A coal sample drying end condition method based on soil moisture sensor

A soil moisture and end condition technology, applied in instruments, scientific instruments, analytical materials, etc., can solve problems such as unfavorable automated sample preparation, unfavorable crushing or pulverizing, affecting overall performance, etc., to achieve a wide range of sample adaptation and easy stable operation. , the effect of long drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

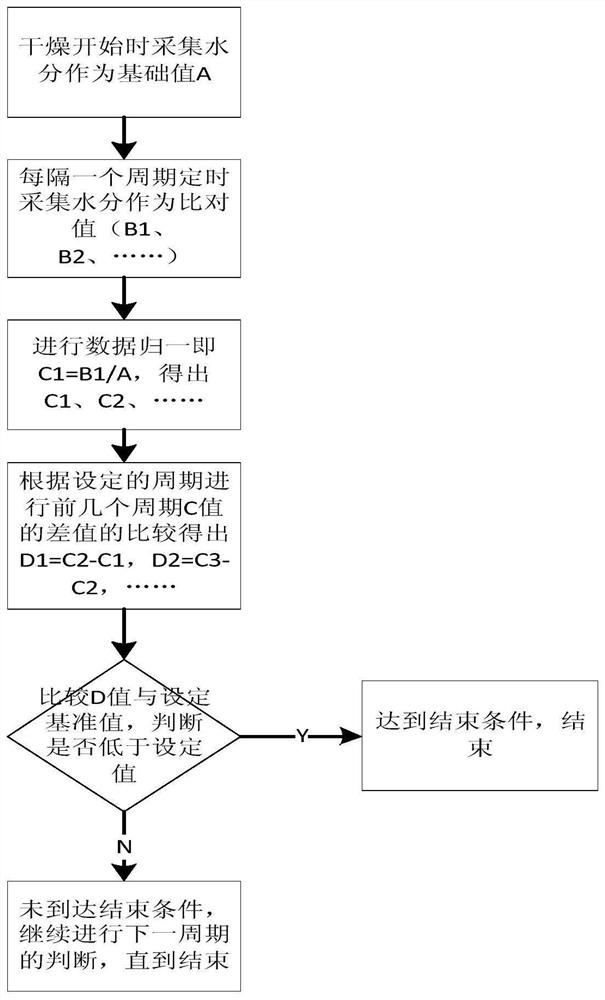

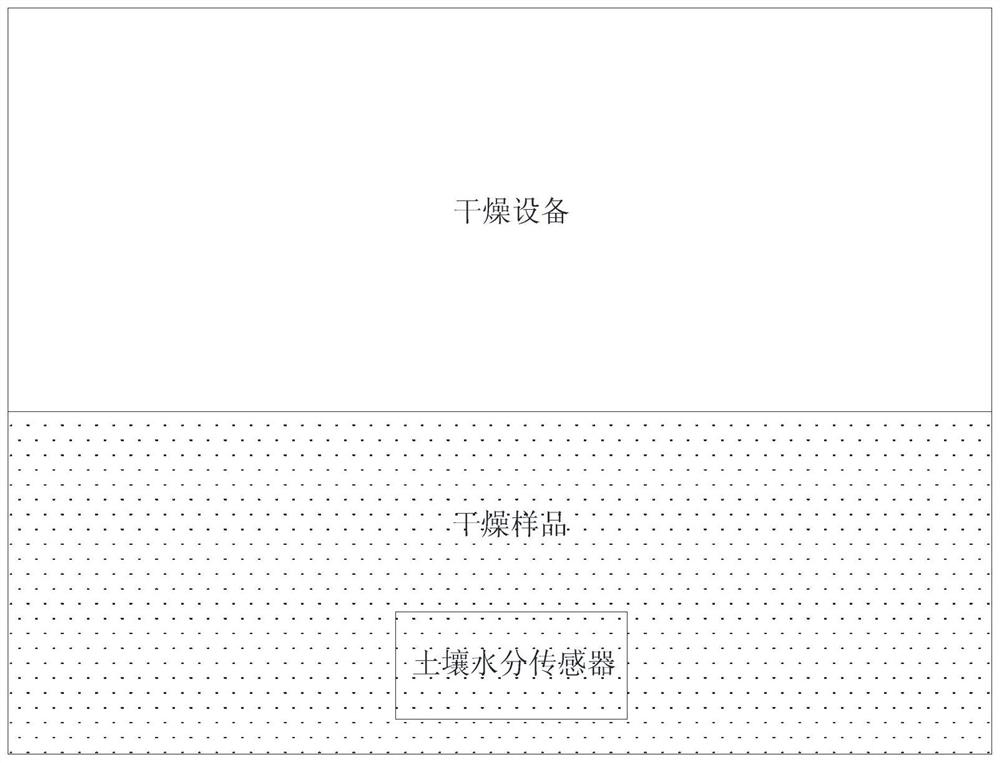

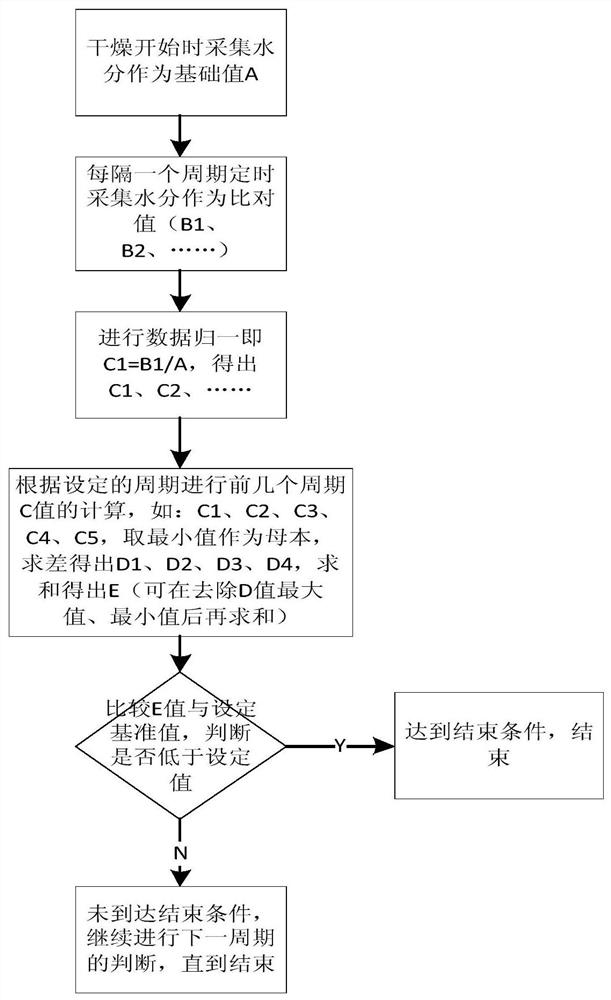

[0024] Such as figure 1 and figure 2 Shown, a kind of coal sample drying end condition method based on soil moisture sensor of the present invention, its steps are:

[0025] S1: Put the soil moisture sensor in the dry sample of the coal sample, and collect the moisture and temperature data of the coal sample during the drying process; the soil moisture sensor uses the FDR or TDR principle to measure the moisture accurately, and has the characteristics of high stability. The biggest advantage is that it can quickly and accurately feed back the change of material moisture, and can achieve a refresh frequency of 1S each time, which is accurate and efficient. The judgment of the end of the condition in the present invention is designed based on the stability of the collected data, if the moisture stability is not high, it is very easy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com