Scratch-resistant and folding-resistant transferring film, production process, and application thereof

A production process and transfer film technology, applied in the field of transfer film, can solve the problem that the transfer coating cannot meet the bending requirements of packaging paper, and achieve the effects of reducing white pollution, improving tensile properties and improving folding resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

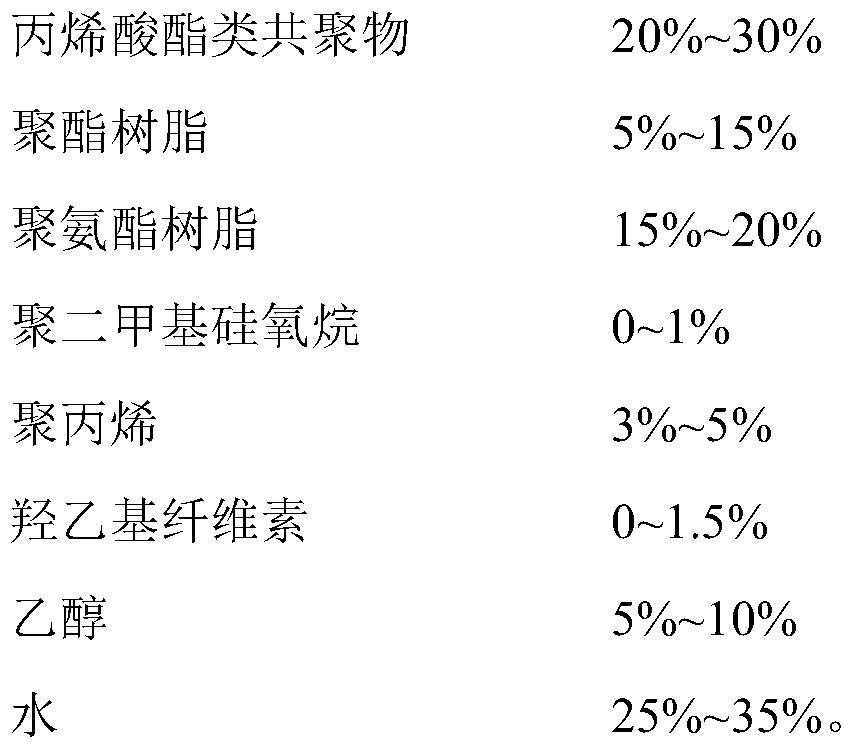

[0035] A scratch-resistant and fold-resistant transfer film, comprising a PET base film and a transfer coating coated on the PET base film, the transfer coating consists of the following components by weight percentage:

[0036]

[0037]

[0038] The production process of the above-mentioned scratch-resistant and fold-resistant transfer film comprises the following steps:

[0039] The first step, preparation of transfer coating paint

[0040] Step 1. Preparation of coating A: Weighing the acrylate copolymer and polyester resin of the formulation amount respectively, and mixing them uniformly to obtain coating A;

[0041] Step 2. Prepare coating B: add ethanol and water in a formula amount to the coating A prepared in step 1, and stir at a speed of 3000 rpm / min for 1 hour to obtain coating B;

[0042] Step 3, preparing coating C: adding a formula amount of polyurethane resin to the coating B prepared in step 2, and stirring at a speed of 3000rpm / min for 0.7h to obtain co...

Embodiment 2

[0049] A scratch-resistant and fold-resistant transfer film, comprising a PET base film and a transfer coating coated on the PET base film, the transfer coating consists of the following components by weight percentage:

[0050]

[0051]

[0052] The production process of the above-mentioned scratch-resistant and fold-resistant transfer film comprises the following steps:

[0053] The first step, preparation of transfer coating paint

[0054] Step 1. Preparation of coating A: Weighing the acrylate copolymer and polyester resin of the formulation amount respectively, and mixing them uniformly to obtain coating A;

[0055] Step 2. Prepare coating B: add ethanol and water in a formula amount to the coating A prepared in step 1, and stir at a speed of 2500rpm / min for 1.5h to obtain coating B;

[0056]Step 3, preparing coating C: adding a formula amount of polyurethane resin to the coating B prepared in step 2, and stirring at a speed of 2500 rpm / min for 1 hour to obtain coa...

Embodiment 3

[0062] A scratch-resistant and fold-resistant transfer film, comprising a PET base film and a transfer coating coated on the PET base film, the transfer coating consists of the following components by weight percentage:

[0063]

[0064] The production process of the above-mentioned scratch-resistant and fold-resistant transfer film comprises the following steps:

[0065] The first step, preparation of transfer coating paint

[0066] Step 1. Preparation of coating A: Weighing the acrylate copolymer and polyester resin of the formulation amount respectively, and mixing them uniformly to obtain coating A;

[0067] Step 2. Prepare coating B: add ethanol and water in a formula amount to the coating A prepared in step 1, and stir at a speed of 3500rpm / min for 0.5h to obtain coating B;

[0068] Step 3, preparing coating C: adding a formula amount of polyurethane resin to the coating B prepared in step 2, and stirring at a speed of 3500rpm / min for 0.5h to obtain coating C;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com