Drying device for food processing

A drying device and food processing technology, applied in drying, drying machine, food preservation and other directions, can solve the problems of uneven drying, inconvenient material turning over, etc., and achieve the effect of uniform drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

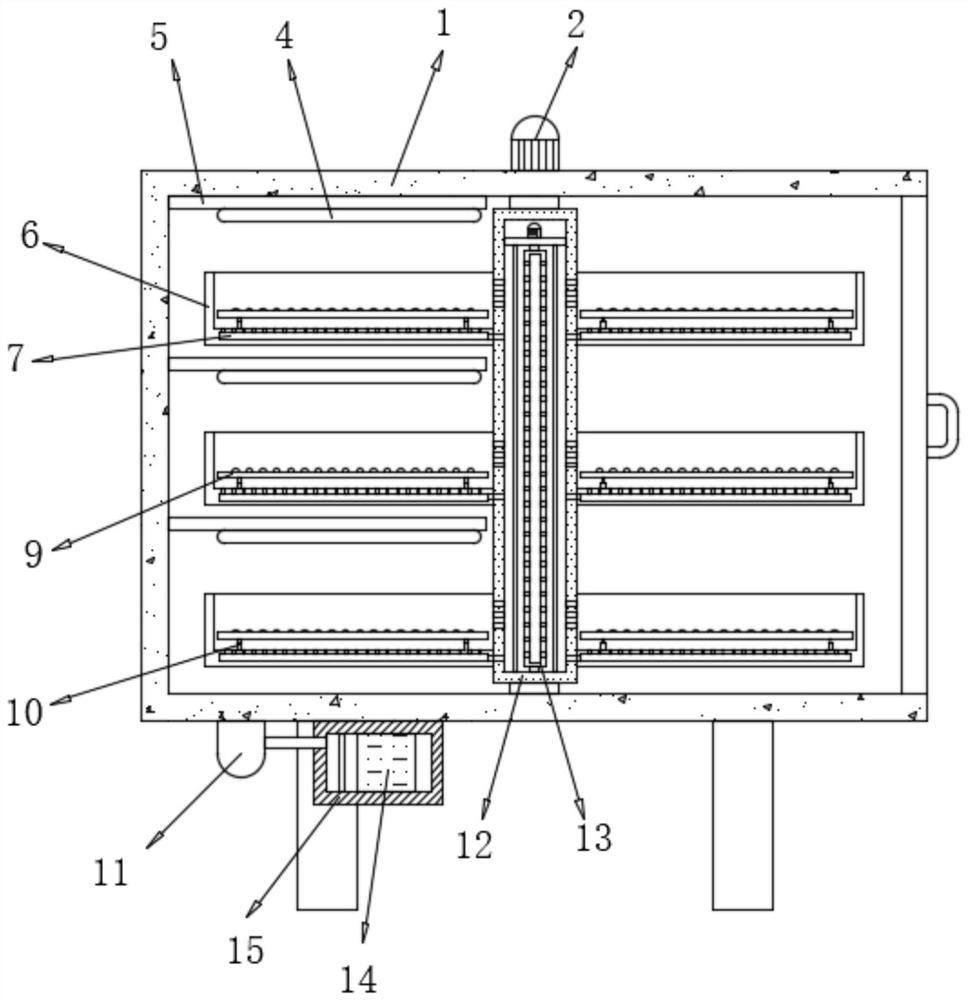

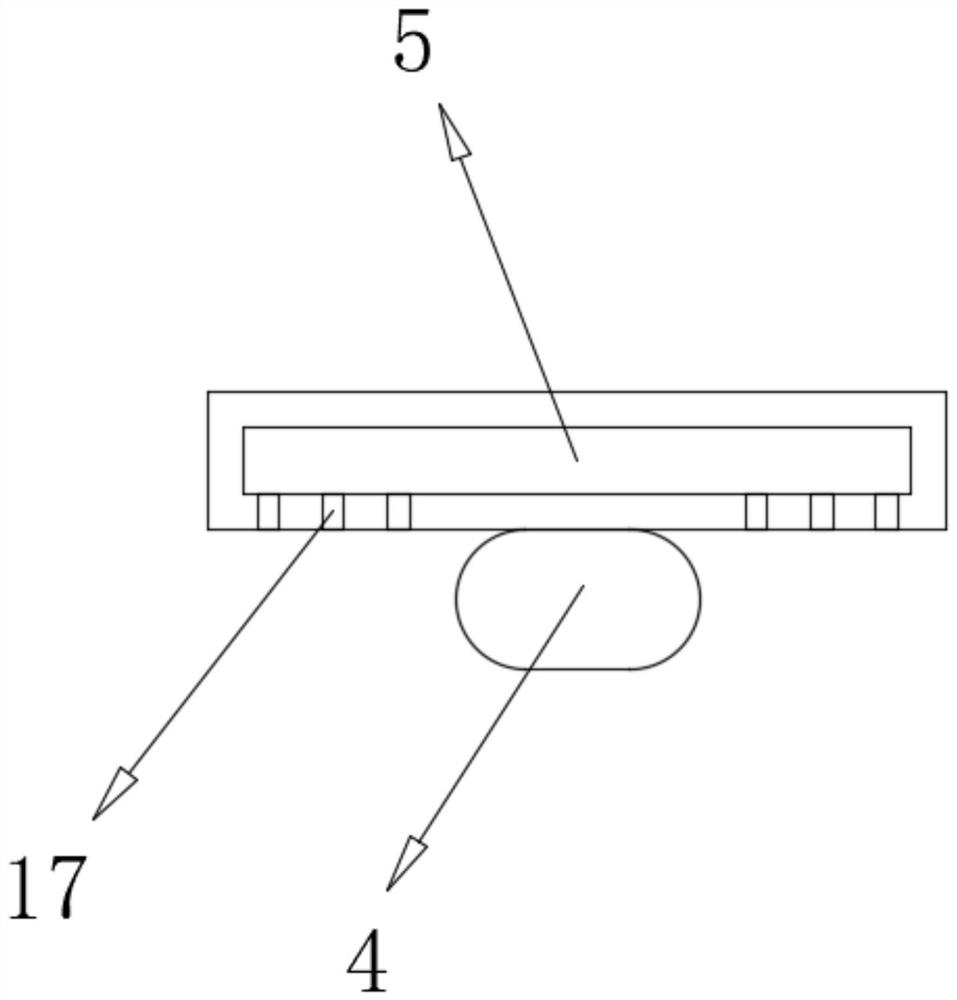

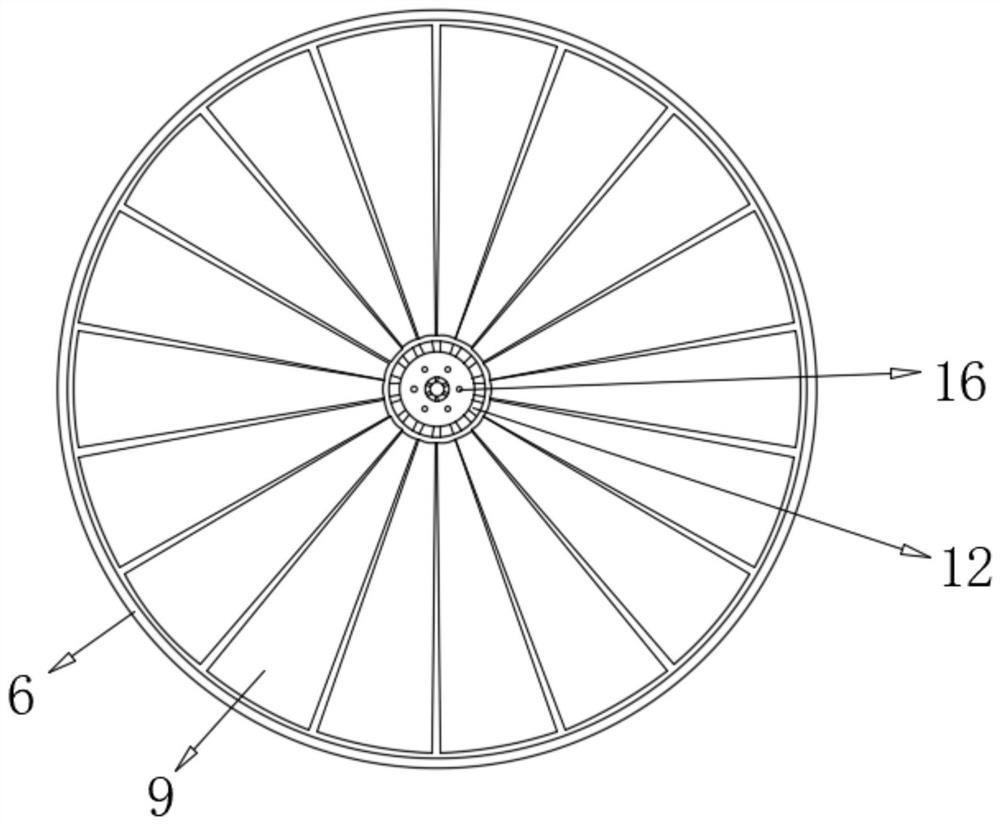

[0027] refer to Figure 1-5 , a drying device for food processing, comprising a box body 1, a box door is hinged on one side of the box body 1, a first drive motor 2 is connected to the top outer wall of the box body 1 through fastening bolts, and the first drive motor 2 The output shaft of the rotating shaft 12 is connected with a rotating shaft 12 through fastening bolts, and the outer peripheral wall of the rotating shaft 12 is connected with uniformly distributed drying tanks 6 through fastening bolts, and the outer peripheral wall of the rotating shaft 12 is provided with evenly distributed third air outlet holes. The opening position of the air hole corresponds to the position of the drying tank 6. The bottom inner wall of the drying tank 6 is connected with the electric telescopic rod 10 by fastening bolts, and the tops of two adjacent electric telescopic rods 10 are connected with the same electric telescopic rod 10 by fastening bolts. One placed screen 9, and the plac...

Embodiment 2

[0036] refer to Figure 6 , a drying device for food processing. Compared with Embodiment 1, the inner wall of the drying tank 6 is connected with the second buffer net plate 8 evenly distributed by the spring, and the outer wall of the rotating shaft 12 is connected by the spring. There are evenly distributed first buffer screens 3 , and the positions of the first buffer screens 3 correspond to the positions of the second buffer screens 8 .

[0037] Working principle: when the material rolls with the inclination of the placed screen 9, the spring, the first buffer screen 3, and the second buffer screen 8 cushion and damp the material, and at the same time, the first buffer screen 3 prevents the material from falling out of the third The pores are clogged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com