Antibacterial conductive polystyrene (PS) composite material and preparation method thereof

A composite material and antibacterial agent technology, applied in the field of antibacterial conductive PS composite materials and their preparation, can solve the problems of limiting the application range of PS composite materials, general antibacterial properties and electrical conductivity, etc., to improve surface structure and performance, and improve interface performance. , the effect of improving interface performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The preparation method of antibacterial agent is as follows:

[0056] (1) Take a certain amount of absolute ethanol, deionized water and nitric acid to be mixed with solution B; the mass ratio of absolute ethanol, deionized water and nitric acid is (120-160): (200-480): (60- 120).

[0057] (2) Weigh a certain amount of butyl titanate, absolute ethanol, and acetic acid, slowly drop butyl titanate into the mixed solution of absolute ethanol and acetic acid under rapid stirring, and prepare solution C; The mass ratio of ester, absolute ethanol and acetic acid is (20-60):(60-90):(120-160).

[0058] (3) Drop solution B into solution C to obtain a uniform and transparent sol; the mass ratio of solution B to solution C is (120-160): (40-60).

[0059] (4) Slowly add AgNO to the sol 3 Solution, after continuing to stir for 4-6h, a light yellow opaque gel was obtained.

[0060] (5) The gel is vacuum-dried at 60-80° C. for 8-10 hours, and the obtained dry gel is then put into a ...

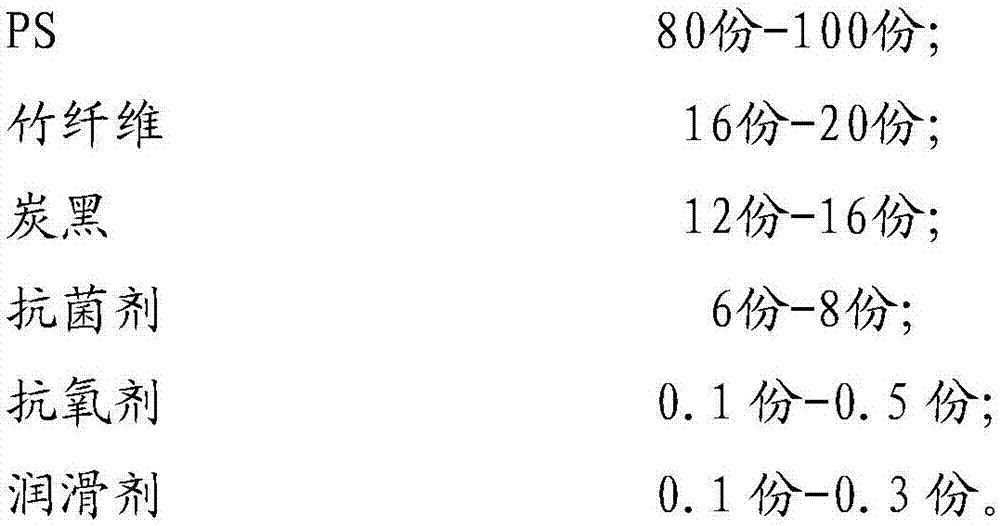

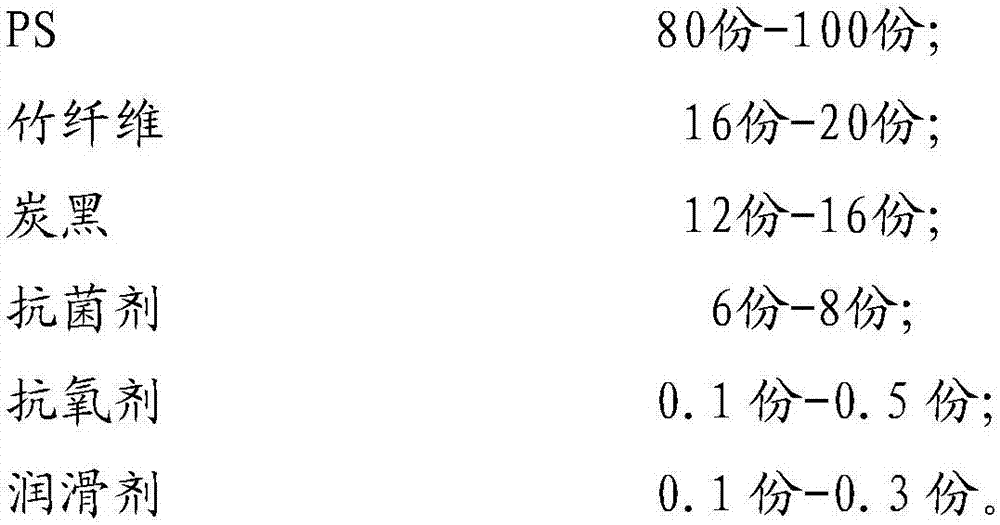

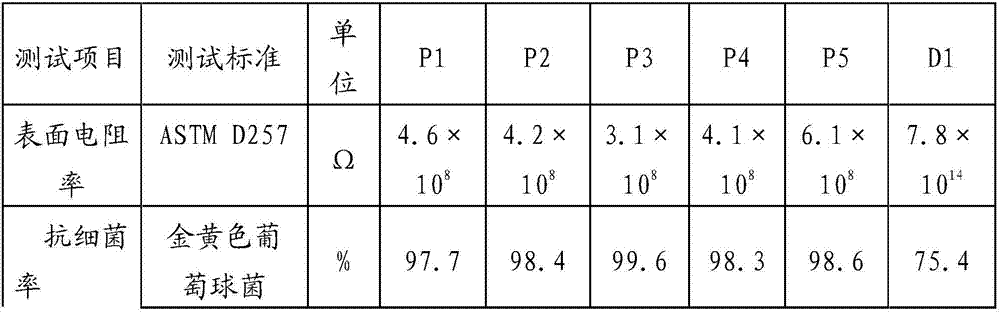

Embodiment 1

[0069] (1) Take by weighing 80 parts of PS, 16 parts of bamboo fiber, 12 parts of carbon black, 6 parts of antibacterial agent, 0.1 part of Irganox168, 0.1 part of zinc stearate and mix and stir evenly to obtain a mixture;

[0070] (2) Extruding and granulating the mixture obtained in the step (1) to obtain PS composite material P1.

[0071] Among them, the temperature and screw speed of each zone of the twin-screw extruder are respectively: the temperature of the first zone is 150°C, the temperature of the second zone is 200°C, the temperature of the third zone is 200°C, the temperature of the fourth zone is 200°C, the temperature of the fifth zone is 200°C, and the temperature of the sixth zone is 200°C. The head temperature is 200°C, and the screw speed is 200r / min.

Embodiment 2

[0073] (1) Weigh 100 parts of PS, 20 parts of bamboo fiber, 16 parts of carbon black, 8 parts of antibacterial agent, 0.1 part of Irganox168, 0.2 part of Irganox1010, 0.2 part of Irganox1330, 0.15 part of sodium stearate, 0.15 part of zinc stearate and mix and stir evenly to obtain a mixture;

[0074] (2) Extruding and granulating the mixture obtained in step (1) to obtain PS composite material P2.

[0075] Among them, the temperature and screw speed of each zone of the twin-screw extruder are respectively: the temperature of the first zone is 170°C, the temperature of the second zone is 240°C, the temperature of the third zone is 240°C, the temperature of the fourth zone is 240°C, the temperature of the fifth zone is 240°C, and the temperature of the sixth zone is 240°C. The head temperature is 240°C, and the screw speed is 280r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com