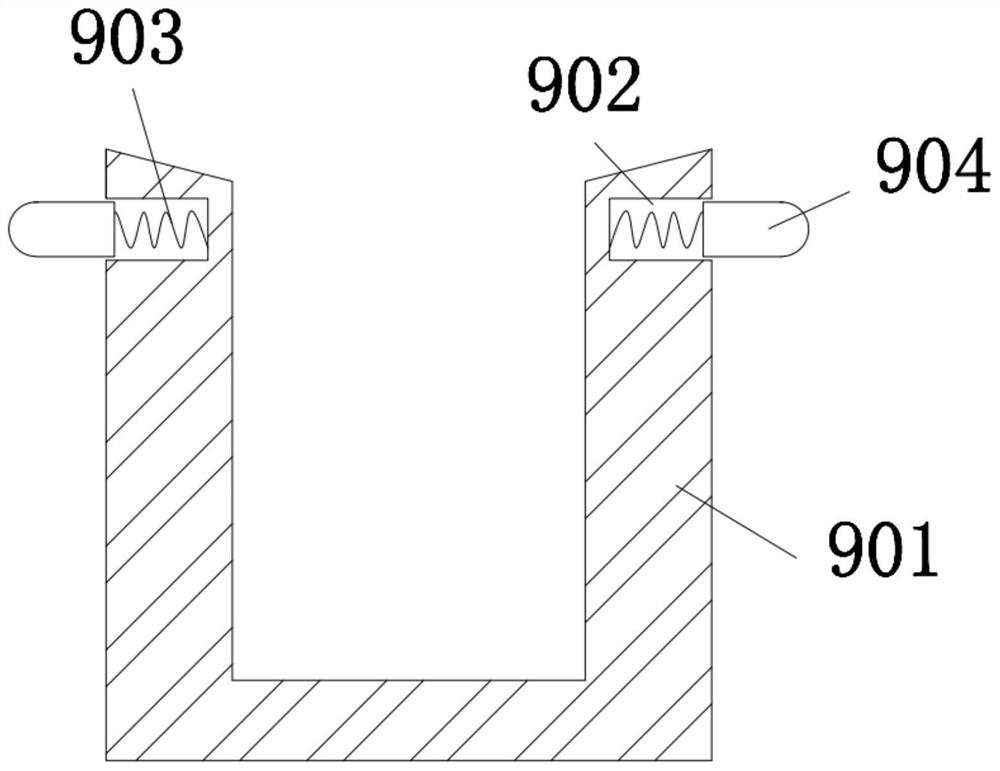

Drying device for spinning

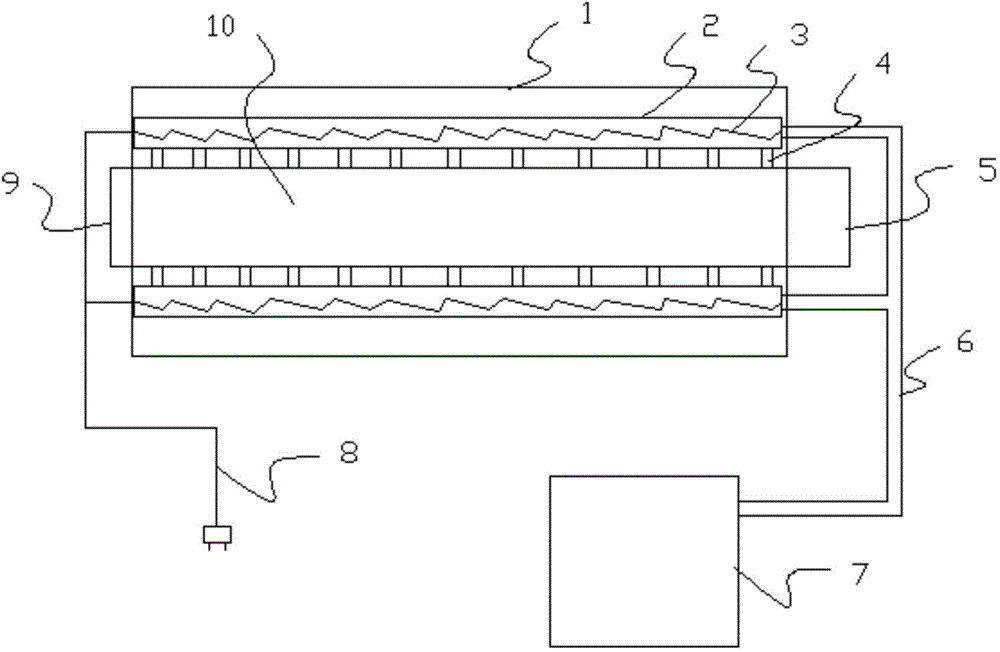

PendingCN104976875AUniform drying effectDrying machines with progressive movementsHeating arrangementEngineeringAir blower

The invention relates to the field of spinning equipment, in particular to a drying device for spinning. The drying device can effectively solve the problem that an original device is not even in drying. The drying device structurally comprises a box of a hollow structure. A drying bin with the two ends stretching out is arranged in the hollow structure. A feeding port is formed in one end of the drying bin, and a discharging port is formed in the other end of the drying bin. Two heating boxes are arranged in the parts, above and below the drying bin, of the box respectively. The heating boxes are communicated with the drying bin through a plurality of connecting pipes respectively. Heating wires are arranged in the heating boxes and connected with an external power line. The same ends of the heating boxes are connected with an air blower through an air inlet pipe. The drying device for spinning is easy to operate, convenient to use and suitable for drying of spun materials.

Owner:SUZHOU DONGMAO TEXTILE IND

Rice drying machine

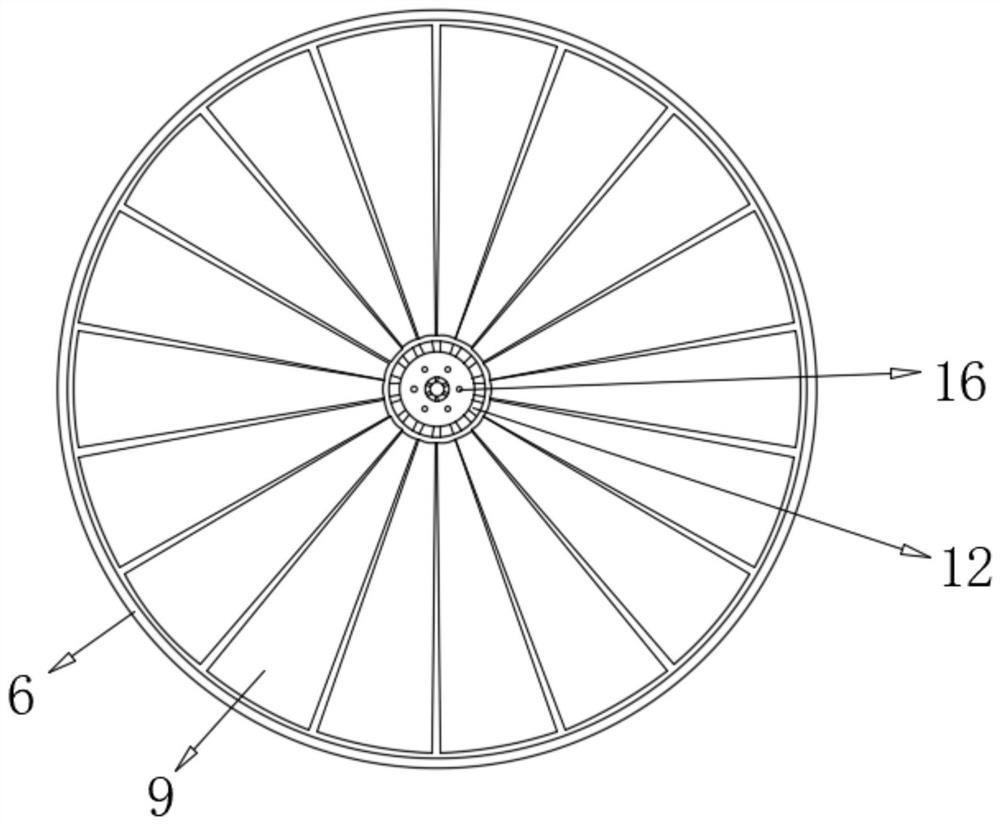

InactiveCN107940971AUniform drying effectDischarge in timeSeed preservation by dryingDrying chambers/containersHollow cylinderAgricultural machinery

The present invention relates to the field of agricultural machinery, in particular to a rice dryer, comprising: an air extraction shell, a rotating jacket, a drying bin, a spiral stirring blade and a heating shaft arranged sequentially from outside to inside; the rotating jacket is It is hollow cylindrical, and its side wall is provided with vent holes; the middle part of the drying chamber is a U-shaped tank with an open top, and its two ends are circular sealing plates, and the drying chamber passes through the circular The circular sealing plate is sealed and connected to the two ends of the rotating jacket, and the area of the circular sealing plate is larger than the U-shaped cross-sectional area of the U-shaped groove body, so that there is a certain gap between the U-shaped groove body and the rotating jacket. The drying bin is provided with a condensation scraper at the gap, the bottom of the condensation scraper is connected to the drying bin, and the top of the condensation scraper is against the inner wall of the rotating jacket .

Owner:福清美丰农林科技有限公司

Quartz sand drying device

PendingCN110108094ASolve the clump problemUniform drying effectDrying solid materials with heatDrying gas arrangementsWater vaporEngineering

The invention discloses a quartz sand drying device. The quartz sand drying device comprises a drying box. Feeding openings are symmetrically formed in the upper portion of the drying box. A hot air inlet is formed in one side of the upper portion of the drying box. Material guide plates are symmetrically arranged in the drying box and comprise inclined plates and vertical plates. Coarse sieve plates are arranged below the material guide plates, and fine sieve plates are arranged below the coarse sieve plates. A preheating cavity is formed by the two inclined plates and the inner wall of the drying box. According to the quartz sand drying device, the hot air inlet is connected with a hot air blower; hot air sequentially enters the preheating cavity and a scattering cavity, and then entersa first drying cavity and a second drying cavity in sequence through coarse screen holes and fine sieve holes; the temperature of the drying box is increased, cleaned quartz sand is fed into the drying box through the feeding openings, is stirred through a stirring rod in the preheating cavity and is preheated and dried, and a large amount of water vapor is discharged from a moisture outlet.

Owner:新沂市创科石英有限公司

Drying barrel structure for spinning

InactiveCN104930828AImprove moisture resistanceImprove insulation effectDrying machines with non-progressive movementsDrying solid materialsPulp and paper industryEnergy consumption

The invention discloses a drying barrel structure for spinning. The drying barrel structure comprises a drying barrel body, a rotating shaft arranged on the drying barrel body, a barrel door arranged on the drying barrel body and drying apparatuses arranged on the drying barrel body. The rotating shaft is arranged in a manner of penetrating the drying barrel body, and the rotating shaft in the drying barrel body is sleeved with a drum capable of winding fabric; a drying thin film is arranged on the inner wall of the drying barrel body, and a heat preservation layer is arranged on the outer surface of the drying thin film; the drying apparatuses are arranged on the inner wall, equipped with the drying thin film and the heat preservation layer, of the drying barrel body, and a movable hinge is arranged on the drying barrel body; the barrel door is hinged to the movable hinge; a first clamping buckle is arranged on the drying barrel body, and a second clamping buckle matched with the first clamping buckle is arranged on the barrel door; and three air outlet pipelines for facilitating exhausting of wet gas are arranged on the upper portion of the drying barrel body. The drying barrel structure is simple in structure, convenient to use and mount, good in drying effect, uniform in drying, low in energy consumption, low in cost and long in service life, saves labor and has the safe and reliable effects, and the fabric can be conveniently put and taken.

Owner:周盈裕

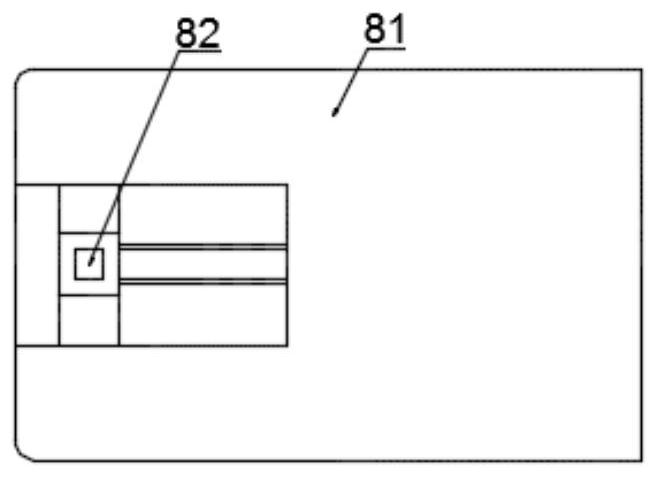

Tea oven-drying equipment with dehumidification module

PendingCN112120092AConsistent temperatureEasy to storePre-extraction tea treatmentEngineeringProcess engineering

The invention discloses tea oven-drying equipment with a dehumidification module. The tea leaf oven-drying equipment comprises a shell, wherein two supporting blocks are symmetrically arranged at thelower end of the shell, an oven-drying cavity, a telescopic cavity and two long cavities are formed in the shell, the two long cavities are both located above the oven-drying cavity, the telescopic cavity is located below the oven-drying cavity, two dehumidification cavities are symmetrically formed in the shell and located on two sides of the oven-drying cavity respectively, an electric heating wire is arranged at the inner bottom of the oven-drying cavity, and meanwhile a compression mechanism and a rotating mechanism are further arranged in the tea oven-drying equipment. According to the tea oven-drying equipment, a gas in an oven-drying chamber is circulated, so that the temperature in the oven-drying chamber is kept consistent. Meanwhile, the heating surface of tea leaves is uniform through the shaking of placement grooves, so that the oven-drying effect is better. Meanwhile, water vapor in the oven-drying chamber is adsorbed through a dehumidification mechanism in the gas circulation process, and thereby the oven-drying effect of the tea oven-drying equipment is improved.

Owner:邹秀兵

Method for drying cashmere loose fibers through radio frequency

ActiveCN105066595AUniform drying effectWon't hurtDrying using combination processesEngineeringHigh water content

The invention discloses a method for drying cashmere loose fibers through the radio frequency, and relates to a method for drying the cashmere loose fibers with the higher water content. The method includes the four steps including centrifugal dewatering, radio frequency drying, strong air exhausting and collecting packaging. Compared with the prior art, the cashmere fibers are dried through the radio frequency so that damage to the surface state and the internal structure of the cashmere fibers can be greatly reduced, and the after-drying moisture regain of the cashmere fibers can be accurately controlled; and meanwhile, the cashmere fibers have the puffing effect, and the physical characteristics such as the elasticity and the compliance of the cashmere fibers are improved.

Owner:CONSINEE GRP CO LTD

Textile drying device

InactiveCN107345755AReasonable structureImprove product qualityDrying machines with progressive movementsHeating arrangementEngineeringAir blower

The invention relates to a drying device, in particular to a textile drying device. According to the technical scheme, the textile drying device comprises a drying box, and the drying box is of a hollow structure; openings are formed in the two sides of the drying box correspondingly; telescopic rods are arranged inside the drying box and arranged on the upper wall and the lower wall of the drying box in a staggered mode; telescopic driving devices are arranged on the portions, close to the inner walls of the drying box, of the telescopic rods, and inner rolling shafts are arranged on the other sides of the telescopic rods; a heating box is arranged on the drying box and communicates with the drying box through a plurality of connecting pipes; a heating wire is arranged in the heating box, and the heating wire is connected with an external power line; and one end of the heating box is connected with an air blower through an air inlet pipe. The textile drying machine has the advantages that the structure is reasonable, the drying effect is uniform, and the quality of textiles can be improved easily.

Owner:蒋满珍

Novel drying cylinder for producing PVC rolling film

PendingCN108534536AUniform drying effectImprove processing qualityDrying gas arrangementsDrying solid materialsCircular discPulp and paper industry

The invention provides a novel drying cylinder for producing a PVC rolling film. The novel drying cylinder comprises a cylinder body, the cylinder body is arranged on a supporting frame, a storage hopper, a material adjusting mechanism and a discharging mechanism are sequentially arranged in the cylinder body from top to bottom, a filter screen is arranged at a storage outlet in the lower end of the storage hopper, the material adjusting mechanism comprises a movable plate and an air cylinder, the discharging mechanism comprises a material distributing barrel and a disc, the disc is arranged below the movable plate, the edge of the disc is fixed to the inner wall of the cylinder body, the material distributing barrel can rotate along the disc, a plurality of material distributing cavitiesare formed in the outer wall of the material distributing barrel, drying bodies are arranged on the left side and the right side of the interior of the cylinder body and are arranged close to the material distributing barrel, and each drying body comprises a drying fan and an air outlet pipe. The novel drying cylinder has the beneficial effects that the material adjusting mechanism and the discharging mechanism are arranged, so that the uniform drying effect on raw materials can be rapidly realized, the processing quality of the raw materials can be improved, and the working efficiency can beimproved.

Owner:浙江康豪诺特装饰材料有限公司

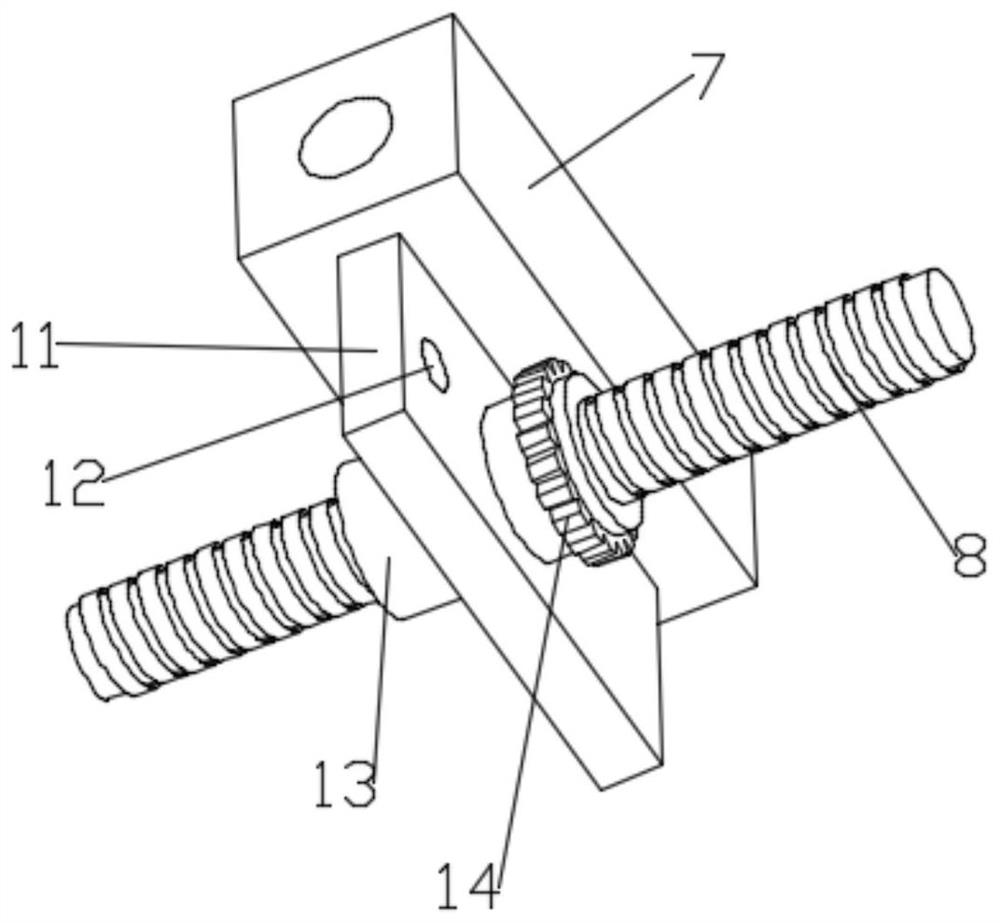

Cleaning device for agricultural machine parts

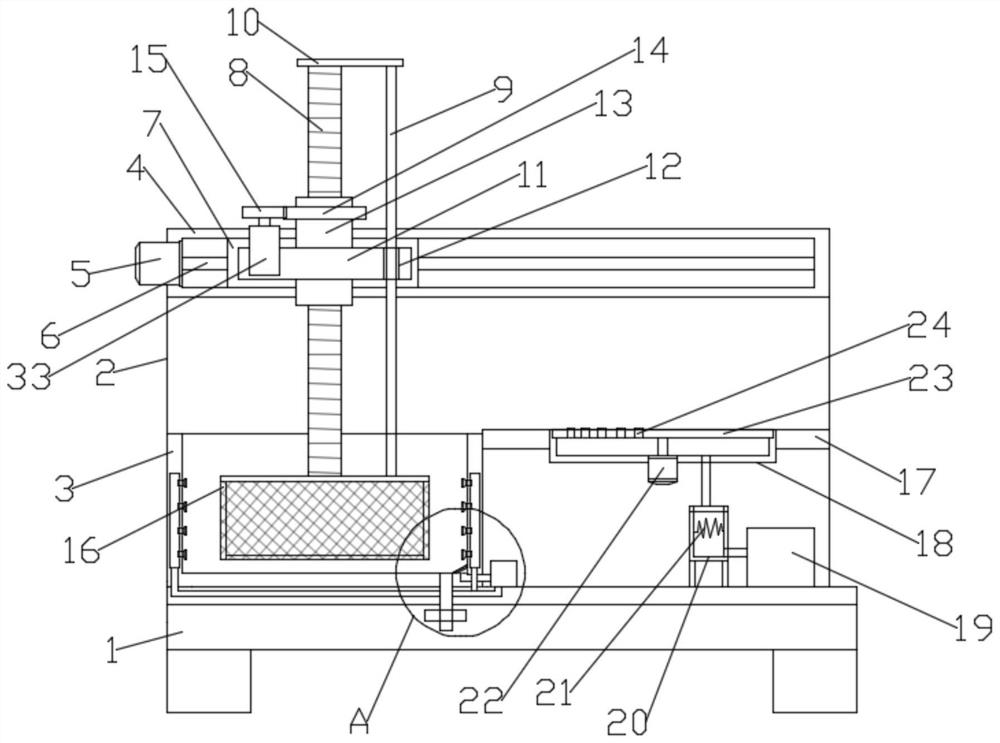

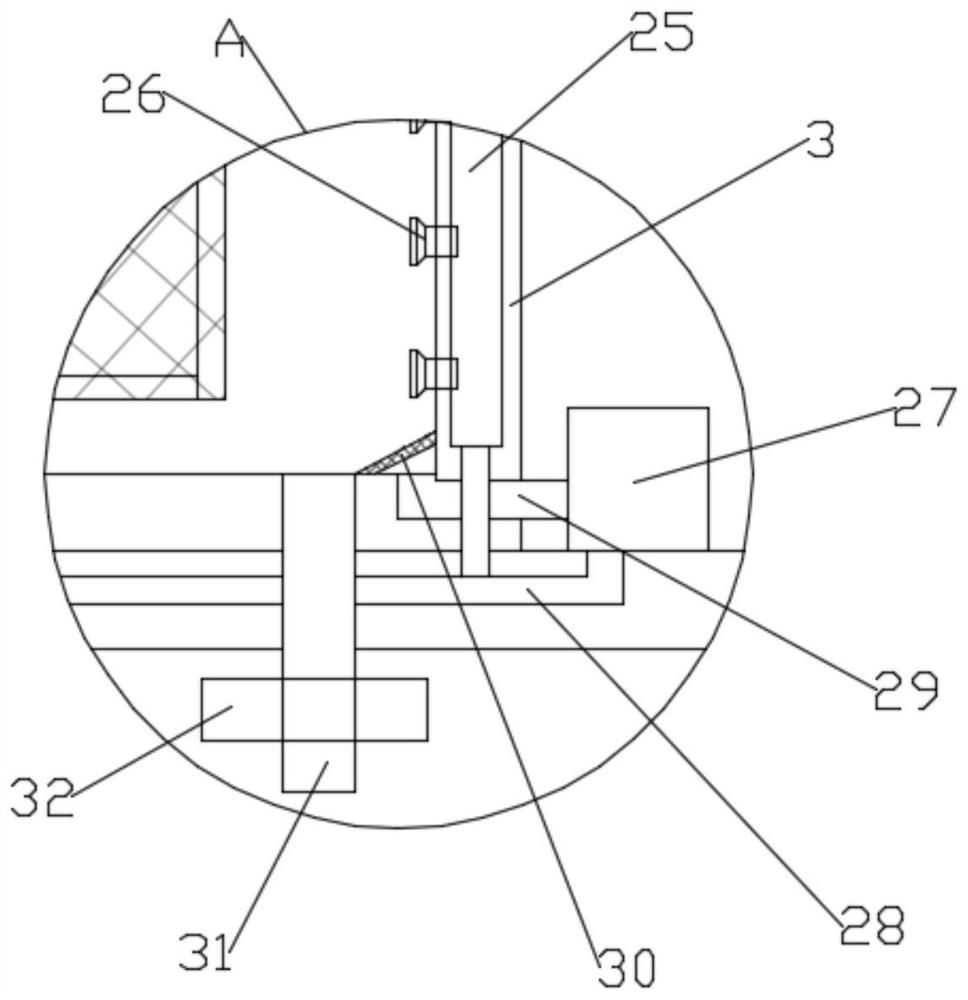

PendingCN111729888AAchieve cleaning effectUniform drying effectDrying gas arrangementsCleaning using liquidsAgricultural scienceMachine parts

The embodiment of the invention relates to the field of agricultural equipment, and particularly discloses a cleaning device for agricultural machine parts. The cleaning device comprises a supportingbase and a supporting top seat, wherein a supporting back plate is fixedly arranged on the upper surface of the rear side of the supporting base, a cleaning box is fixedly arranged at the top end of the supporting back plate, an adjusting lead screw is rotationally arranged on the supporting top seat, and an adjusting sliding block horizontally arranged on the supporting top seat in a sliding modeis arranged on the adjusting lead screw in a threaded connection and sleeving mode. According to the cleaning device, the height position of a net cage is adjusted through an arranged height adjusting assembly, so that the net cage extends into the cleaning box, then a liquid spraying assembly is used for spraying cleaning liquid to the net cage, and then the effect of cleaning parts in the net cage is achieved; and after cleaning, the net cage is suspended above a supporting platform by adjusting the horizontal position of an adjusting sliding block, and then the parts in the net cage suspended above the supporting platform are blown and dried through an air blowing assembly.

Owner:HUNAN AGRICULTURAL UNIV

Drying device for biological organic fertilizer raw materials and with good drying effect

InactiveCN107726790AImprove drying effectImprove drying efficiencyManure dryingDrying gas arrangementsEngineeringOrganic fertilizer

The invention relates to the technical field of bio-organic fertilizers, and discloses a drying device for raw materials of bio-organic fertilizers with good drying effect. , the top of the body is fixedly connected with a blower, the output end of the blower is fixedly connected with an air outlet pipe, one end of the air outlet pipe is fixedly connected with the heating body, one side of the heating body is fixedly connected with a discharge pipe, and one end of the discharge pipe passes through The body communicates with the surface of the connecting pipe. The bio-organic fertilizer raw material drying device with good drying effect, through the cooperation of the blower and the heating body, the staff control the operation of the blower and the heating body at the same time, the temperature inside the heating body will rise rapidly, and the blower can supply heat The heat inside the body is discharged to the inside of the body, and the temperature inside the body can be heated up quickly, so that the raw materials can be dried in a large area, the drying efficiency is improved, and the drying of raw materials is more obvious.

Owner:江苏恒源生物有机肥有限公司

Sludge low-temperature drying mechanism for sludge treatment

InactiveCN109734281AImprove drying rateAvoid the phenomenon of uneven drying effectSludge treatment by de-watering/drying/thickeningVapor–liquid separatorAir filter

The invention discloses a sludge low-temperature drying mechanism for sludge treatment. The sludge low-temperature drying mechanism comprises a closed sludge drying chamber; the closed sludge drying chamber is equipped with a sludge inlet, multiple layers of end-to-end connected conveying net belts and a sludge outlet from top to bottom; two fans, including a first fan and a second fan, are arranged at an interval on the lower side of the bottom layer of conveying net belt; an air filtering device is arranged on the upper side of the top layer of conveying net belt; a condenser is arranged onthe left side of the air filtering device; an output end of the condenser is connected with an input end of a heat exchanger; the output end of the heat exchanger is connected with the input end of aliquid storage tank; the output end of the liquid storage tank is connected with a first input end of a gas-liquid separator; a bulk collecting device is arranged on the bottom in the closed sludge drying chamber; the bulk collecting device comprises a sludge collecting mechanism and a sludge conveying mechanism. The sludge low-temperature drying mechanism for sludge treatment is capable of solving the problems that the drying effect of the sludge low-temperature drying device is uneven, the energy utilization efficiency is low and the blanking materials are difficult to be collected.

Owner:徐蒙蒙

Areca nut baking device

InactiveCN103598664AUniform flowStable flowFood processingDrying gas arrangementsTemperature UnitEngineering

The invention discloses an areca nut baking device. The areca nut baking device is characterized in that the device comprises a baking chamber, a baking trolley is placed in the baking chamber, an areca nut placing partition net is arranged in the baking trolley, and an air inlet is formed in one lateral side of the baking trolley; the device further comprises a heat pump device providing hot air for the baking trolley, the heat pump device comprises an air source heat pump high-temperature unit placed outside the baking chamber and an indoor draught fan connected with the air source heat pump high-temperature unit, a hot air outlet is formed in the indoor draught fan, a partition board is arranged between the indoor draught fan and the baking trolley, an air supply port enabling the hot air discharged from the hot air outlet of the indoor draught fan to flow into the air inlet of the baking trolley is formed in the bottom of the partition board, and an air returning port is formed in the upper portion of the partition board. Due to the fact that the partition board is arranged between the indoor draught fan and the baking trolley, heat can be utilized more sufficiently, and more energy is saved.

Owner:GUANGZHOU DERON HEAT SOURCE FACILITIES

Convenient-to-carry dryer for industrial ceramic

ActiveCN109163515AEasy to moveImprove drying efficiencyDrying gas arrangementsDrying chambers/containersCeramicMaterials science

The invention relates to the field of ceramic production, in particular to a convenient-to-carry dryer for industrial ceramic. The convenient-to-carry dryer for the industrial ceramic can facilitate placing and carrying of the ceramic, guarantee the drying quality of the ceramic and improve the ceramic drying efficiency. The convenient-to-carry dryer for the industrial ceramic comprises hinges, abox door, a first bearing block, a limiting plate, universal wheels, a drying box, a first mounting plate, a guide plate, a rotating plate, a second mounting plate, an annular sliding rail, a fixing block, a first inserting rod, a pulling plate and the like. The box door is hinged to a drying box through the hinges, and the first bearing block is embedded in the bottom of the drying box. Accordingto the dryer, the carrying work can be conveniently carried out when the ceramic is dried, the ceramic drying efficiency can be improved, and the effect that the ceramic can be uniformly dried is guaranteed.

Owner:怀仁市锦泰陶瓷有限公司

Seed drying system

InactiveCN103168838BMeet the requirements of drying workInhibition of germinationFood processingDrying gas arrangementsCold airAgricultural science

The invention discloses a seed drying system. The seed drying system comprises a pre-storage tower (1), a drying tower (2), a cooling tower (3), a hot air blowing device and two cold air blowers, wherein the pre-storage tower (1), the drying tower (2) and the cooling tower (3) respectively comprise a tower body, a feeding port arranged at the upper part of the tower body, a discharging port arranged at the lower part of the tower body, an air inlet cavity arranged outside the tower body, as well as an air inlet pipe (4) and an air outlet pipe (5) arranged inside the tower body, the lower surfaces of the air inlet pipe (4) and the air outlet pipe (5) have vent holes (6), one end of the air inlet pipe (4) is communicated with the air inlet cavity, the other end of the air inlet pipe (4) is sealed, and two ends of the air outlet pipe (5) are communicated with air outside the tower body. The seed drying system has the beneficial effects of satisfying the requirements on the drying operation of a large number of seeds which needs to be completed in a short period of time during a seed harvesting period, and being high in degree of automation, simple and convenient to operate, small in occupied area, uniform in drying effect and high in heat exchange efficiency.

Owner:CHENGDU JINZHUO AGRI

Drying device for food processing

InactiveCN111838502AUniform drying effectEasy flipFood preservationDrying gas arrangementsStructural engineeringMechanical engineering

The invention discloses a drying device for food processing. The drying device comprises a box body, a box door is hinged to one side of the box body. A first driving motor is arranged on the outer wall of the top of the box body; a rotating shaft is arranged on an output shaft of the first driving motor; drying grooves which are evenly distributed are formed in the outer wall of the circumferenceof the rotating shaft, third air outlet holes which are evenly distributed are formed in the outer wall of the circumference of the rotating shaft, the opening positions of the third air outlet holescorrespond to the positions of the drying grooves, electric telescopic rods are arranged on the inner walls of the bottoms of the drying grooves, and the same placing net plate is arranged at the tops of every two adjacent electric telescopic rods. The inclination angle of the placing net plate can be adjusted through the electric telescopic rod, materials roll and turn over towards the rotatingshaft when inclining towards the rotating shaft along with the placing net plate, or the materials roll and turn over away from the rotating shaft when inclining away from the rotating shaft along with the placing net plate, the materials are turned over conveniently, and it is guaranteed that drying is more uniform.

Owner:马迎锋

Textile fabric uniform drying box for textile production

InactiveCN111912205AQuick releaseImprove drying efficiencyDrying machines with progressive movementsDrying solid materialsStructural engineeringDrive motor

The invention belongs to the field of textile equipment, and particularly relates to a textile fabric uniform drying box for textile production. The textile fabric uniform drying box for textile production comprises a box body, a driving motor, an air heater and a winding roller, the side wall of the box body is provided with an exhaust hole, the upper end of the box body is provided with a hot air pipe, and the two ends of the hot air pipe correspondingly communicate with the air heater and the interior of the box body; and a wind wheel is rotatably connected to the inner side wall of the hotair pipe, a rotating shaft is coaxially and fixedly connected to the lower end of the wind wheel, the lower end of the rotating shaft extends into the box body and is fixedly connected with a horizontally-arranged rotating ring, a supporting plate is arranged below the rotating ring, the supporting plate is fixed to the inner top surface of the box body through a connecting rod, and a plurality of sliding cylinders are fixedly connected to the lower surface of the supporting plate. According to the textile fabric uniform drying box, all positions of textile fabric can be sequentially unfoldedand dried in the box body, the uniform and good drying effect is achieved, meanwhile, impact blocks repeatedly beat and beat the textile fabric, rapid dissipation of water in the textile fabric is promoted, and the drying efficiency is greatly improved.

Owner:王连欢

Wood board drying device based on moisture content control

InactiveCN111895755AImprove drying uniformityImprove drying efficiencyDrying gas arrangementsDrying chambers/containersElectric machineAgricultural engineering

The invention discloses a wood board drying device based on moisture content control, and relates to the technical field of wood board processing devices. The device comprises a drying box, one side of the drying box is provided with a box door, the top of the drying box is provided with an exhaust port, the bottom of the drying box is provided with a rotating motor, the output end of the rotatingmotor is coaxially and fixedly connected with a placement frame, the placement frame is rotationally connected into the drying box, multiple partition plates parallel to one another are fixedly connected into the placement frame, and the placement frame is divided into multiple placement cavities by the partition plates in the vertical direction. According to the device, when wood boards to be dried are dried, a heat supply fan inputs hot air flow into the drying box through air distribution pipes, and the hot air flow flows into all the placement cavities through an air distribution plate array to conduct two-face simultaneous drying on the wood boards on moving wheels in the placement cavities, so that the drying efficiency is improved; and meanwhile, along with low-speed rotation of the rotating motor, the placement frame drives the wood boards to be dried to rotate at a low speed, so that the drying uniformity of the single wood board is improved.

Owner:赵伟

Tea drying device

InactiveCN108709381AGuaranteed qualityImprove processing efficiencyDrying gas arrangementsDrying chambers/containersGround rollerAgricultural engineering

The invention discloses a tea drying device which comprises a base. Brackets are fixedly connected to the two sides of the top of the base, and the ends, away from the base, of the brackets are fixedly connected with a box body. A screening hopper is fixedly connected to the bottom of the box body, a grinding roller is arranged in the screening hopper, and the inner wall of the grounding roller isfixedly connected with a rotating shaft. One end of the rotating shaft is in rotating connection with the screening hopper, the other end of the rotating shaft penetrates through the screening hopperand extends to the outside of the screening hopper. The end, located outside the screening hopper, of the rotating shaft is connected with a first motor, and an auxiliary roller is in rolling connection with the outer surface of the grinding roller. A drying box is arranged in the box body, and one side of the outer wall of the drying box is in rotating connection with the box body through a short rod. The invention relates to the technical field of tea processing. According to the tea drying device, tea leaves can be evenly dried, the complete leaf shape of the tea leaves can be kept, the tea leaves are screened to guarantee the quality of high-quality tea, and inferior tea leaves are made to dry tea powder.

Owner:浙江托峰农业科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com