High protein feed prepared by using waste yeast mud and its method

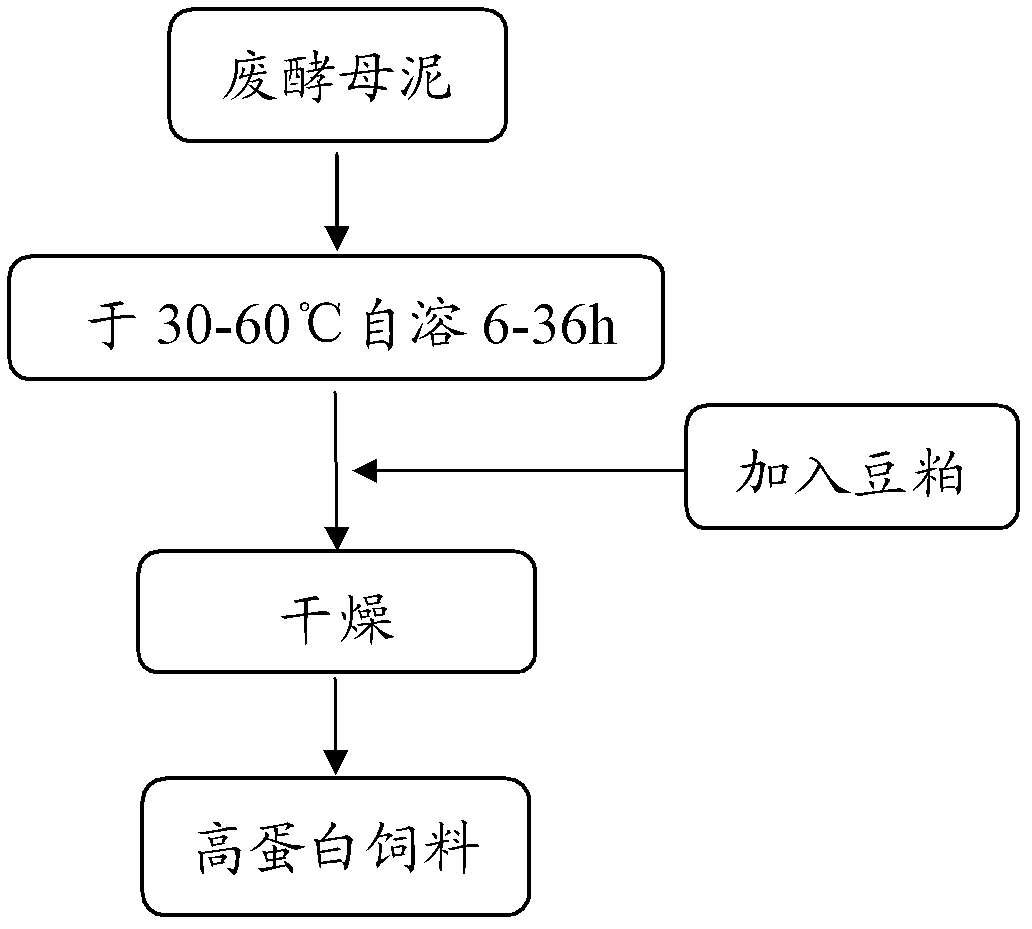

A technology for high-protein feed and waste yeast mud is applied in the field of product waste recycling, which can solve the problems of poor drying effect, long drying time, and difficulty in crushing, and achieves improved leached protein content, high protein content, and high drying efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

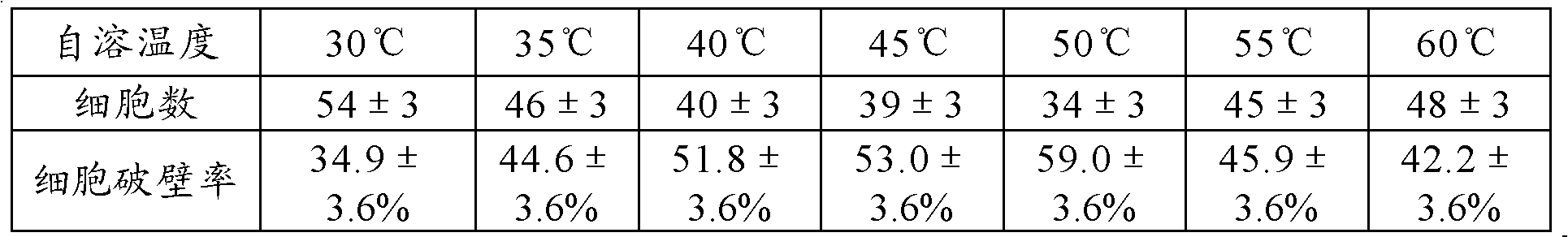

[0028] Example 1 Effect of different water additions, autolysis temperature, and autolysis time on the cell wall breaking rate of waste yeast sludge autolysis

[0029] Take the waste yeast producing β-mannanase for feeding, add appropriate amount of distilled water, mix well, and autolyze at a certain temperature for a period of time; after taking it out, dilute it to a certain multiple, observe it with a hemocytometer under a microscope, and calculate the individual yeast cells Count and calculate the cell wall breaking rate.

[0030] Wherein, cell wall breaking rate (%)=number of yeast cells after autolysis / number of yeast cells before autolysis×100%; the experimental data are the average values of three parallel experiments for each group of samples.

[0031] Design different water addition, autolysis temperature, and autolysis time, and find the optimal condition range for waste yeast sludge autolysis through single factor test. The test design and test results are shown...

Embodiment 2

[0039] Embodiment 2 Response surface analysis method establishes optimum autolysis condition

[0040] Based on the test results obtained in Example 1, a response surface test was designed. According to the Box-Benhnken central combination experiment design principle, select the factor interval that has a greater influence on the autolysis of waste yeast slime. The autolysis time, autolysis temperature and water addition are represented by A, B and C respectively. Each independent variable is represented by The three levels of low, medium and high are coded with -1, 0 and 1 respectively. The three levels selected for autolysis time (A) are: 18h, 24h and 30h; the three levels selected for autolysis temperature (B) are 45°C, 50°C and 55°C; the three levels selected for the water addition (C) are 0%, 50% and 100%, see Table 4.

[0041] Table 4 Experimental factor levels and coding

[0042]

[0043] After the design is completed, carry out the test grouping, use BBX software t...

Embodiment 3

[0050] Example 3 Verification experiment of Kjeldahl method on optimal autolysis conditions of waste yeast sludge

[0051] Take the waste yeast sludge left after fermenting β-mannanase for feeding, put it in a 50ml centrifuge tube, add 50% distilled water, shake evenly, put it at 50°C for 24 hours; take it out and digest it, and use The automatic Kjeldahl azotometer measures the protein content in the supernatant, and the test result is: the mass fraction of the dissolved protein accounting for the dry matter of the yeast slime is 12.3%, which is close to the theoretical value 13.7% obtained in Example 2, thus proving The optimization results are real and effective.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com