Preparation process of low-cost environment-friendly anti-corrosion floor

A preparation process, low-cost technology, applied in the direction of manufacturing tools, wood processing appliances, floors, etc., can solve the problems of poor performance and high price of environmentally friendly flooring, and achieve the effect of cost reduction, cost saving, and excellent environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

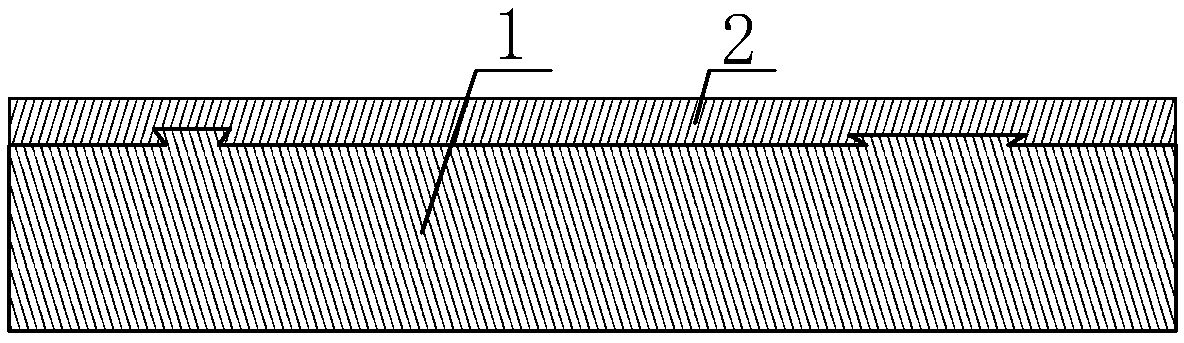

[0036] The first step is to make the anti-corrosion surface layer 2 through the wooden material treated with anti-corrosion agent;

[0037] Wherein, the preservative consists of the following raw materials in parts by weight:

[0038] 12-14 parts of boric acid, 2-4 parts of disodium octaborate, 10-12 parts of dicyandiamide ammonium, 6-8 parts of sodium fluoride, 9-11 parts of diammonium hydrogen phosphate, 42-50 parts of ammonium sulfate, 2 parts of copper oxide -4 parts, carboxymethylcellulose 1-3 parts.

[0039] In the present embodiment, the concrete proportioning of this preservative is as follows:

[0040] 13 parts of boric acid, 3 parts of disodium octaborate, 11 parts of dicyandiamide, 8 parts of sodium fluoride, 9 parts of diammonium hydrogen phosphate, 48 parts of ammonium sulfate, 4 parts of copper oxide, 1 part of carboxymethyl cellulose.

[0041] The preparation method of this preservative in the present embodiment is as follows:

[0042] (1) Mix 2-4 parts of co...

Embodiment 2

[0053] The difference between this embodiment and embodiment 1 is that the proportioning of each substance is different in this embodiment:

[0054] Among them, 12 parts of boric acid, 4 parts of disodium octaborate, 12 parts of ammonium dicyanide, 6 parts of sodium fluoride, 10 parts of diammonium hydrogen phosphate, 42 parts of ammonium sulfate, 2 parts of copper oxide, and 3 parts of carboxymethyl cellulose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com