Textile drying device

A drying device and textile technology, applied in drying, drying machine, heating device and other directions, can solve the problems of unqualified product quality, uneven drying of textiles, unable to meet the needs of use, etc., to achieve reasonable structure, reduce Humidity, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

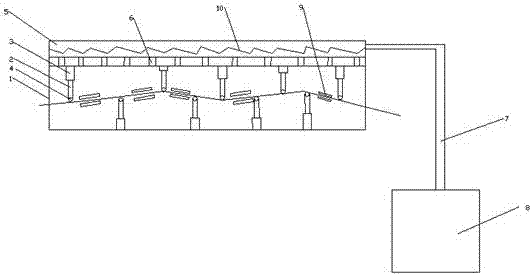

[0016] The textile drying device of the present invention includes a drying box 1, the drying box 1 is a hollow structure, openings are arranged on both sides of the drying box 1, and the inside of the drying box 1 is A telescopic rod 2 is provided, and the telescopic rod 2 is arranged on the upper and lower walls of the drying box 1 in a staggered manner. The telescopic rod 2 is provided with a telescopic drive device 3 close to the inner wall of the drying box 1. The other side of the telescopic rod 2 is provided with an inner roller 4, and a heating box 5 is provided above the drying box 1, and the heating box 5 communicates with the drying box 1 through a plurality of connecting pipes 6, so that A heating wire 10 is arranged inside the heating box 5 , and the heating wire 10 is connected to an external power line, and one end of the heating box 5 is connected to a blower 8 through an air inlet pipe 7 .

[0017] Preferably, as a possible embodiment, electric heating grids 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com