Cleaning device for agricultural machine parts

A technology of cleaning device and agricultural machinery, which is applied in the direction of cleaning method using liquid, dryer, drying gas arrangement, etc., can solve the problems of inability to dry agricultural machinery parts, unsatisfactory cleaning effect, and reducing the practicability of cleaning device, etc. To achieve the effect of improving uniform drying effect and uniform hot air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

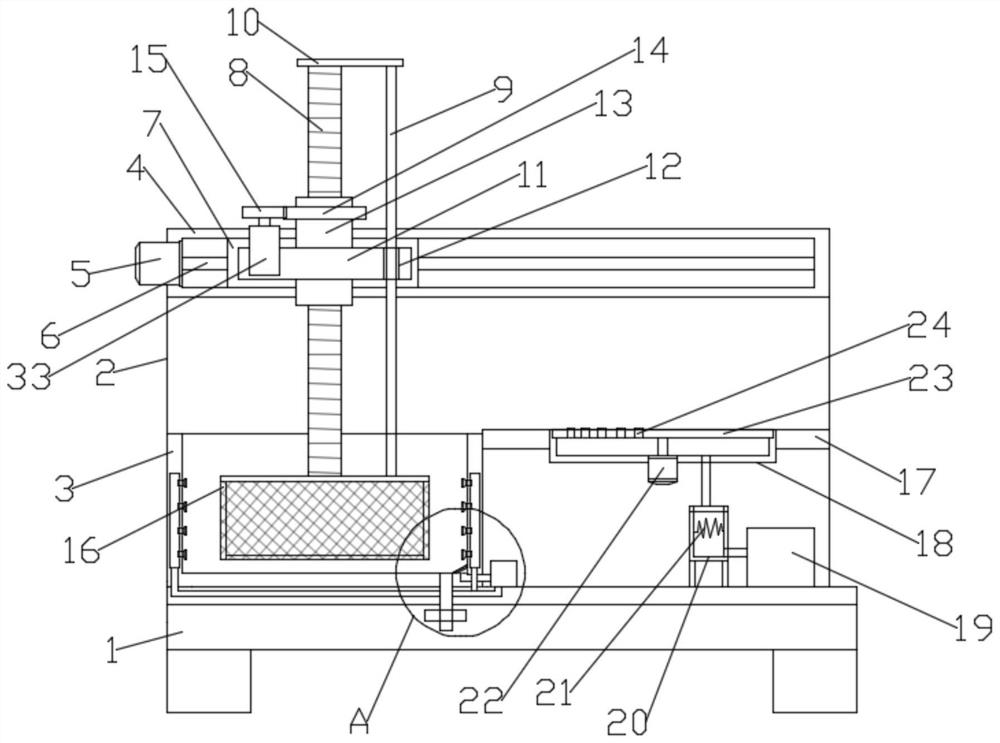

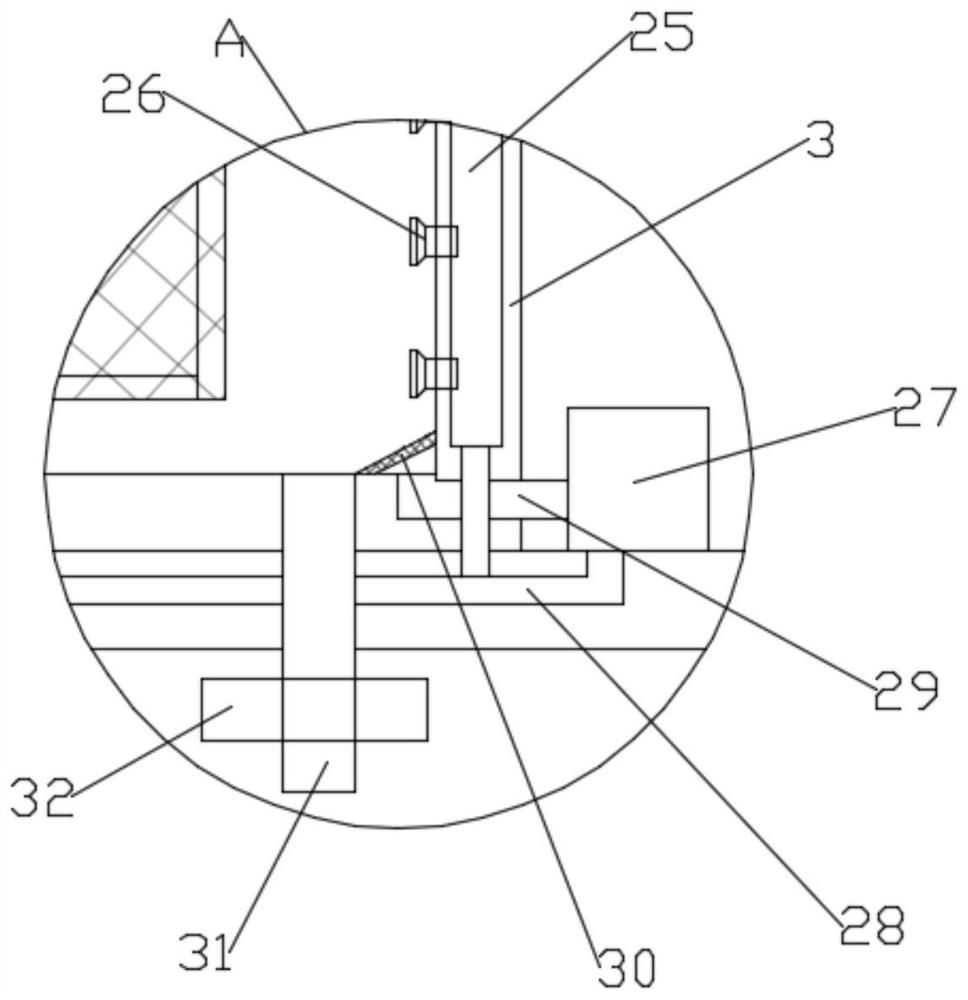

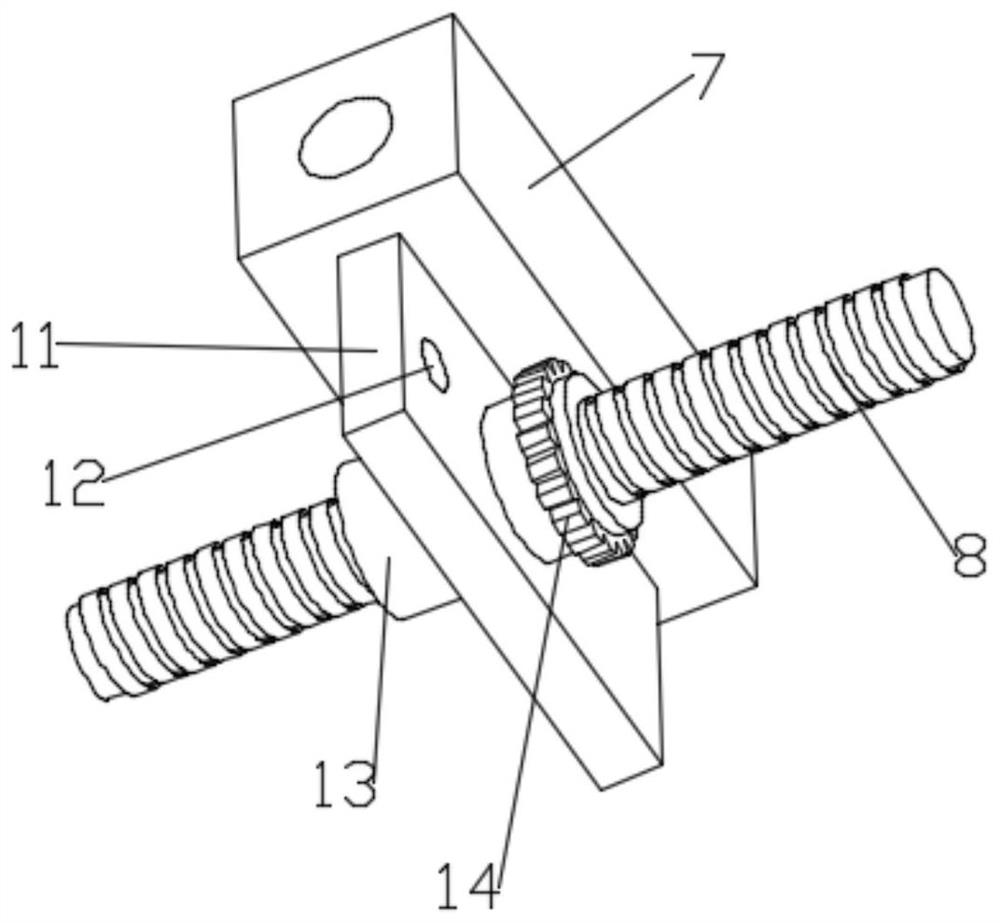

[0025] Such as Figure 1-3 As shown, in the embodiment provided by the present invention, a cleaning device for agricultural machinery parts includes a support base 1, and a support back plate 2 is fixedly arranged on the rear upper surface of the support base 1, and the support back plate 2 The top of the top is fixedly provided with a cleaning box 3, a supporting top seat 4, and an adjusting screw rod 6 is rotated on the supporting top seat 4, and the adjusting slider 7 arranged on the supporting top seat 4 is slid horizontally through a threaded connection. Located on the adjusting screw 6, one end of the supporting top seat 4 is also equipped with a first forward and reverse servo motor 5 for driving the adjusting screw 6 to rotate. Therefore, the embodiment of the present invention utilizes the first positive and negative The reverse servo motor 5 drives the adjustment screw mandrel 6 to rotate, and then the horizontal position of the adjustment slider 7 on the support to...

Embodiment 2

[0030] Such as Figure 1-3 As shown, in the embodiment provided by the present invention, a cleaning device for agricultural machinery parts includes a support base 1, and a support back plate 2 is fixedly arranged on the rear upper surface of the support base 1, and the support back plate 2 The top of the top is fixedly provided with a cleaning box 3, a supporting top seat 4, and an adjusting screw rod 6 is rotated on the supporting top seat 4, and the adjusting slider 7 arranged on the supporting top seat 4 is slid horizontally through a threaded connection. Located on the adjusting screw 6, one end of the supporting top seat 4 is also equipped with a first forward and reverse servo motor 5 for driving the adjusting screw 6 to rotate. Therefore, the embodiment of the present invention utilizes the first positive and negative The reverse servo motor 5 drives the adjustment screw mandrel 6 to rotate, and then the horizontal position of the adjustment slider 7 on the support to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com