Tuyere special for hot air drying of gravure press and drying oven with same

A technology of hot air drying and gravure printing machine, which is used in general parts of printing machinery, printing machines, printing and other directions, can solve the problems of unreasonable structure of air nozzles and ovens, unable to meet the needs of the industry, and low drying efficiency. The effect of optimizing the hot air velocity field and temperature field, improving the utilization efficiency and prolonging the drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

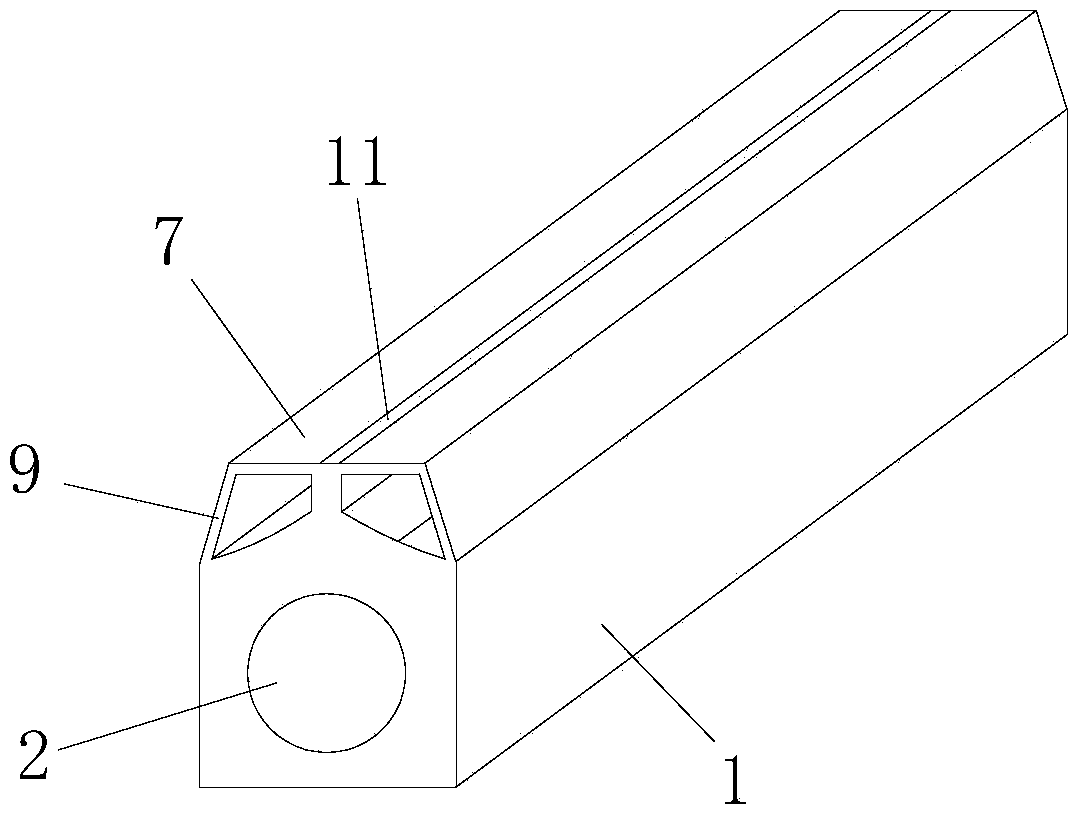

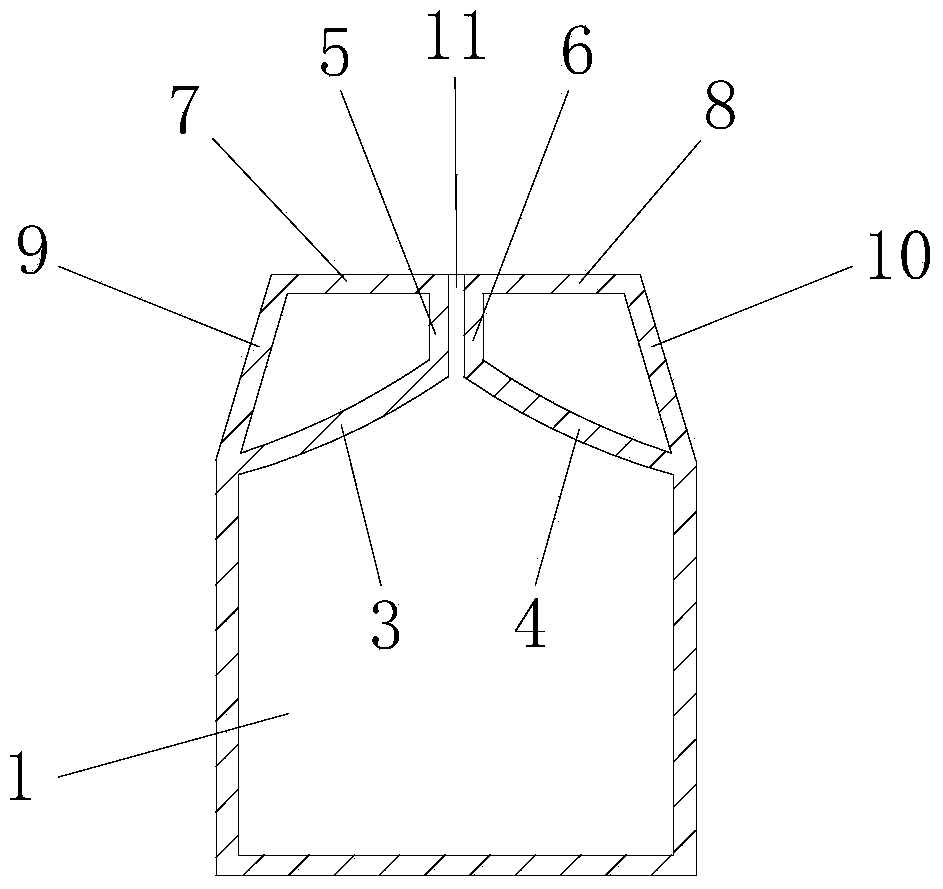

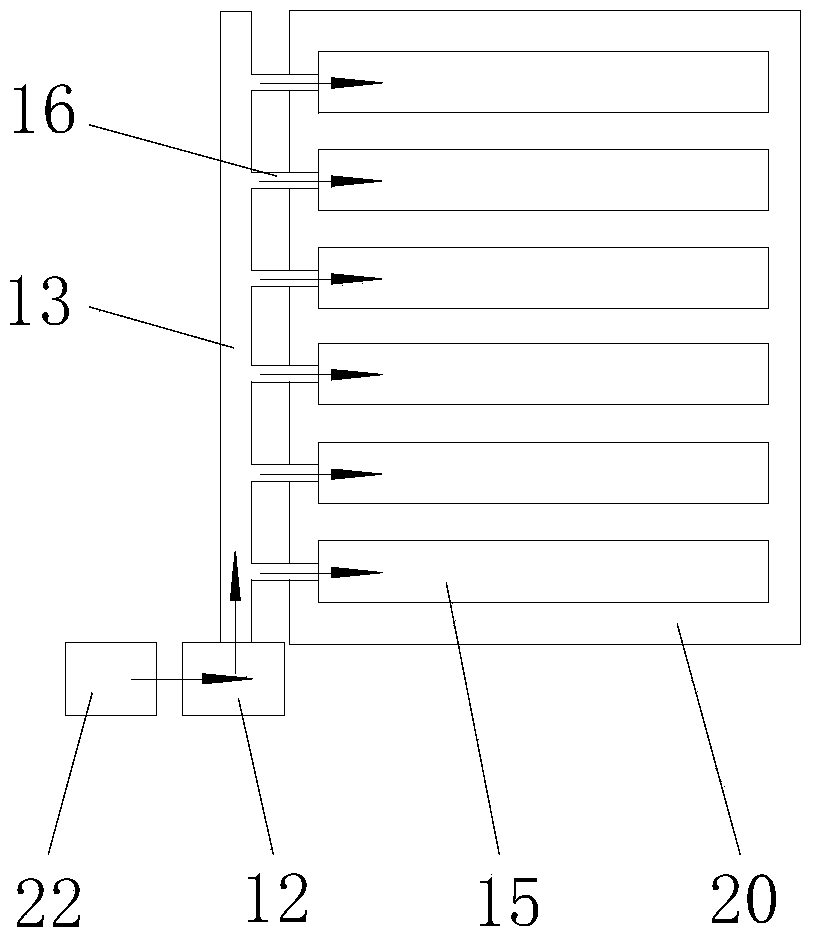

[0021] refer to figure 1 , figure 2 , a special air nozzle for hot air drying of a gravure printing machine, comprising a nozzle box 1, the end of the nozzle box 1 is provided with a nozzle air inlet 2, and the inside of the tuyere box 1 is provided with a The left guide surface 3 and the right guide surface 4 arranged symmetrically in the length direction, one side of the left guide surface 3 and the right guide surface 4 are respectively connected with the left and right inner walls of the tuyere box body 1, and the other The sides are respectively connected with a symmetrical left air outlet surface 5 and a right air outlet surface 6, the left air outlet surface 5 and the right air outlet surface 6 are parallel planes, the left air outlet surface 5 and the right air outlet surface 6 The free side is respectively connected with a symmetrical left platform area 7 and a right platform area 8, and the angle formed between the left platform area 7 and the right platform area 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com