Grain microwave and fluidization combined drying equipment, drying method and application

A combined drying and fluidization technology, applied in the field of grain storage, can solve the problems of low hot air utilization rate and large floor area, and achieve the effect of low drying efficiency, high drying efficiency and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

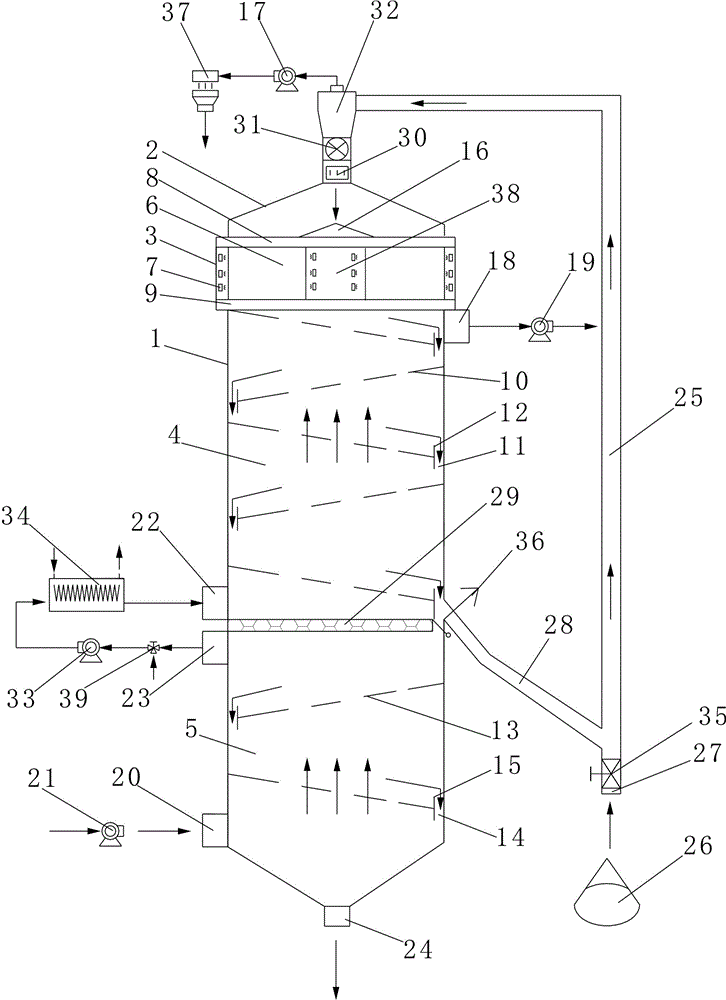

[0053] Grain Microwave Fluidization Combined Drying Equipment and Effects:

[0054] The effective size of tower body 1 is 1500×1000×8600mm (length×width×height);

[0055] Dimensions of microwave section 3: 1500×1000×3600mm (length×width×height), among which, the size of leakage energy suppressor 8 and leakage energy suppressor 9: 1500×1000×1600mm (length×width×height), opening 60mm;

[0056] Drying section 4 size: 1500×1000×4000mm (length×width×height),

[0057] Cooling section 5 size: 1500×1000×1000mm (length×width×height);

[0058] Cooling fan: HDSR150 three-lobe Roots blower, matching motor power 11kW, air volume 22.0m in the air inlet state 3 / h;

[0059] Hot air fan: HDSR250 three-lobe Roots blower, matching motor power 22kW, air volume 90.4m in the air inlet state 3 / h;

[0060] Heat exchanger: BN series plate heat exchanger;

[0061] Fluidized plate: opening rate is 60%, inclination angle is 3°, the effective size of channel section is 60mm×1000mm, ten plates are ...

Embodiment 2

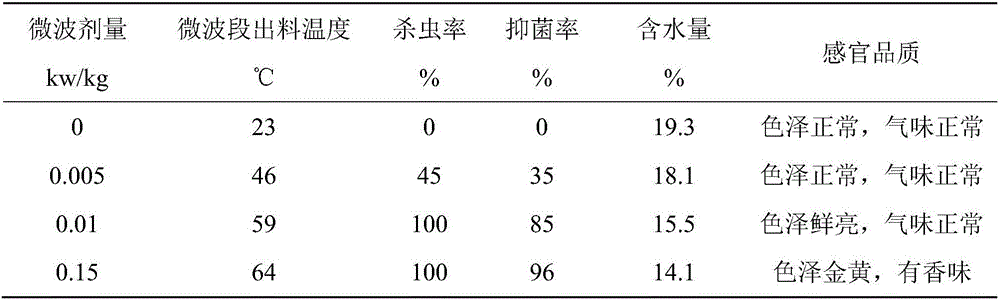

[0071] Embodiment 2: Microwave is to the effect of preheating, desinsection, bacteriostasis:

[0072] Adopt the equipment model and configuration of Example 1, adjust the microwave dosage, and dry the paddy. The initial temperature of the paddy is 23° C., and the total number of bacteria is 63000 cuf / g. Record the results of the microwave dosage on paddy preheating, insecticidal and antibacterial effects. As shown in Table 1. For the calculation methods of insecticidal rate, bacteriostatic rate and water content, please refer to "Xijun Zhang, Shanbai Xiong, Siming Zhao. Effect of Microwave Treatment on Rice Quality [J], Chinese Agricultural Sciences, 2009, 42(1): 224-229". It can be seen from Table 1 that microwaves have obvious effects on rice preheating, insecticide, and sterilization. When the rice microwave temperature reaches 61°C, the insecticidal rate can reach 100%, and the bacteriostatic rate can reach 85%. The amount of water is significantly reduced and rice qualit...

Embodiment 3

[0075] Embodiment 3: Effect comparison of fluidized treatment on heat transfer:

[0076] Adopt the equipment model and configuration of Example 1, adjust the air velocity of the empty pipe, dry the wheat, detect the influence of fluidization on the heat transfer of wheat, record the discharge temperature of the drying section and the discharge temperature of the cooling section, the results are shown in Table 2 shown. It can be seen from Table 2 that the higher the air velocity in the empty pipe, the higher the discharge temperature in the drying section, the lower the discharge temperature in the cooling section, and the faster the water content decreases, which shows that the fluidization treatment is beneficial to the heat transfer of wheat and accelerates The water loss rate of wheat and the high air velocity in the empty pipe can also speed up the cooling speed of the cooling section to ensure that the discharge temperature is within a reasonable range.

[0077] Table 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com