Textile fabric uniform drying box for textile production

A technology for drying boxes and textile fabrics, applied in drying, dryers, progressive dryers, etc., can solve problems such as unevenness and slow drying speed, and achieve the goal of improving drying efficiency and promoting rapid release Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

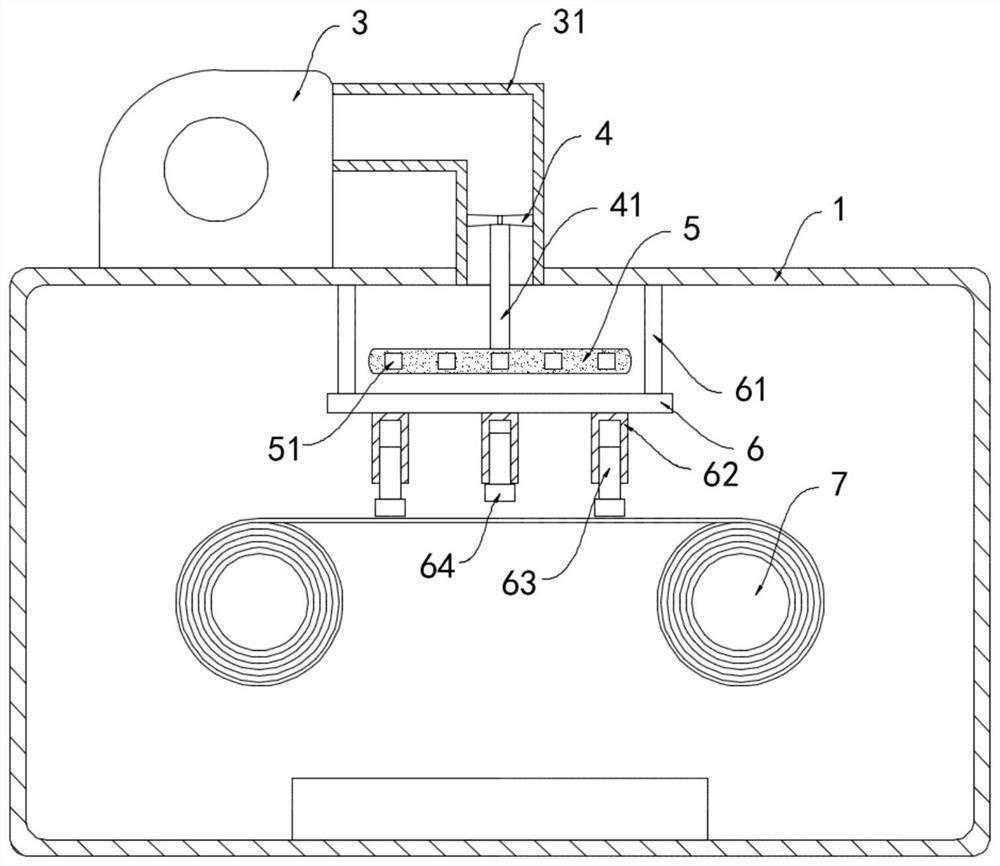

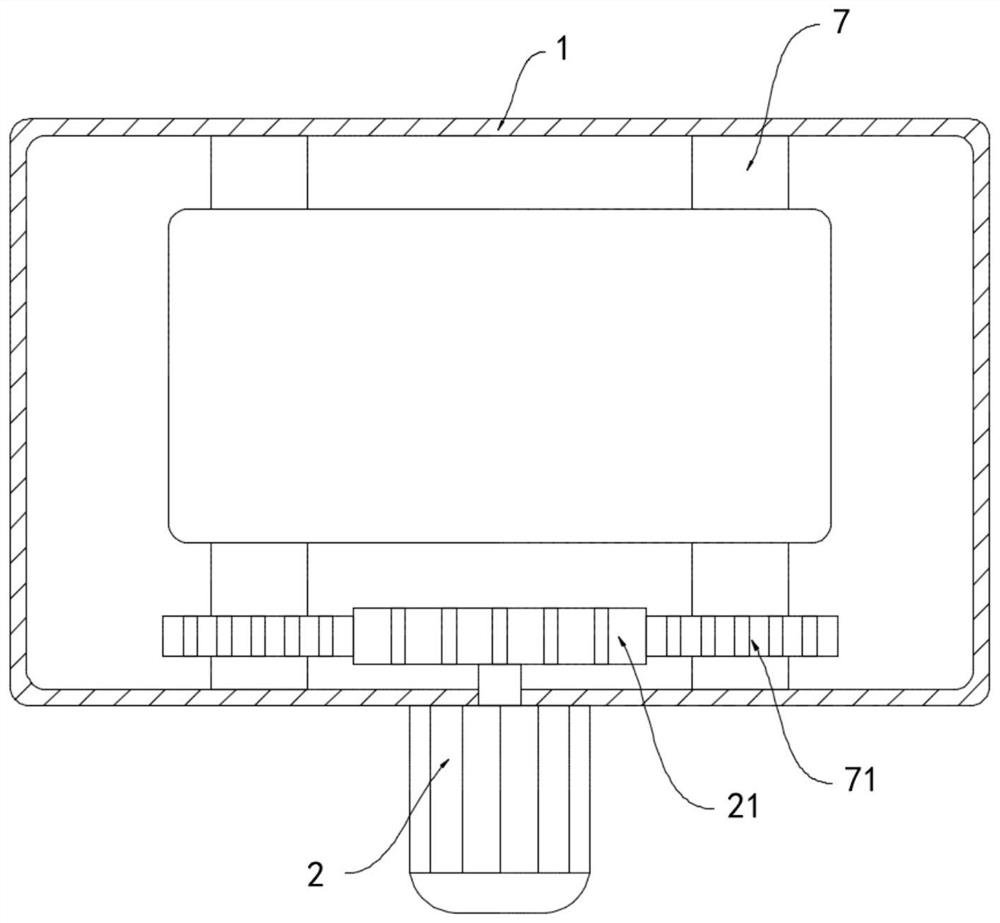

[0021] like Figure 1-3 As shown, a uniform drying box for textile fabrics for textile production includes a box body 1, a drive motor 2, a hot air blower 3 and a take-up roller 7, and an exhaust hole is provided on the side wall of the box body 1;

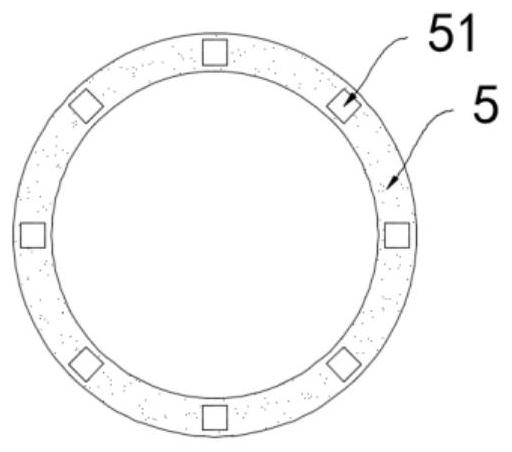

[0022] The upper end of casing 1 is equipped with hot-blast pipe 31, and the two ends of hot-blast pipe 31 are communicated with hot air blower 3 and casing 1 interior respectively, and the inner side wall of hot-blast pipe 31 is connected with wind wheel 4, and the wind wheel 4 The lower end is coaxially fixedly connected with a rotating shaft 41. The lower end of the rotating shaft 41 extends into the box body 1 and is fixedly connected with a horizontally arranged rotating ring 5. A support plate 6 is arranged below the rotating ring 5. The supporting plate 6 is connected to the box through a connecting rod 61. The inner top surface of the body 1 is fixed, the lower surface of the support plate 6 is fixedly connected with a plu...

Embodiment 2

[0027] like Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that: the connecting rod 61 is wound with a multi-turn closed coil 8, and the winding direction of the closed coil 8 is perpendicular to the direction of the magnetic field line of the magnet block 51, so the magnet block 51 During the rotation process, the closed coil 8 can continuously cut the magnetic lines of the magnet block 51 to generate an induced current, and the lower surface of the impact block 64 is equipped with a heating sheet 9, and the two ends of the closed coil 8 are respectively coupled to the two poles of the heating sheet 9 .

[0028] In this embodiment, during the rotation of the magnet block 51, the magnetic field lines of the magnet block 51 are continuously cut in the closed coil 8 to generate an induced current, which supplies power to the heating sheet 9, and the heating sheet 9 contacts with the woven cloth briefly with the impact block 64. To avoid deformati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com