Rice drying machine

The technology of a paddy dryer and a drying bin is applied in the directions of dryer, drying, grain drying, etc., which can solve the problems of low drying efficiency, inability to remove moisture in time, and moisture in grains, and achieve a uniform drying effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

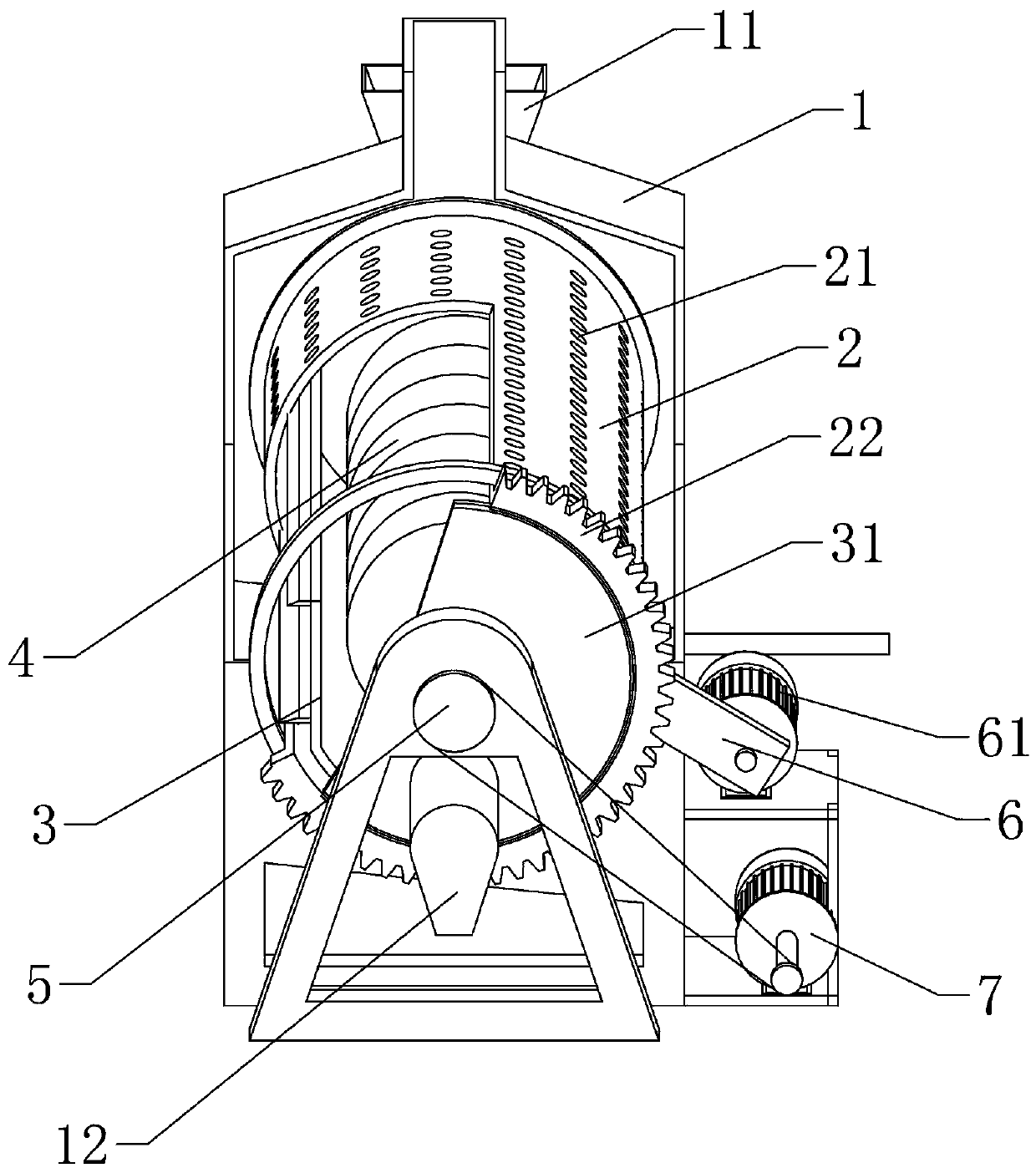

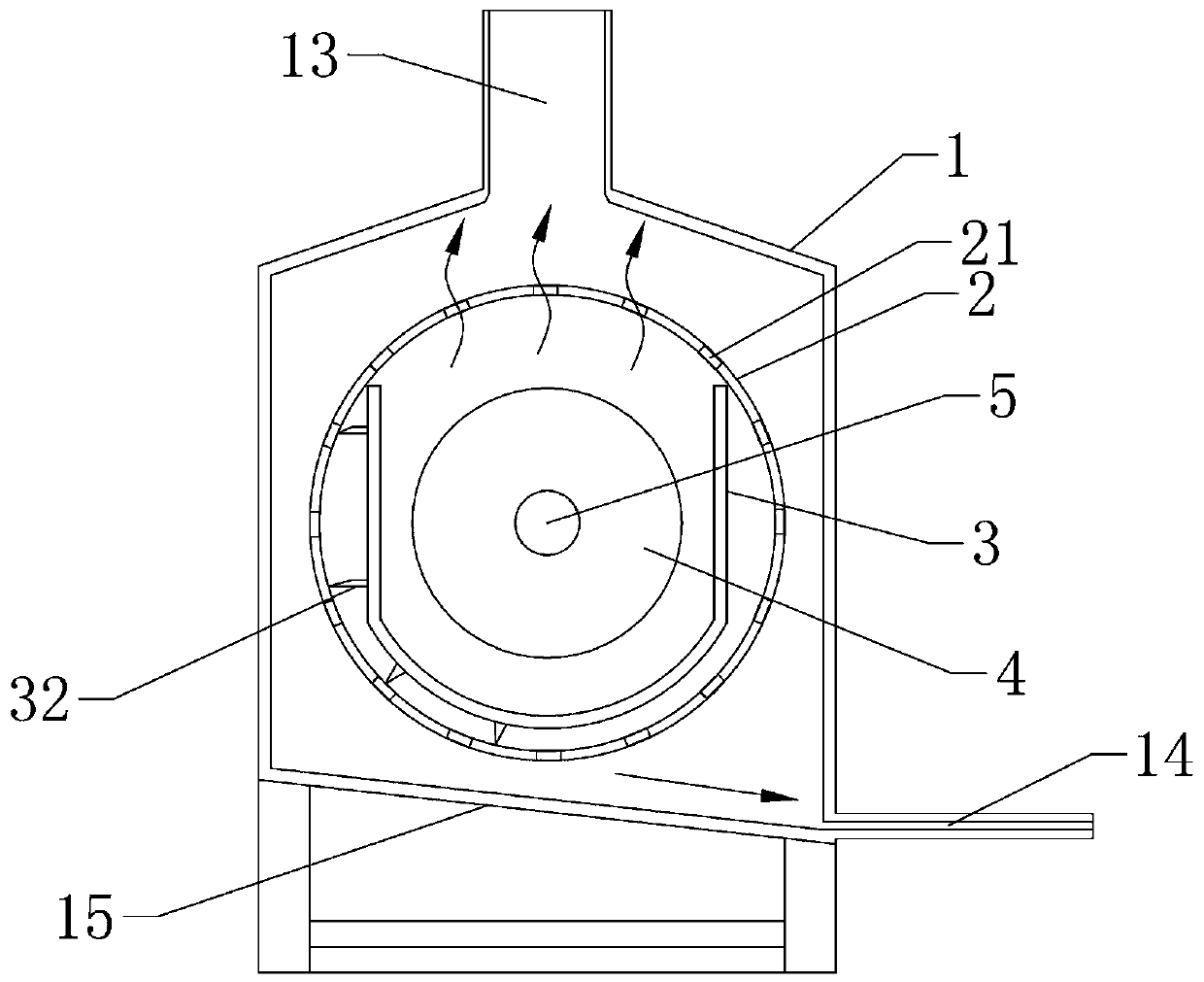

[0020] according to Figure 1 ~ Figure 3 As shown, a rice dryer includes: an air extraction shell 1, a rotating jacket 2, a drying bin body 3, a spiral stirring blade 4 and a heating shaft 5 arranged sequentially from the outside to the inside, and the inside of the heating shaft 5 is provided with an electric Heating pipe.

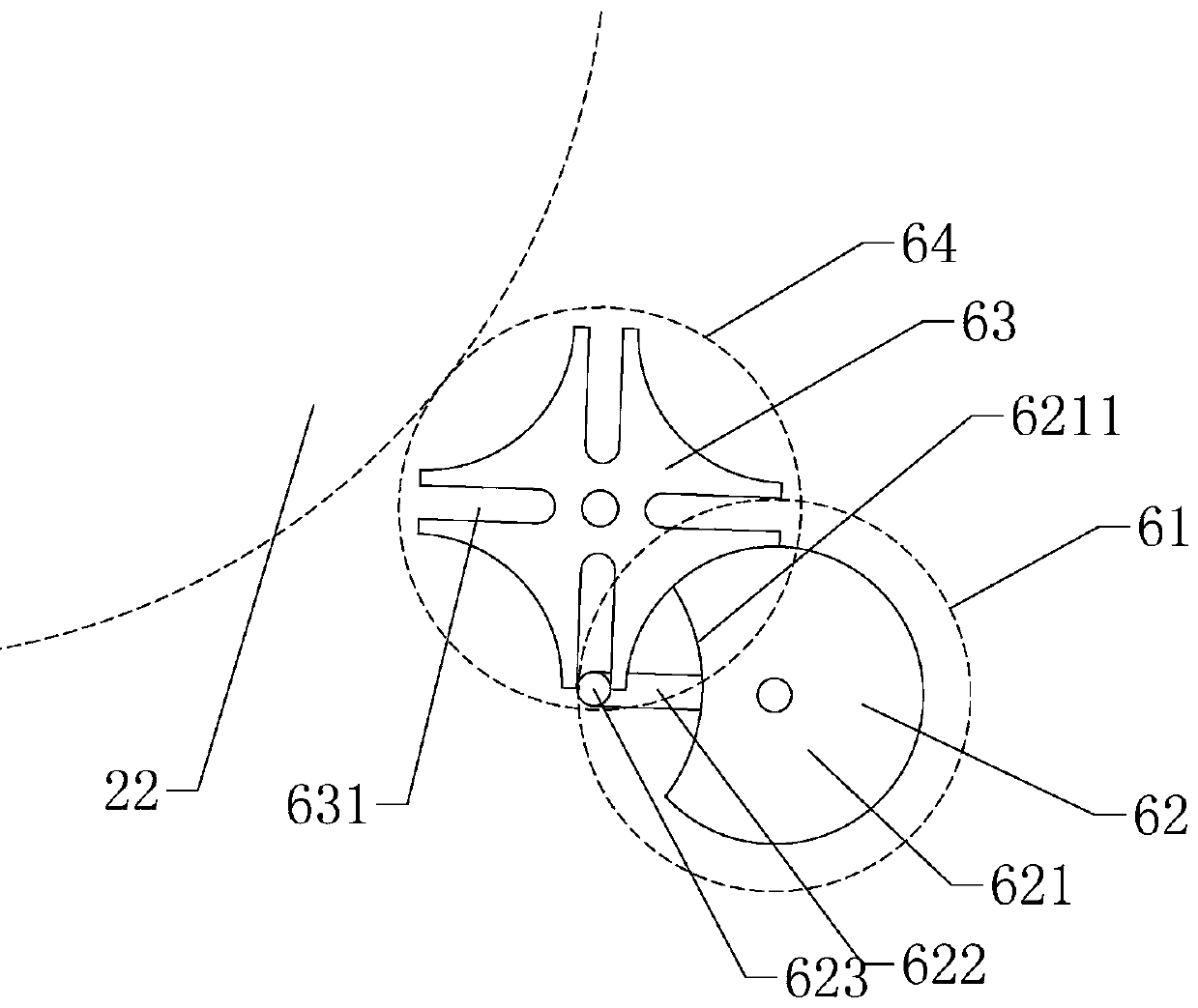

[0021] The rotating jacket 2 is in the shape of a hollow cylinder, and its side wall is provided with an exhaust hole 21. The middle part of the drying chamber body 3 is a U-shaped groove body with an open top, and its two ends are circular sealing plates 31. The drying chamber body 3 The two ends of the rotating jacket 2 are sealed and connected through the circular sealing plate 31. The area of the circular sealing plate 31 is larger than the U-shaped cross-sectional area of the U-shaped tank body, so that there is a certain gap between the U-shaped tank body and the rotating jacket 2 , the drying chamber body 3 is provided with a condensate scrape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com