Patents

Literature

54results about How to "Low drying efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Energy-saving quality-keeping method in the dewatering course of high-water fruit vegetables or aquatic products

InactiveCN101138359ALow drying efficiencyExtended drying timeFood processingFruits/vegetable preservation by dehydrationFreeze-dryingEngineering

A method for saving energy and guaranteeing the quality in the process of dehydration of fruit and vegetable with high water content or water product; the method belongs to the food processing technical field of fruit and vegetable or water product. The present invention adopts the combined processing of hot air drying and hot pump drying or the combined processing of freeze drying and hot pump drying to dehydrate the fruit and vegetable with high water content or water product; with the present invention, energy can be saved by 45 to 60 percent and the appearance and quality of the product are near the simple ordinary dried products. The process is that the raw materials of vegetable and fruit or water product are cleaned, cut and burnt; and then the raw materials are cooled and centrifugally dehydrated; the dehydrated raw materials are seasoned and settled; the settled raw materials are dried by the method of hot pump combined drying and then cooled down for storage; and then metal-detecting process is implemented on the materials and the materials are packed. The present invention adopts the novel process of hot pump combined drying for dehydration; the fruit and vegetable or water product after being dehydrated with the hot pump combined drying are characterized by low heating temperature, short production time, excellent quality and low energy consumption.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

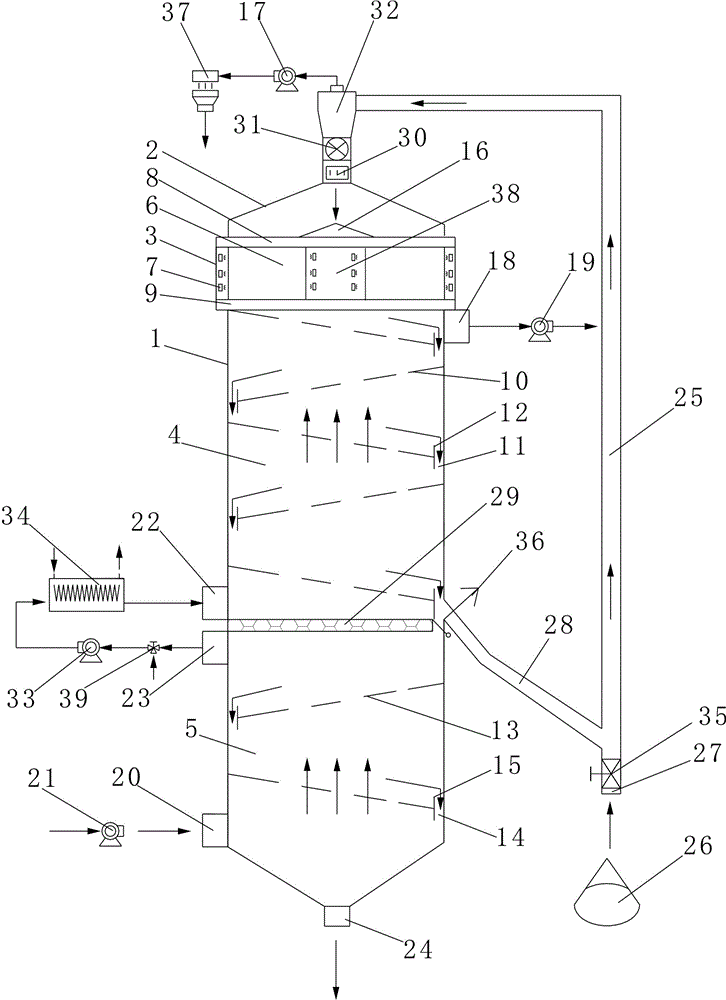

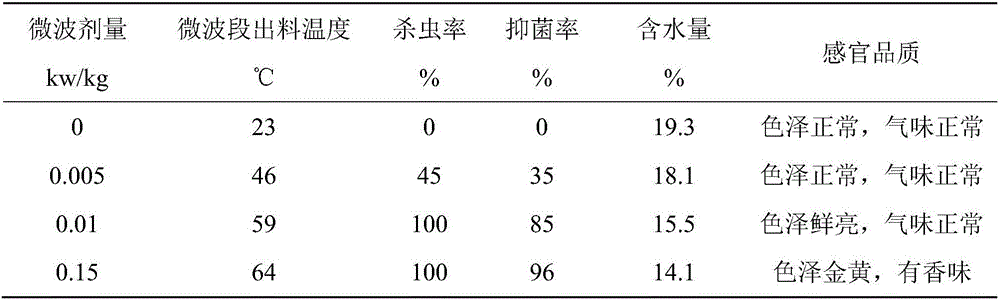

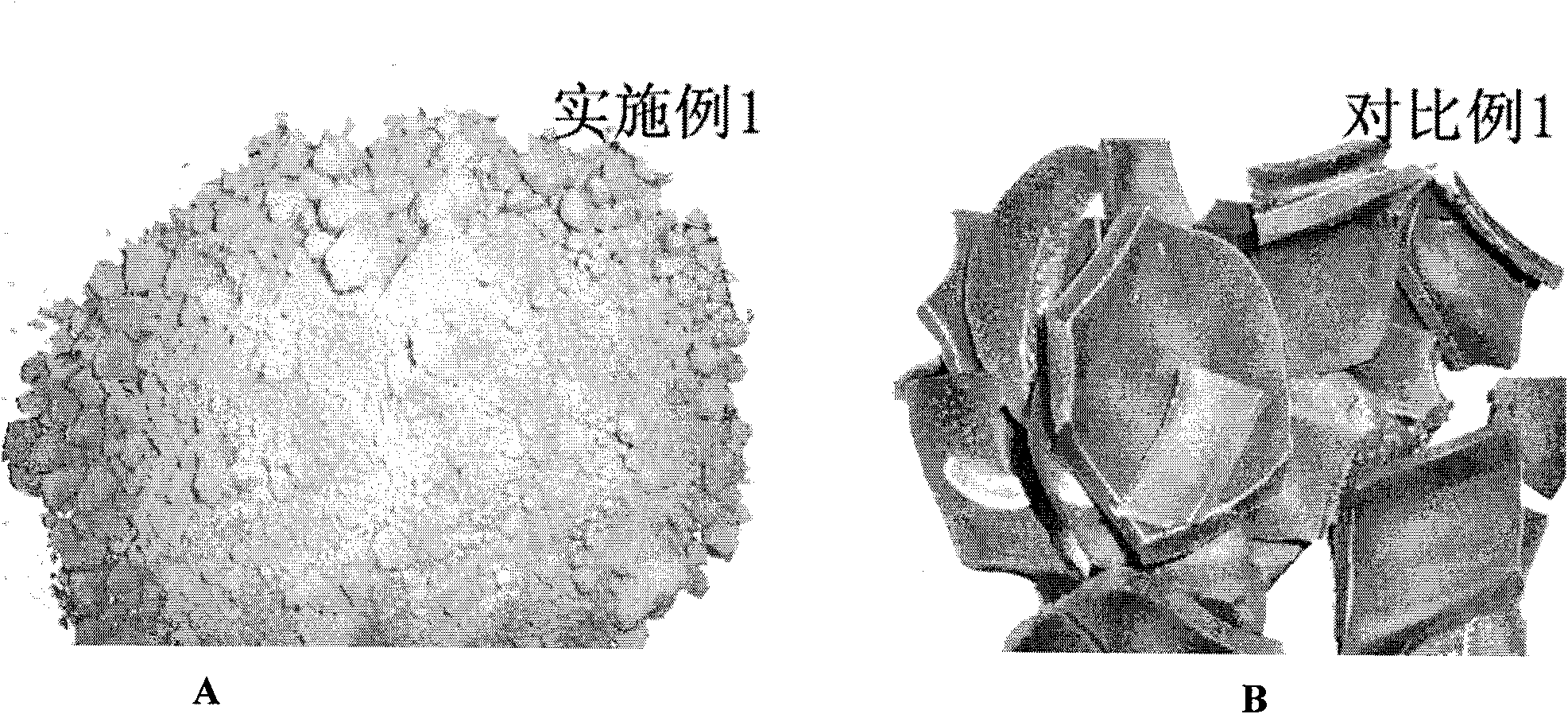

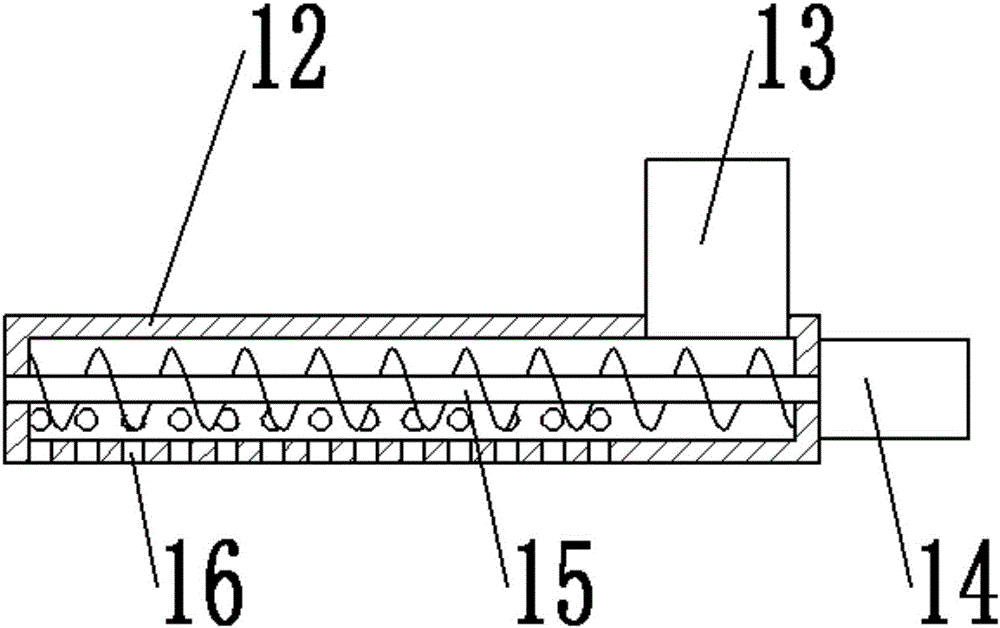

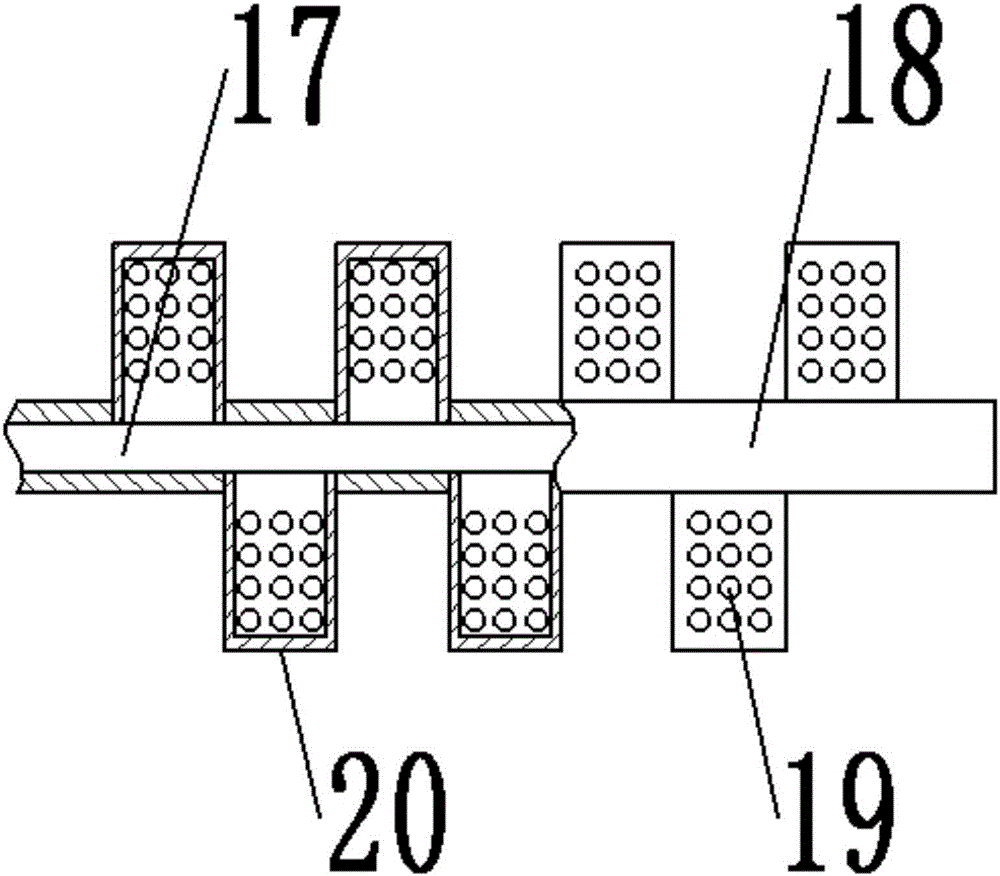

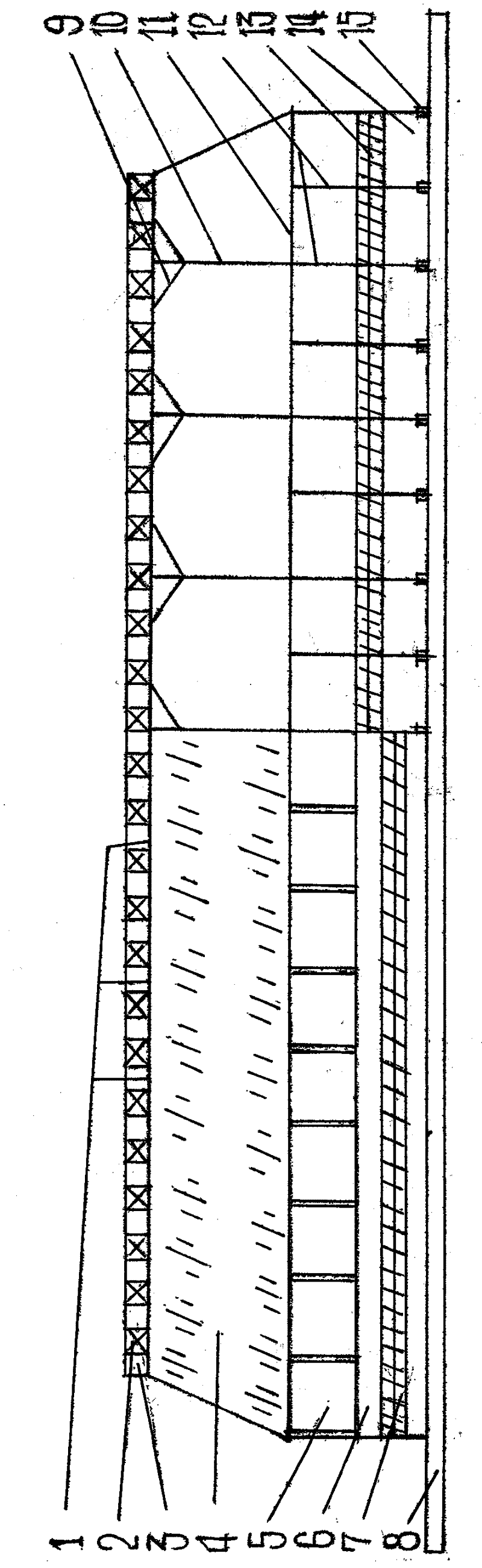

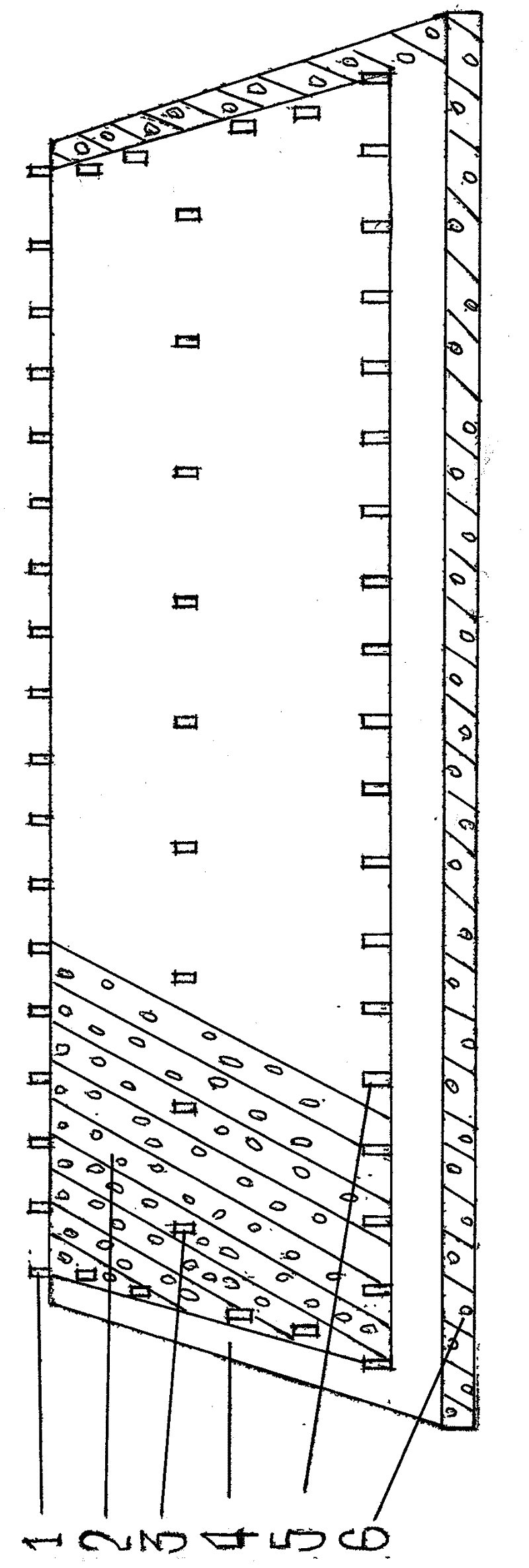

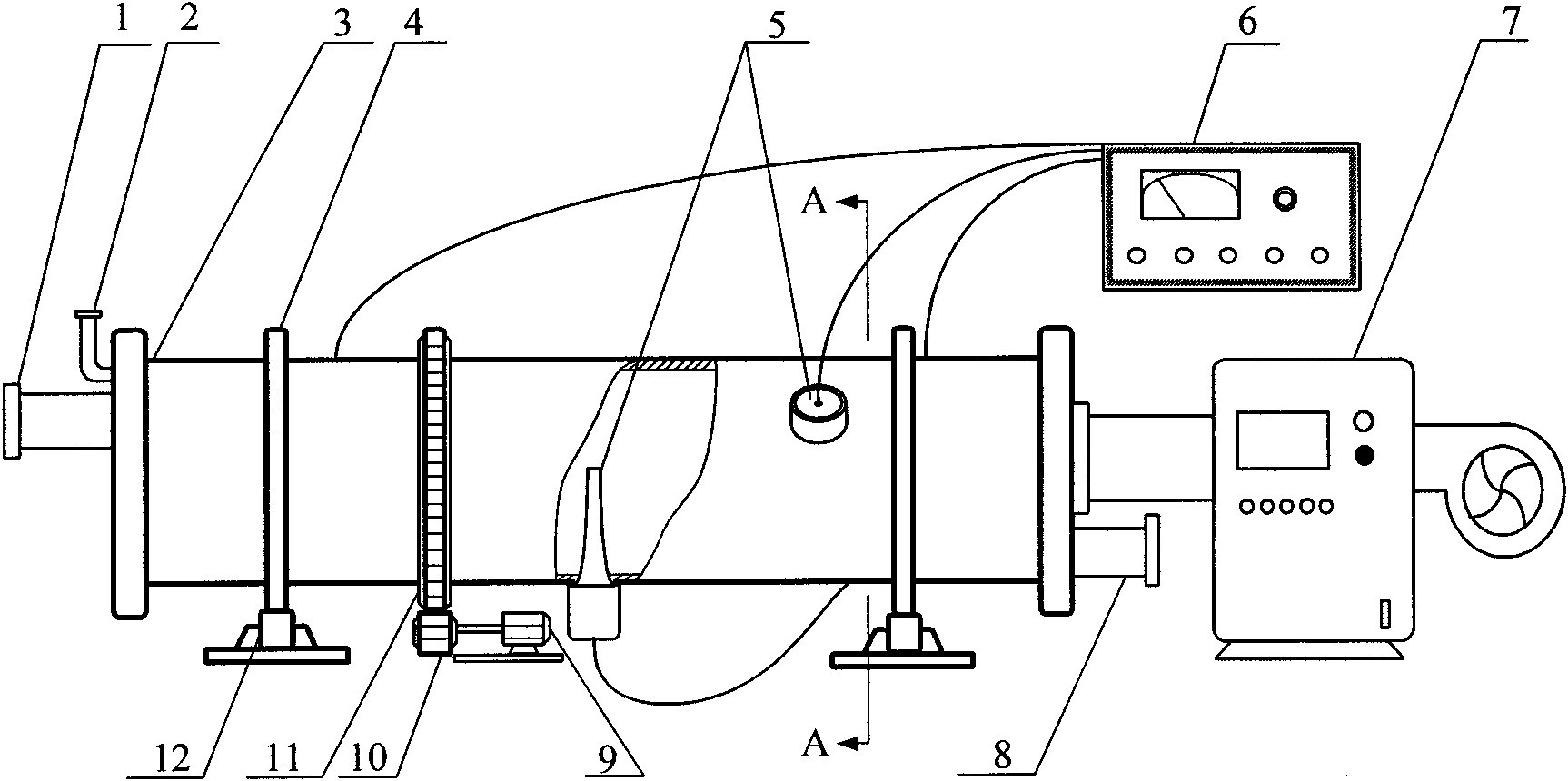

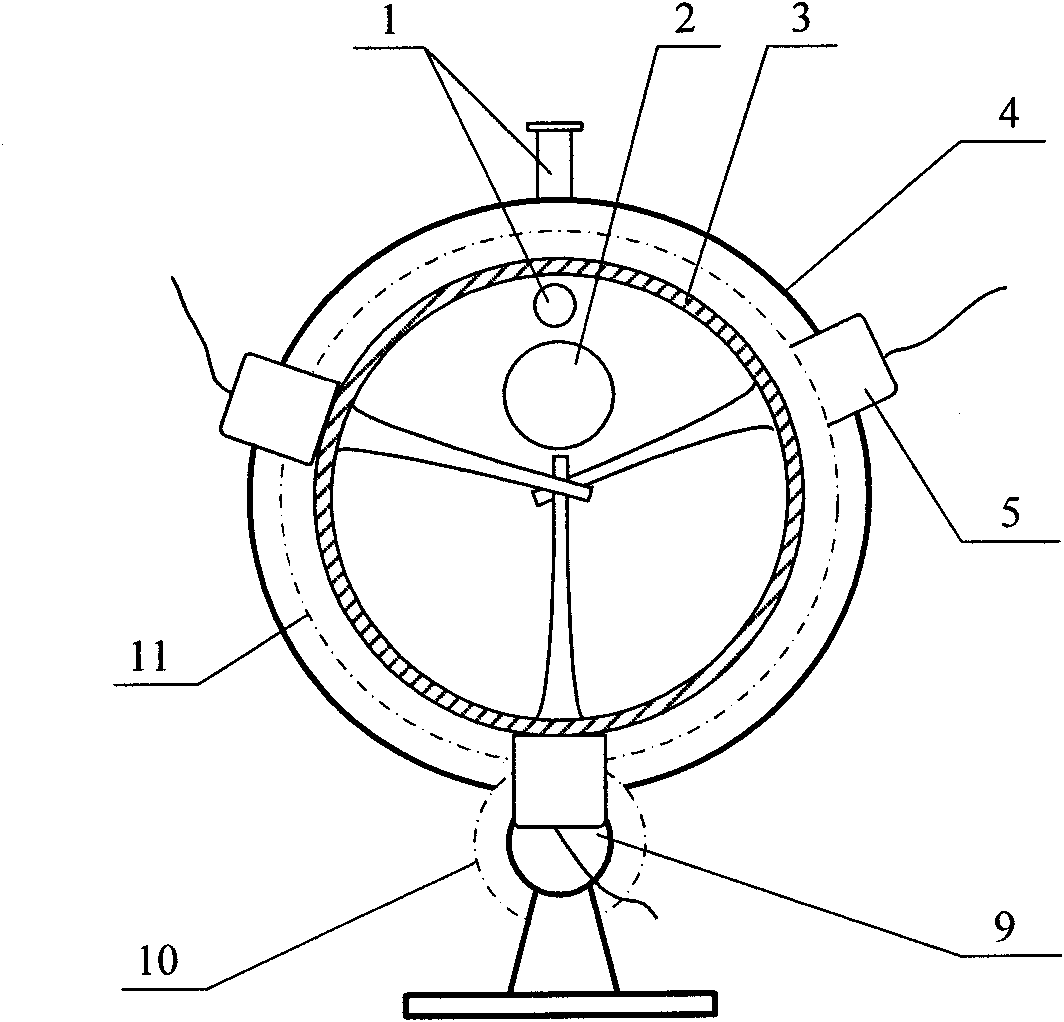

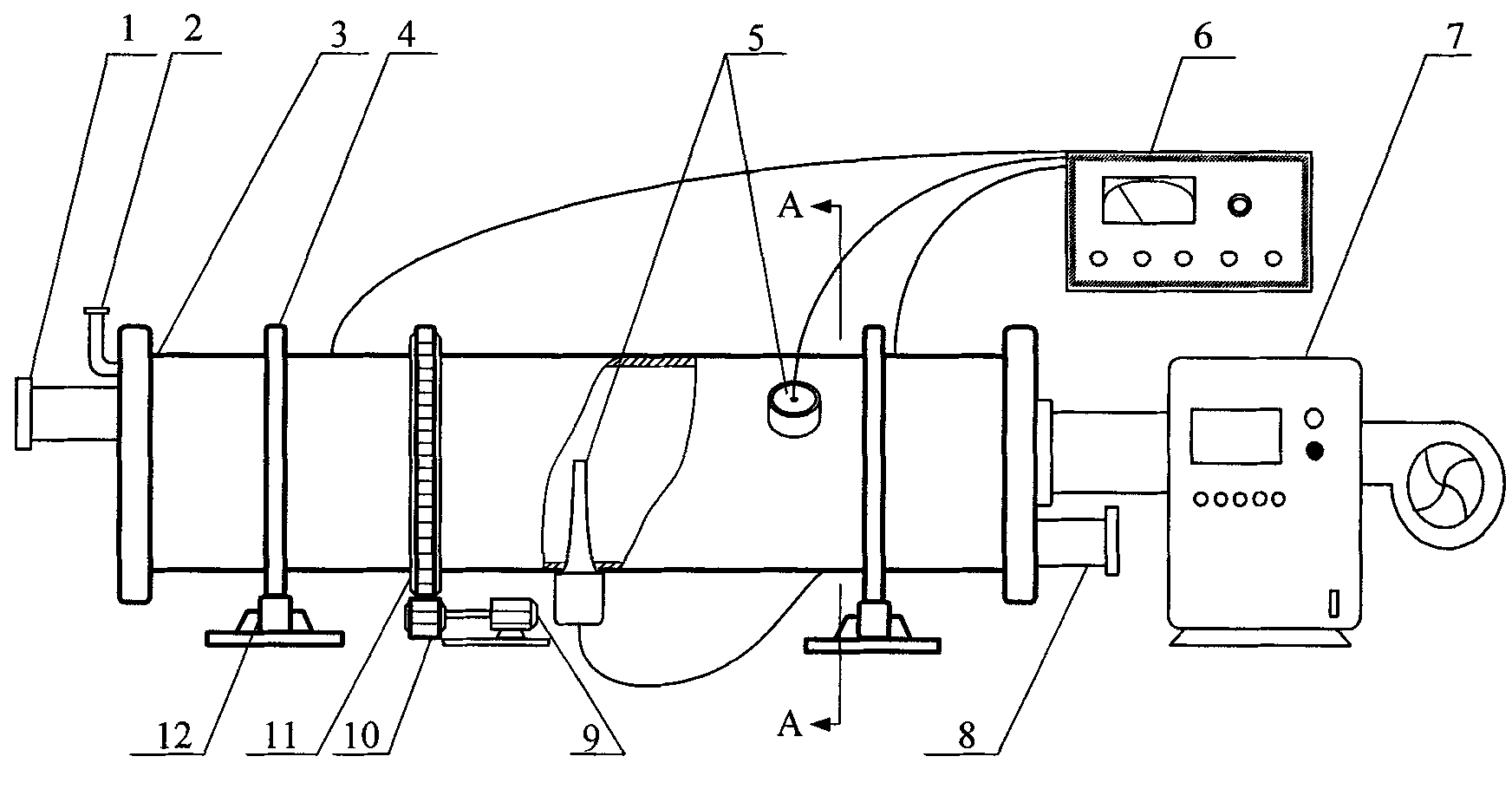

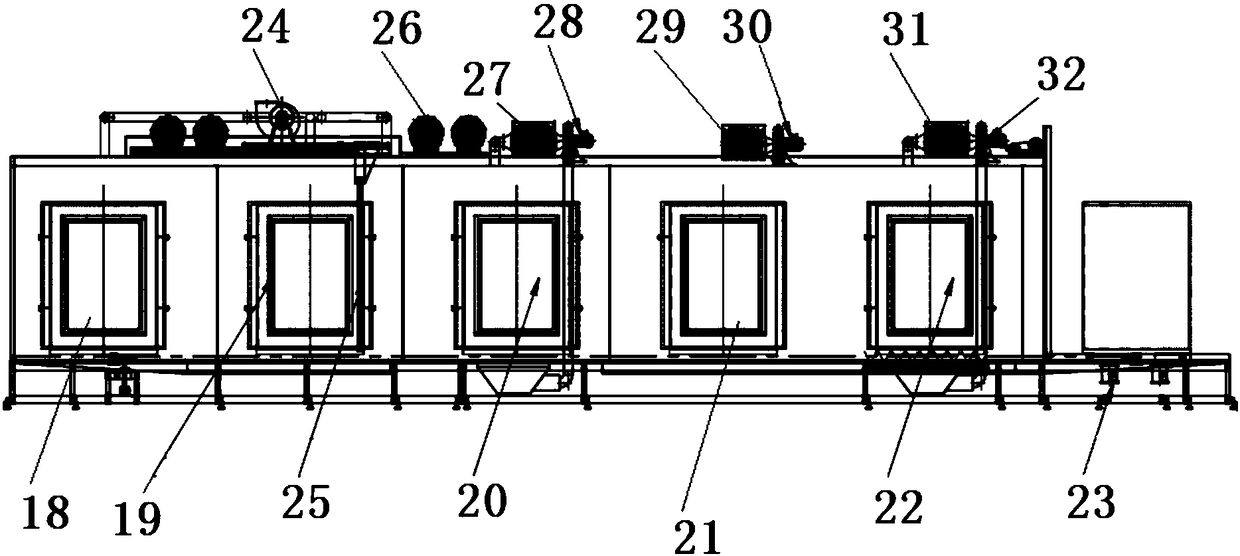

Grain microwave and fluidization combined drying equipment, drying method and application

ActiveCN105928323AReach killEfficient killingDrying solid materials with heatDrying gas arrangementsMicrowaveEngineering

The invention discloses grain microwave and fluidization combined drying equipment, a drying method and application. The equipment comprises a tower body; and the tower body is provided with a buffer bin, a microwave section, a drying section and a cooling section in sequence from top to bottom. The drying section and the cooling section respectively include multiple fluidization plates staggered on upper and lower layers; one ends of the fluidization plates are fixedly connected with the tower body, and baffle plates are mounted at the other ends; and overflow channels are formed between the baffle plates and the tower body. An exhaust port of the cooling section communicates with a hot air intake ports of the drying section via a hot air fan and a heat exchanger; hot air exhausted by the cooling section is leaded into the drying section; and afterheat thereof is fully used to save the energy. The drying method comprises three steps of microwave preheating, fluidization drying and fluidization cooling. The drying equipment and the drying method use the microwave and fluidization combined drying, have the characteristics of high drying efficiency and uniform drying, can realize functions of insecticide and bacteriostasis, and can be used for drying such grains with good fluidity as paddy, wheat and corn.

Owner:HUAZHONG AGRI UNIV

Method for drying apple pieces by nitrogen source low-oxygen heat pump

InactiveCN103444857AExtended storage timeLess nutrient lossFruits/vegetable preservation by irradiation/electric treatmentFood processingQuinoneVitamin C

The invention belongs to the field of drying of agricultural products, and particularly relates to a method for drying apple pieces by a nitrogen source low-oxygen heat pump. The method comprises the following steps of cutting applies into pieces after the apples are selected, peeled and seeded, performing color protection, shape fixation, blanching and draining, drying the apple pieces in a nitrogen source heat pump dryer, drying the apple pieces in a vacuum drying box, and sealing and storing the apple pieces. According to the method, the drying energy consumption is reduced, the drying efficiency is improved, and the shortcomings of low drying efficiency and long drying time in the later drying period of heat pump drying are overcome; the apple pieces are subjected to heat pump drying and vacuum low-temperature drying after the color protection and blanching treatment, so that the problems of reduction of the gloss of the apple pieces and changes in colors are effectively solved; phenolic substances in the apples can be prevented from being oxidized to generate quinone, the oxidation loss of vitamin C can be reduced, the color and the texture of the apple pieces can be prevented from being damaged by an oxidation effect in a drying process, and dry products with natural colors can be obtained.

Owner:HENAN UNIV OF SCI & TECH

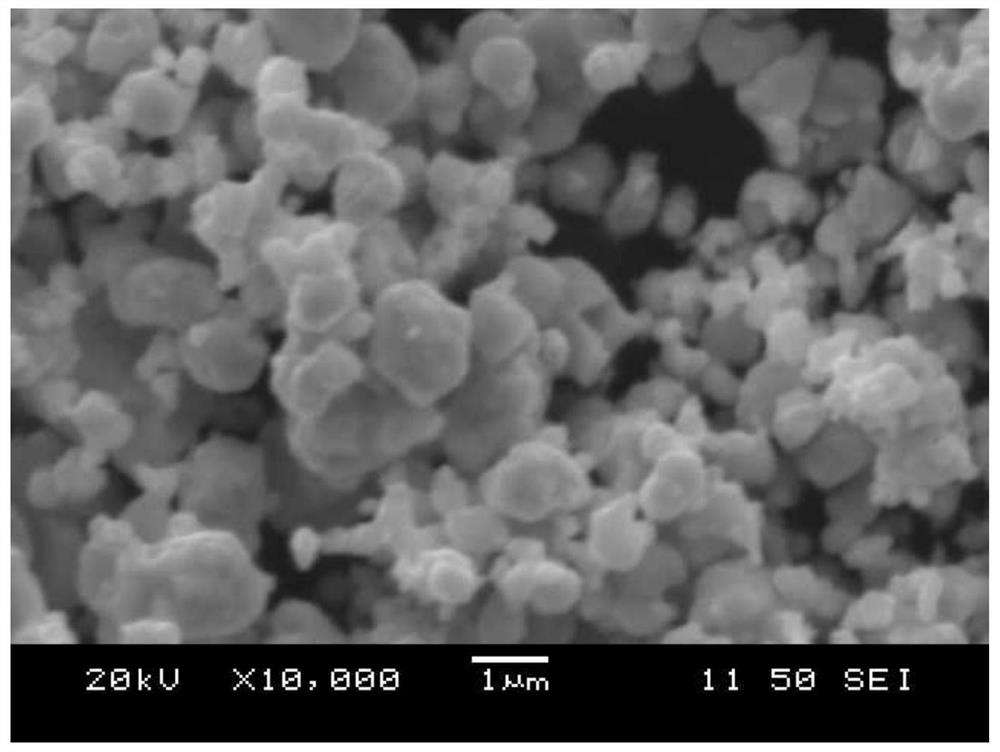

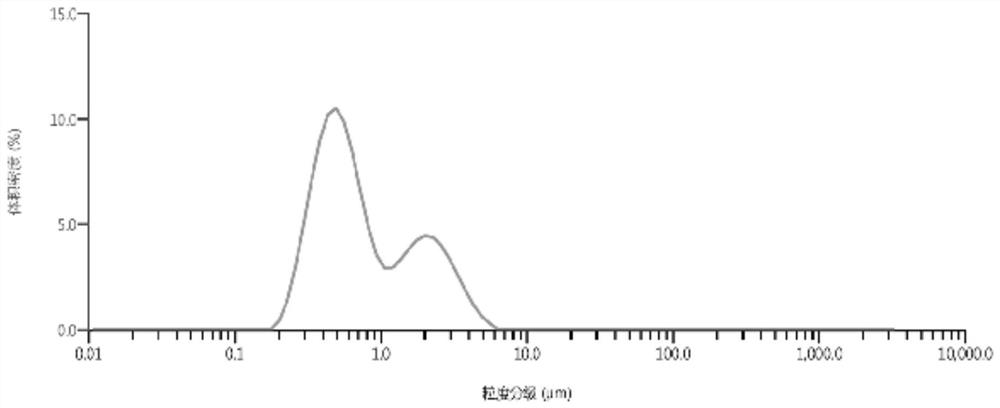

Method for preparing easily mixed high filling clay/rubber nano composite material

The invention discloses a method for preparing an easily mixed high filling clay / rubber nano composite material, which comprises the following steps of: blending rubber emulsion and clay / water suspension; breaking the emulsion by using electrolyte solution; forming flocculation granules of 1 to 100 microns; performing separation by using a hydraulic cyclone, washing and concentration; performing atomization and drying by using a spray drying process; and preparing powdery clay / rubber nano composite material with high clay filling quantity and high dispersion. The spray drying process solves the difficulty that the flocculated composite material with high clay filling part has fine colloidal particles and is not easy to filter and dry and the problem of difficult subsequent mixing and processing process and dispersion caused by hardening of the colloidal particles after the composite glue with high clay filling part is dried. Meanwhile, because the drying time of the product is shortened to dozens of seconds from several hours, the product has the advantages of low ageing, good dispersion and high performance.

Owner:BEIJING UNIV OF CHEM TECH

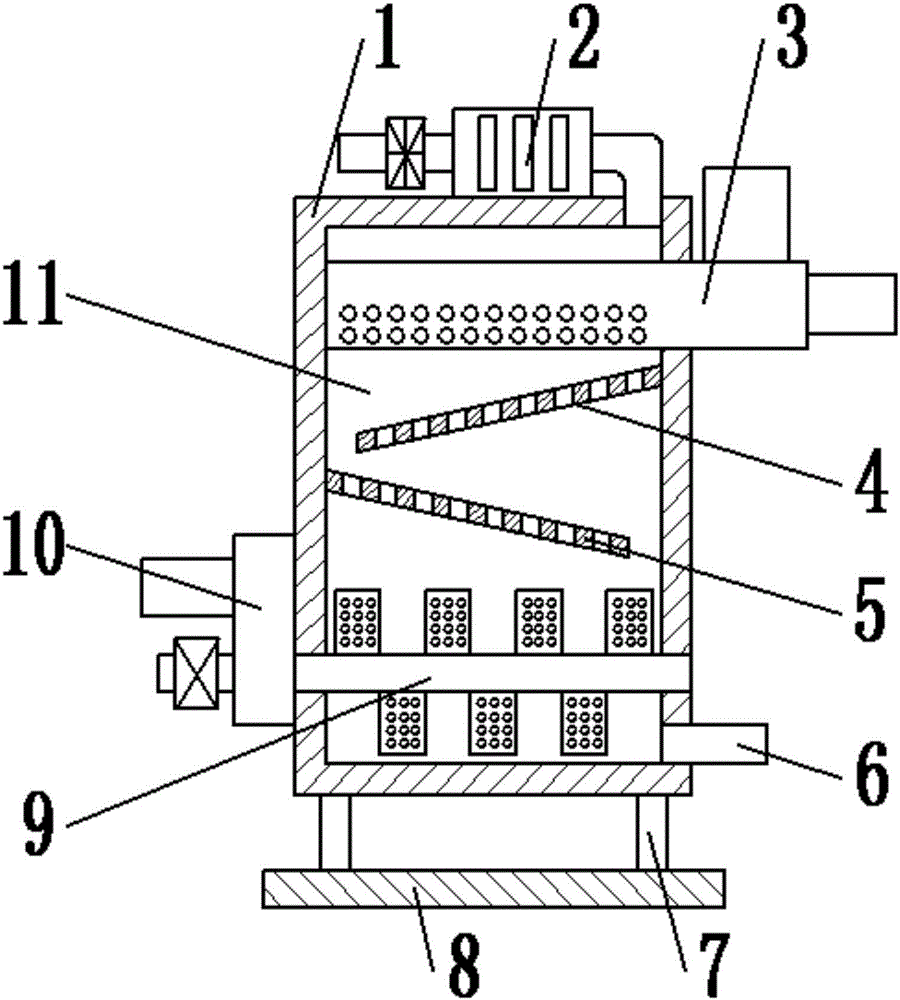

Pueraria powder hot air drying equipment with dehumidifying device

InactiveCN106440740APrevent drying efficiency from decreasingIncrease drying speedGranular material dryingDrying gas arrangementsEngineeringAir drying

The invention provides pueraria powder hot air drying equipment with a dehumidifying device. The pueraria powder hot air drying equipment comprises a tank body. A drying cavity is formed in the tank body. A feeding device is arranged on the top of the drying cavity. An upper material guide plate and a lower material guide plate are arranged in the middle of the drying cavity. A stirring device is arranged at the bottom of the drying cavity. The feeding device is composed of a conveying pipe and a feeding pipe. The upper material guide plate and the lower material guide plate are obliquely arranged. Multiple through holes are evenly formed in the surface of the upper material guide plate and the surface of the lower material guide plate. The stirring device is composed of a stirring shaft and stirring pieces. One end of the stirring shaft is connected with a drying and driving device. The drying and driving device is composed of a transmission box, a rotary motor and an air inlet pipe. The dehumidifying device is arranged on the top face of the tank body and is composed of a dehumidifying pipe, a filtering tank and a dehumidifier. According to the pueraria powder hot air drying equipment, the situation that too much pueraria powder is added once and consequently the drying efficiency is lowered is prevented through the feeding device; the falling distance of pueraria powder is increased through the upper material guide plate and the lower material guide plate; and the pueraria powder is dried efficiently through the drying and driving device.

Owner:ZHENGZHOU YOUAI NETWORK TECH CO LTD

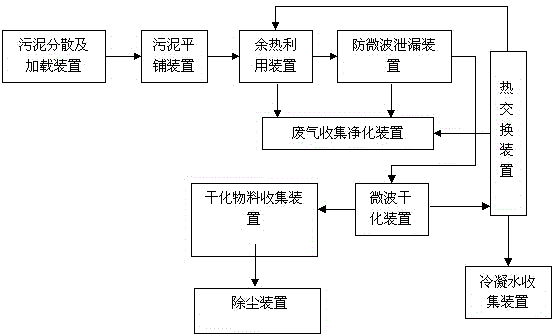

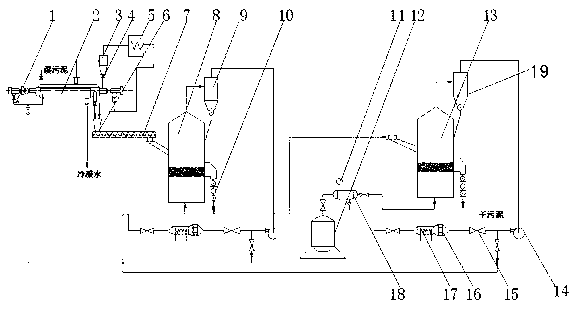

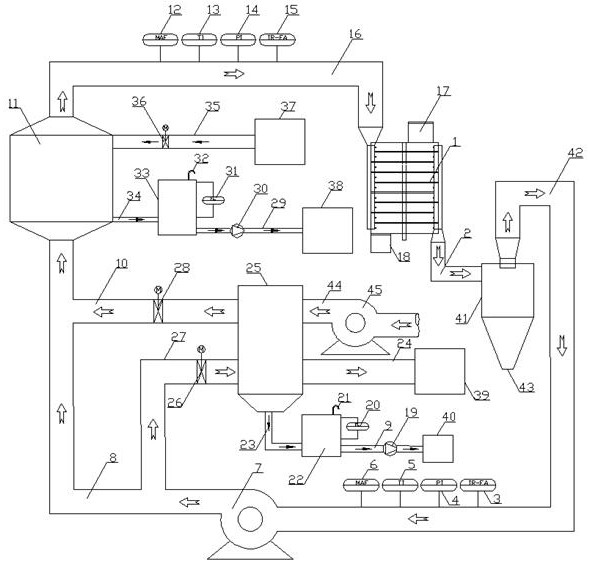

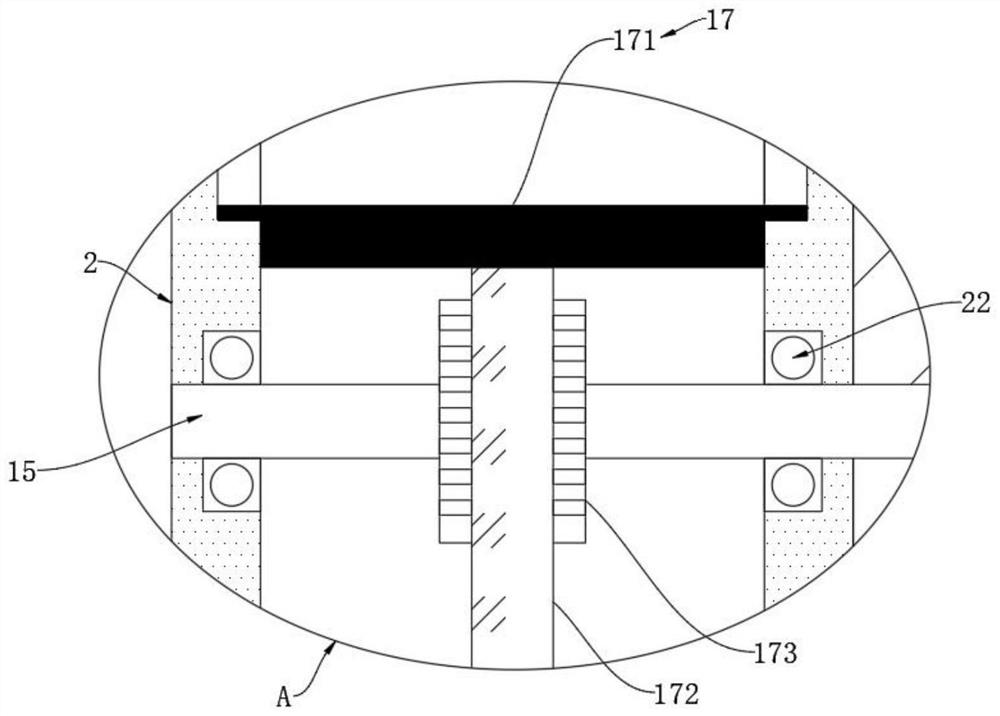

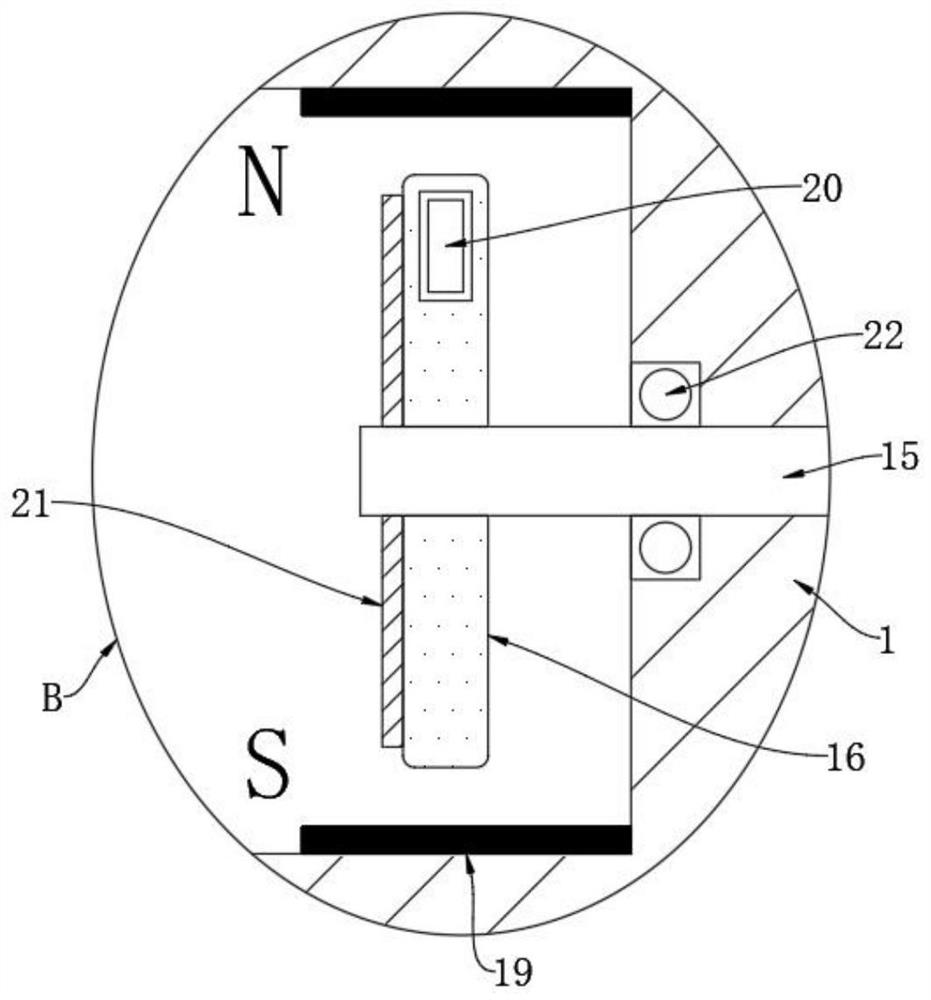

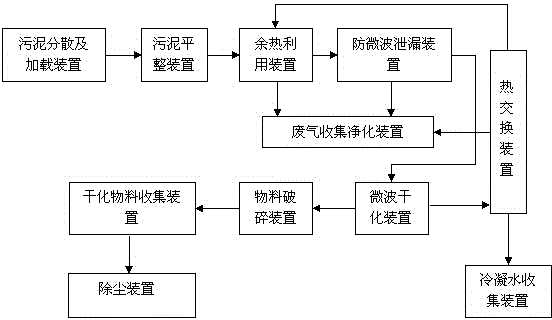

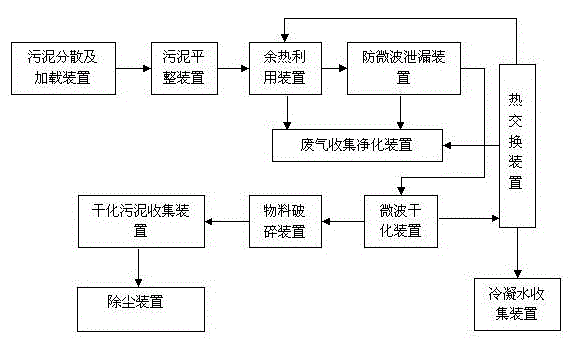

Organic fine-particle sludge drying method and movable drying system

ActiveCN104150738AEfficient water removalExcellent water removal efficiencySludge treatment by de-watering/drying/thickeningSludgeProcess engineering

The invention discloses an organic fine-particle sludge drying method and a movable drying system. The method and the system are realized with a microwave selective absorption characteristic. Microwave is the main approach of drying, and is not an auxiliary measure. According to the invention, the method is not aimed at a specific type of organic fine-particle sludge. With the method provided by the invention, high-efficiency dehydration is realized, wherein the dehydration efficiency can reach 1.6kg water / kWh. With the method, an existing method for drying with a combination of various approaches and microwave technology is simplified; production cost is reduced; and efficiency is improved. Through the arrangement of a heat exchanger device, heat can be efficiently recycled, and energy recycling rate can be improved. Compared with prior arts, a device designed according to the invention has a smaller volume. The device can be vehicle-mounted and can be moved, such that sludge drying treatment can be carried out at any place. Therefore, with the method and the system, sludge drying is flexible and convenient.

Owner:华东理工常熟研究院有限公司

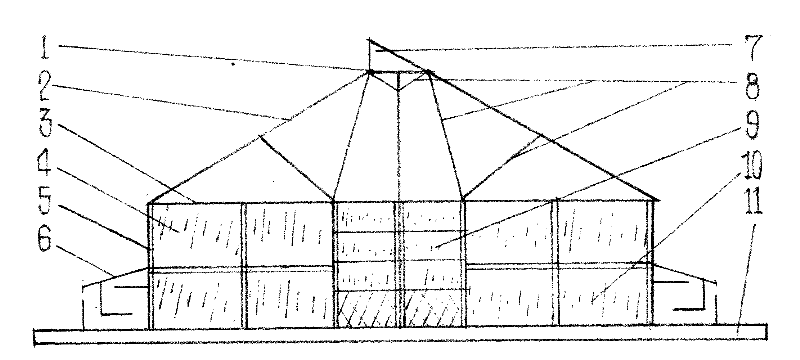

Sea tangle airing sunlight room and construction method and purpose thereof

InactiveCN102444300AIncrease the number of peopleLow drying efficiencyAgricultural buildingsClimate change adaptationAdditional valuesEngineering

The invention discloses a sea tangle airing sunlight room and a construction method and a purpose thereof. The sea tangle airing sunlight room comprises a plane foundation, a wall body, a preheating bin, a roof building, a venting window, an airing device and can be constructed into a movable room or an immovable room, an inclined plane type sunlight room and a scale type managed sunlight room. The various sunlight rooms are all used for airing sea tangles into dried products. The sea tangle airing sunlight room improves 30% of deep processing additional value of sea tangle cultivating enterprises and 3 times of airing efficiency, saves 70% of airing area and 50% of labor power, and reduces labor intensity.

Owner:蒲增军

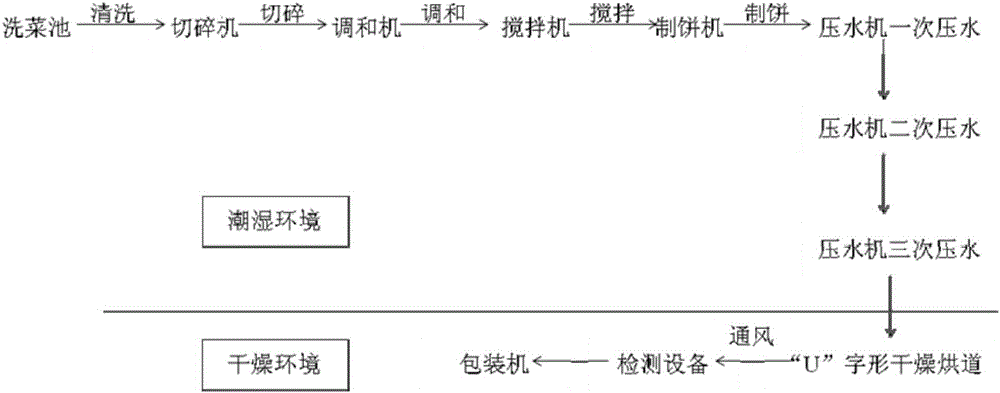

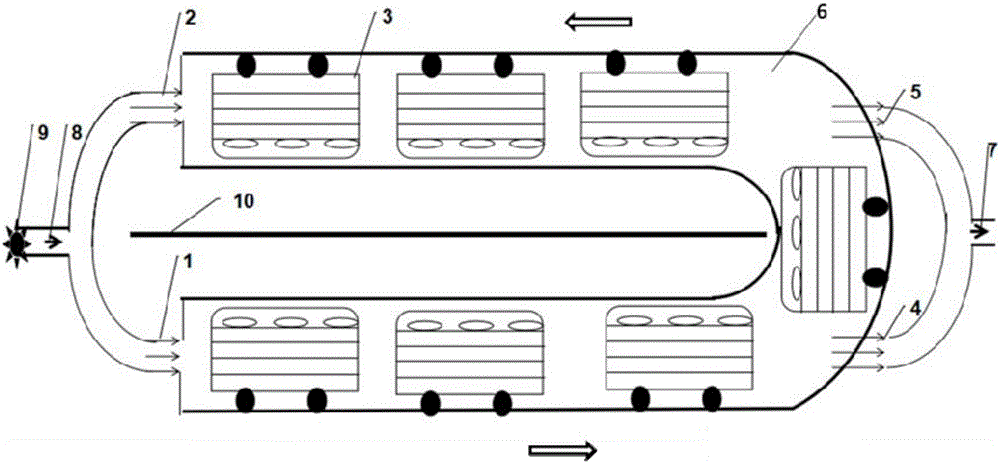

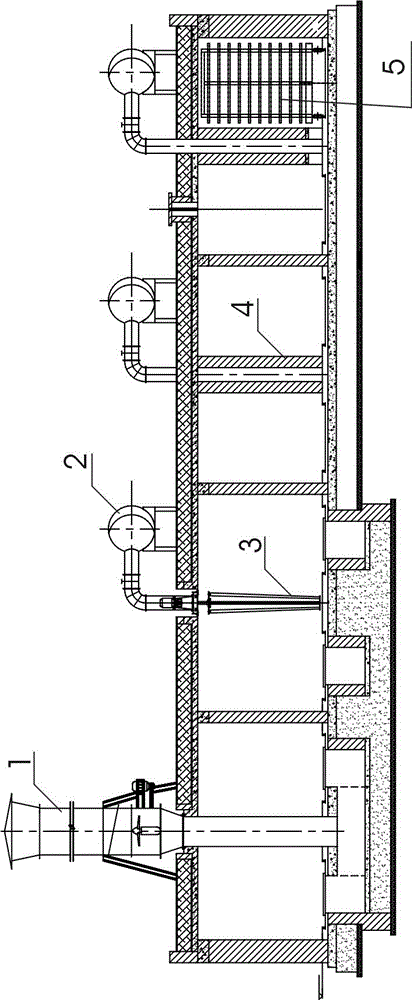

Method and device for drying and processing of porphyra haitanensis

PendingCN106387734AReduce moisture contentAvoid re-dryingFood processingFood dryingWater contentEngineering

The invention discloses a method and device for drying and processing of porphyra haitanensis. The main body of the drying processing device is a 'U' shaped pipe, and is provided with a porphyra haitanensis conveying device, a heating device and a ventilation and heat dissipation device; the porphyra haitanensis conveying device is a cart, the heating device comprises a hot air boiler and hot air pipes, and the ventilation and heat dissipation device comprises a fresh vegetable end exhaust port, a dry vegetable end exhaust port and a moisture exhaust port. The method comprises the following steps: washing porphyra haitanensis, chopping, blending, stirring and making cake to obtain a porphyra haitanensis cake; conducting pressing-dehydration of the porphyra haitanensis cake by external forces in a water press by three times, and then placing the porphyra haitanensis cake in a 'U' shaped dry bake channel; drying at 60-70 DEG C for 45-75min to obtain the finished product of the porphyra haitanensis. The prepared finished product has low water content, can meet the conditions of long-term preservation and avoid the situation of secondary re-drying. Scattering of moisture-containing hot gas in all directions is reduced, environmental pollution is reduced, and moisture loss and heat loss in the heating boiler are reduced.

Owner:NINGBO UNIV

High efficiency and energy saving fly ash sintered brick making method

ActiveCN104129972AEasy to transformLow drying efficiencySolid waste managementBrickResource utilization

The invention provides a high efficiency and energy saving fly ash sintered brick making method. The optimization of granularity graduation of shale powder and the introduction of a single layer drying process capable of realizing large-scale continuous production solve the problems of low strength and easy deformation of green bricks in the drying process of ultrahigh-content fly ash sintered bricks, and multi-time mixing, forced mixing, heat insulation time prolongation processes further improve the product stability, so the large-scale industrial production of ultrahigh-content fly ash sintered bricks is successfully realized, the sintered bricks obtained in the invention has high yield, excellent strength and reduced weight, and energy consumed by sintering is effectively reduced. The selection of a kiln top and a hanging structure made of a sintered refractory material improves the acid corrosion resistance of a kiln body, can effectively adapt to the production of high--sulfur high-carbon fly ash sintered bricks, solves the problem of difficult utilization of fly ash from a circulating fluidized bed power plant, and improves the resource utilization rate.

Owner:西安瑞泰机械设备制造有限公司

Method for drying Hami melon slices by nitrogen source low oxygen heat pump

InactiveCN103416475AExtended storage timeLess nutrient lossFood processingFruits/vegetable preservation by heatingQuinoneVitamin C

The invention belongs to the field of agricultural product drying, and particularly relates to a method for drying Hami melon slices by a nitrogen source low oxygen heat pump. The method comprises the steps of selecting Hami melons, removing peels and pulp of the Hami melons, conducting slicing, conducting color protection and type fixing, blanching, draining, conducting drying in a nitrogen source heat pump drying machine, and conducting drying, sealing and storing in a vacuum drying box. According to the method, the drying energy consumption is reduced, the drying efficiency is improved, the defects that in the drying later stage, the heat pump is low in drying efficiency and long in time required by drying are overcome, heat pump drying and vacuum low-temperature drying are carried out after color protection and blanching treatment, and therefore the problems that the brightness of the Hami melon slices is reduced, and the color is changed are solved. According to the method, phenolic substances in the Hami melon slices can be restrained from being oxidized to generate quinone, the oxidation loss of vitamin C is reduced, damage, caused by oxidation in the drying process, to the color and texture of the Hami melon slices can be avoided, and dried products with the natural color are obtained.

Owner:HENAN UNIV OF SCI & TECH

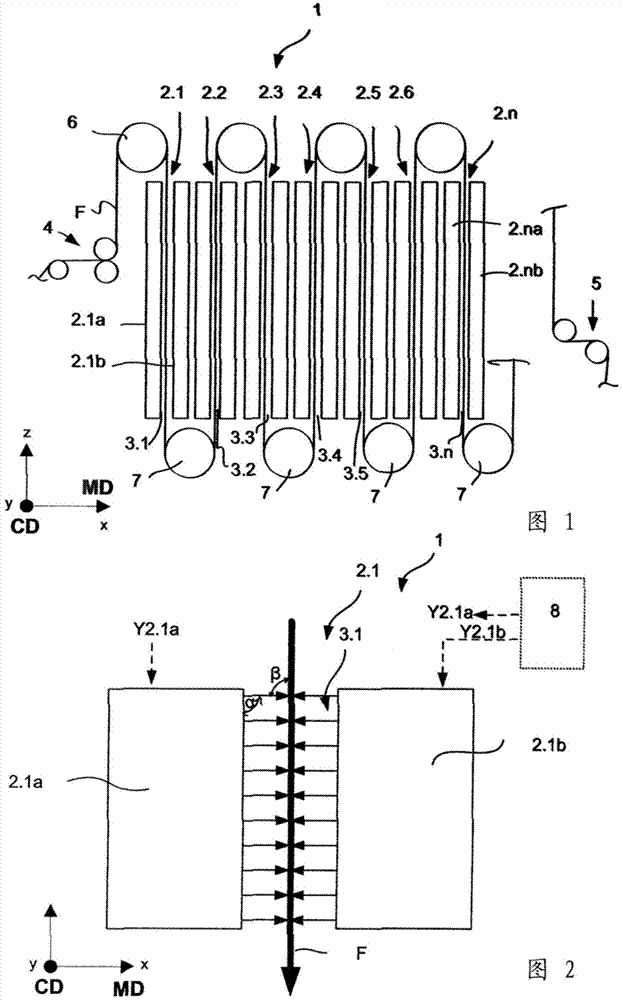

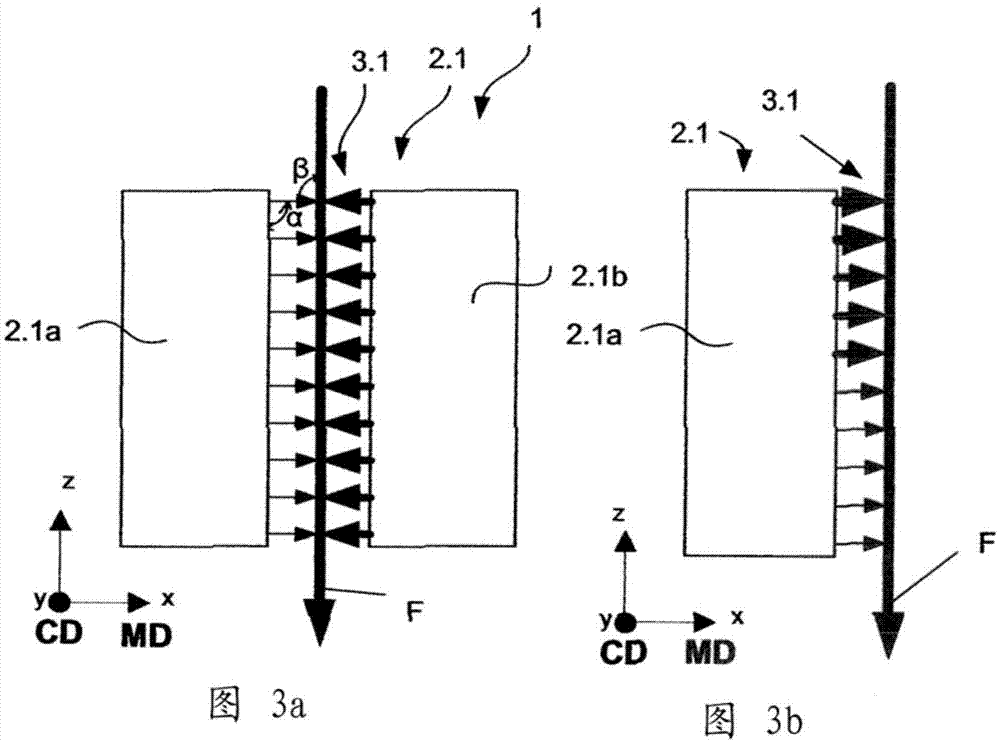

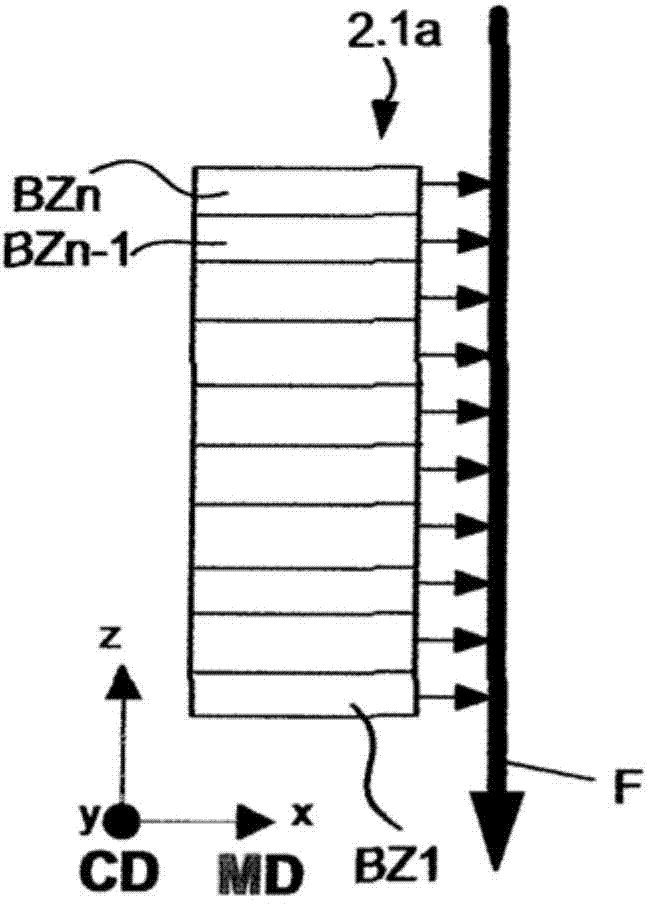

Method for drying a fibrous web in a drying device, and drying device

ActiveCN103597140AImprove drying efficiencyLow drying efficiencyDryer sectionPhysical paper treatmentFiberEngineering

Owner:VOITH PATENT GMBH

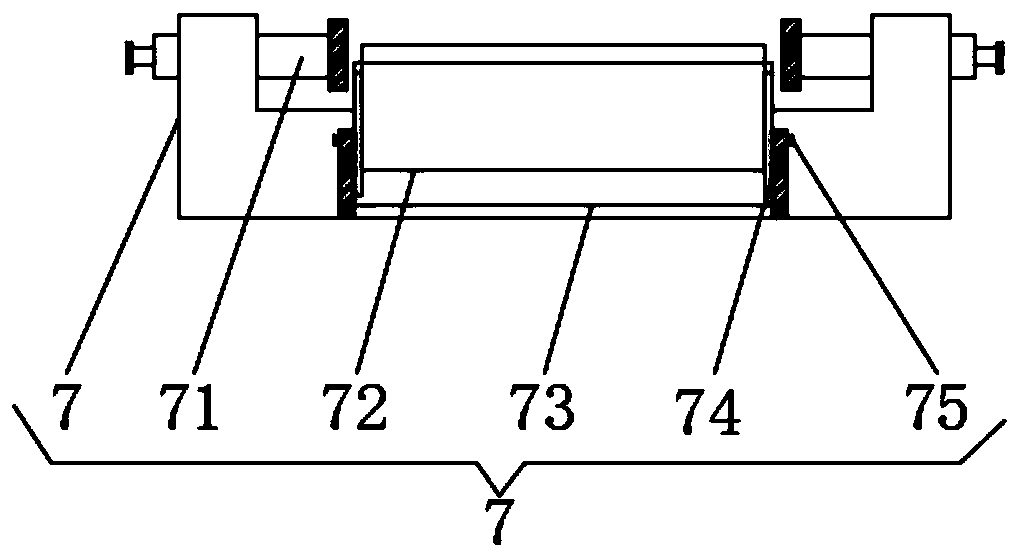

Sludge ultrasonic roller drier

InactiveCN101857347AImprove drying efficiencyLow drying efficiencySludge treatment by de-watering/drying/thickeningSludgePulp and paper industry

The invention discloses a sludge ultrasonic roller drier. A drying cylinder is provided with a feeding opening, an exhaust opening, an ultrasonic probe and a discharging opening, wherein the ultrasonic probe is inserted into the drying cylinder and is connected with an ultrasonic generator; a hot air generator is connected with the drying cylinder; the drying cylinder is sleeved with a gear ring and a rolling ring; the rolling ring is arranged on a riding wheel and is supported by the riding wheel; the drier also comprises an adjustable speed motor; and the output shaft of the adjustable speed motor is provided with a gear which is engaged with the gear ring. In the process of drying, sludge is stirred continuously along with the rotation of the drying cylinder so as to finish drying under the combined action of ultrasonic wave and a hot air device. Due to the adoption of the sludge ultrasonic roller drier, the shortcomings of low efficiency, high operating cost and the like in the conventional sludge drying equipment are overcome; dewatering performance of the sludge is improved in a short period; a drying rate is improved; treating cost is reduced; and simultaneously sludge floc particles become uniform and fine by the ultrasonic wave so as to contribute to post sludge resource treatment and improve energy ultilization rate.

Owner:SOUTHEAST UNIV

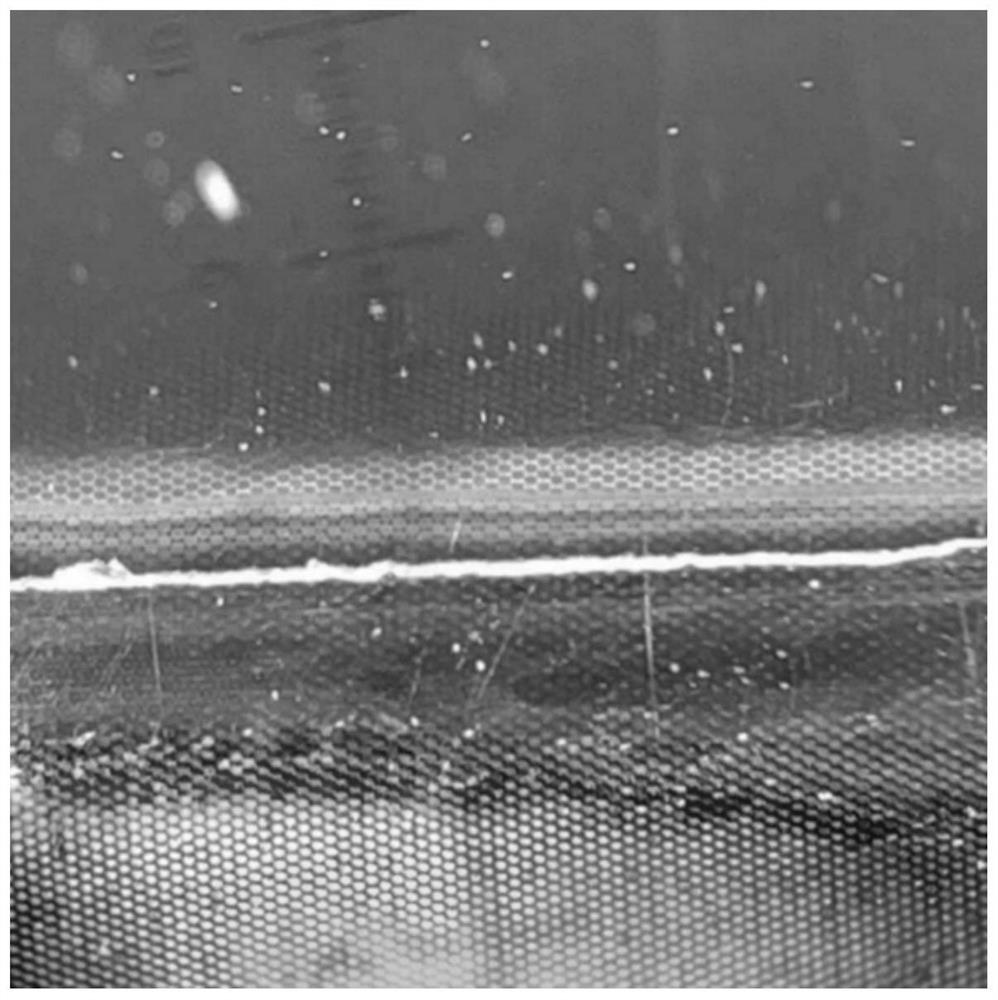

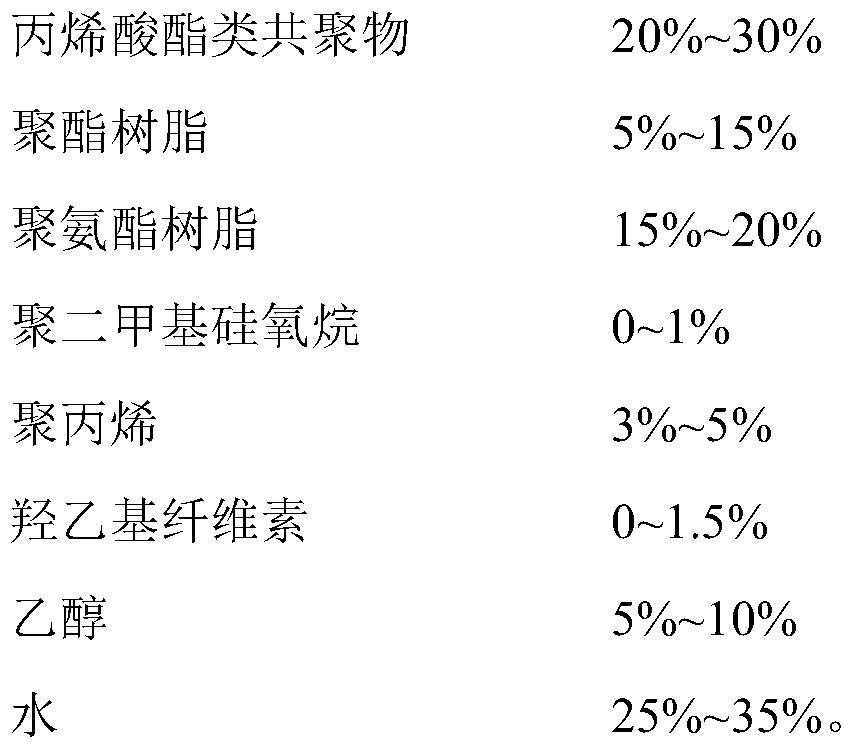

Scratch-resistant and folding-resistant transferring film, production process, and application thereof

InactiveCN111845177AImprove tensile propertiesImprove folding resistanceDecorative surface effectsChemistryPolypropylene

The invention relates to the technical field of transferring film, in particular to a scratch-resistant and folding-resistant transferring film, a production process, and application thereof. The scratch-resistant and folding-resistant transferring film comprises a PET base film and a transferring coating layer coating on the PET base film. Coating on the transferring coating layer is composed ofacrylate copolymer, polyester resin, polyurethane resin, polydimethylsiloxane, hydroxyethyl cellulose, polypropylene, ethanol, and water. The acrylate copolymer can improve the scratch-resistant performance of the transferring coating layer. The polyurethane resin can improve the tensile performance of the transferring coating layer, so as to improve the folding-resistant performance of the transferring coating layer. The synergistic effect of the acrylate copolymer and the polyurethane resin enables the transferring coating layer to have high film-forming performance and tensile performance.After the transferring film is attached to a wrapping paper by transferring glue, the PET base film is stripped off. The scratch-resistant and folding-resistant transferring coating layer does not have cracks during the bending process of the wrapping paper, and the wrapping paper cannot be exposed.

Owner:DONGGUAN K LASER TECH

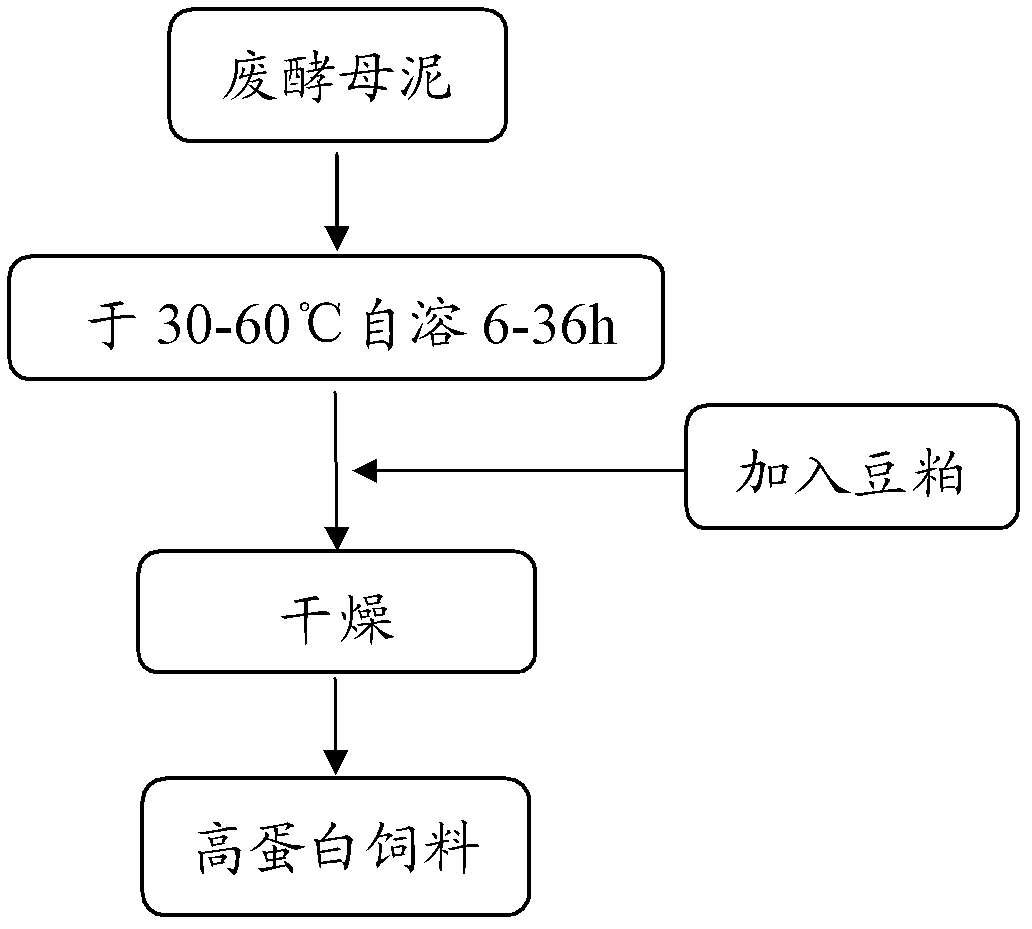

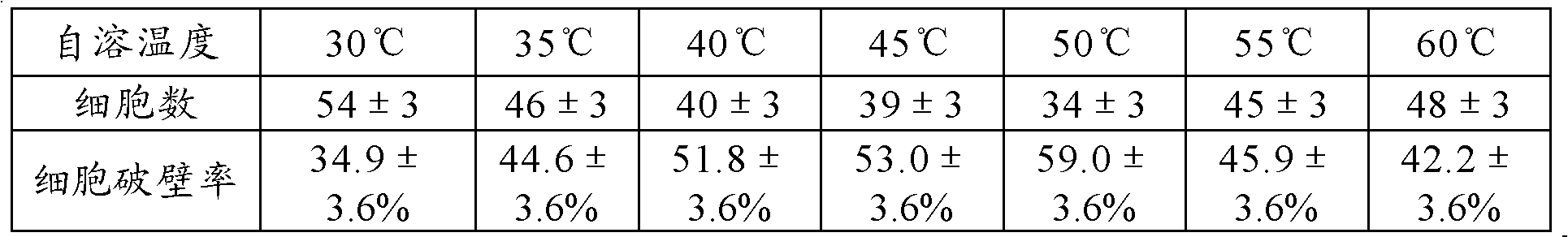

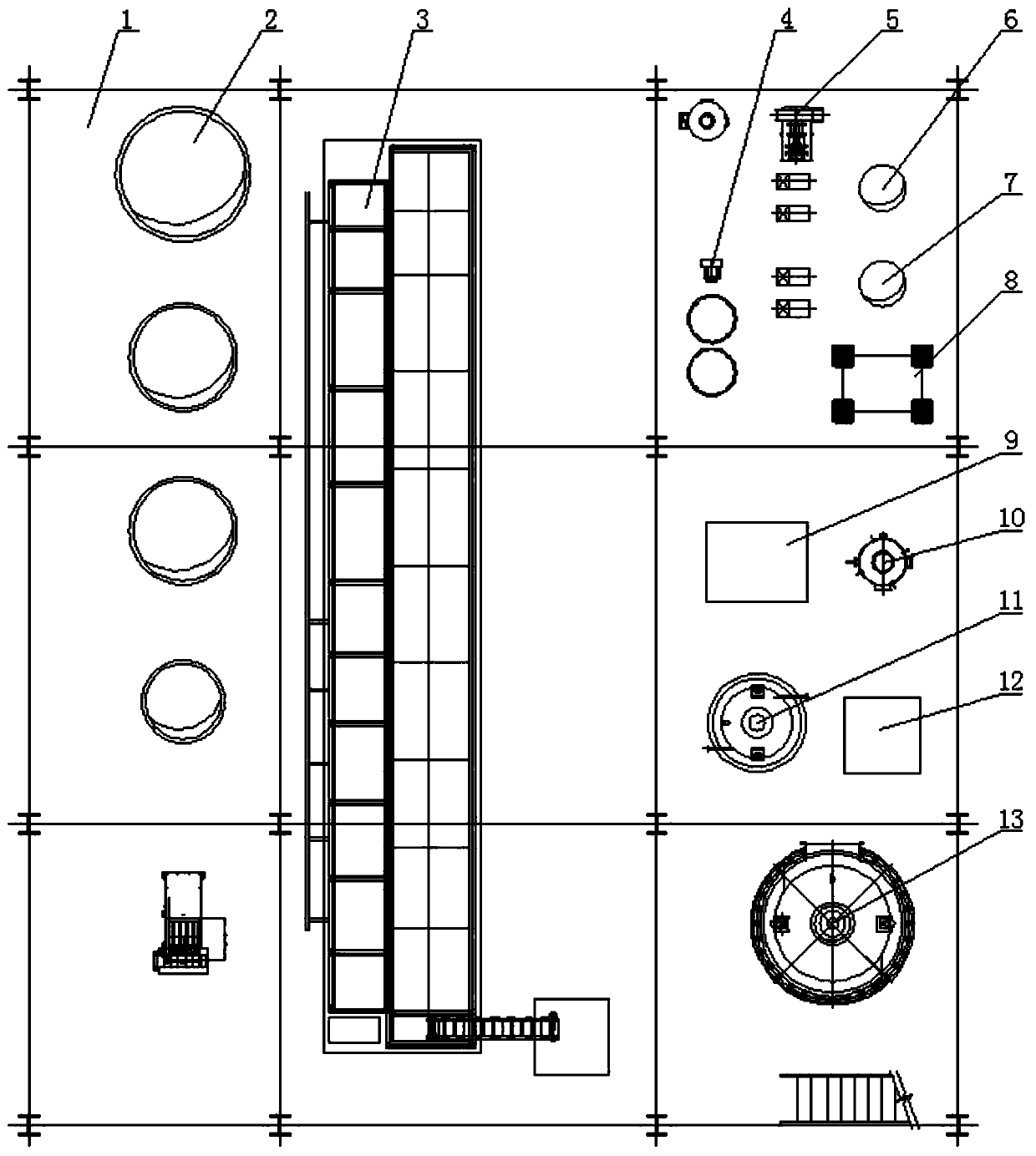

High protein feed prepared by using waste yeast mud and its method

InactiveCN102488090APromote dissolutionHigh soluble protein contentFood processingAnimal feeding stuffHigh concentrationBiotechnology

The invention discloses a high protein feed prepared by using waste yeast mud and its method. The method comprises the following steps: adding the waste yeast mud in water and uniformly mixing, self-dissolving for 6-36 hours at the temperature of 30-60 DEG C, adding soybean meal and uniformly stirring, drying to prepare the high protein feed, wherein the waste yeast mud is the waste yeast mud capable of producing beta-mannanase or beer. By calculating every kilogram of waste yeast mud, the amount of the water is 0-2kg, the addition of soybean meal is 0.5-2kg. According to the invention, the high protein feed contains dissolved protein with high concentration, and is safe and nontoxic. An autolysis method is used for breaking wall of the yeast cells, no other substance can be introduced, the operation is simple and the energy consumption is low; soybean meal which is taken as a raising agent is added when drying for effectively raising the drying efficiency, the cost can be saved, the soybean meal is a high protein substance, the obtained product can be taken as the high protein feed without separation, and can be prepared to high protein feed by adding common auxiliary materials.

Owner:ZHEJIANG UNIV

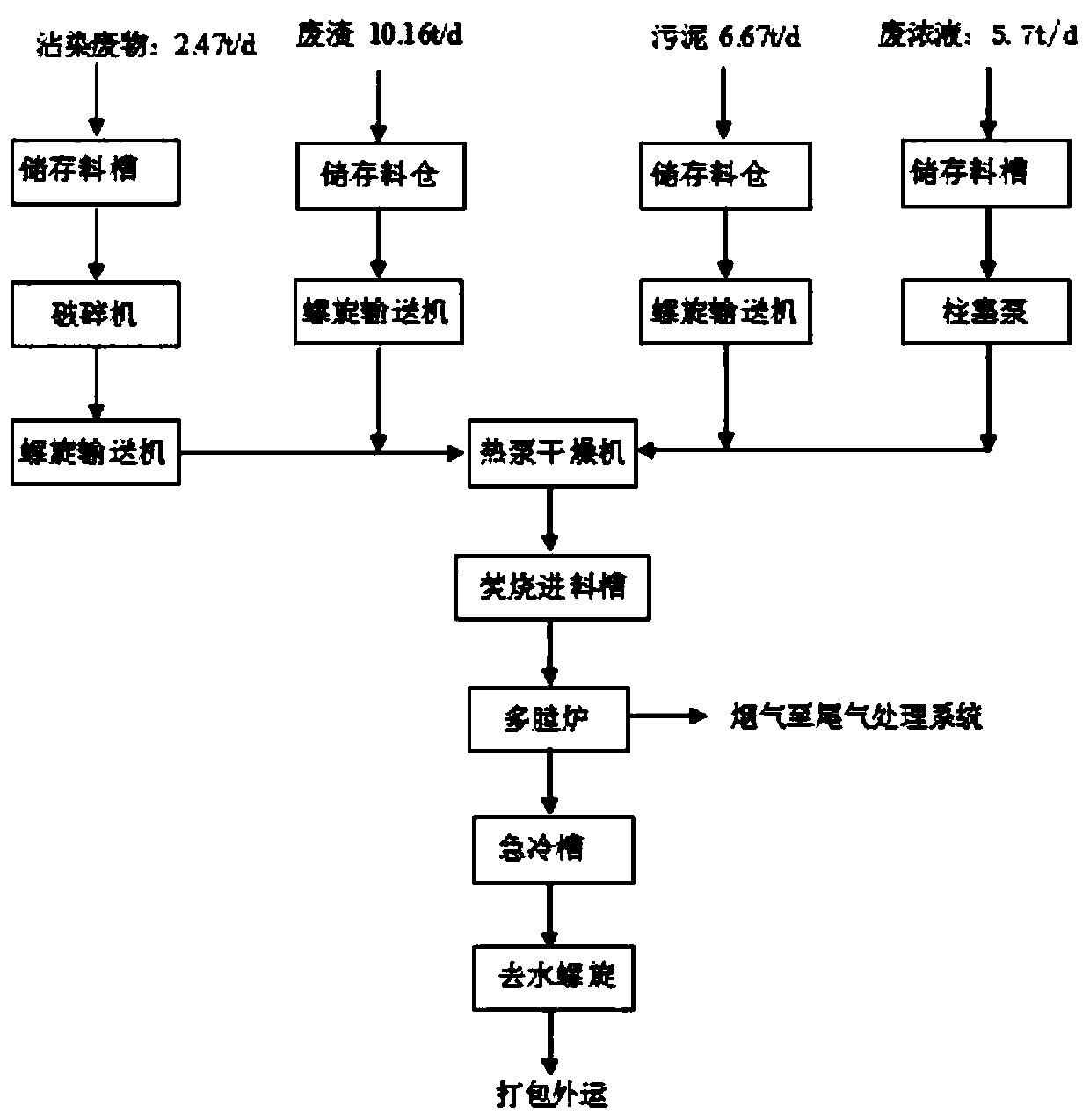

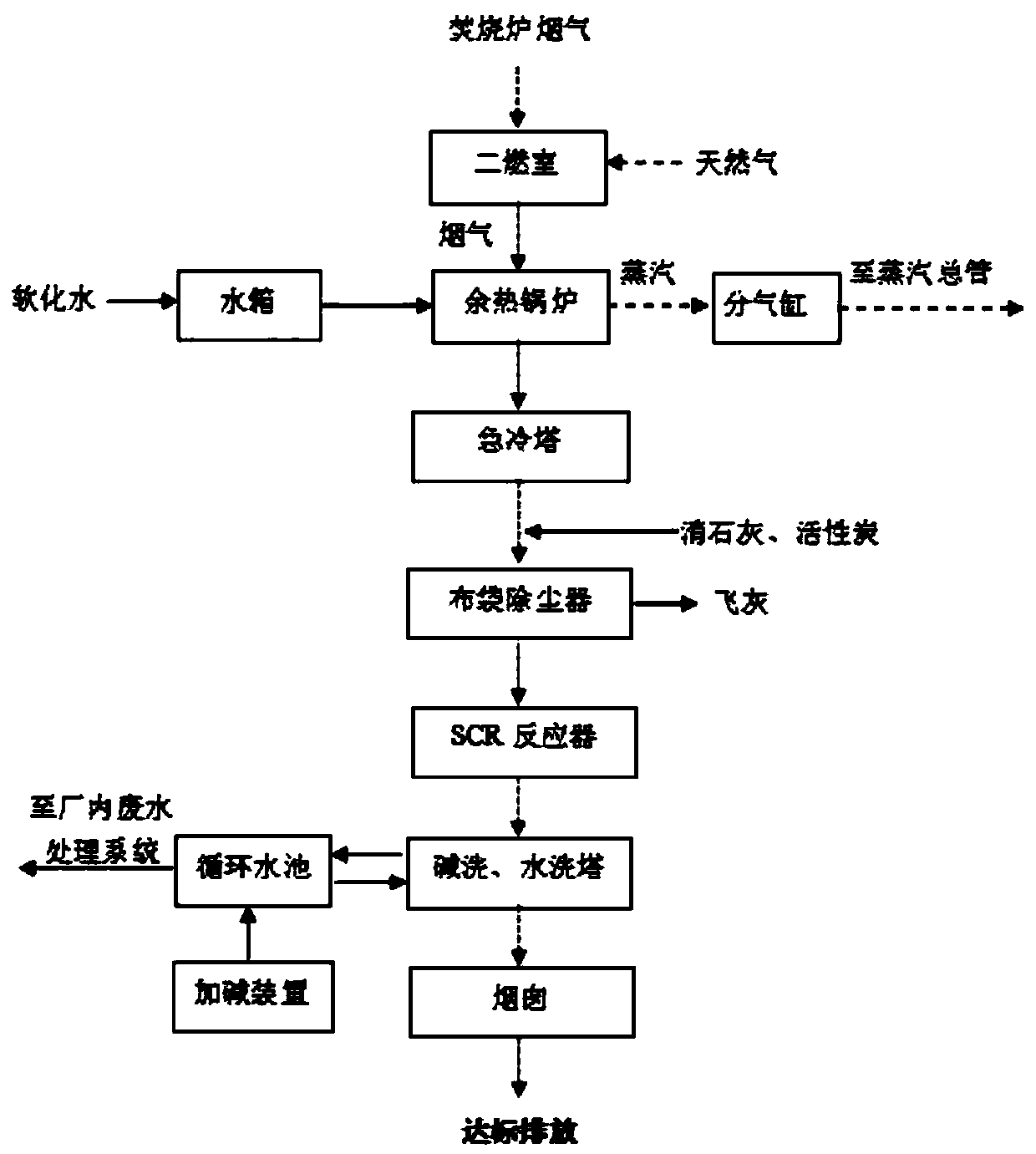

Treatment system for harmless and reduction of solid waste and solid waste treatment method

PendingCN111536520AGood processing effectReduce energy consumptionIncinerator apparatusExhaust gasProcess engineering

The invention belongs to the technical field of solid waste treatment, and relates to harmless and reduction equipment and method, in particular to a treatment system for harmless and reduction of solid waste and a solid waste treatment method. The treatment system comprises a solid waste storage bin and a dryer, a plurality of storage cavities are arranged in the solid waste storage bin, each material storage cavity is used for containing solid waste and sludge, the discharging end of each material storage cavity is in communication with the feeding end of the dryer, the solid waste and the sludge are mixed in the dryer in proportion, the discharging end of the dryer is provided with a tail gas treatment device, a multi-hearth furnace device and a quenching tank, flue gas generated by thedryer is in communication with the tail gas treatment device, waste residues generated by the dryer are in communication with the multi-hearth furnace device, and fly ash generated by the dryer is incommunication with the quenching tank.

Owner:TIANJIN TISUN ITASCA TECH

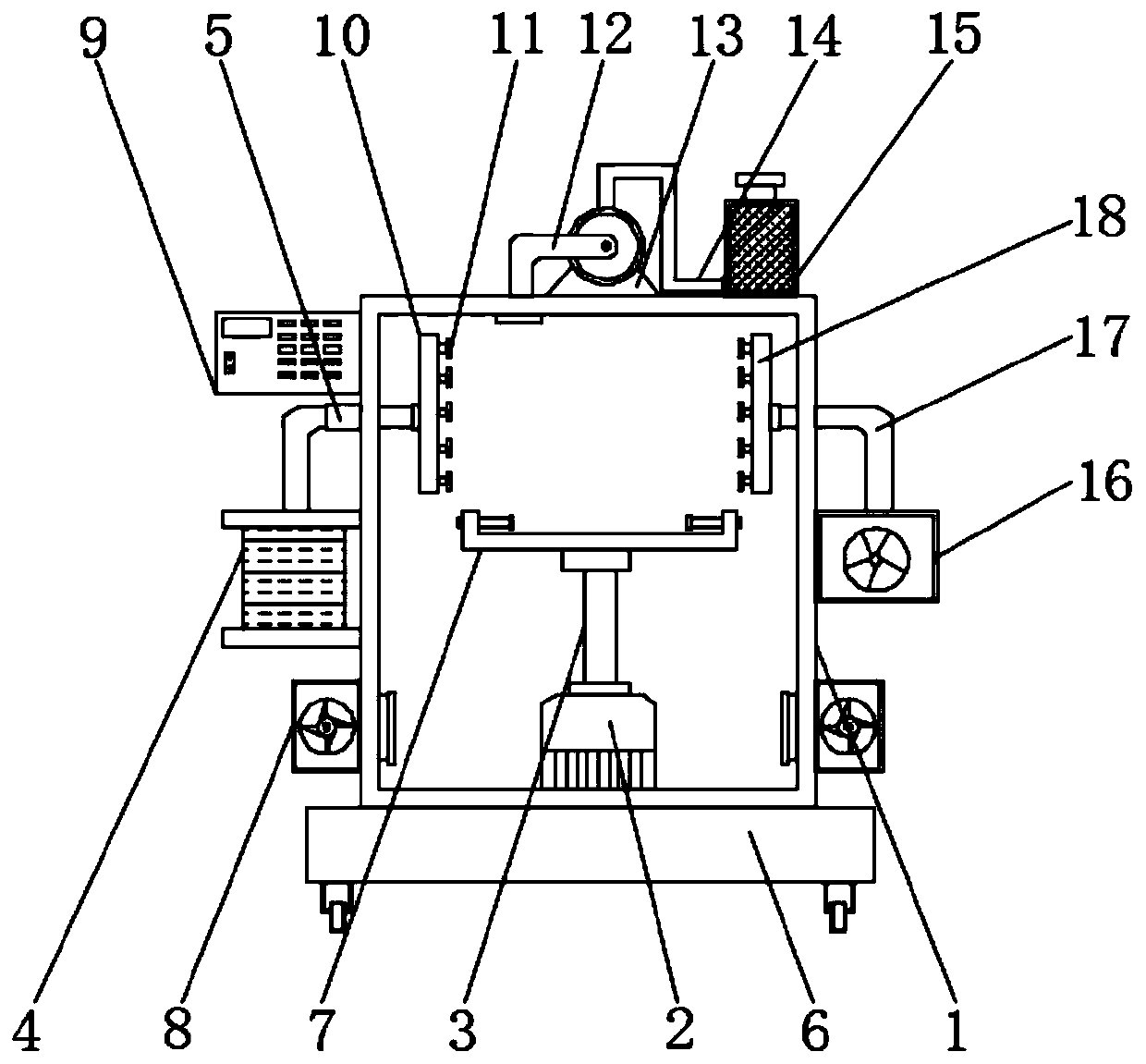

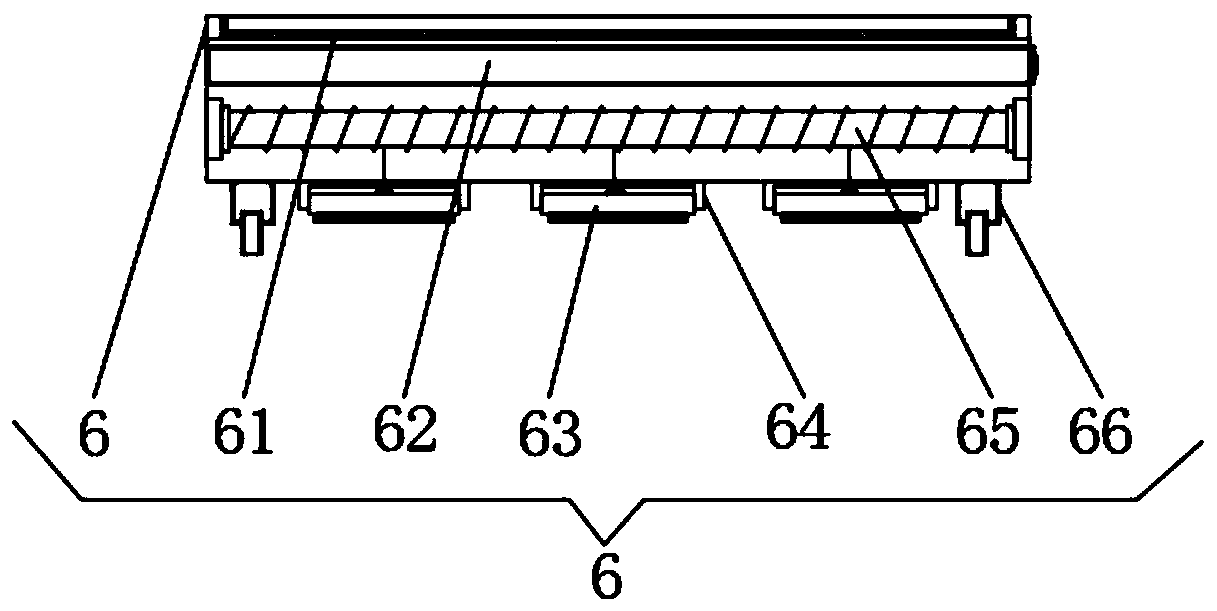

Art design sample coloring, drying and dust removing device

The invention discloses an art design sample coloring, drying and dust removing device. The device comprises a dust removing device main body, wherein the outer surfaces of the two sides of the lowerend of the main body of the dust removing device are each fixedly provided with a fan mechanism; the outer surface of the lower end of the main body of the dust removing device is fixedly provided with a cleaning base; and the inner surface of the central portion of the main body of the dust removing device body is provided with a motor; and the outer surface of the upper end of the motor is provided with a rotating shaft. According to the device, the cleaning of dye in the dust removing device is carried out conveniently by means of the cleaning base, the interior of the dust removing deviceis prevented from being corroded, a certain protective effect is achieved, and convenience is brought to people during use; by the arrangement of a platform mechanism, it is convenient for people to fix the art design sample and color the bottom of the sample, so that the quality of the coloring is ensured, and convenience is brought to people during use; and by the arrangement of the fan mechanisms, the hot air in the dust removing device is circulated more smoothly inside, so that the drying effect is improved and convenience is brought to people during use.

Owner:JIANGSU MARITIME INST

Vacuum vitrescence drying machine

PendingCN106616215AAvoid damageIntegrity guaranteedFood preservationPulp and paper industryRefrigeration

The invention belongs to the field of drying equipment and in particular relates to a vacuum vitrescence drying machine which comprises a material tank, a heating unit, a vacuum unit and a condensation unit, wherein the heating unit comprises a heating plate and a heater, the heating plate is arranged in the material tank and used for accommodating materials, and the heater is arranged outside the material tank and used for providing heat for the heating plate; the vacuum unit comprises a roots pump and a rotary vane pump; the condensation unit comprises a primary cold trap, an auxiliary cold trap and a refrigeration unit which is used for refrigerating the primary cold trap and the auxiliary cold trap; the primary cold trap is arranged between the roots pump and the material tank, and the auxiliary cold trap is arranged between the rotary vane pump and the roots pump; the refrigeration unit comprises refrigeration coils and a refrigeration machine, the refrigeration coils are arranged in the primary cold trap and the auxiliary cold trap, and the refrigeration machine is used for refrigerating the refrigeration coils. The primary cold trap and the auxiliary cold trap can fully response wave crest impact, moisture can be fully gathered, the moisture is prevented from infiltering into a vacuum pump system due to not being gathered, the vacuum maintenance of a whole system is prevented from being affected, and the drying efficiency is prevented from descending.

Owner:李云

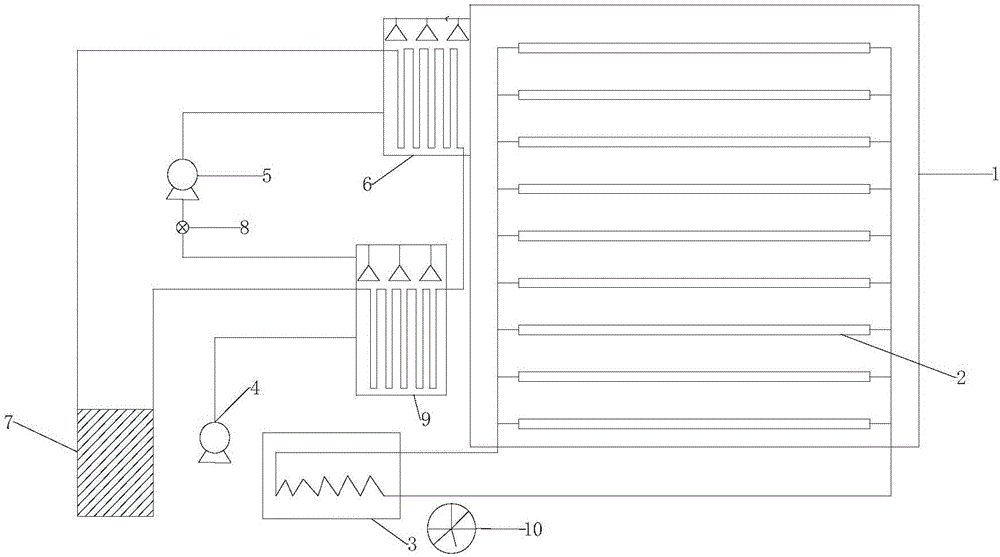

Sludge superheated steam triple-effect combined drying device

InactiveCN102936088ARealize rational utilizationLow drying efficiencySludge treatment by de-watering/drying/thickeningThermodynamicsSludge

The invention relates to a sludge superheated steam triple-effect combined drying device. One end of a first-effect dryer is connected with a steam pipe. The other end of the first-effect dryer is connected with a separation device I through a discharging device. The separation device I is connected to a condenser. The condenser is connected to the first-effect dryer. A material storage device is arranged below the first-effect dryer. The storage device is connected to one end of a feeding and molding device. The other end of the feeding and molding device is connected to a second-effect dryer. A separation device II is connected to the upper part on a side of the second-effect dryer through a steam pipe. A material storage hopper of the second-effect dryer is connected to a third-effect dryer through a pipe. Compared with a traditional hot-air convective drying process, the device provided by the invention has the characteristics that: energy cascade utilization is realized, and energy efficiency is higher than a single-effect drying process. Harmful gas amount of a sludge processing process is greatly reduced, and tail gas processing cost is reduced.

Owner:NANCHANG HANGKONG UNIVERSITY

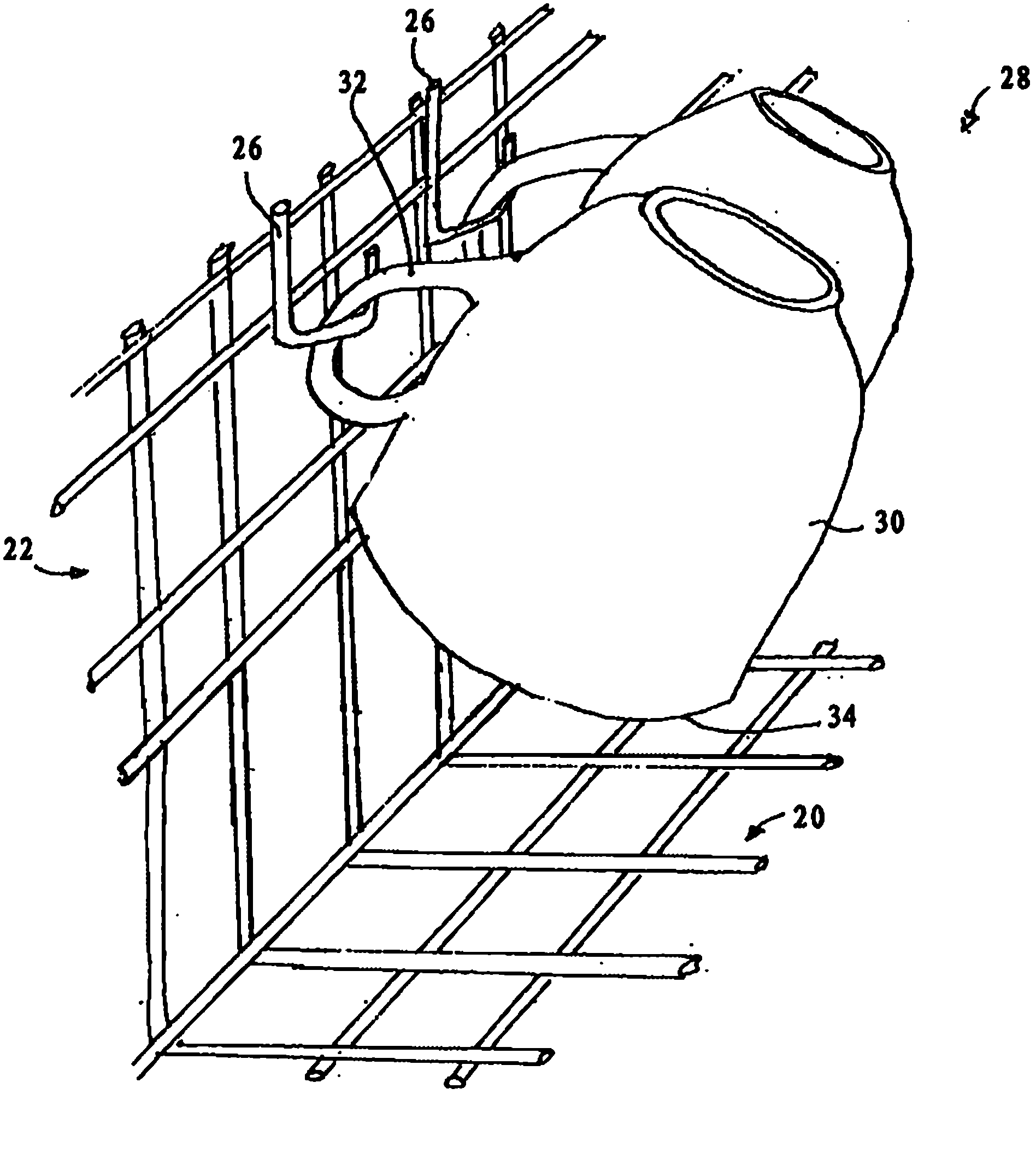

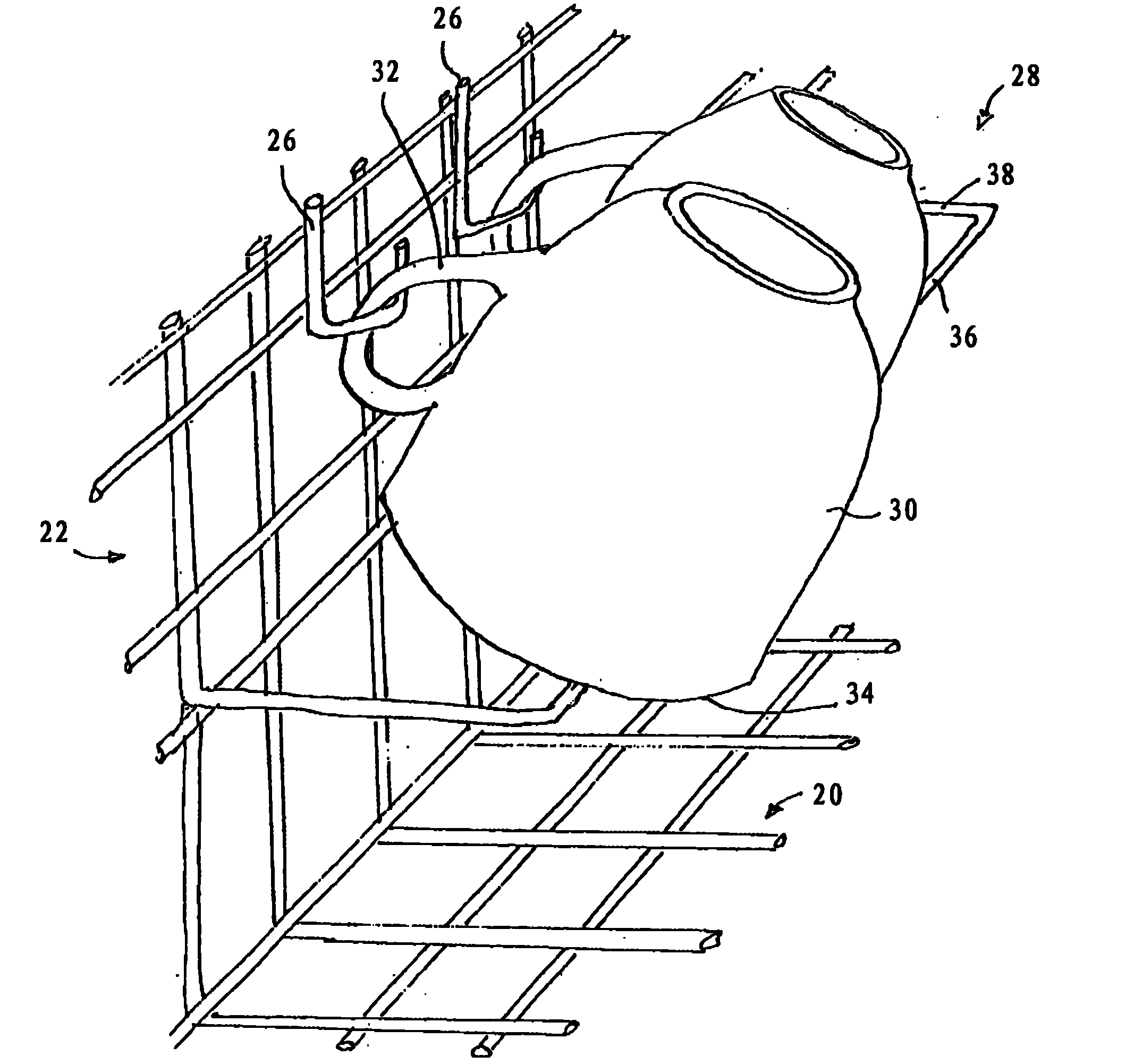

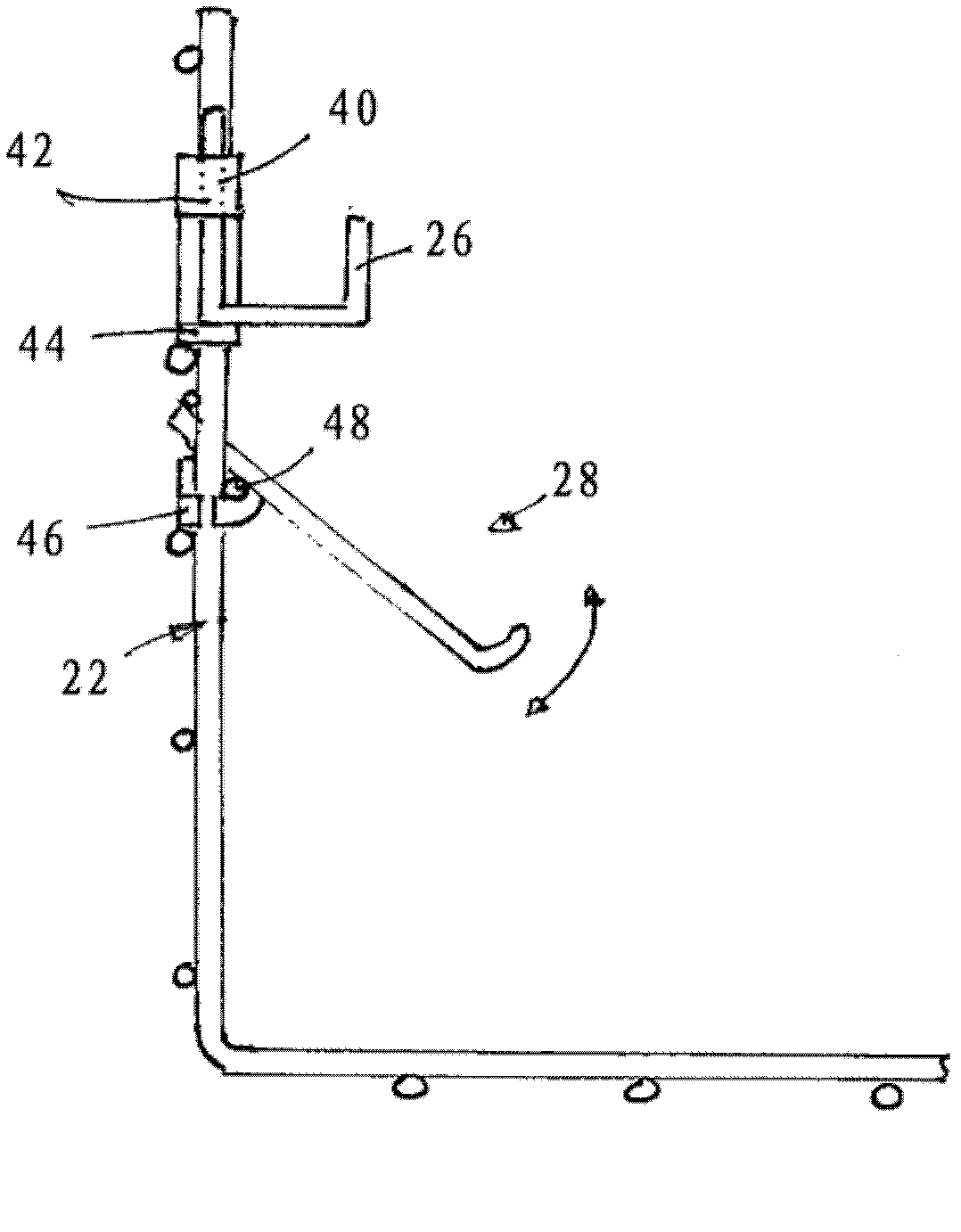

Dishwasher basket with cup support

InactiveCN102227186ALow drying efficiencyStable supportTableware washing/rinsing machine detailsEngineeringClosed loop

The present invention relates to dishwasher basket comprising a cup support, characterized in that said cup support comprises at least one essentially U- shaped hook adapted for supporting a handle of a tableware item that has a handle that is shaped as a closed loop.

Owner:ELECTROLUX HOME PROD CORP NV

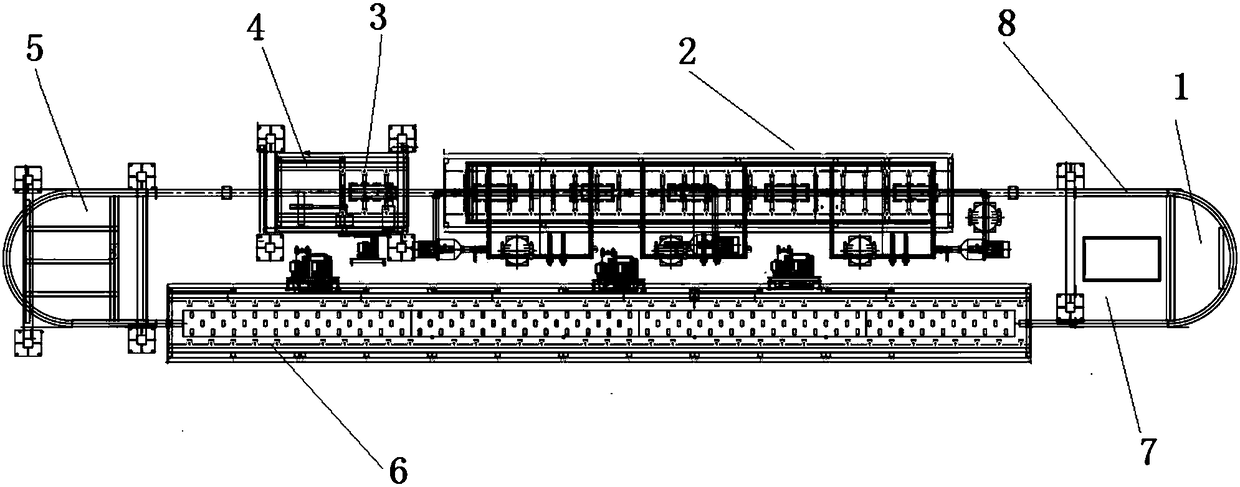

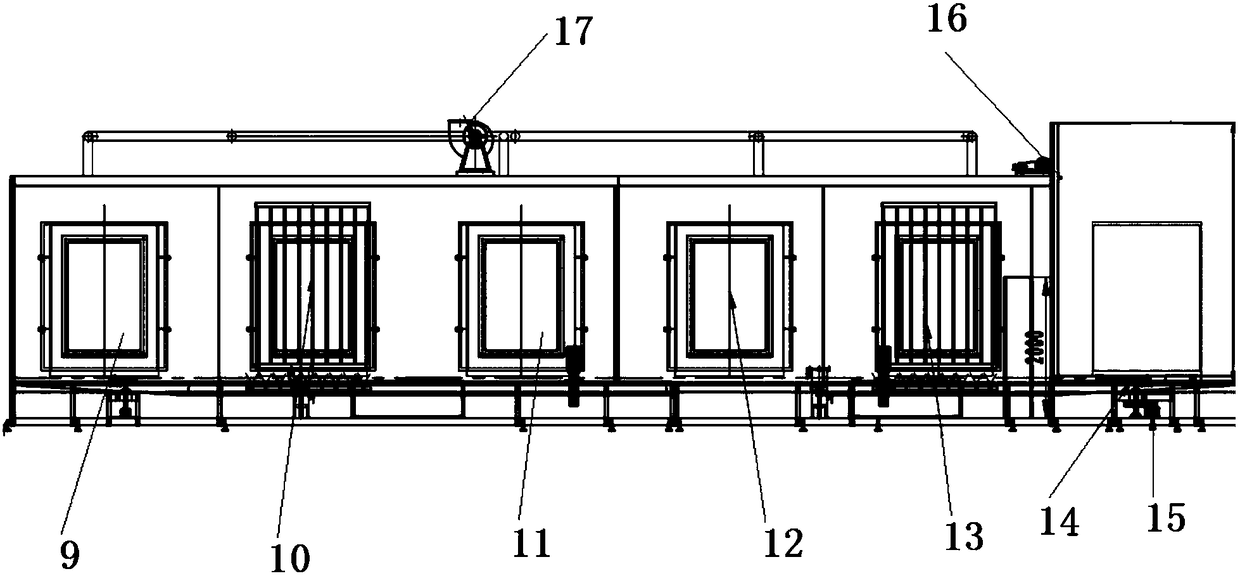

A method for mass cleaning and drying carbon fiber composite parts

ActiveCN106040645BAvoid scratchesEasy to integrateDrying gas arrangementsCleaning using liquidsProduction lineProcess engineering

The invention discloses a method for cleaning and drying carbon fiber composite work-pieces in batches. The method includes the operation steps of feeding, first-time cleaning, liquid dripping at empty positions, spraying and rinsing, liquid dripping at empty positions, wind cutting, manual inspecting, buffering and preheating, hot air drying and cooling and discharging. The technological cleaning requirement of the carbon fiber composite work-pieces is met through the method, and the method is suitable for the automatic cleaning and drying technology of the carbon fiber composite work-pieces. Compared with traditional cleaning machines, the method has the advantages that scratches of the work-pieces caused by washing can be avoided, deformation of the work-pieces caused by drying can be avoided, and the low drying efficiency caused by partial water accumulation of the work-pieces can be avoided; and a production line has the advantages that the integration level is high, the production efficiency is high, operation is safe, maintenance is convenient and fast and the effects of energy conservation and environmental protection are realized.

Owner:康得复合材料有限责任公司

Novel air medium type sludge drying system

PendingCN112661383AScientific and reasonable structureEasy to useSludge treatment by de-watering/drying/thickeningDispersed particle separationSludgeHot blast

The invention discloses a novel air medium type sludge drying system which comprises a sludge drying machine, the bottom end of the sludge drying machine is connected with an air outlet duct, the air outlet duct is connected with an inlet of a cyclone dust collector, the top end of the cyclone dust collector is connected with a circulating air return duct, and the bottom end of the cyclone dust collector is connected with an ash discharge port. The circulating air return duct is connected with the inlet of a circulating fan. The sludge drying system is scientific and reasonable in structure and safe and convenient to use, a closed hot air circulation sludge drying system is adopted, a hot air heating system with electricity or steam as a heat source is high in operation energy consumption, a system with a heat pump as a hot air heating device is complex in structure, a waste gas condensation system generates a large amount of condensed waste water, and the treatment cost is high; in addition, components and flow of the hot air can be changed after the hot air is recycled for a long time, and finally safety of system equipment and stability of a system are affected.

Owner:上海国惠环境科技股份有限公司

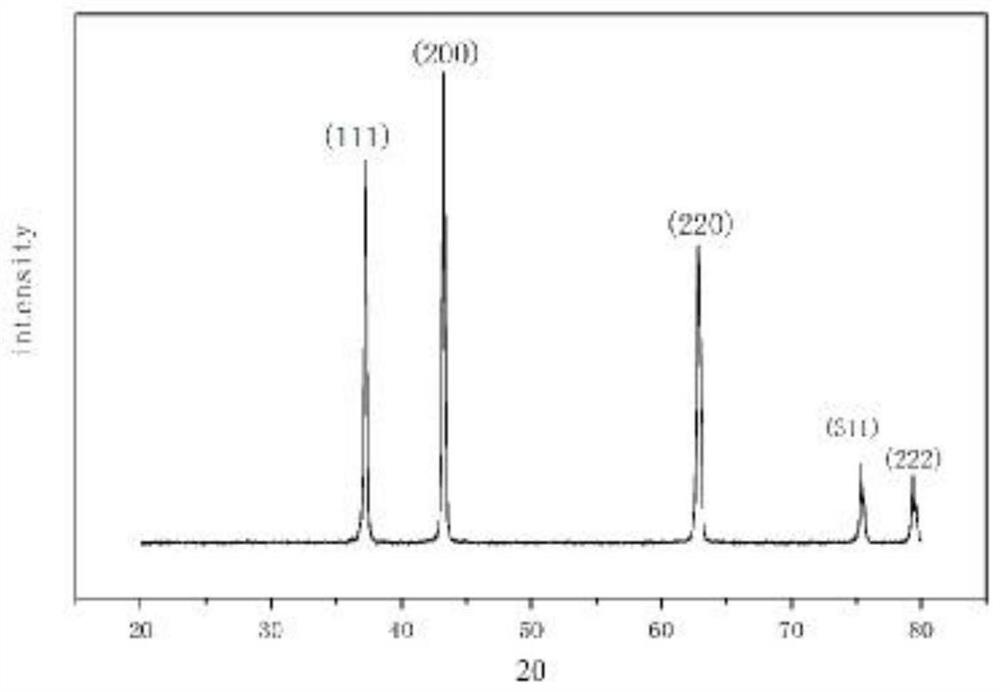

Gel casting preparation method of nickel oxide-based ceramic target material

The invention relates to a gel casting preparation method of a nickel oxide-based ceramic target material. The gel casting preparation method comprises the following steps of A, preparing raw materials, B, preparing a premixed solution, C, preparing high-fluidity slurry, D, preparing a biscuit, E, degumming the biscuit: carrying out gradient heating on the biscuit, and carrying out furnace coolingto obtain a degummed blank, F, sintering: specifically, enabling the blank to be subjected to vacuum gradient sintering with the first gradient temperature of 650-800 DEG C, the temperature rising speed not higher than 1.5 DEG C / min, and the heat preservation time not shorter than 2 hours, heating to a second gradient temperature of 900-1200 DEG C at a heating speed of not higher than 1 DEG C / min, keeping the temperature for not less than 5 hours, cooling and molding, and G, machining, specifically, conducting or not conducting machining according to needs. The preparation method can be usedfor preparing the nickel oxide-based ceramic target material with good conductivity, higher purity and fine grain size, and is simple and convenient to operate and low in cost.

Owner:北京航大微纳科技有限公司

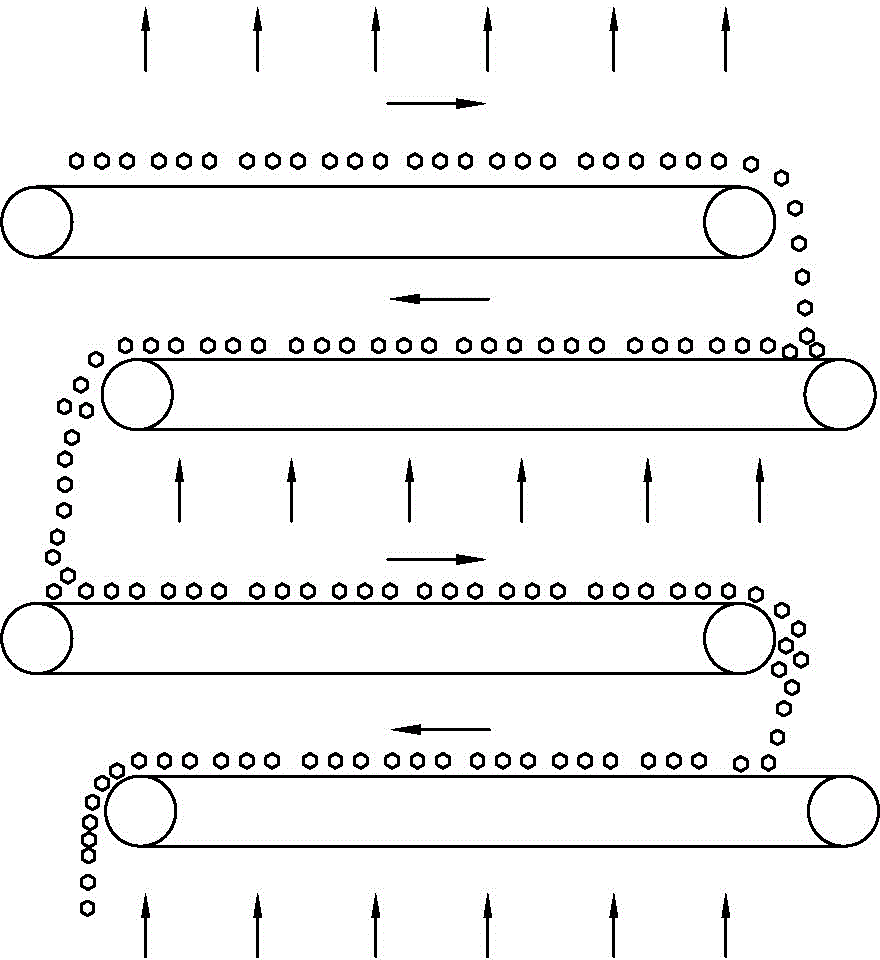

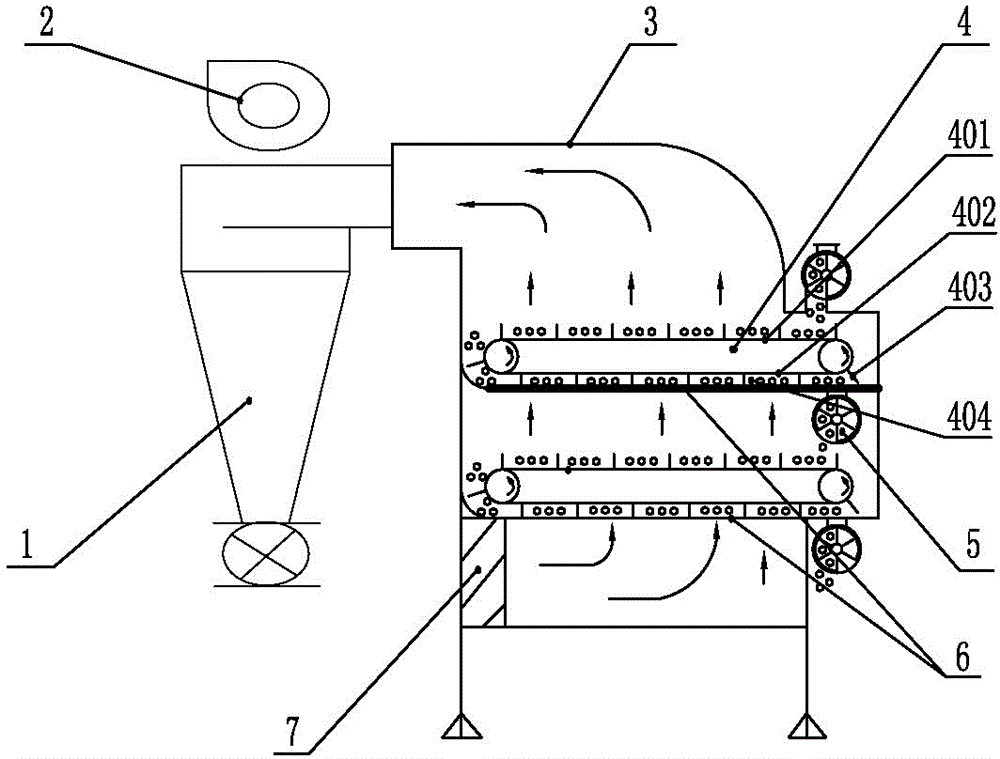

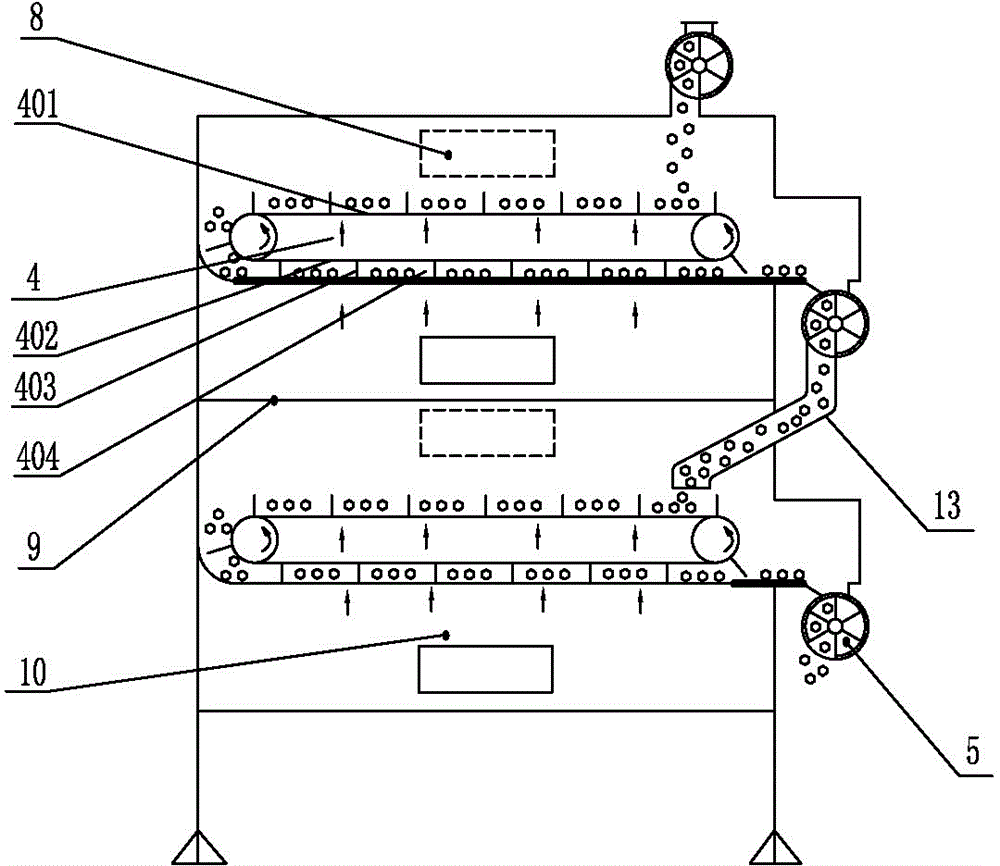

Belt type fluidized drying machine

ActiveCN102679699BDry evenlyPrevent splashDrying solid materials with heatHearth type furnacesEngineeringMechanical engineering

Owner:江苏丰尚烘干设备有限公司

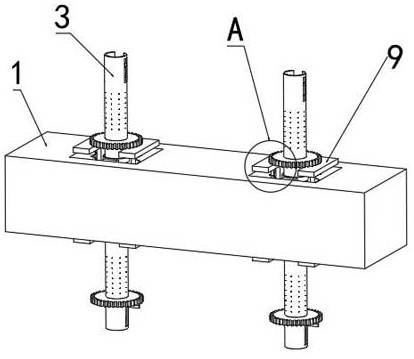

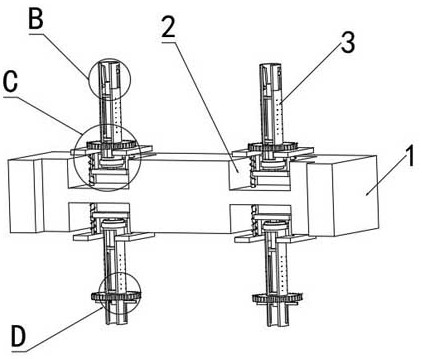

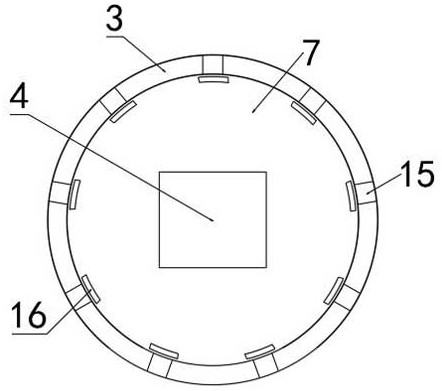

A drying device for mechanical parts with a central hole

ActiveCN113623962BEasy accessPrevent slippingDrying gas arrangementsDrying chambers/containersEngineeringMechanical engineering

The invention discloses a drying device for mechanical parts with a central hole. The limiting rods set by the parts; the blocking mechanism, the blocking mechanisms are multiple groups, and the multiple groups of the blocking mechanisms are respectively used to prevent the mechanical parts from sliding down from the multiple limiting rods under the action of their own gravity; the driving part , the driving part is used to provide a driving force for the pull rod to move vertically in the installation opening. Through the cooperation of the blocking mechanism and the driving part, when the rotating plate is rotating, the parts on the plurality of limit rods on the upper surface of the rotating plate will not slide off from the limiting rods, and the blocking mechanism will not work at this time. It is convenient for the staff to take it, and multiple sets of blocking mechanisms on the multiple limit rods on the lower surface of the turntable will work to prevent the parts from slipping and avoid the cumbersome steps of installing the stopper.

Owner:南通众德机械制造有限公司

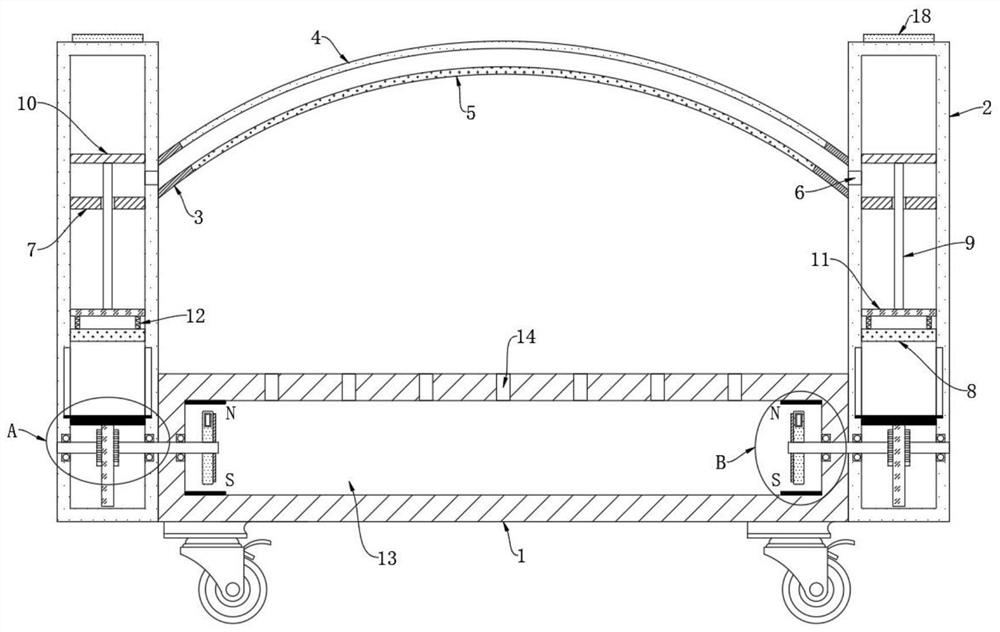

Traditional Chinese medicine airing device based on temperature change and using method thereof

InactiveCN112344678AExtended drying timeImprove drying efficiencyDrying gas arrangementsCastorsThermodynamicsProcess engineering

The invention belongs to the field of traditional Chinese medicine processing, and particularly relates to a traditional Chinese medicine airing device based on temperature change and a using method thereof. The traditional Chinese medicine airing device comprises an airing platform, supports are fixedly connected to the side walls of the two sides of the airing platform, each support is of a hollow structure, and a frame is fixedly connected between the two supports. Planar glass is embedded in the upper side wall of the frame. The temperature change of sunlight in one day can be utilized, sothat the magnetism of an electromagnetic block can be changed according to the temperature, strong sunlight at noon can softly irradiate Chinese wolfberry, the airing time of the Chinese wolfberry isgreatly prolonged, the drying efficiency is improved, the labor loss caused by manually carrying the Chinese wolfberry back and forth is avoided, through cooperation of a transmission device and fanblades arranged on the traditional Chinese medicine airing device, hot air with a certain temperature can slowly act on the back face of the Chinese wolfberry through vent holes, and the drying efficiency of the Chinese wolfberry is greatly improved.

Owner:胡娜

Method for drying Hami melon slices by nitrogen source low oxygen heat pump

InactiveCN103416475BExtended storage timeLess nutrient lossFood processingFruits/vegetable preservation by heatingQuinoneVitamin C

The invention belongs to the field of agricultural product drying, and particularly relates to a method for drying Hami melon slices by a nitrogen source low oxygen heat pump. The method comprises the steps of selecting Hami melons, removing peels and pulp of the Hami melons, conducting slicing, conducting color protection and type fixing, blanching, draining, conducting drying in a nitrogen source heat pump drying machine, and conducting drying, sealing and storing in a vacuum drying box. According to the method, the drying energy consumption is reduced, the drying efficiency is improved, the defects that in the drying later stage, the heat pump is low in drying efficiency and long in time required by drying are overcome, heat pump drying and vacuum low-temperature drying are carried out after color protection and blanching treatment, and therefore the problems that the brightness of the Hami melon slices is reduced, and the color is changed are solved. According to the method, phenolic substances in the Hami melon slices can be restrained from being oxidized to generate quinone, the oxidation loss of vitamin C is reduced, damage, caused by oxidation in the drying process, to the color and texture of the Hami melon slices can be avoided, and dried products with the natural color are obtained.

Owner:HENAN UNIV OF SCI & TECH

Method for drying inorganic fine-grained sludge and movable drying system

ActiveCN104150739AEfficient water removalSimplified drying methodSludge treatment by de-watering/drying/thickeningSludgeEngineering

The invention discloses a method for drying inorganic fine-grained sludge and a movable drying device. The selective absorption characteristic of microwaves is utilized, the microwaves are taken as a main drying measure rather than an auxiliary measure, and the method provided by the invention does not need to be specific to specific kinds of inorganic fine-grained sludge. Efficient dehydration is realized, and the highest dehydrating efficiency can be up to 1.6kg of water / kWh; the conventional method which combines a plurality of measures with a microwave technology is simplified, the production cost is lowered, and the benefit is increased; heat can be effectively utilized circularly by arranging a heat exchanger, and the cyclic utilization ratio of energy is increased; and compared with the prior art, the designed equipment has the advantages of small size, can be moved on a vehicle, facilitates sludge drying at any place, and is convenient and flexibile.

Owner:华东理工常熟研究院有限公司

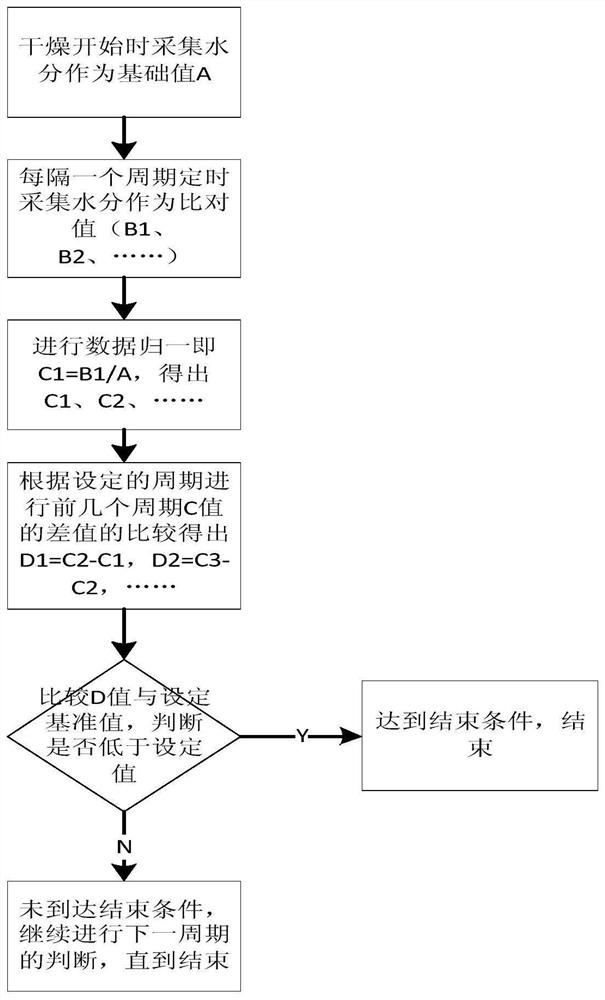

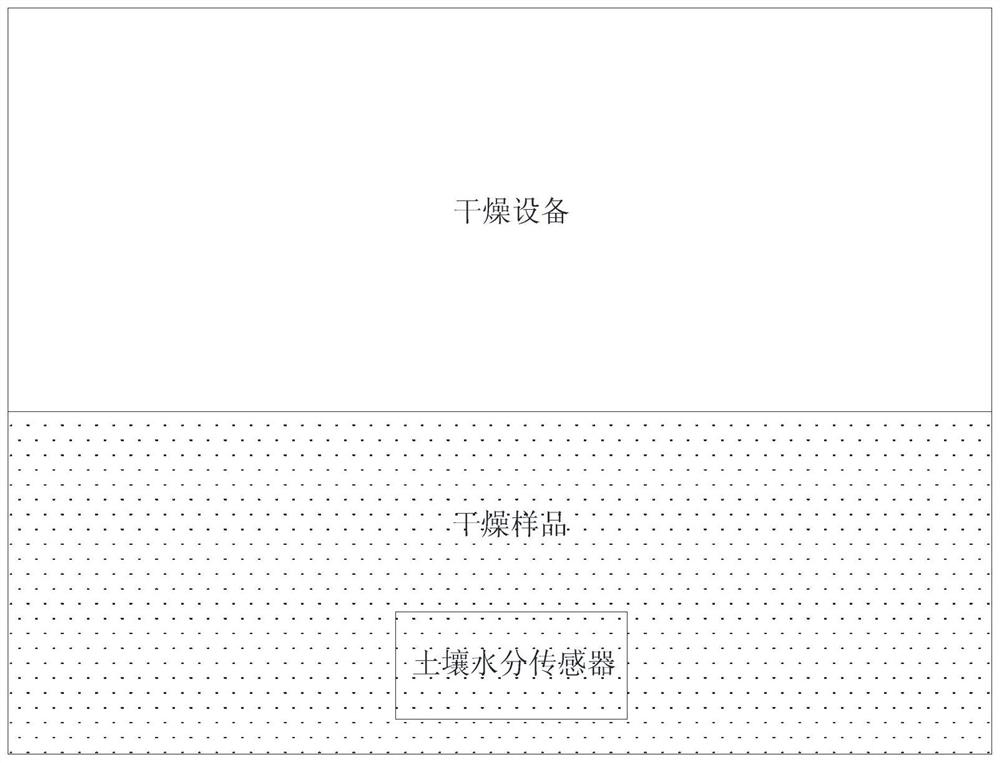

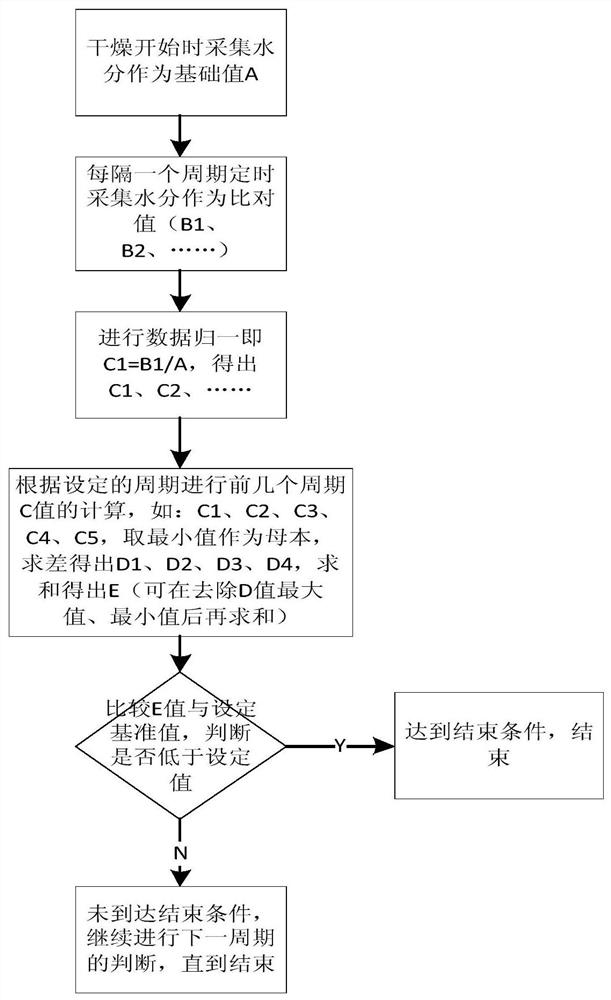

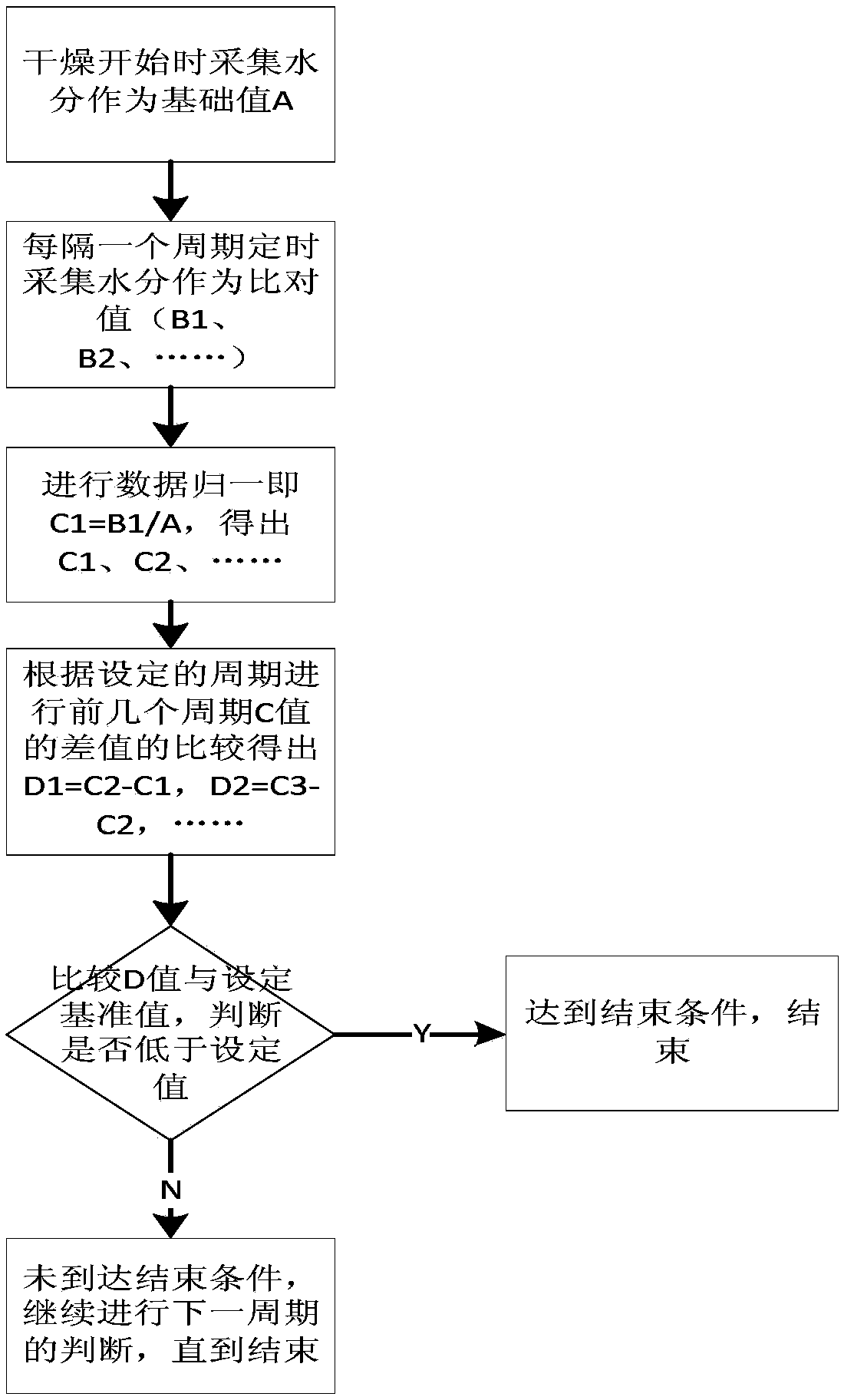

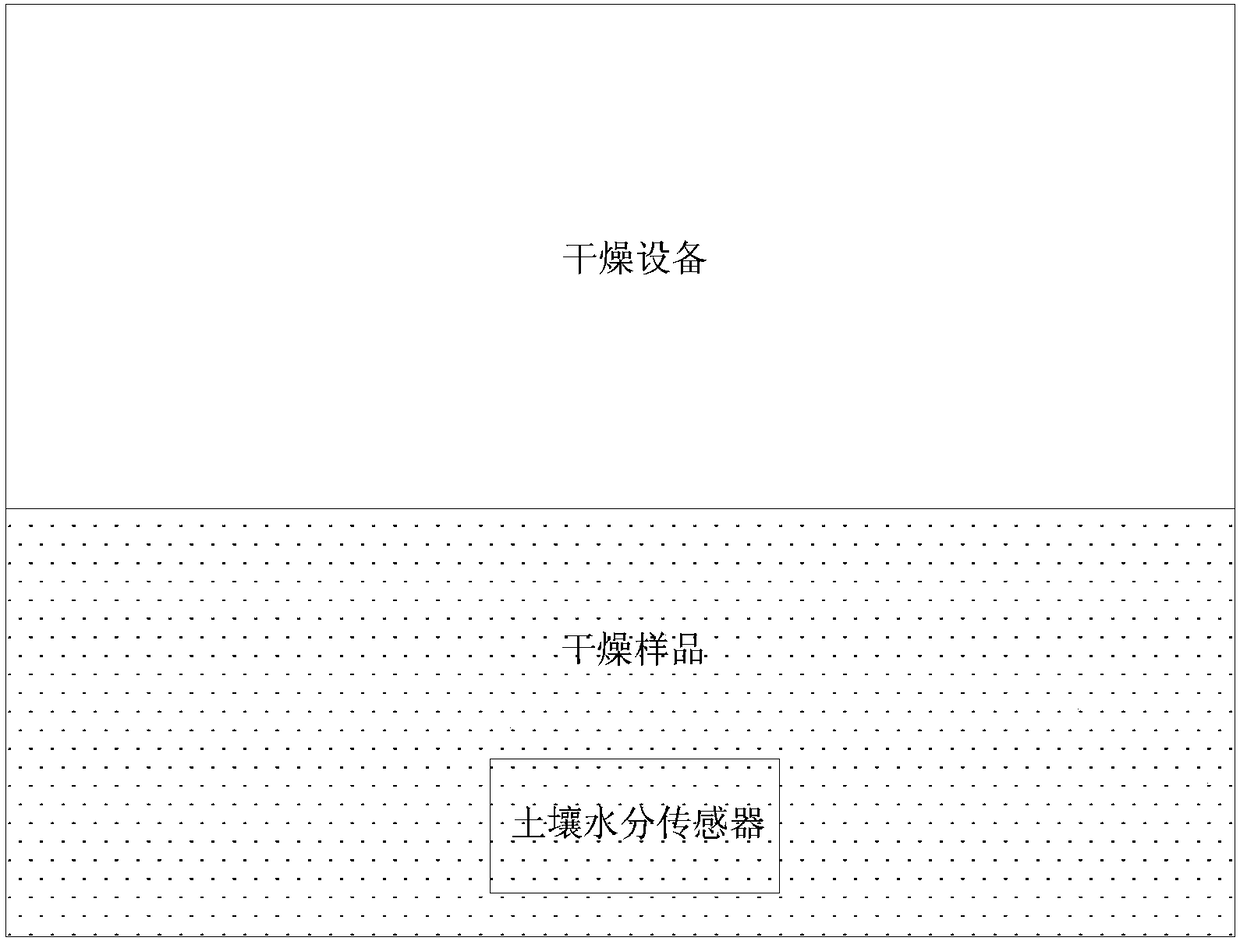

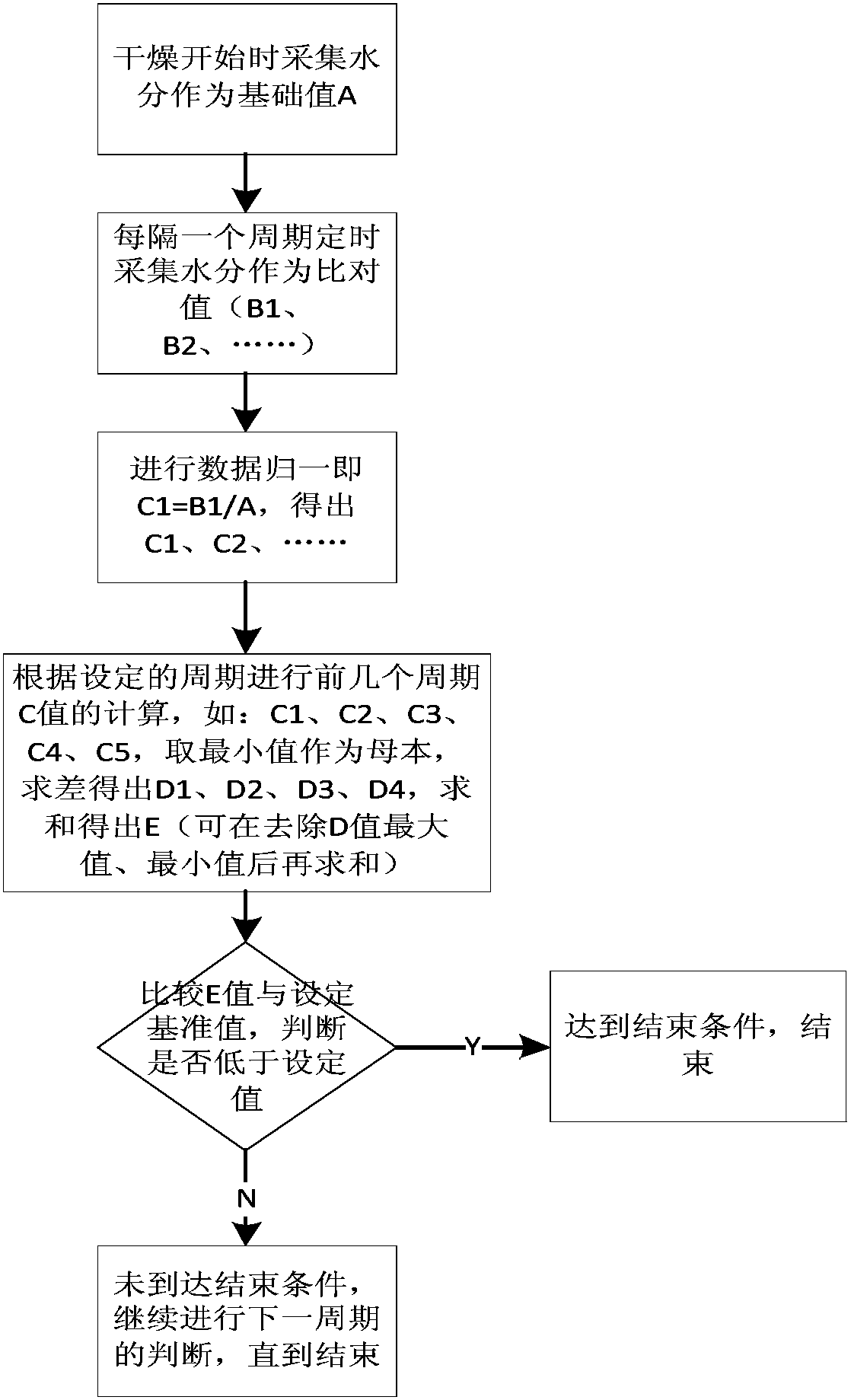

A coal sample drying end condition method based on soil moisture sensor

ActiveCN108241047BIncrease efficiency in the drying processImprove representationPreparing sample for investigationFuel testingSoil scienceSoil moisture sensor

The invention discloses a soil moisture sensor based coal sample drying end condition method, comprising the following steps: S1: collecting moisture data of a coal sample in the drying process by using a soil moisture sensor; S2: performing data normalizing operation on the moisture data obtained in step S1; that is, a ratio C is obtained by dividing an initial measurement basis value A from a measurement value B of each cycle; S3: performing deviation calculation; a change rate D of gradient is obtained by deviation calculation of adjacent cycle C values, and whether a drying condition is reached is judged by comparison between the difference value, that is, the change rate D of the gradient, and a standard value; if reaching the end condition ending; and if not reaching the end condition, continuing judgment of the next cycle until ending. The method has the advantages of being simple in principle, easy to realize, and capable of automatically judging drying end condition and ending, and meeting the requirement of subsequent links.

Owner:HUNAN SUNDY SCI & TECH DEV

Soil moisture sensor based coal sample drying end condition method

ActiveCN108241047AIncrease efficiency in the drying processImprove representationPreparing sample for investigationFuel testingSoil scienceSoil moisture sensor

The invention discloses a soil moisture sensor based coal sample drying end condition method, comprising the following steps: S1: collecting moisture data of a coal sample in the drying process by using a soil moisture sensor; S2: performing data normalizing operation on the moisture data obtained in step S1; that is, a ratio C is obtained by dividing an initial measurement basis value A from a measurement value B of each cycle; S3: performing deviation calculation; a change rate D of gradient is obtained by deviation calculation of adjacent cycle C values, and whether a drying condition is reached is judged by comparison between the difference value, that is, the change rate D of the gradient, and a standard value; if reaching the end condition ending; and if not reaching the end condition, continuing judgment of the next cycle until ending. The method has the advantages of being simple in principle, easy to realize, and capable of automatically judging drying end condition and ending, and meeting the requirement of subsequent links.

Owner:HUNAN SUNDY SCI & TECH DEV

A drying method and mobile drying system for inorganic fine-grained sludge

ActiveCN104150739BEfficient water removalSimplified drying methodSludge treatment by de-watering/drying/thickeningSludgeEngineering

The invention discloses a method for drying inorganic fine-grained sludge and a movable drying device. The selective absorption characteristic of microwaves is utilized, the microwaves are taken as a main drying measure rather than an auxiliary measure, and the method provided by the invention does not need to be specific to specific kinds of inorganic fine-grained sludge. Efficient dehydration is realized, and the highest dehydrating efficiency can be up to 1.6kg of water / kWh; the conventional method which combines a plurality of measures with a microwave technology is simplified, the production cost is lowered, and the benefit is increased; heat can be effectively utilized circularly by arranging a heat exchanger, and the cyclic utilization ratio of energy is increased; and compared with the prior art, the designed equipment has the advantages of small size, can be moved on a vehicle, facilitates sludge drying at any place, and is convenient and flexibile.

Owner:华东理工常熟研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com