Patents

Literature

167results about How to "Low cleanliness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

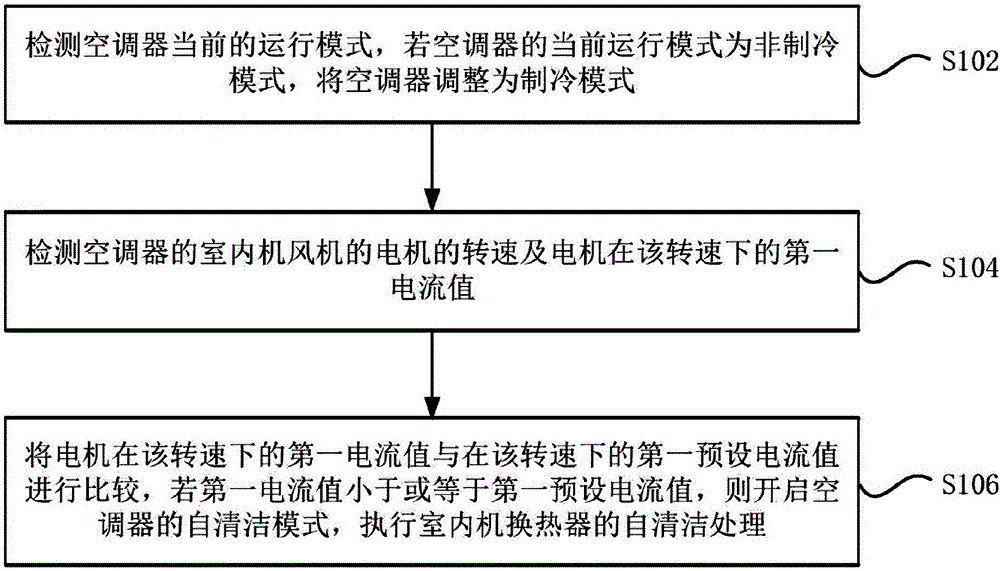

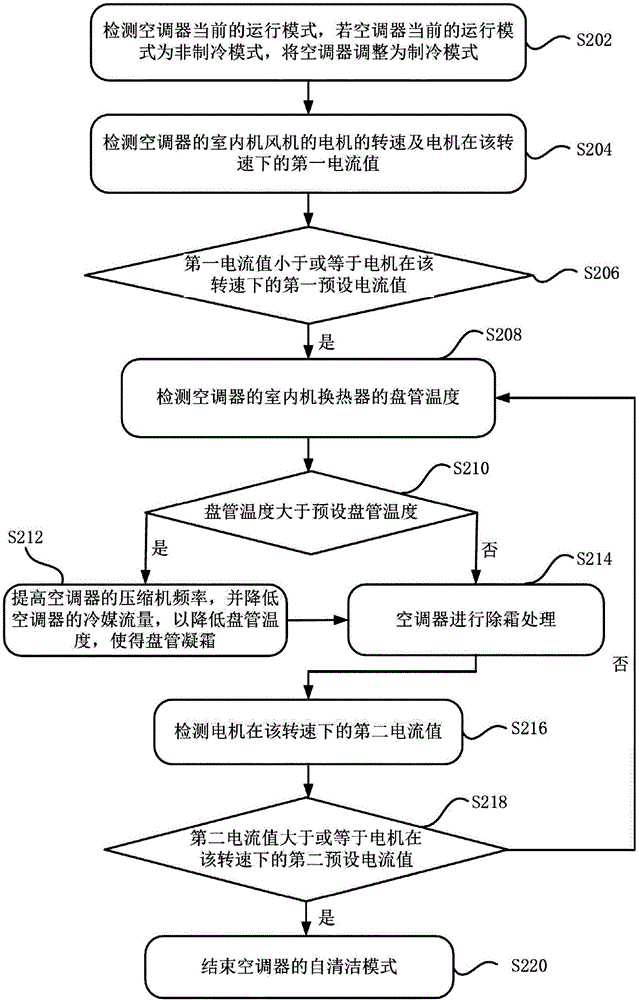

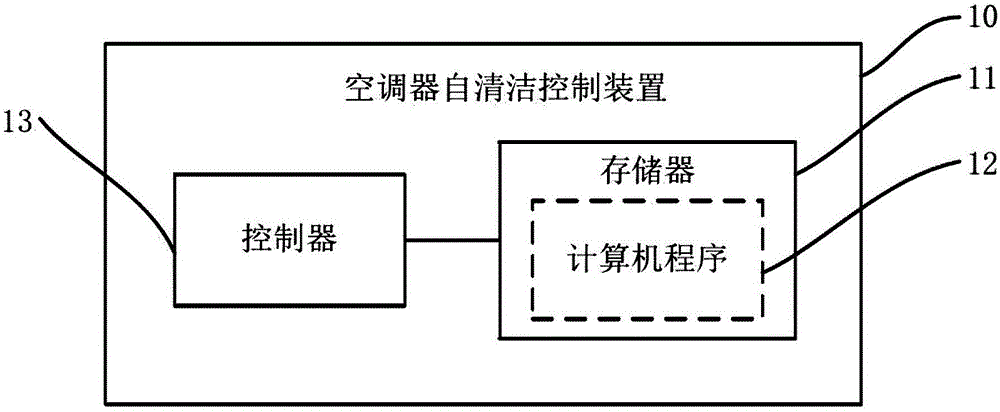

Self-cleaning control method and device for air conditioner

InactiveCN107525209AHigh precisionImprove user experienceSpace heating and ventilation safety systemsLighting and heating apparatusElectric machineOperation mode

The invention provides a self-cleaning control method and device for an air conditioner. The self-cleaning control method comprises the steps that the current operation mode of the air conditioner is detected, and if the current operation mode of the air conditioner is a non-refrigerating mode, the air conditioner is adjusted to be in a refrigerating mode; the rotating speed of a motor of a fan of an indoor unit of the air conditioner and the first current value of the motor under the rotating speed are detected; and the first current value of the motor under the rotating speed is compared with a first preset current value of the motor under the rotating speed, if the first current value is smaller or equal to the first preset current value, a self-cleaning mode of the air conditioner is started, and self-cleaning treatment of a heat exchanger of the indoor unit is carried out. The air conditioner can start the self-cleaning function automatically, and the self-cleaning effect of the air conditioner is promoted.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

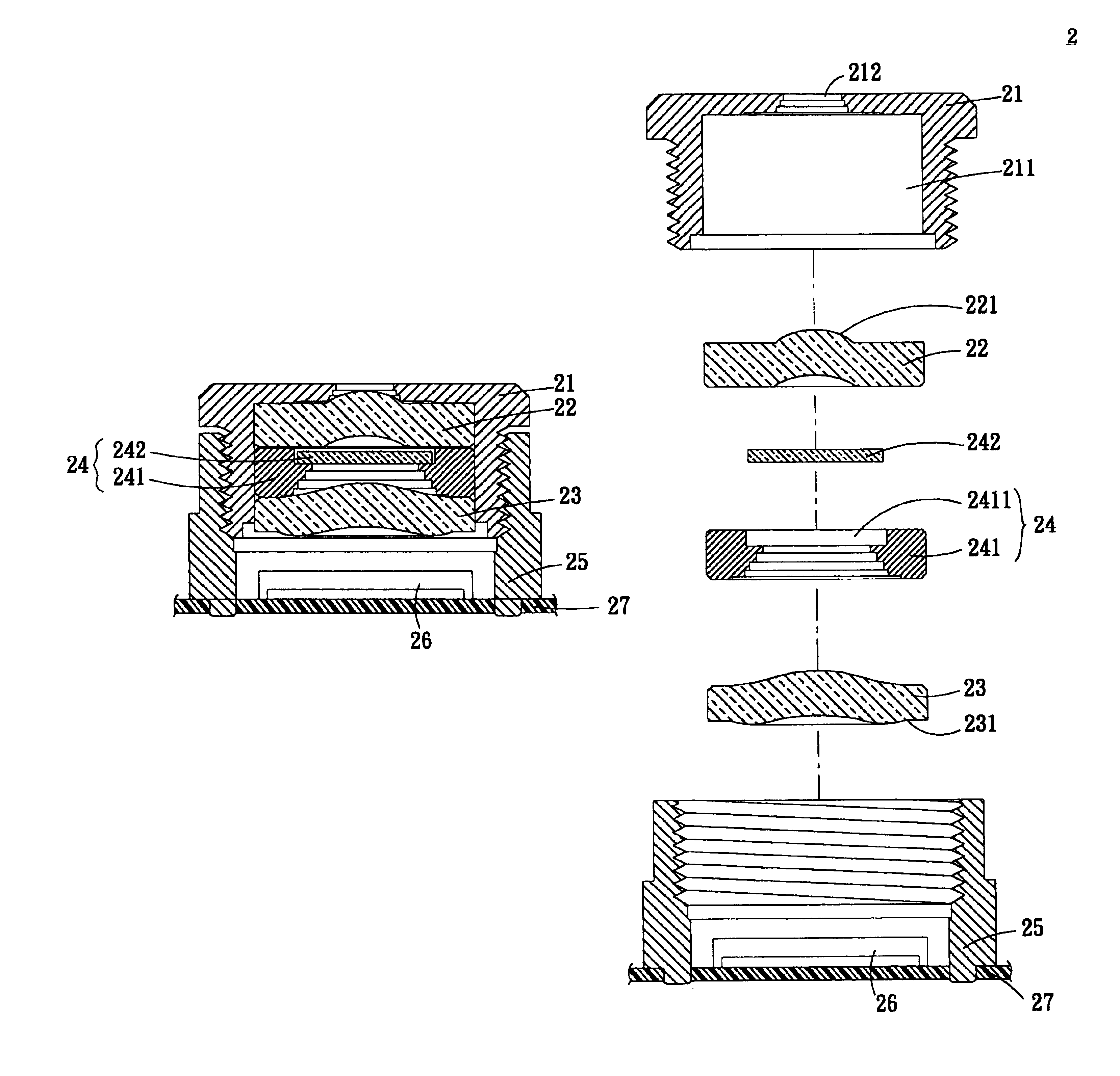

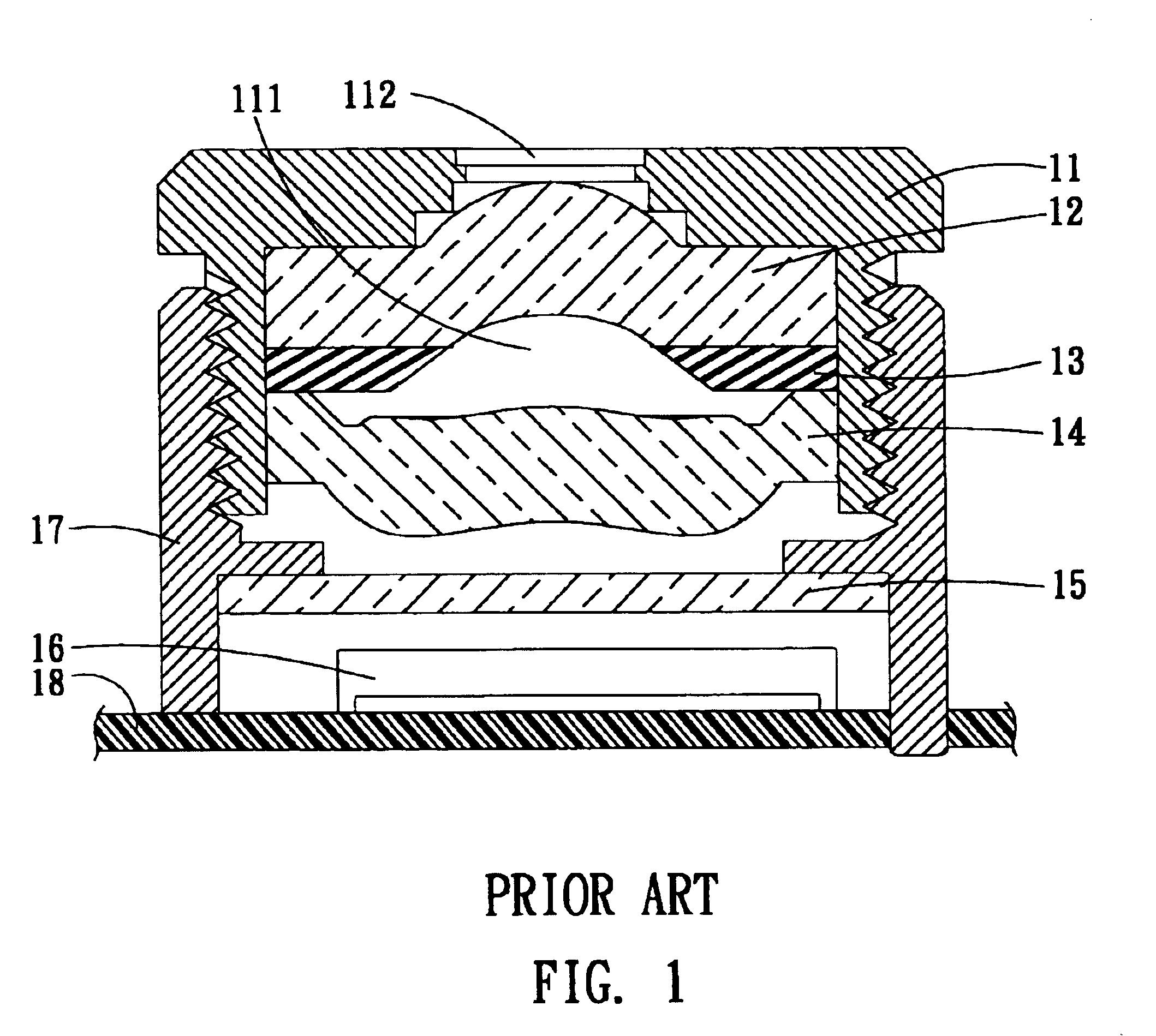

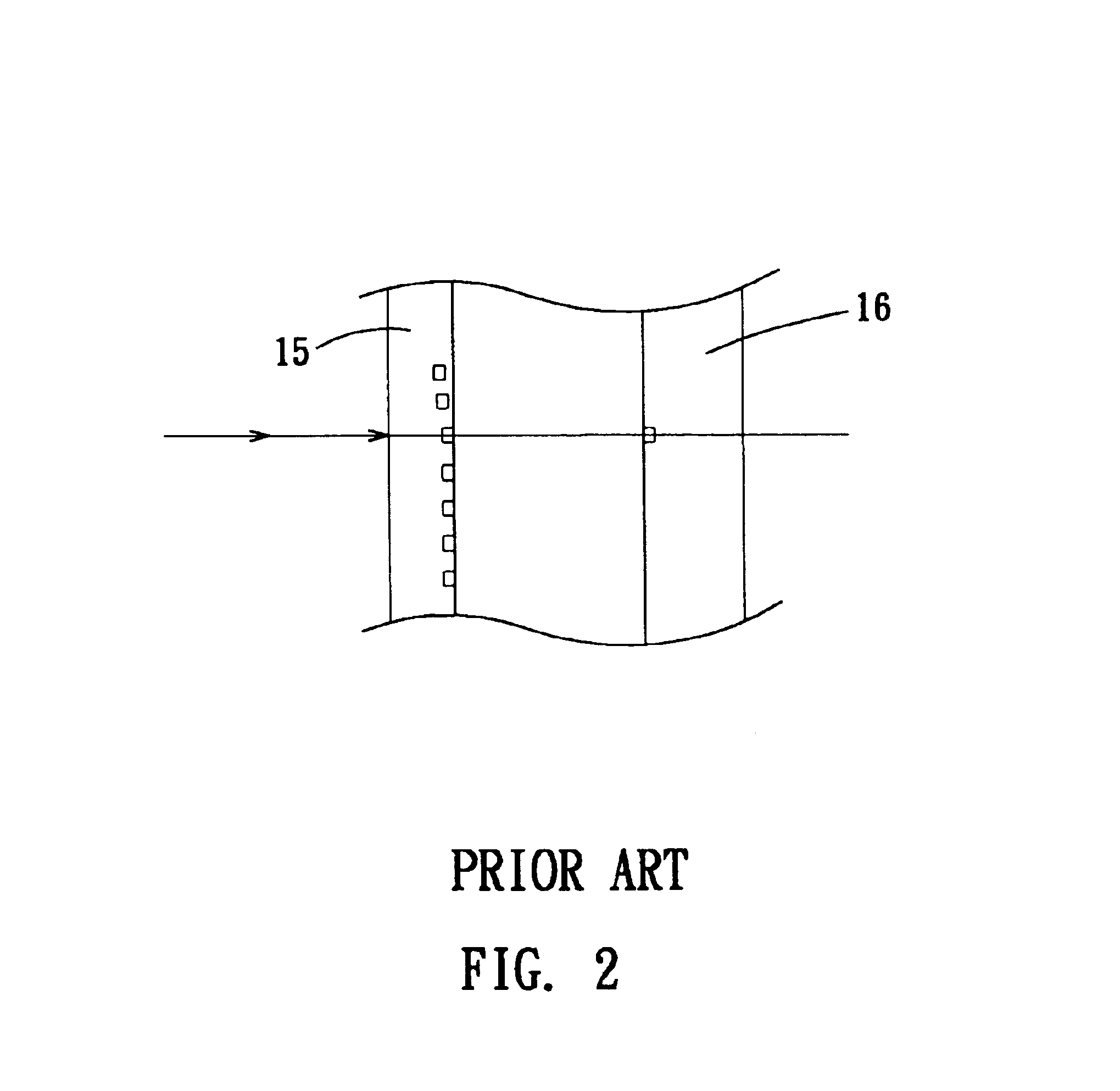

Camera lens assembly

ActiveUS6898030B1Improve cleanlinessIncrease productionMountingsCamera body detailsCamera lensOptical Module

A camera lens includes a barrel, a first lens, a second lens and an optical filter module. The barrel includes a first container and a diaphragm. The first lens is disposed in the first container next to the diaphragm. The second lens is disposed in the first container with a distance from the first lens. The optical filter module is disposed in the first container between the first and the second lenses.

Owner:CALLAHAN CELLULAR L L C

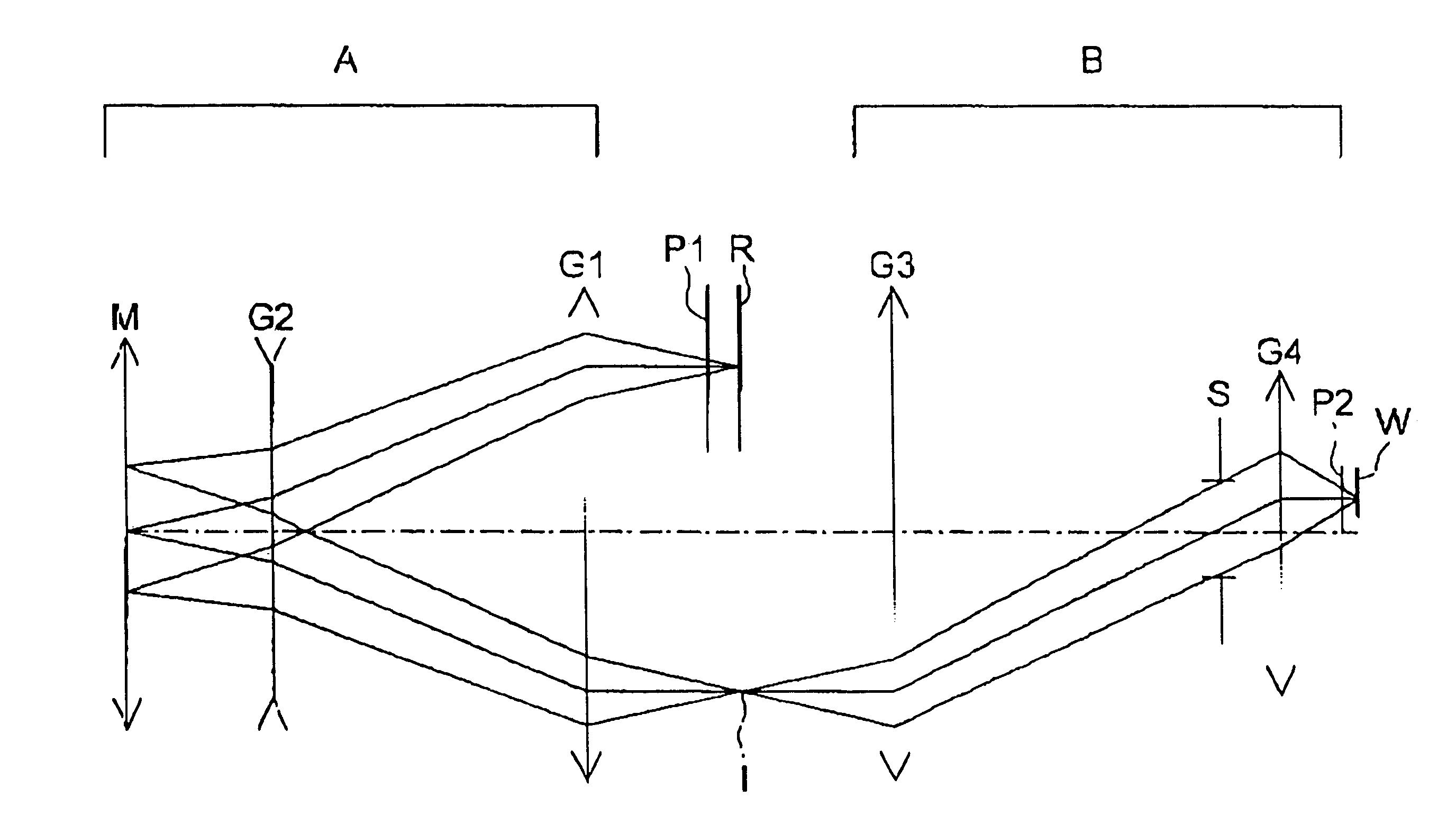

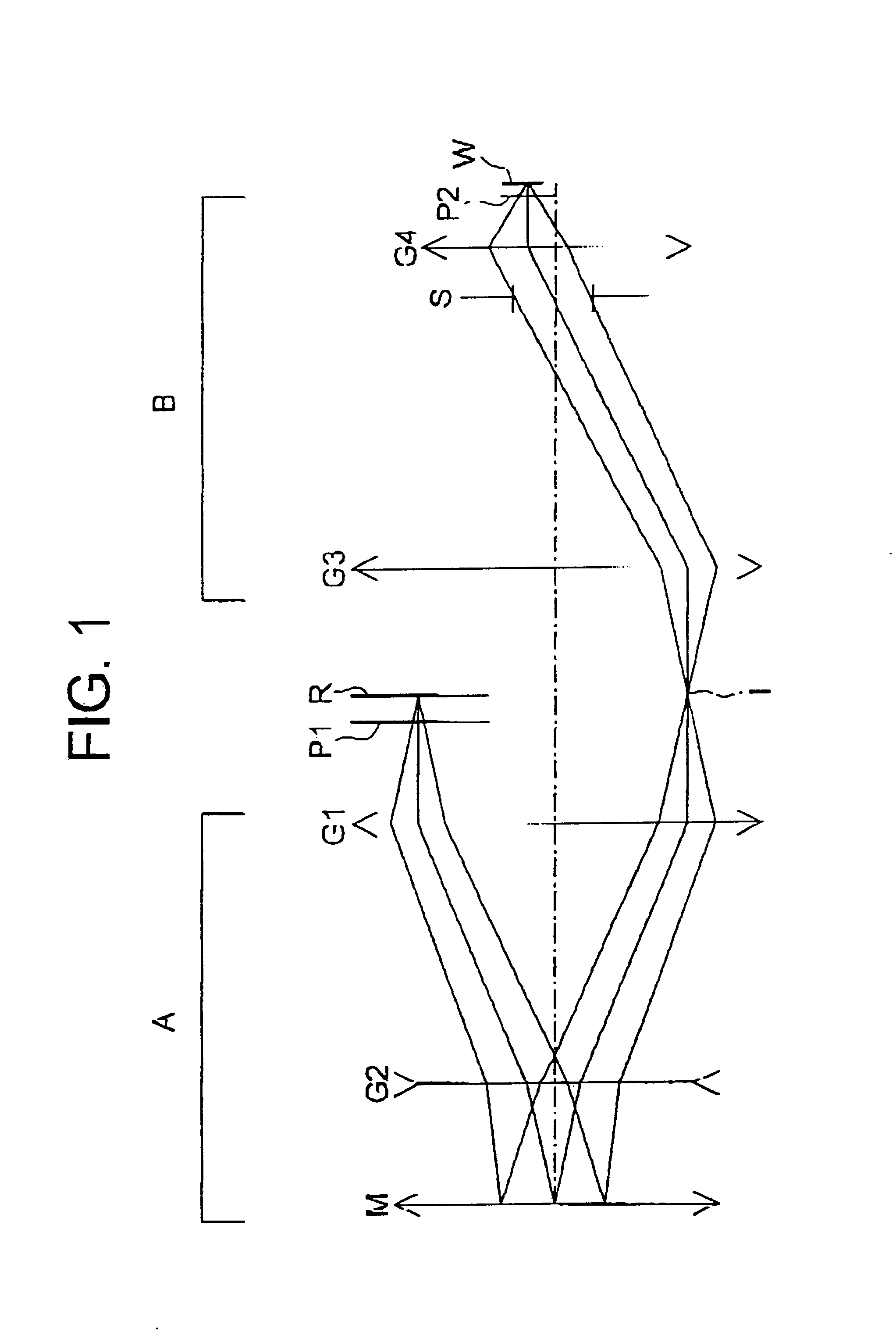

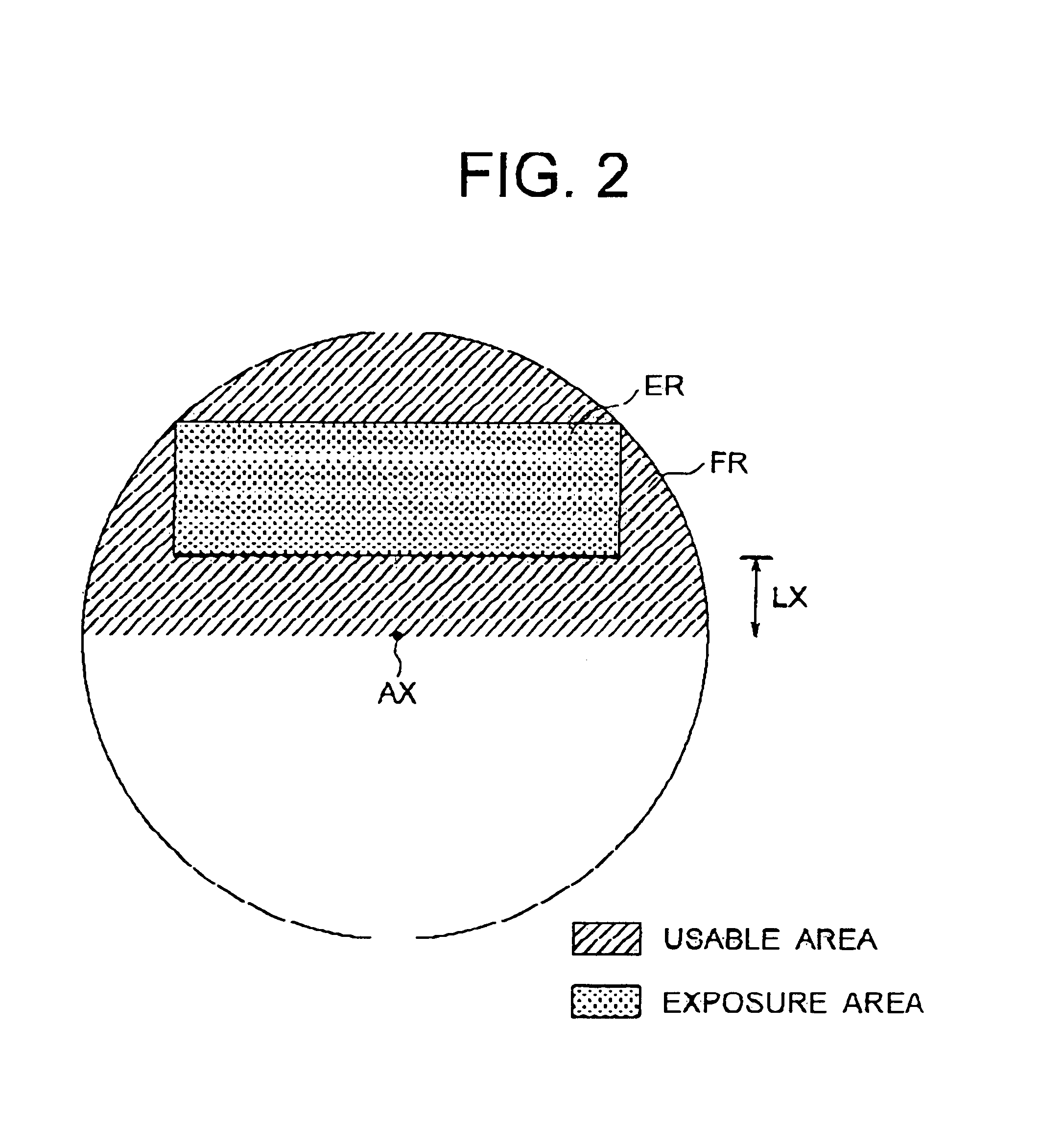

Projection exposure apparatus, projection exposure method and catadioptric optical system

InactiveUS6707616B1Reduce lossesHigh resolutionPhotomechanical exposure apparatusMicrolithography exposure apparatusProjection opticsLength wave

A projection exposure apparatus has an illumination optical system 3 for illuminating a mask formed with a pattern with beams of radiation, and a projection optical system for forming an image of the pattern on a workpiece on the basis of radiation from the mask. The illumination optical system supplies an illumination radiation having a center wavelength of 180 nm or smaller, and the projection optical system includes at least one concave mirror, fifteen or less pieces of refracting lenses, and four or more aspherical surfaces.

Owner:NIKON CORP

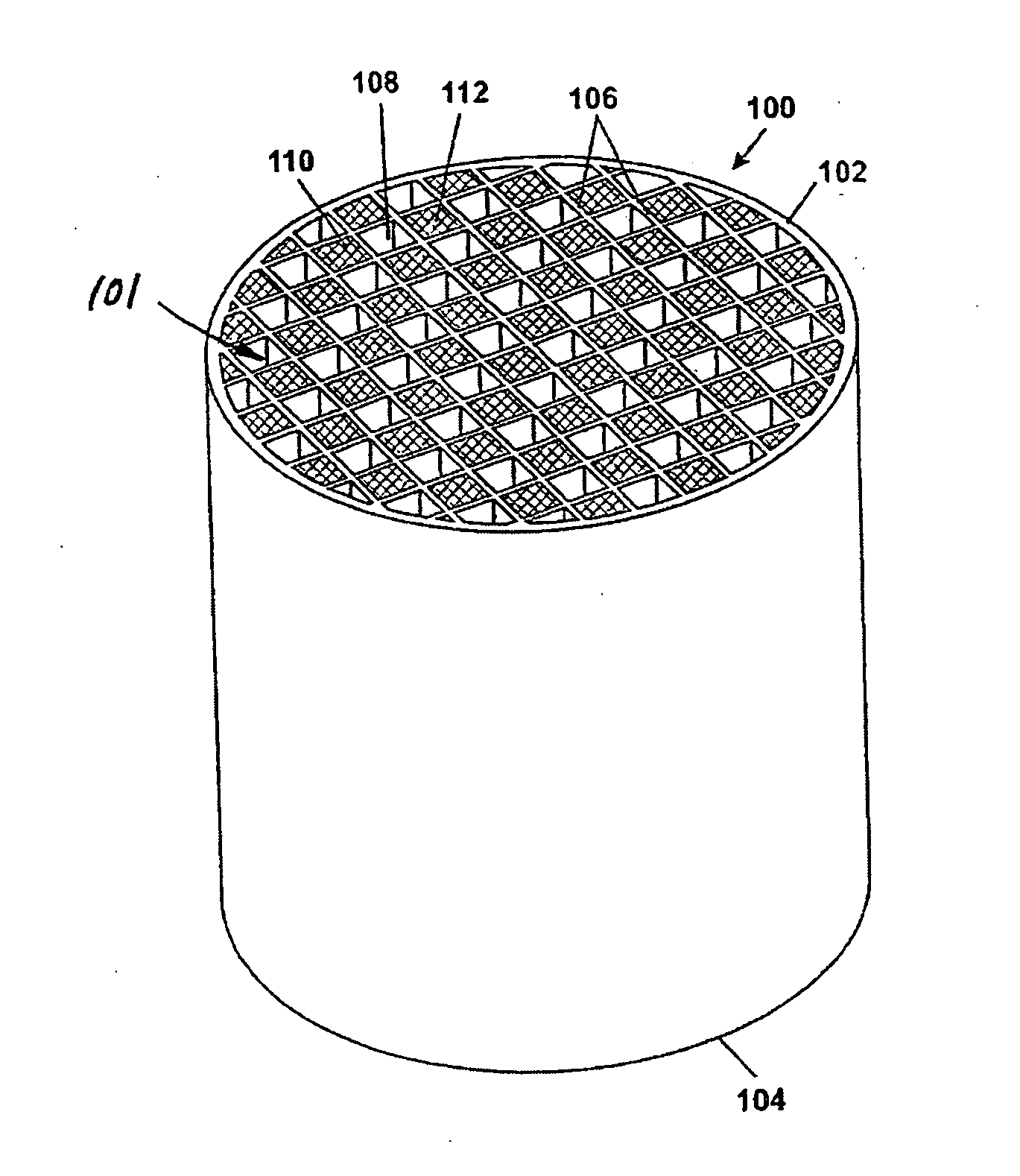

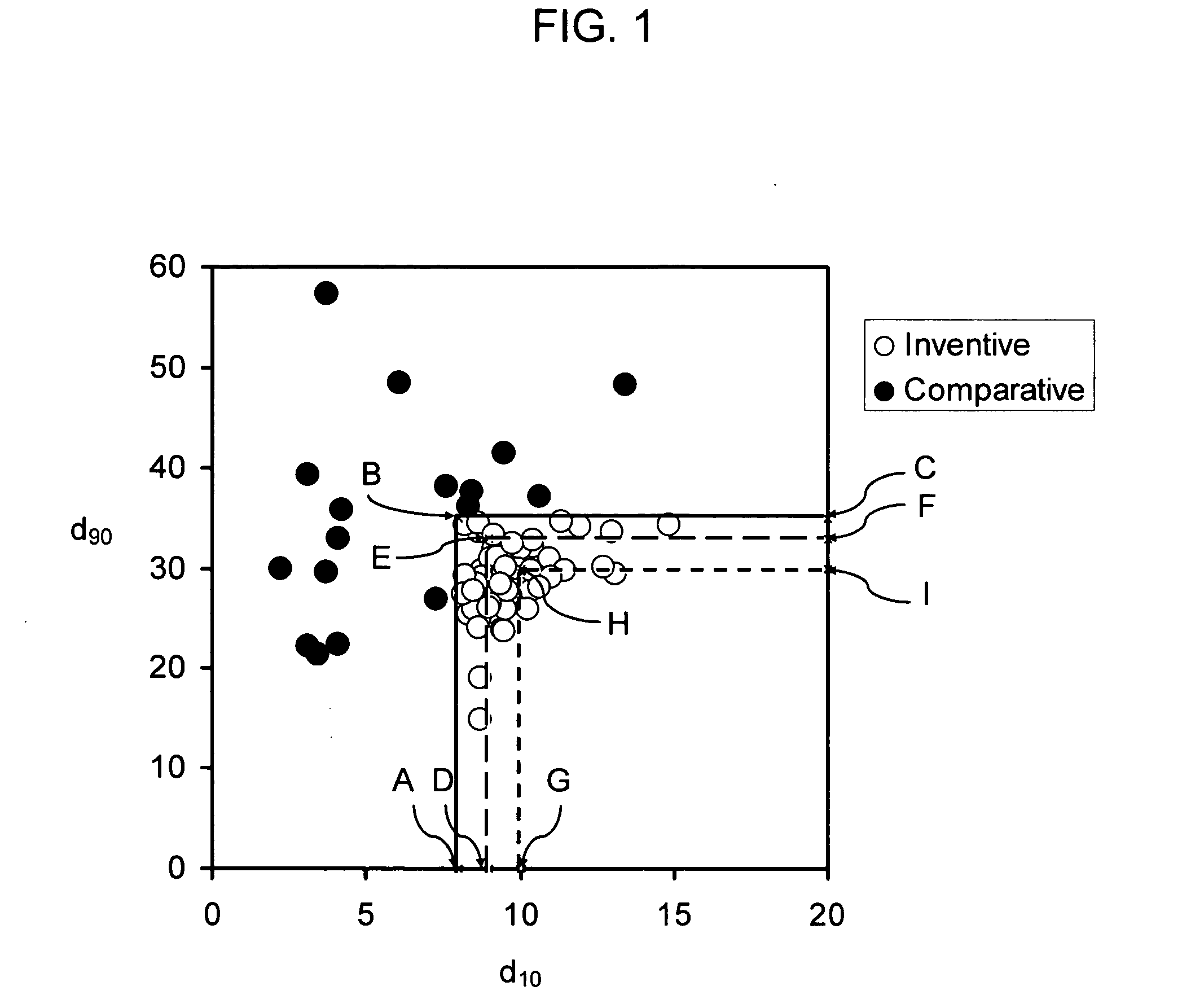

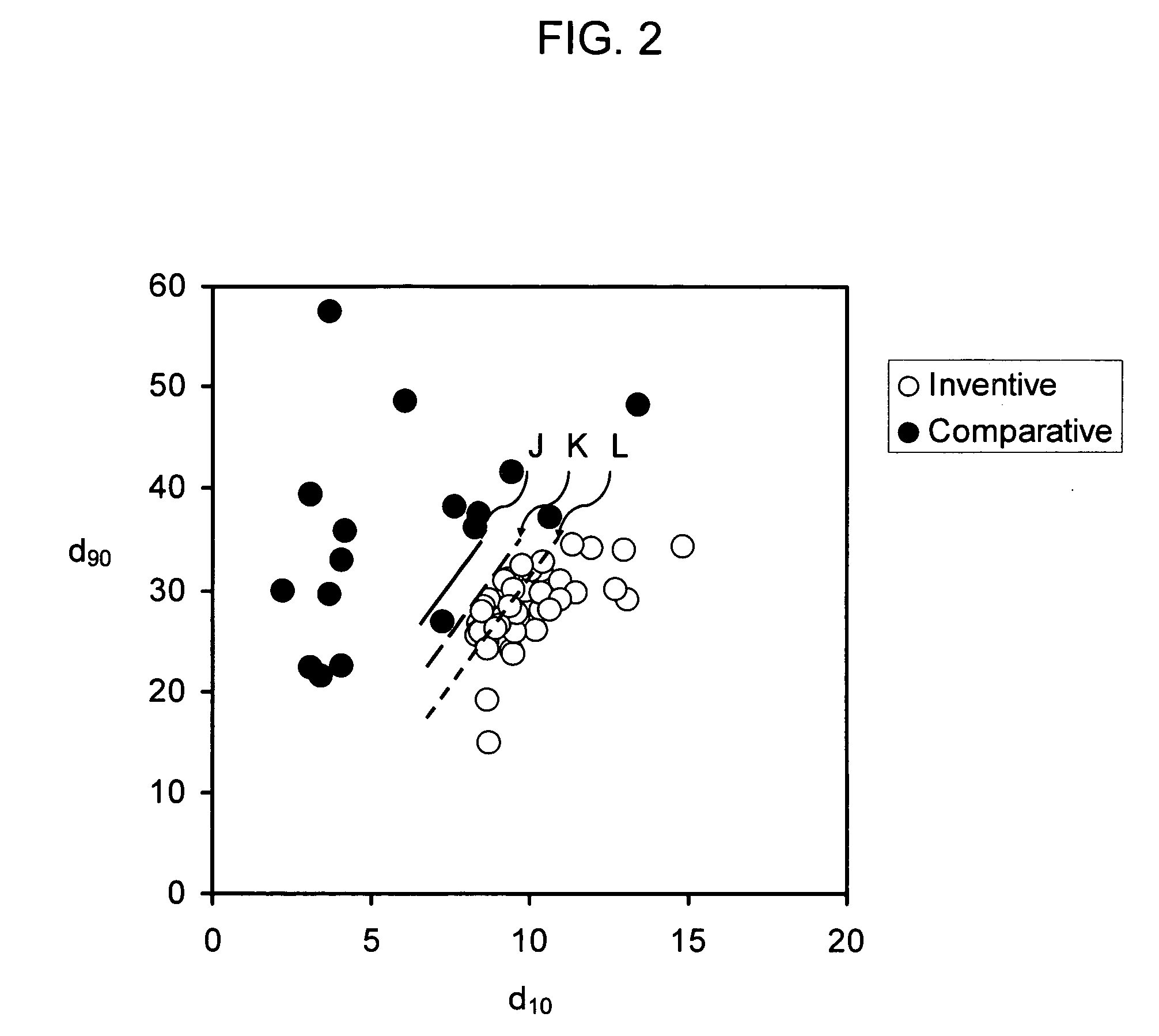

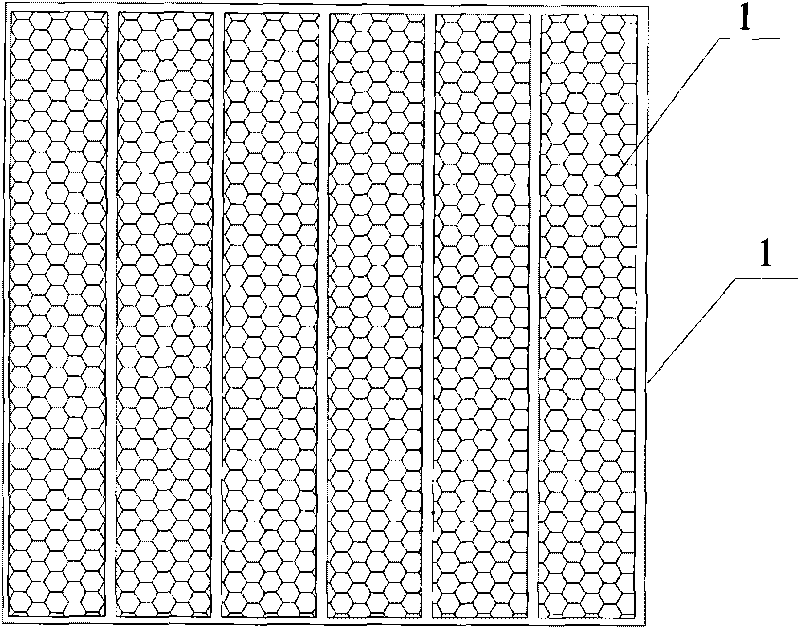

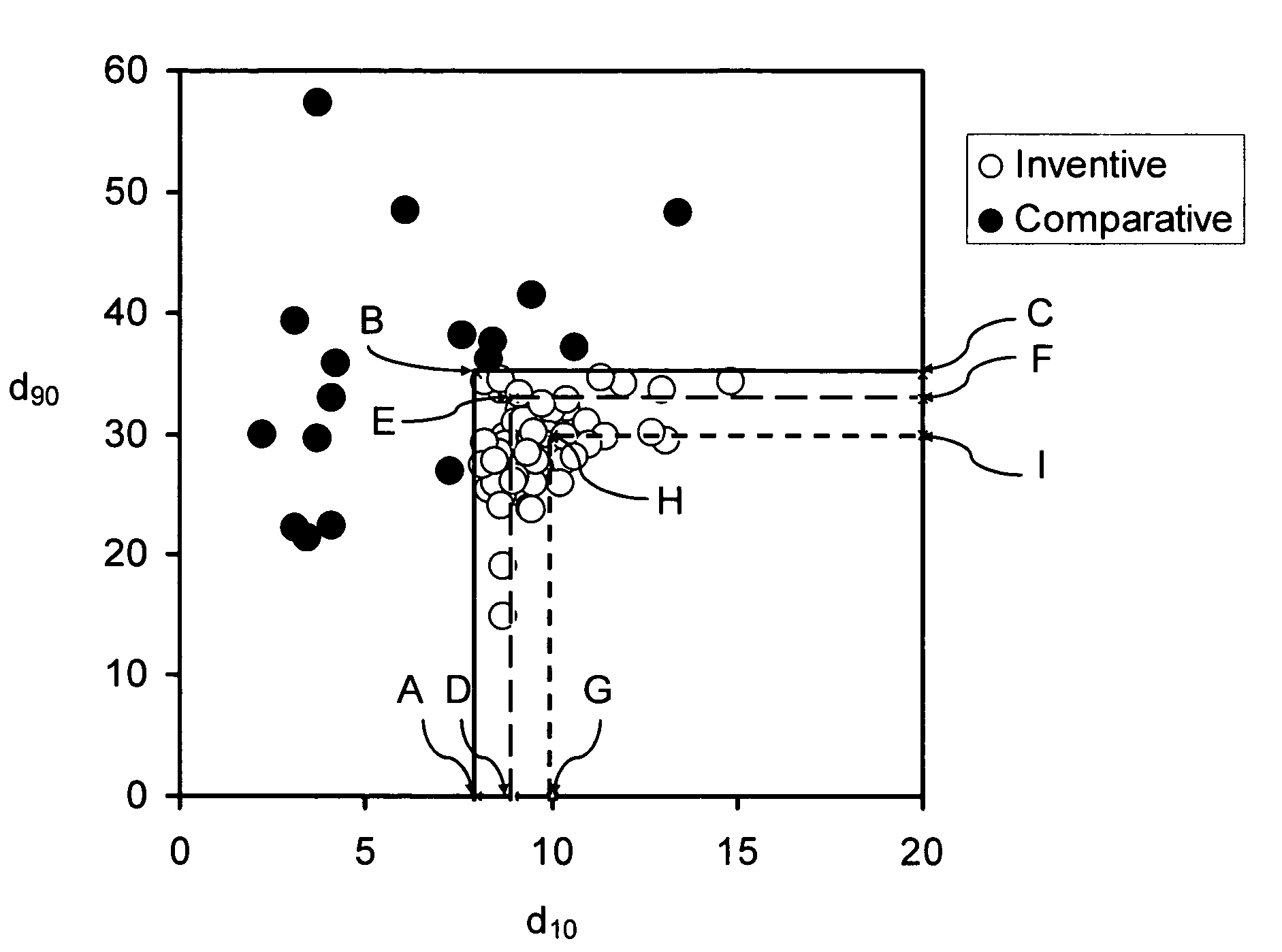

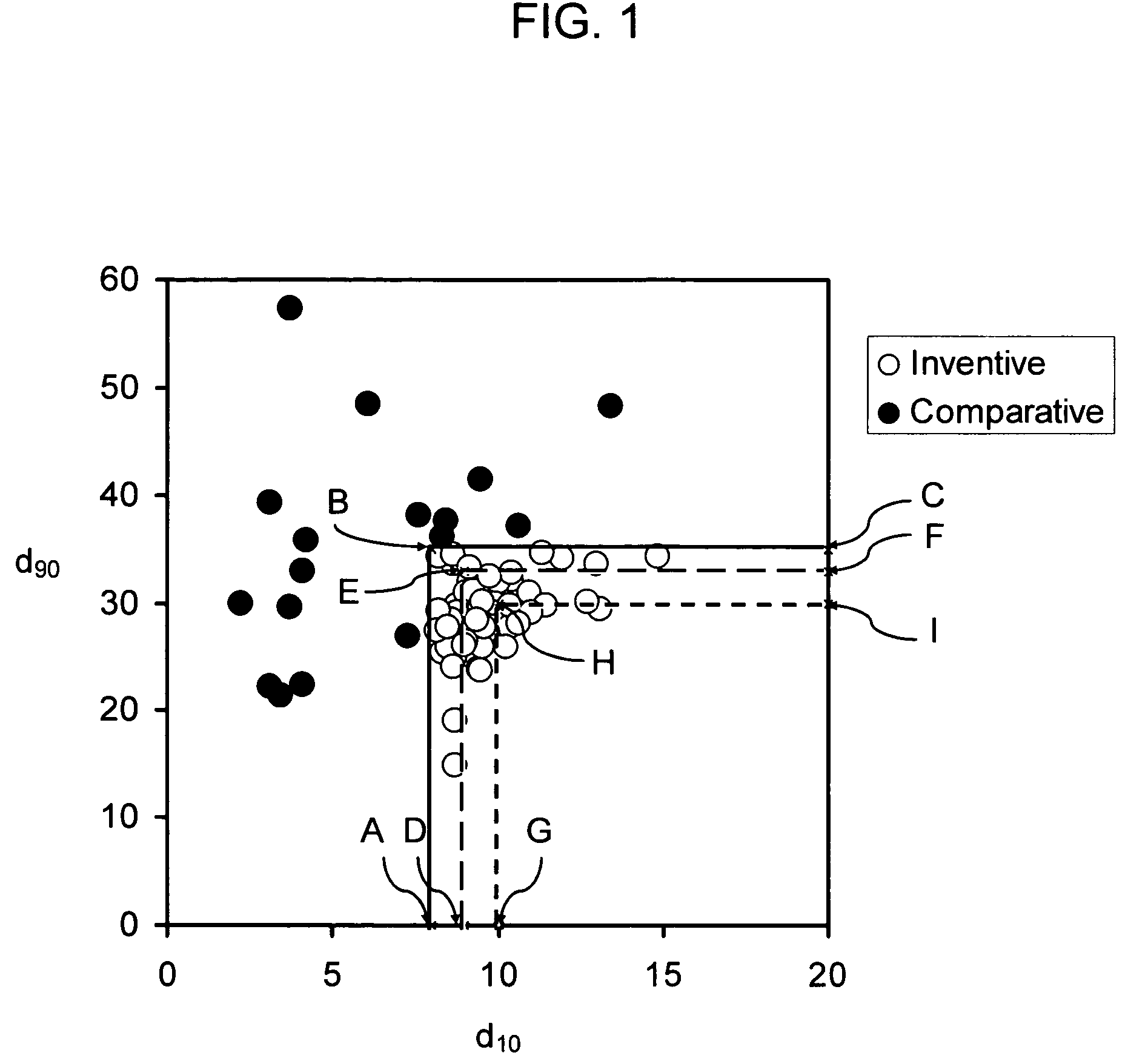

Narrow pore size distribution cordierite ceramic honeycomb articles and methods for manufacturing same

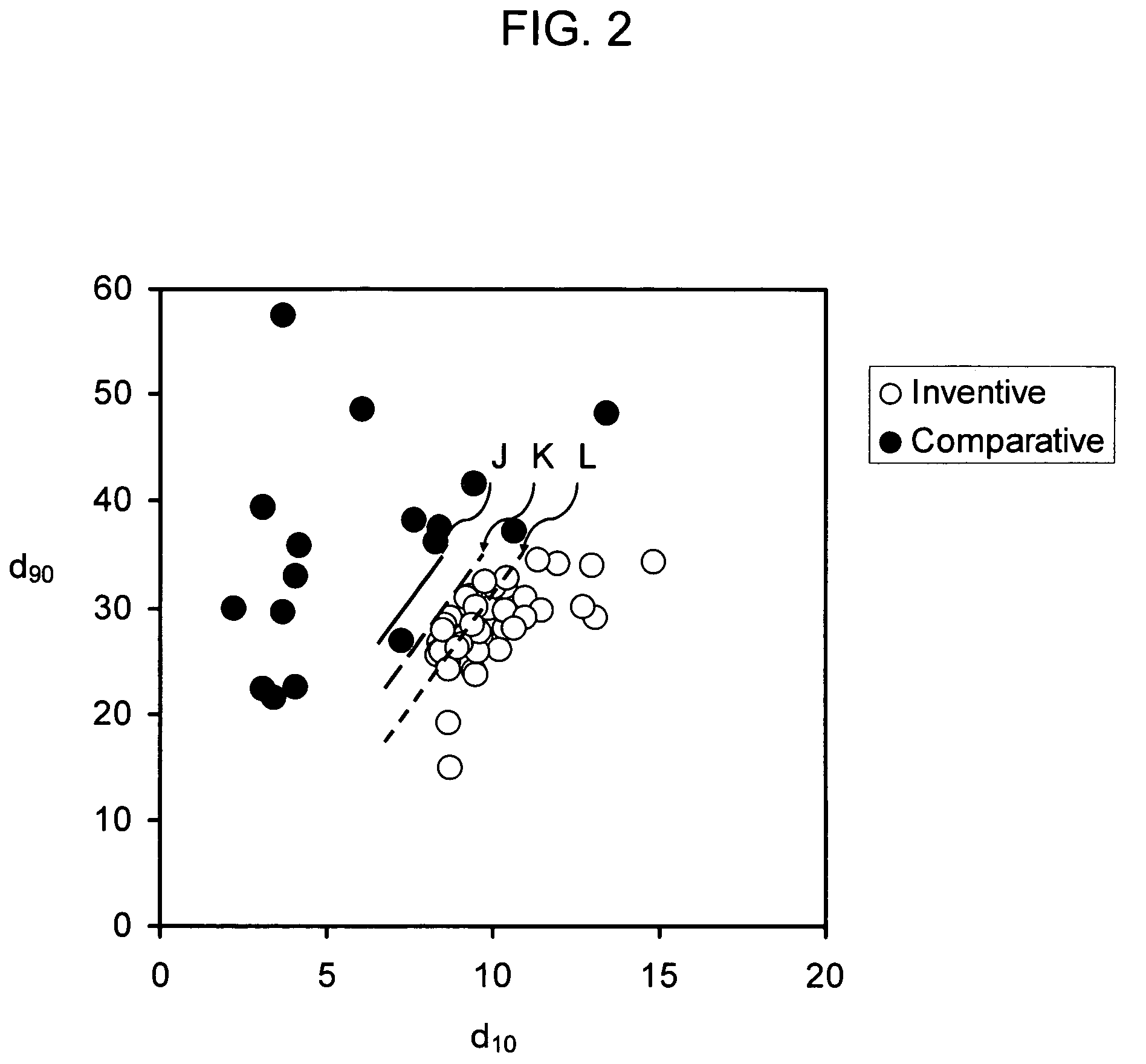

ActiveUS20080047243A1Low cleanlinessLow pressureCombination devicesDispersed particle filtrationFiltrationHeat resistance

Disclosed are ceramic honeycomb articles, which are composed predominately of a crystalline phase cordierite composition. The ceramic honeycomb articles possess a microstructure characterized by a unique combination of relatively high total porosity of less than 54%, and relatively narrow pore size distribution having a d10 pore diameter of not less than 8 μm, a d90 pore diameter of not greater than 35 μm, and a value of df=(d50−d10) / d50 of less than 0.50. The articles exhibit high thermal durability and high filtration efficiency coupled with low pressure drop across the filter. Such ceramic articles are particularly well suited for filtration applications, such as diesel exhaust filters or DPFs. Also disclosed are methods for manufacturing the ceramic articles of the present invention.

Owner:CORNING INC

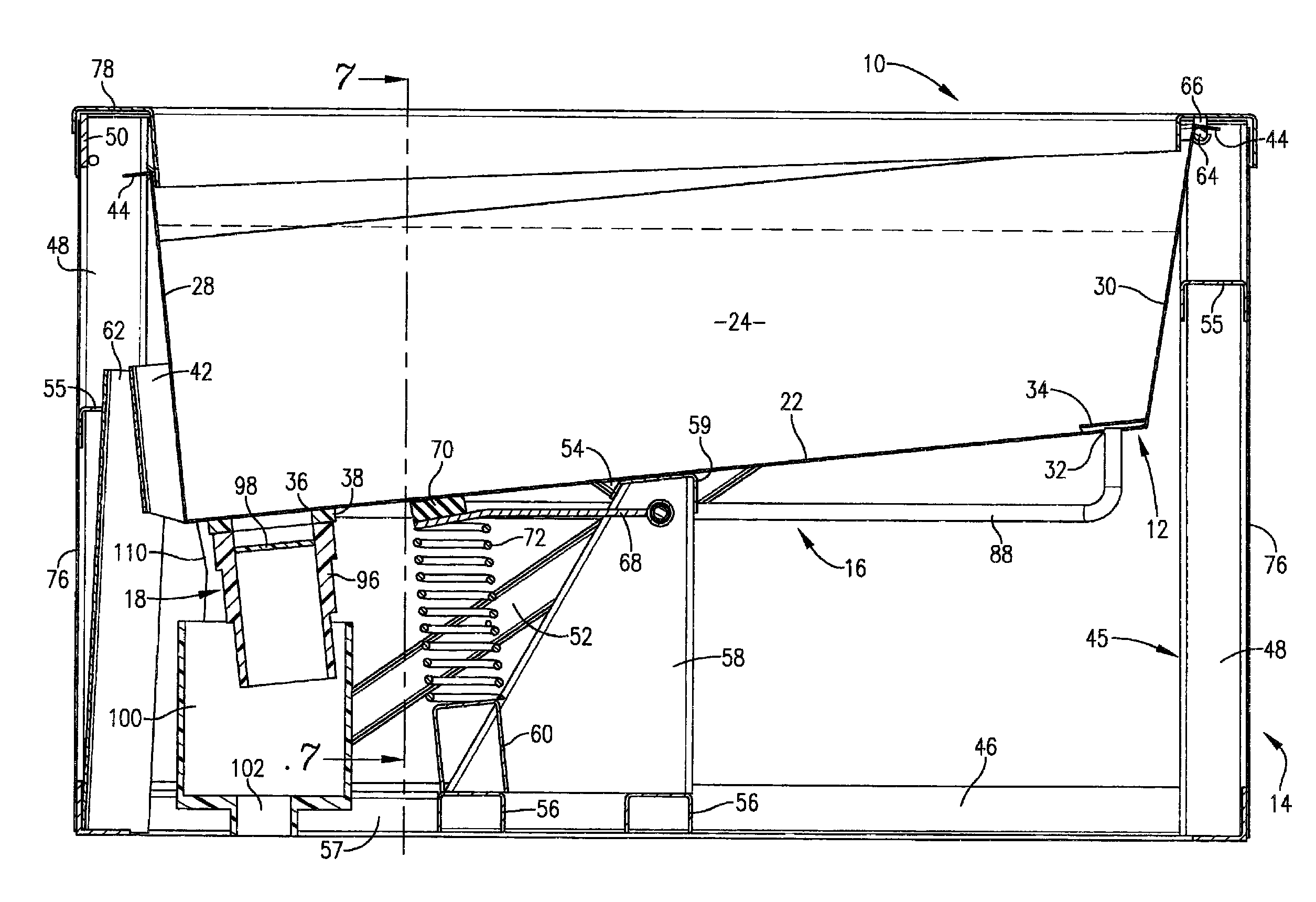

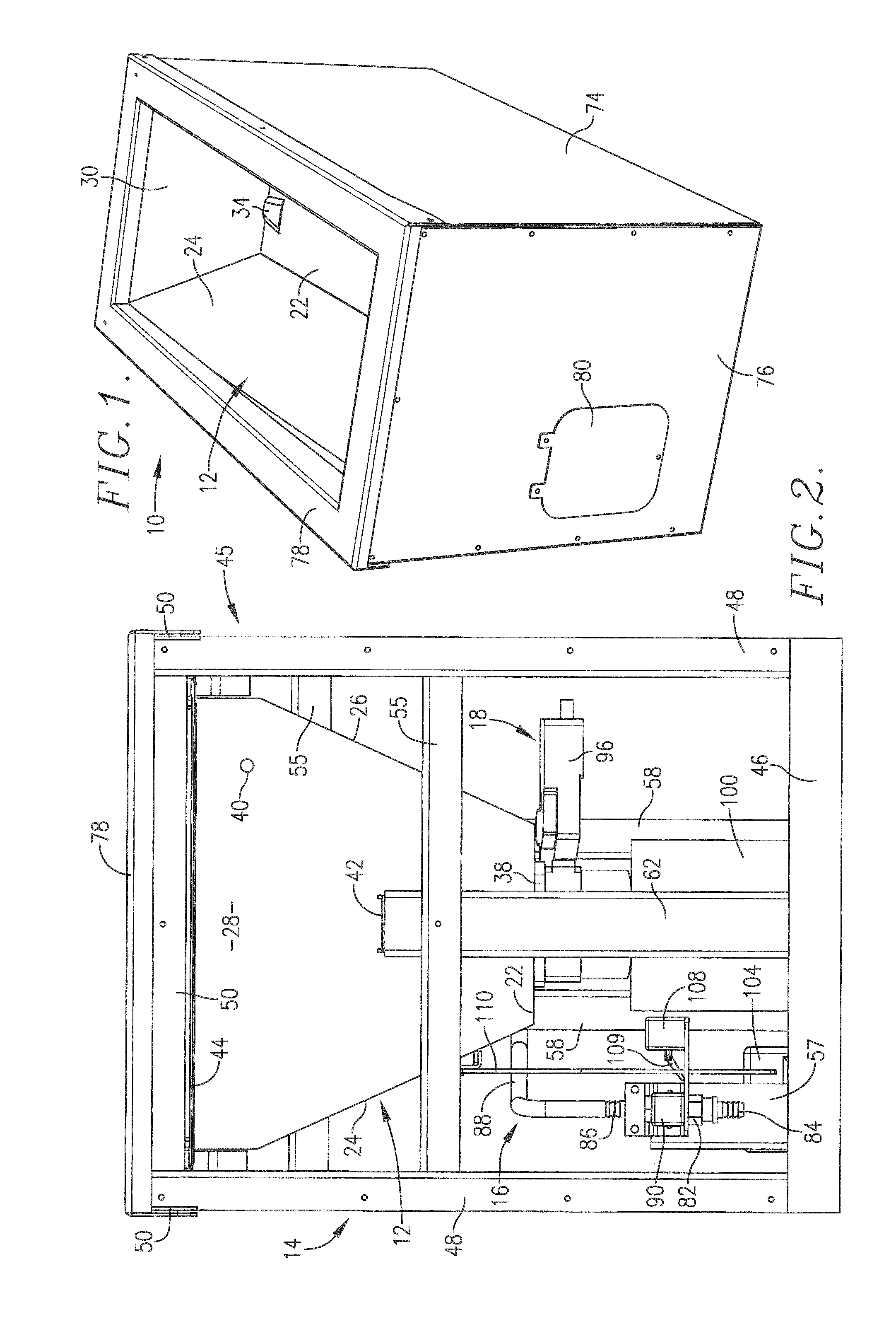

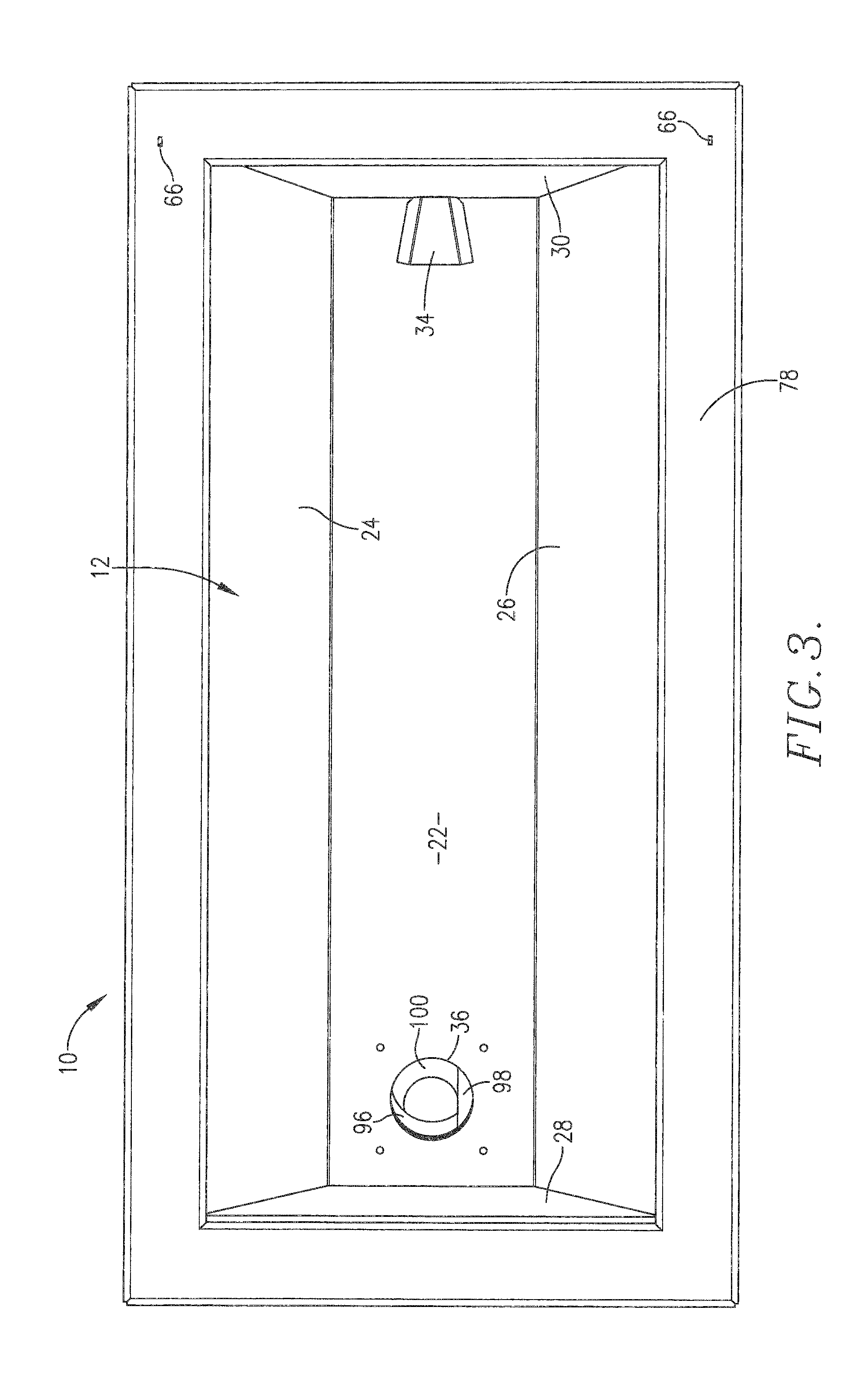

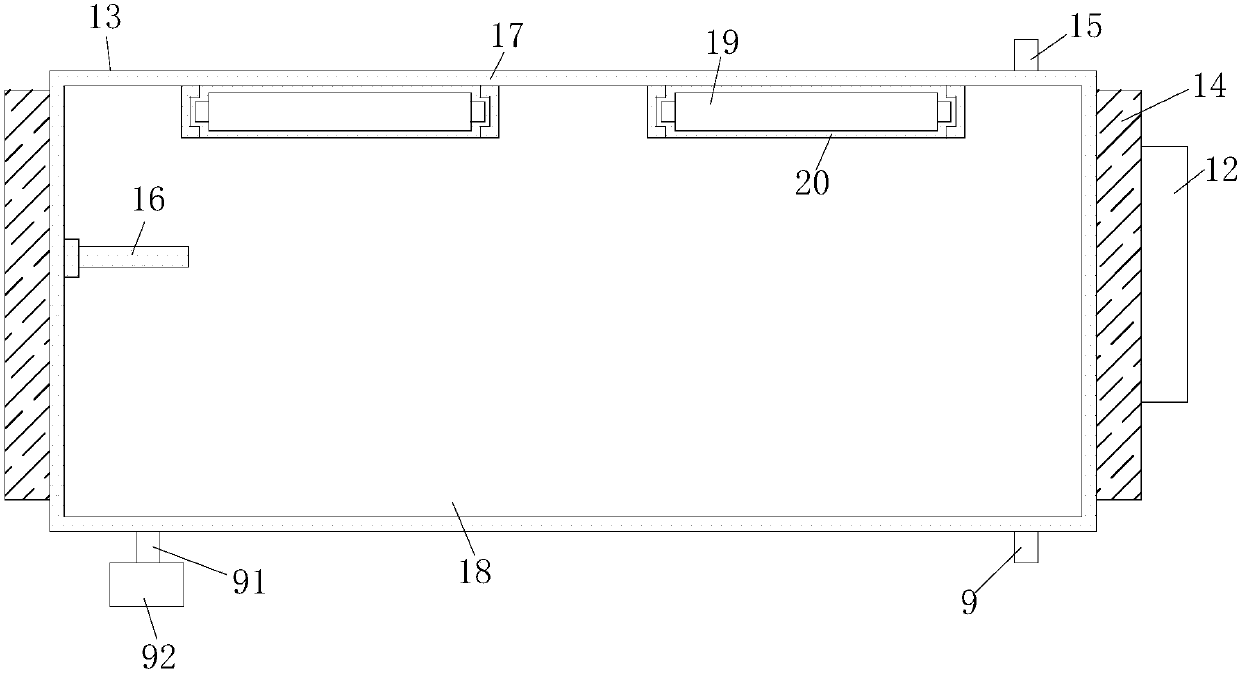

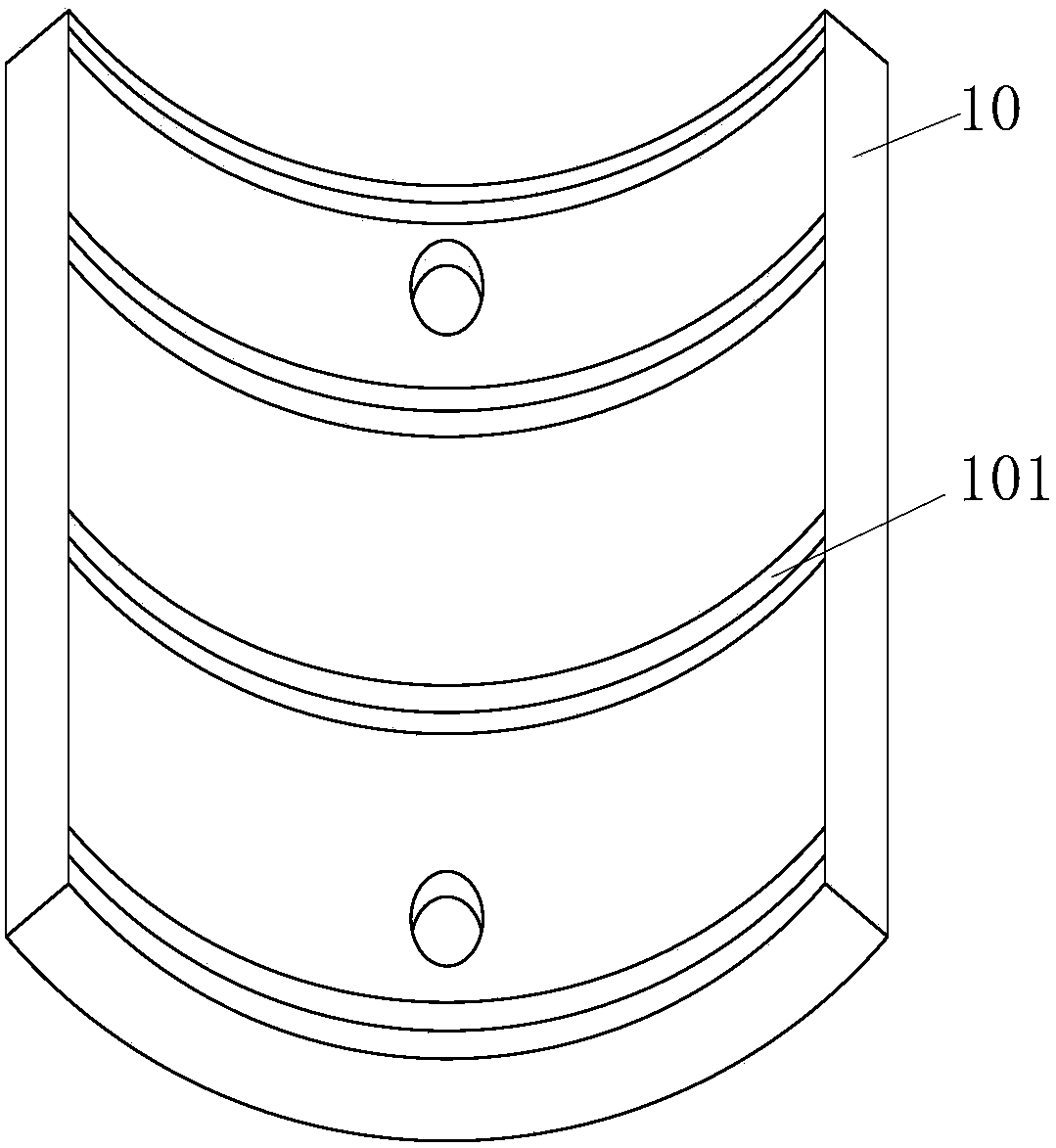

Self-cleaning animal watering device

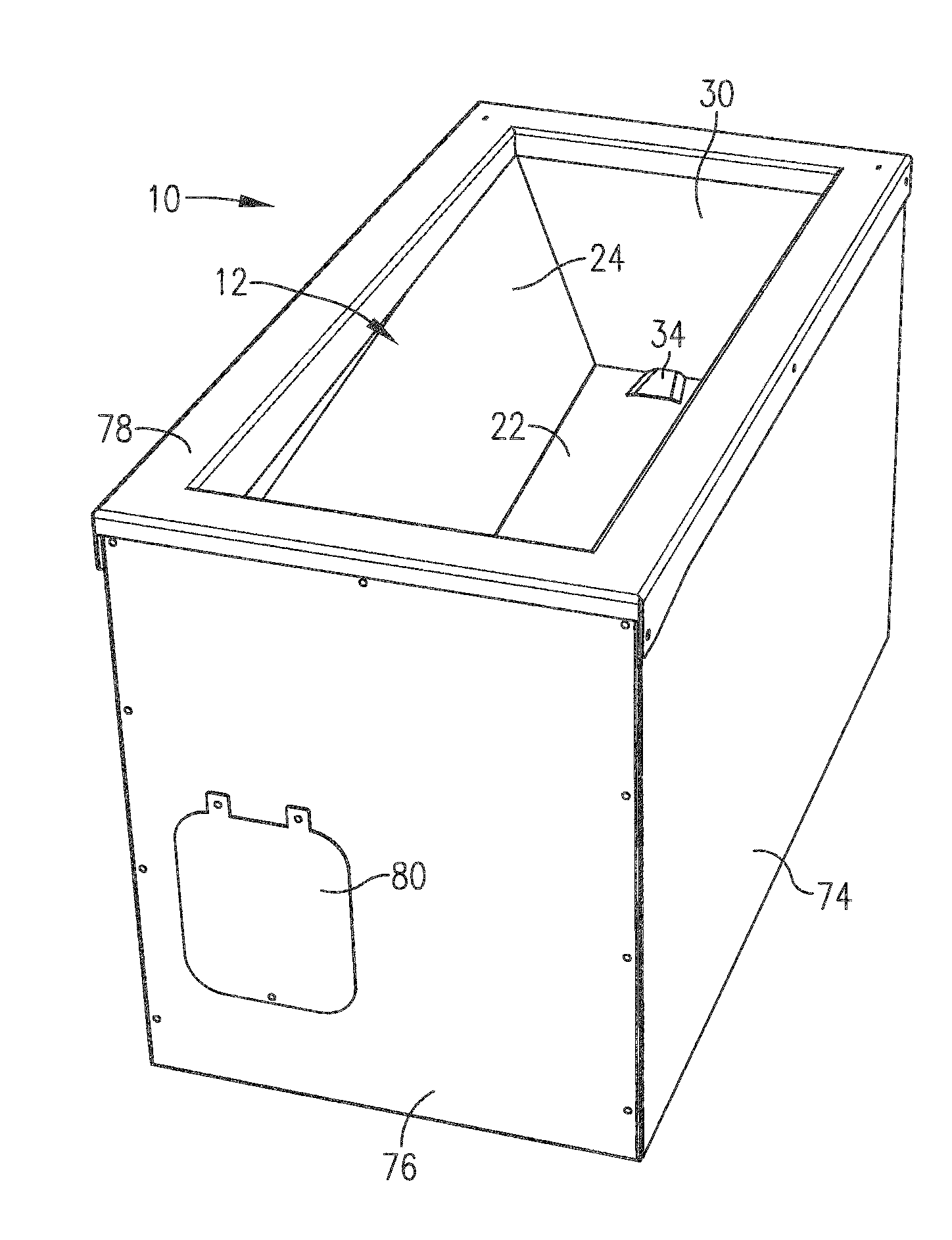

A self-cleaning, low-maintenance, water-saving automated animal watering device (10) is provided which includes a watering tank (12) moveable between a lower, water-full condition and an upper, water-low condition. Preferably, one end of the tank (12) is pivotally supported by a pivot shaft (64), while the other end of the tank is biased upwardly via a lower lift spring (72). The device (10) also has a water fill assembly (16) operably coupled with tank (12) to selectively fill the tank (12) when needed, and a drain valve assembly (18) also coupled with tank (12) in order to completely drain the tank (12) on a periodic basis. A control assembly (20) is coupled with at least the tank (12) and drain valve assembly (18), and is operable to actuate the drain valve assembly (18) after a predetermined number of movements of the tank (12) between the elevated and lowered positions thereof.

Owner:KANSAS STATE UNIV RES FOUND

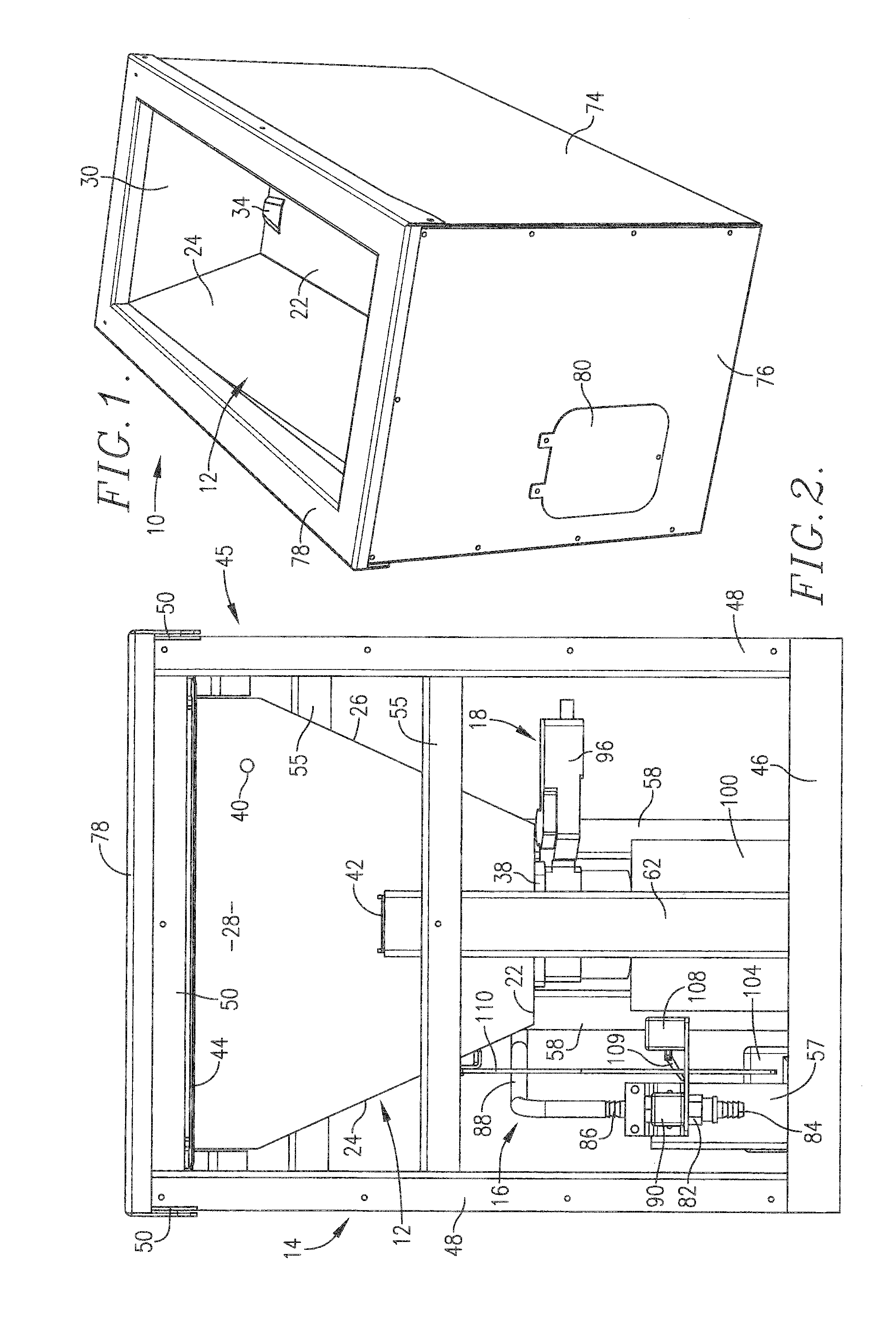

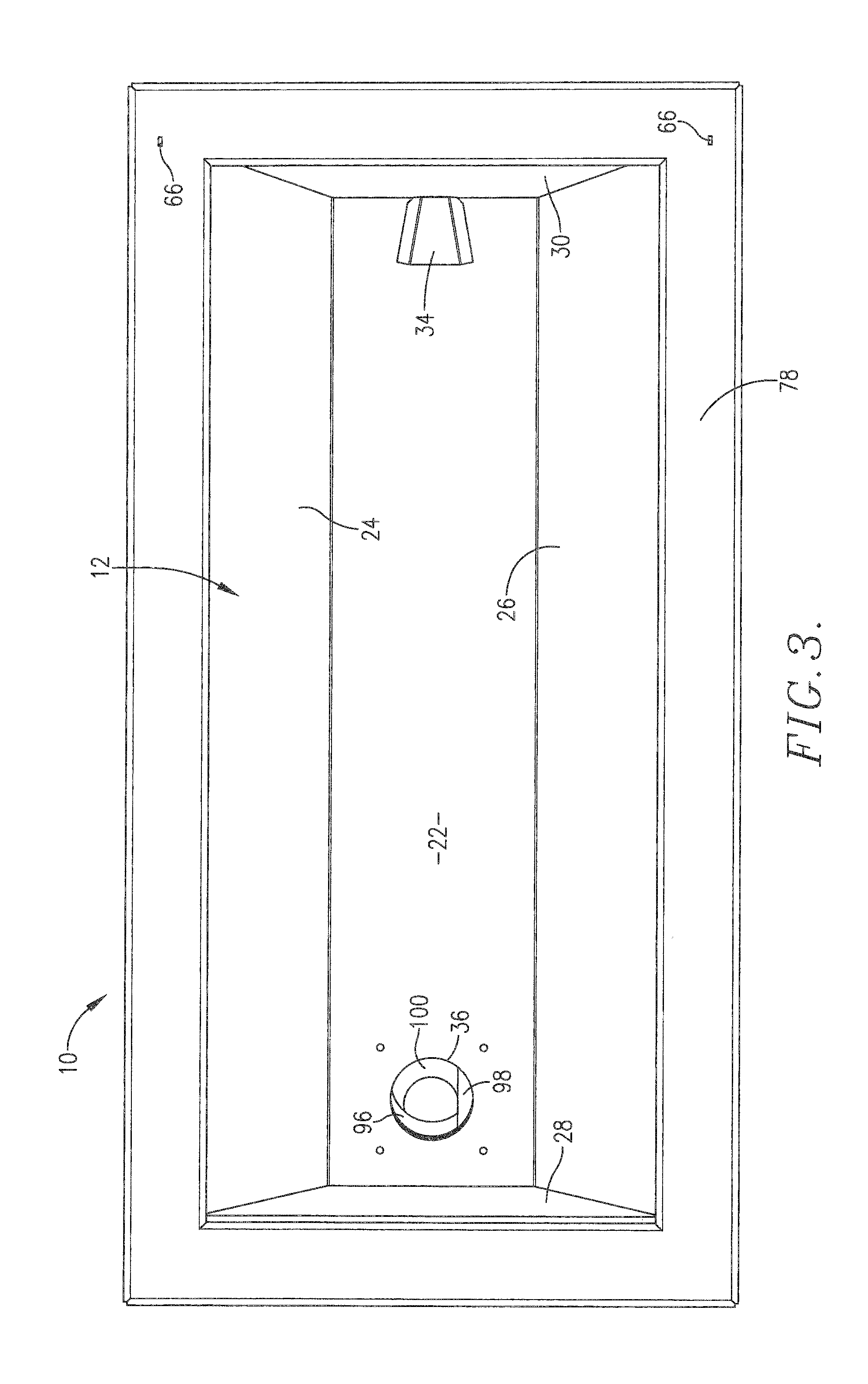

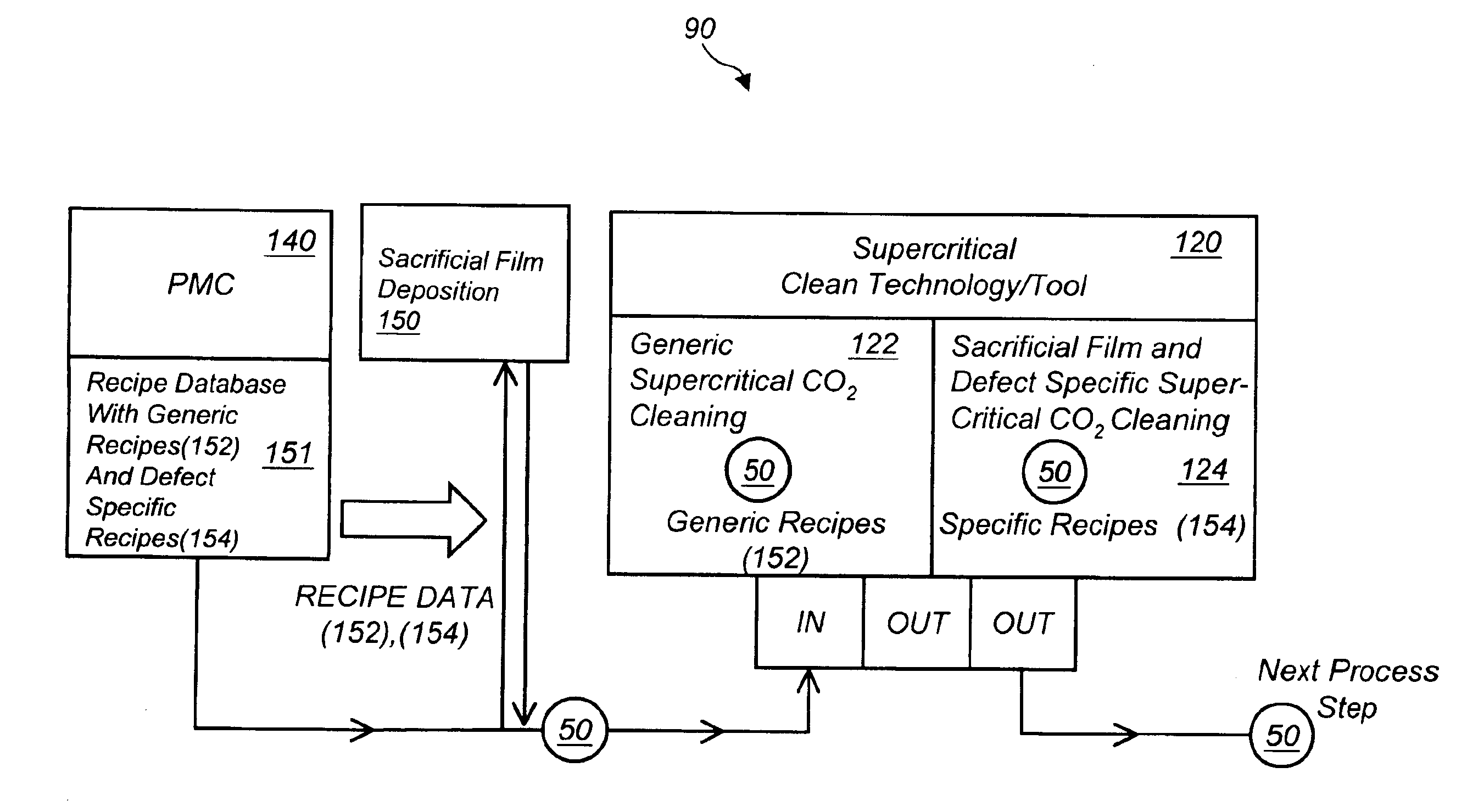

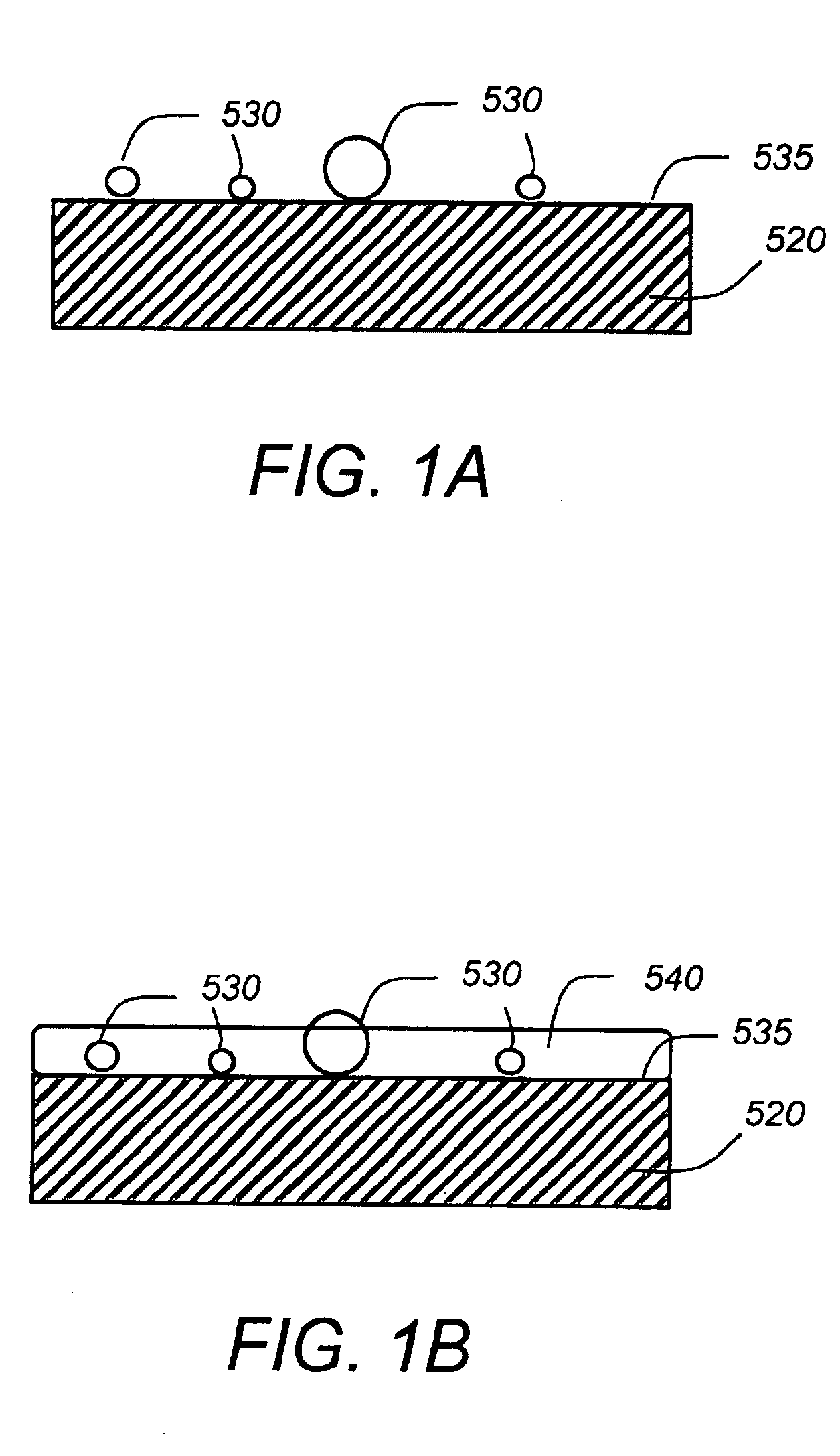

Apparatus and method for semiconductor wafer cleaning

InactiveUS6858089B2Small footprintReduce defect levelHollow article cleaningSemiconductor/solid-state device manufacturingEngineeringImproved method

An improved method for removing contaminant particles from a surface of a semiconductor wafer includes forming a sacrificial film on the surface of the wafer and then removing the sacrificial film by supercritical fluid cleaning. The removal of the sacrificial film via the supercritical fluid cleaning process facilitates removing the contaminant particles. The method further includes identifying and characterizing the contaminant particles and creating a record of the contaminant particle data. The composition of the sacrificial film is selected based on the contaminant particles data and the supercritical cleaning recipe is selected based on the composition of the sacrificial film and the contaminant particles data.

Owner:CASTRUCCI PAUL P

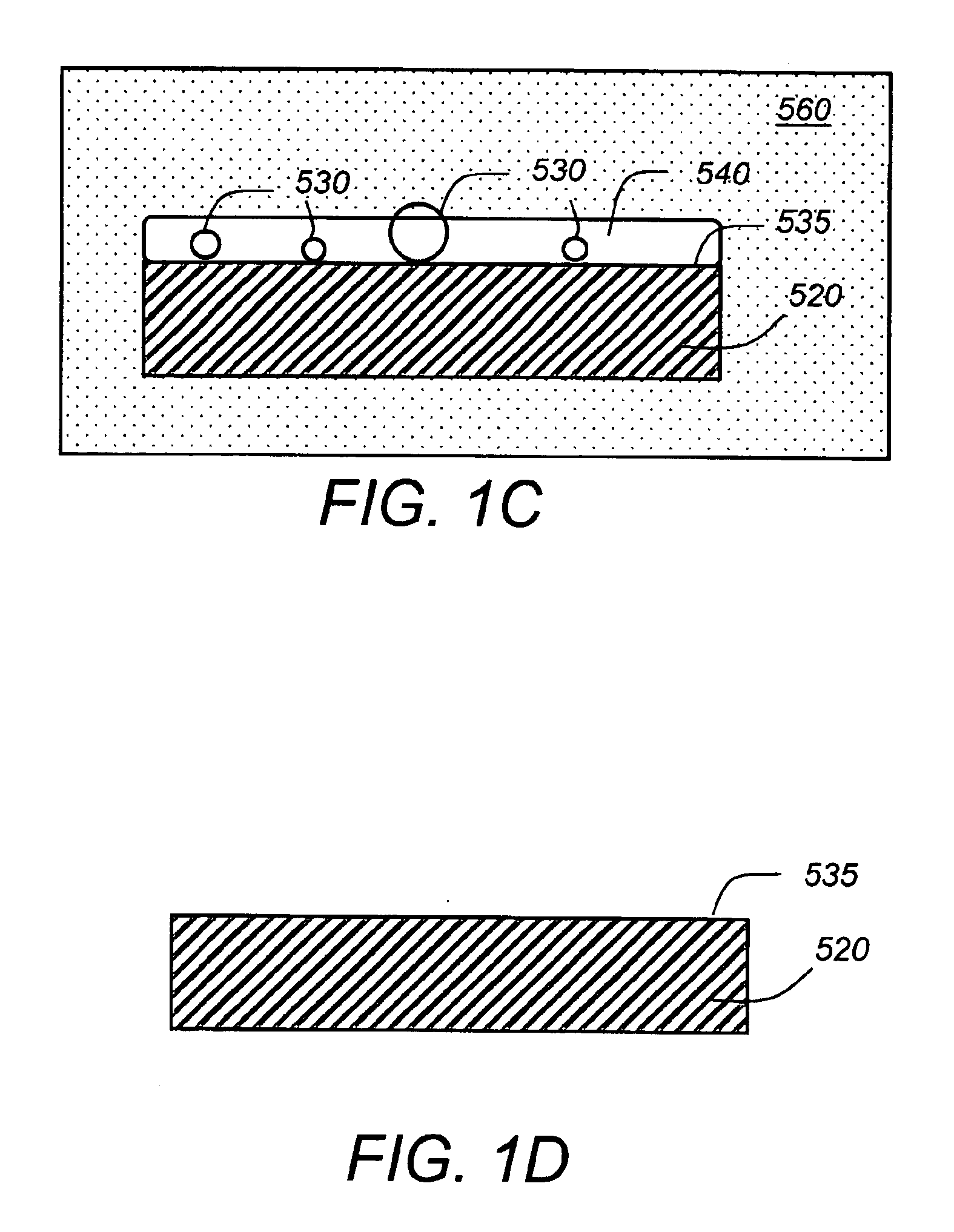

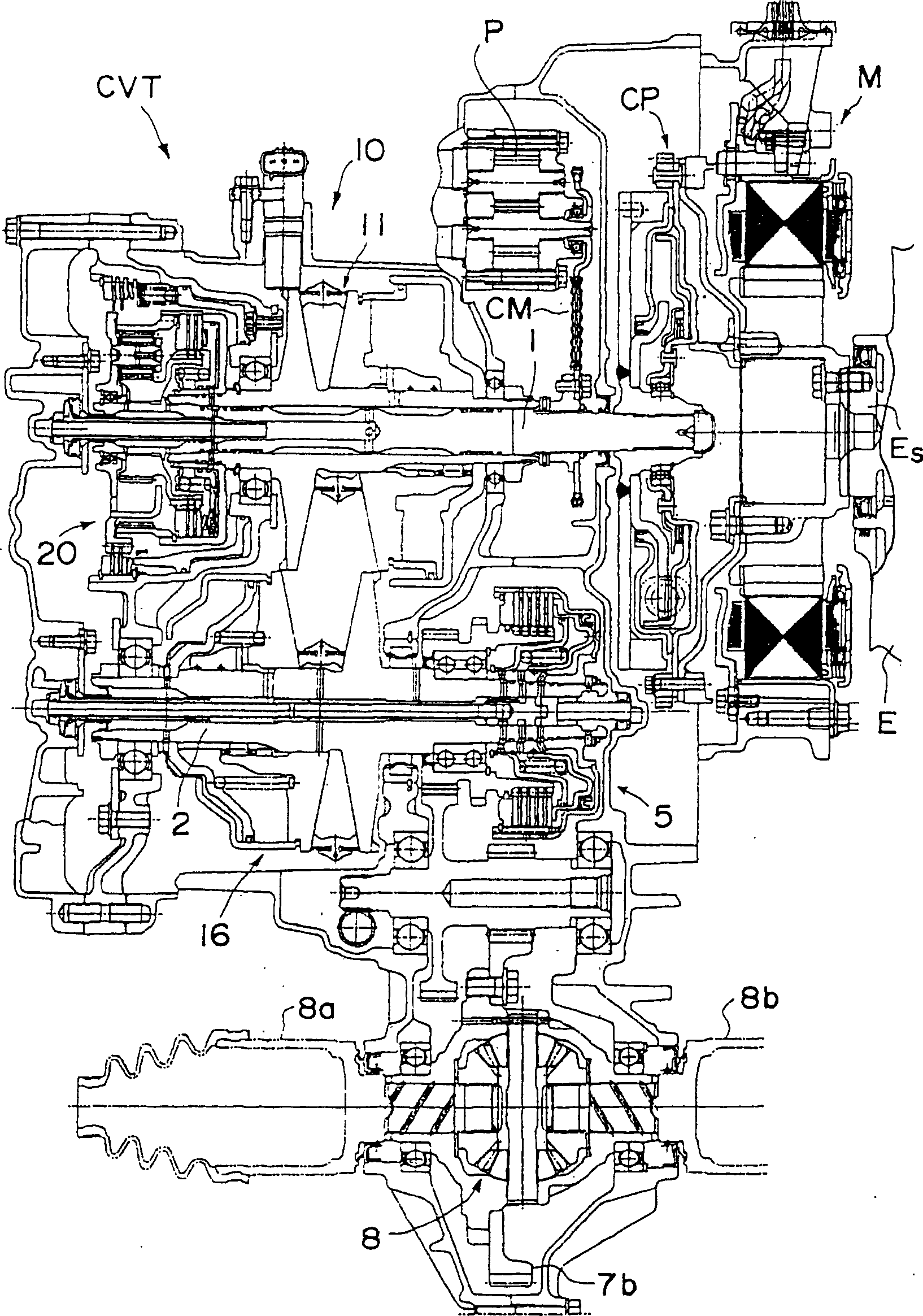

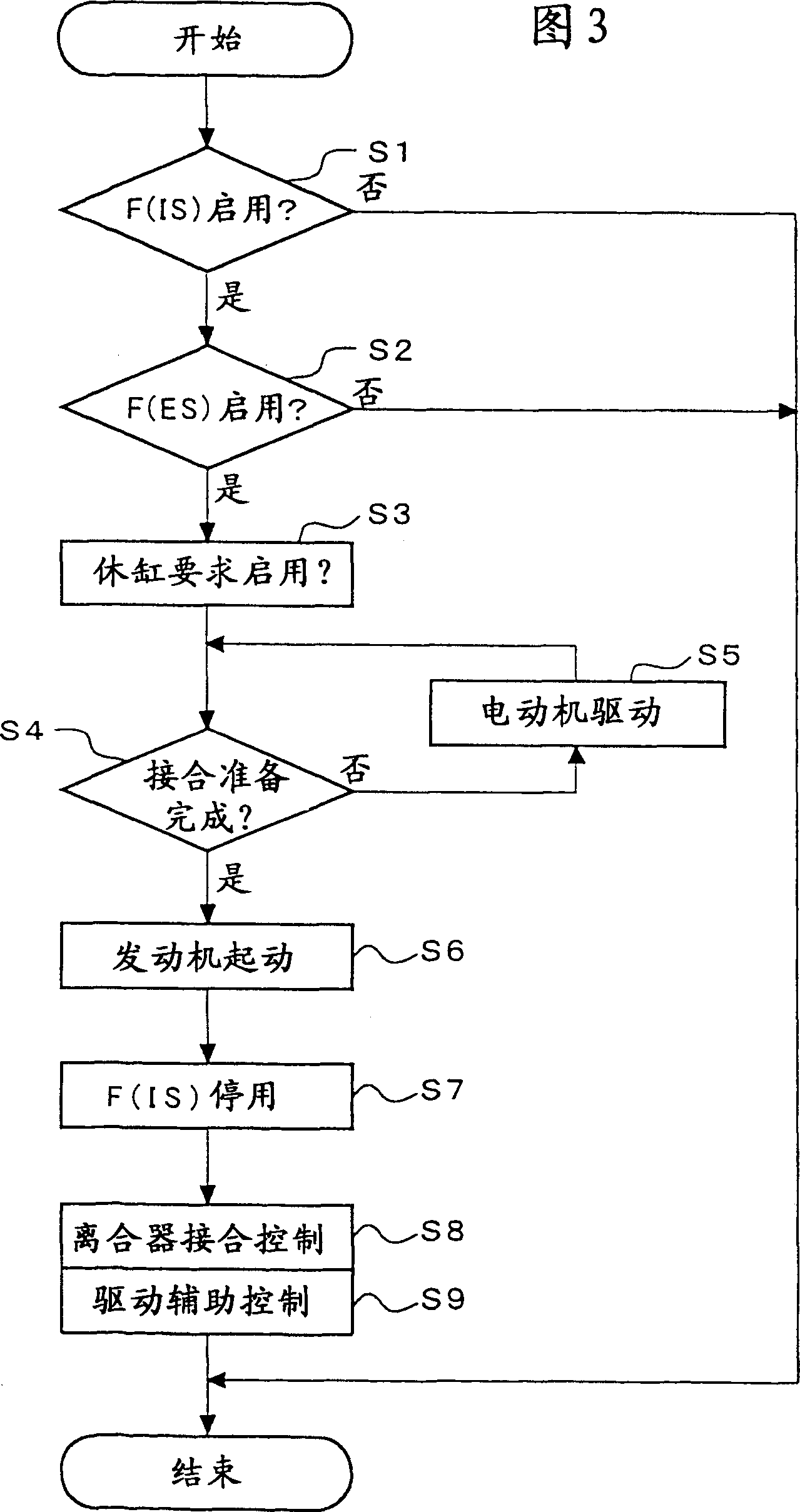

Power transmission controller for vehicle

InactiveCN1412034AProduce a sense of incongruitySmooth switchingClutchesPower operated startersControl systemHydraulic pump

A vehicular power-transmission control system comprises a continuously variable transmission CVT, which transmits the output of an engine E to wheels, a starting clutch 5, which controls the transmission of power in the continuously variable transmission, an electrical motor generator M, which can assist the engine in rotational drive, and a hydraulic pump P, which is connected to the output shaft of the engine. When the vehicle, which has come into a halt with the engine consequently stopped in an idling elimination control, is to be restarted, the power-transmission control system controls the electrical motor generator to rotate the output shaft of the engine, to which fuel supply is not allowed, thereby to drive the pump. Thereafter, when the starting clutch receiving a hydraulic pressure from the hydraulic pump starts its engagement, the power-transmission control system starts the operation of the engine.

Owner:HONDA MOTOR CO LTD

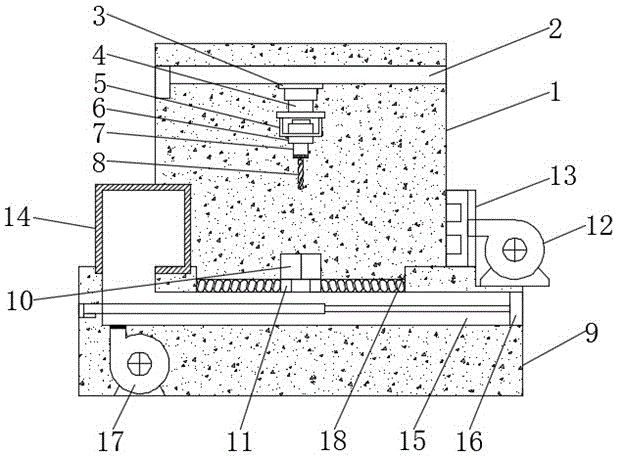

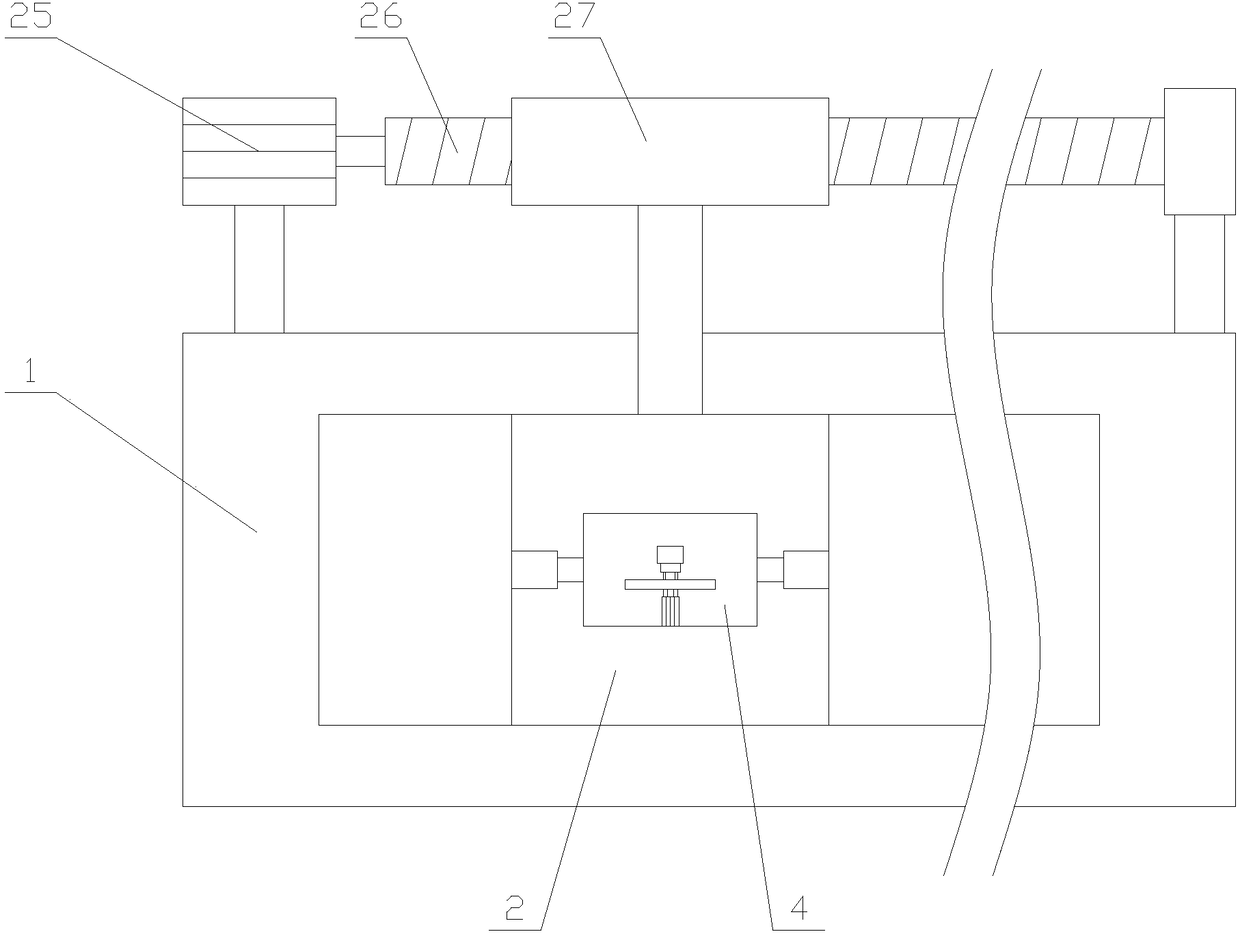

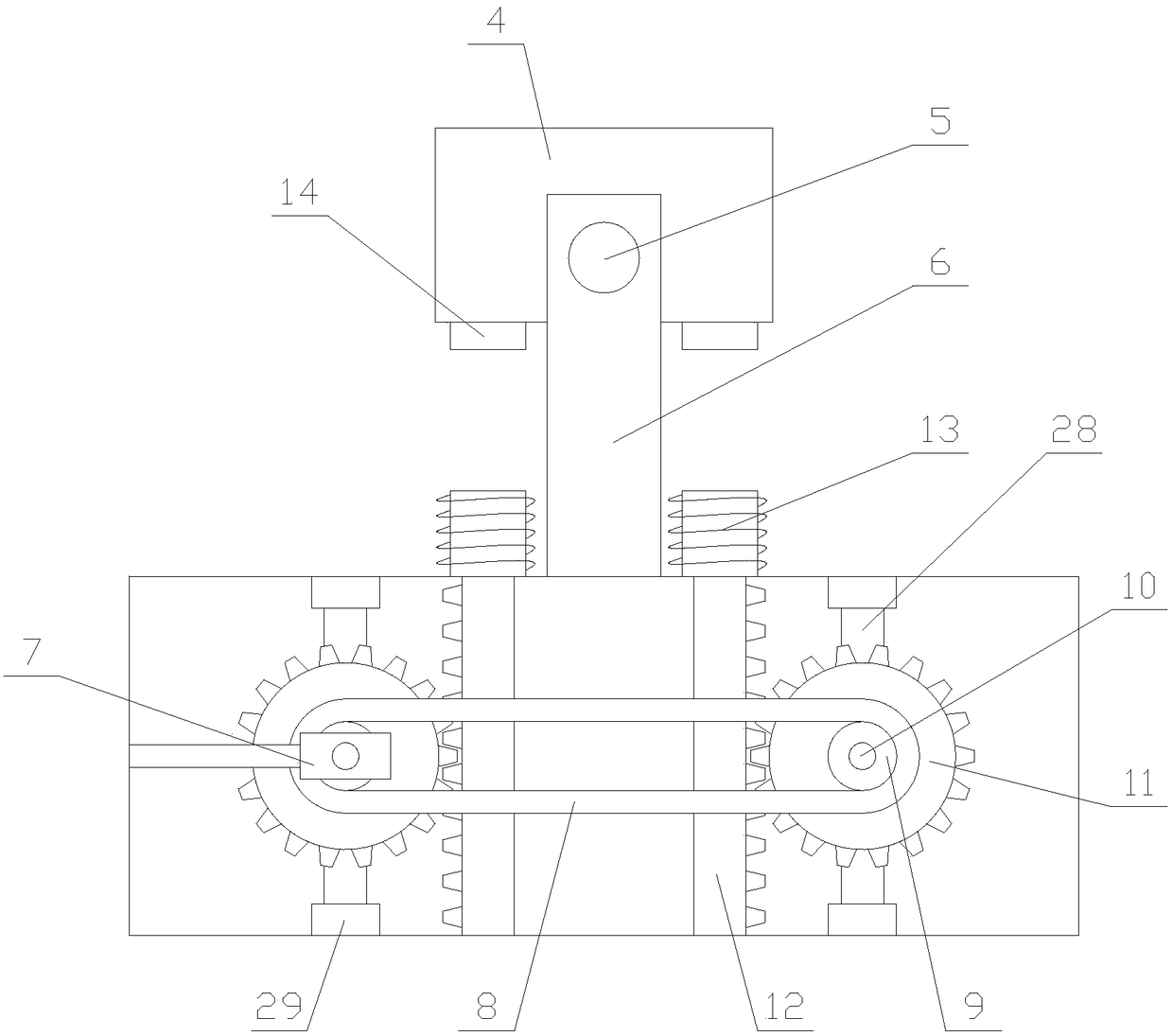

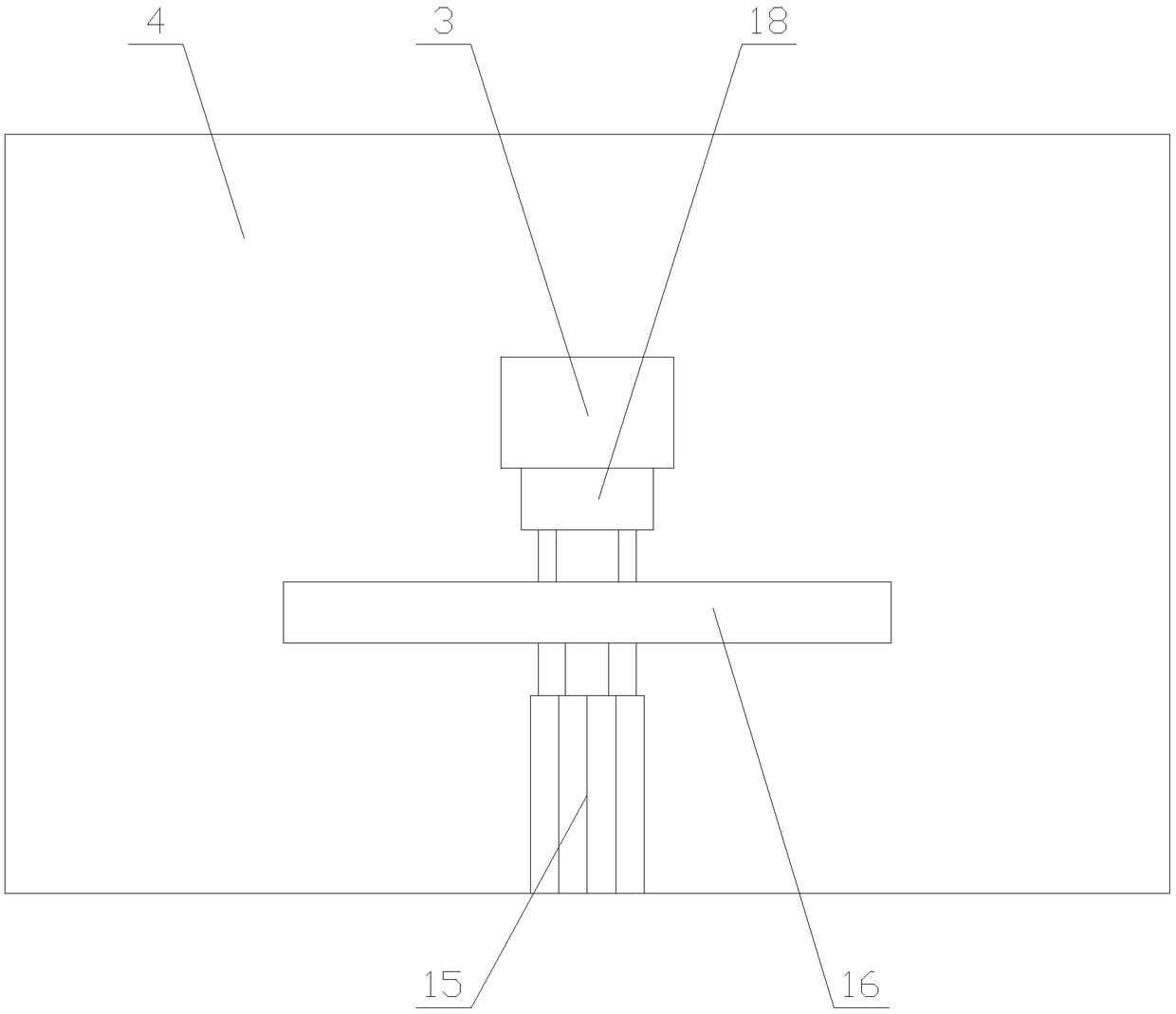

Drilling machine facilitating scrap collection

InactiveCN106514421AEasy to collectReduce precisionMaintainance and safety accessoriesBoring/drilling machinesFixed frameWorkload

The invention discloses a drilling machine facilitating scrap collection. The drilling machine comprises a support and a base. A linear motor is arranged on a top plate of the support. The bottom end of the linear motor is provided with a moving plate. The bottom end of the moving plate is provided with a telescopic rod. The bottom end of the telescopic rod is provided with a fixed frame. The middle portion of the bottom end of the fixed frame is connected with a pneumatic drilling machine in a sleeving mode. According to drilling machine facilitating scrap collection, wind generated by a draught fan is distributed through a flow distribution pipe to blow machined metal products; a suction fan operates to suck wind on a collection frame; wind flows to blow scraps generated after machining into the collection frame, and the scraps fall into a collection cavity; the electric telescopic rod operates to drive a cleaning plate to clean the scraps out of the collection cavity. Accordingly, scrap collection is facilitated, and the workload of workers is reduced. Heat generated during metal product machining is reduced. The cleanliness of the machine is guaranteed. The service life of the machine is prolonged. The machining precision of metal products is guaranteed.

Owner:WUXI CAIYUN MACHINERY & EQUIP

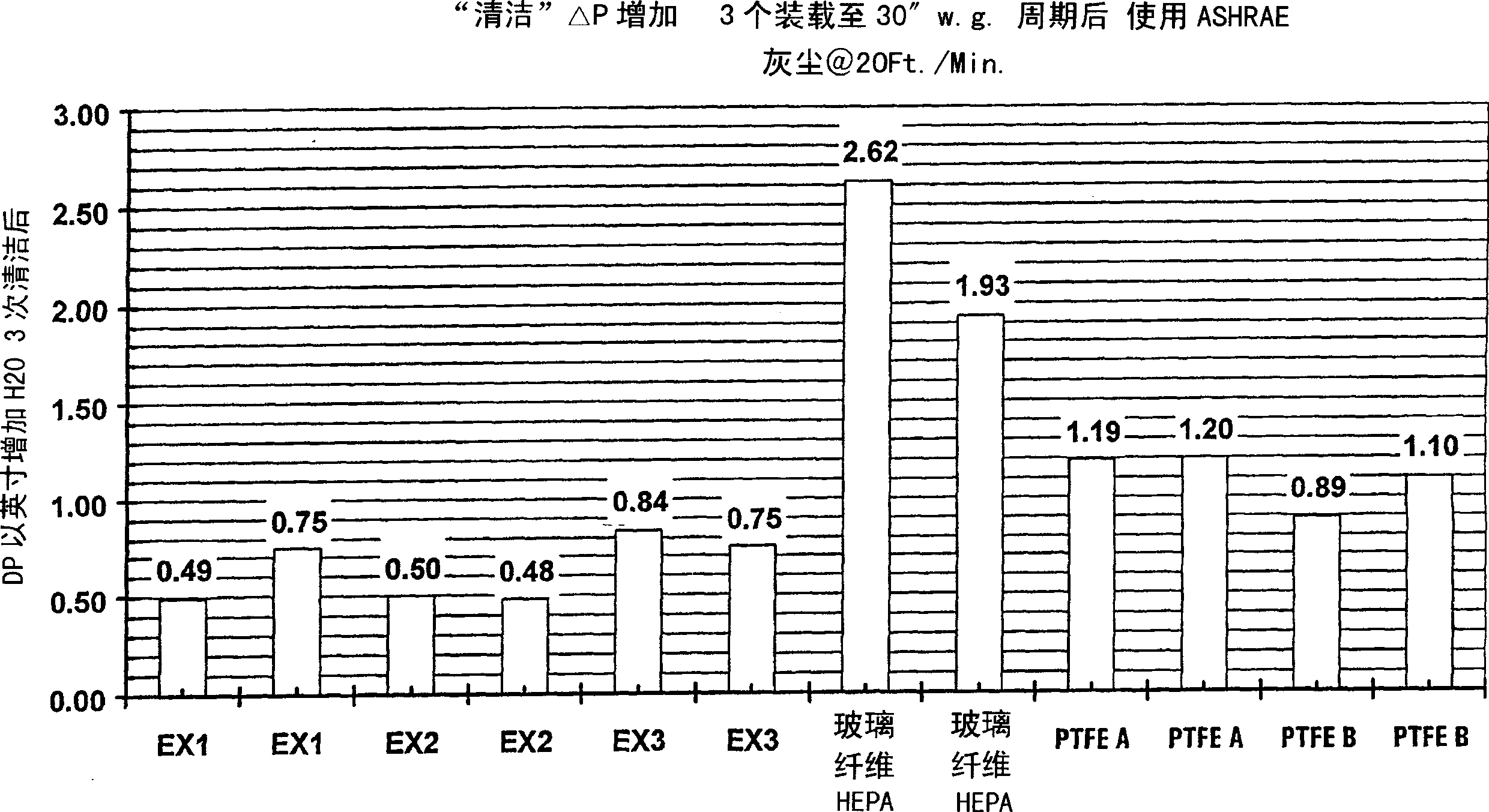

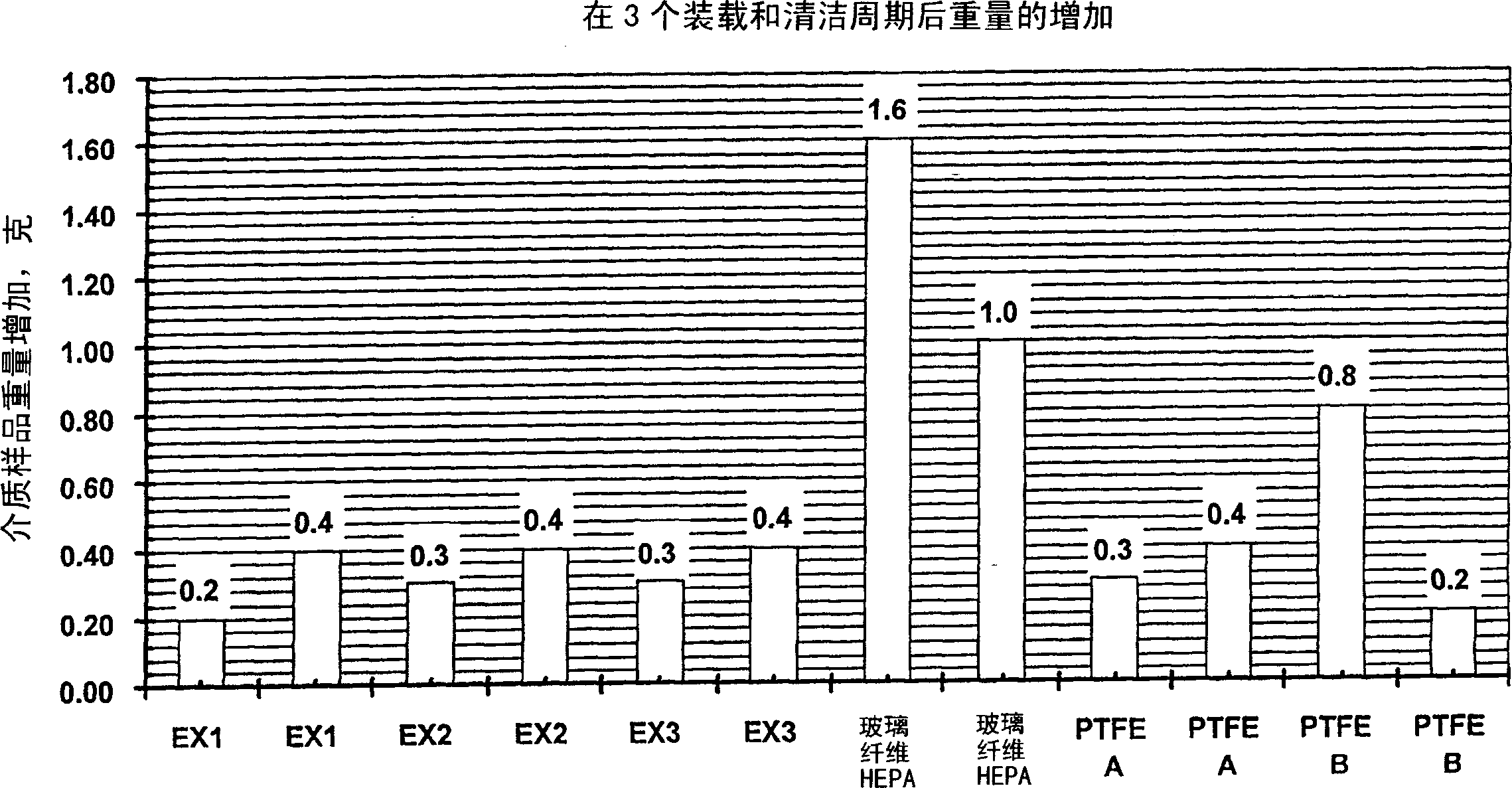

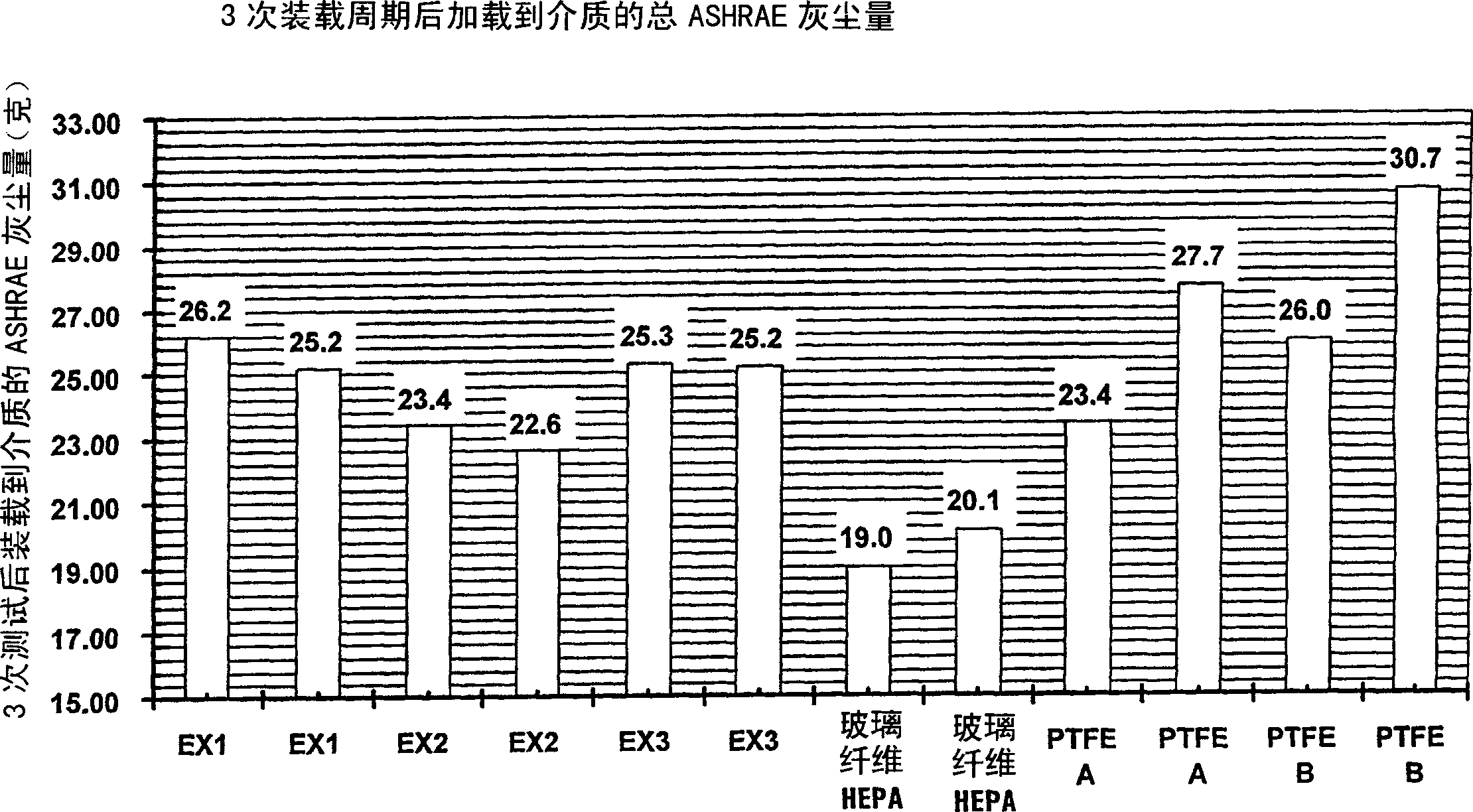

Cleanable high efficiency filter media structure and applications for use

ActiveCN1809408ALow cleanlinessImprove securityHuman health protectionDispersed particle filtrationEngineeringIndustrial setting

Filter elements, usually in cylindrical or flat plate form, are available in dry or wet / dry vacuum cleaners. The filter element can be flushed with a normal stream of water, or by gently tapping on a solid object, or by using a compressed air stream, but has very good filtration characteristics even for sub-micron particles in residential or industrial environments. The filter element has a combination of nanofiber filter layers on a substrate. The fiber diameter of the nanofibrous layer is about 0.05-0.5 micron, and the basis weight of the nanofibrous layer is about 3×10 -7 -6×10 -5 gm-cm -2 , the air permeability is about 1-1000ft / min 0.5 inches (water) ΔP, and the pore size is about 0.01-100 microns. The substrate layer is preferably folded, including a basis weight of about 0.2 oz-yd -2 -350lb3000ft -2 , a thickness of about 0.001-0.2 inches, and an overall filter permeability of about 1-200 ft-min -1 , 0.5 inches (water) ΔP, at 10ft-min -1 The speed removal efficiency of 0.76 micron particles is about 10-99.99995%.

Owner:DONALDSON CO INC

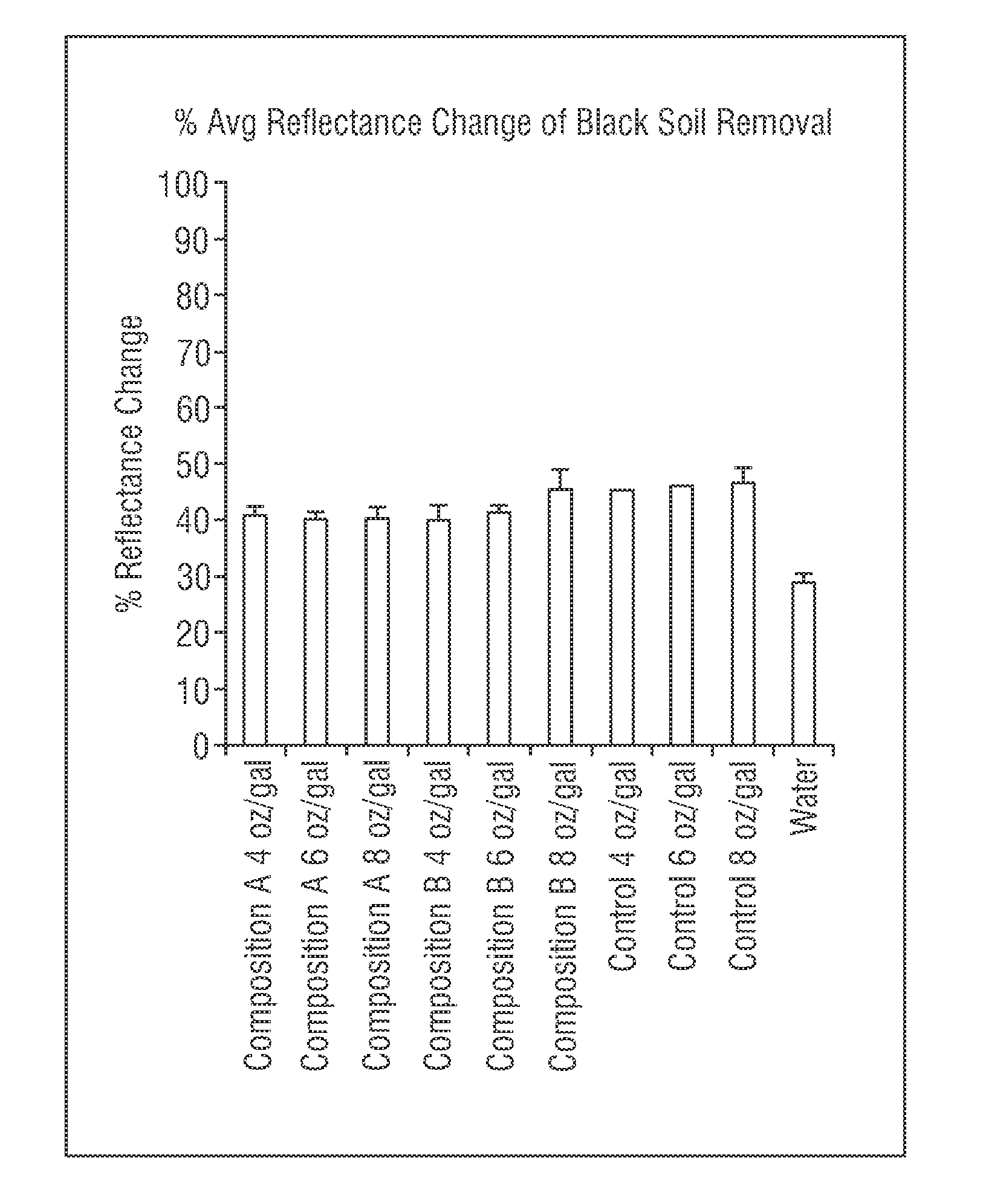

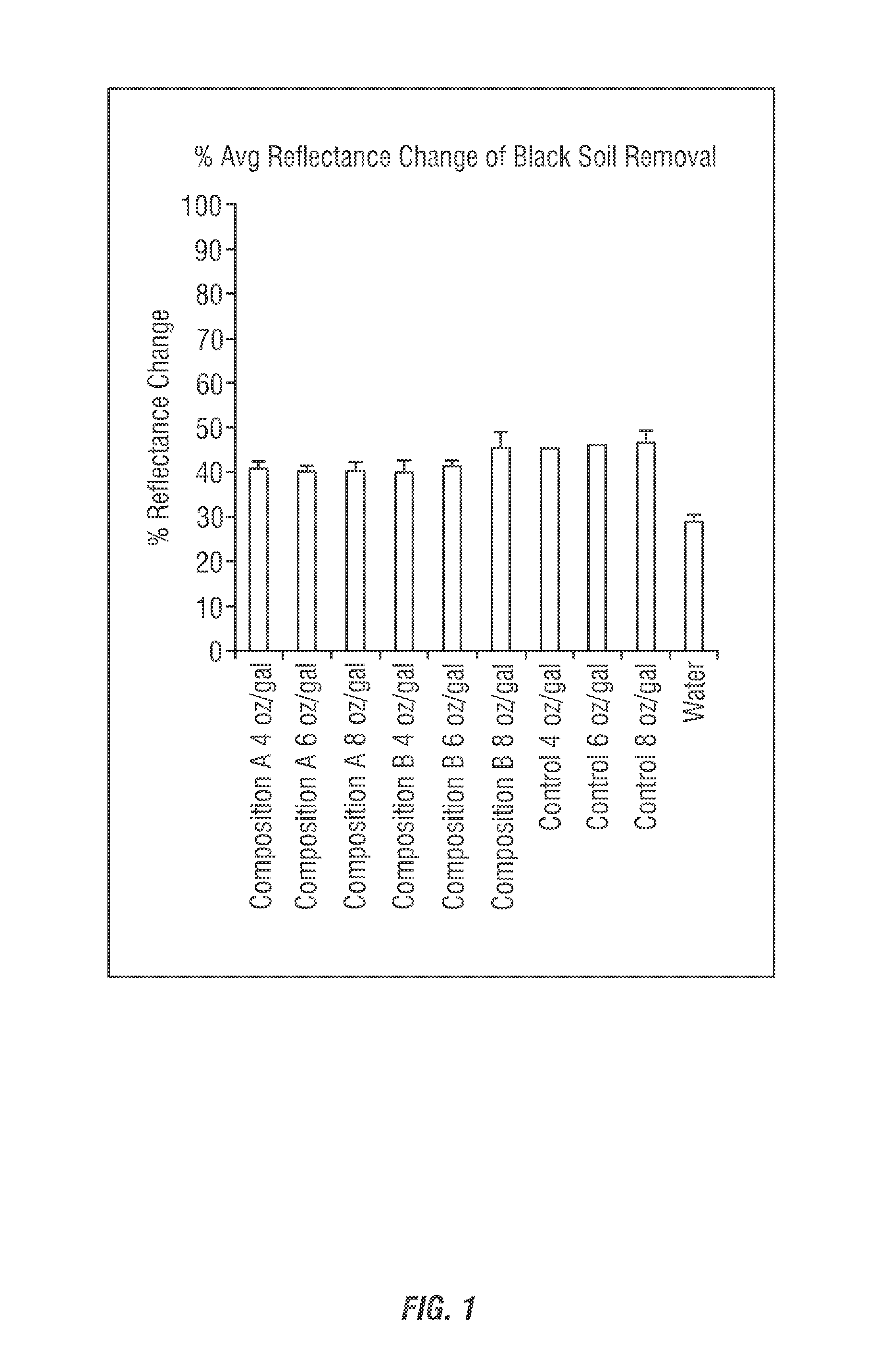

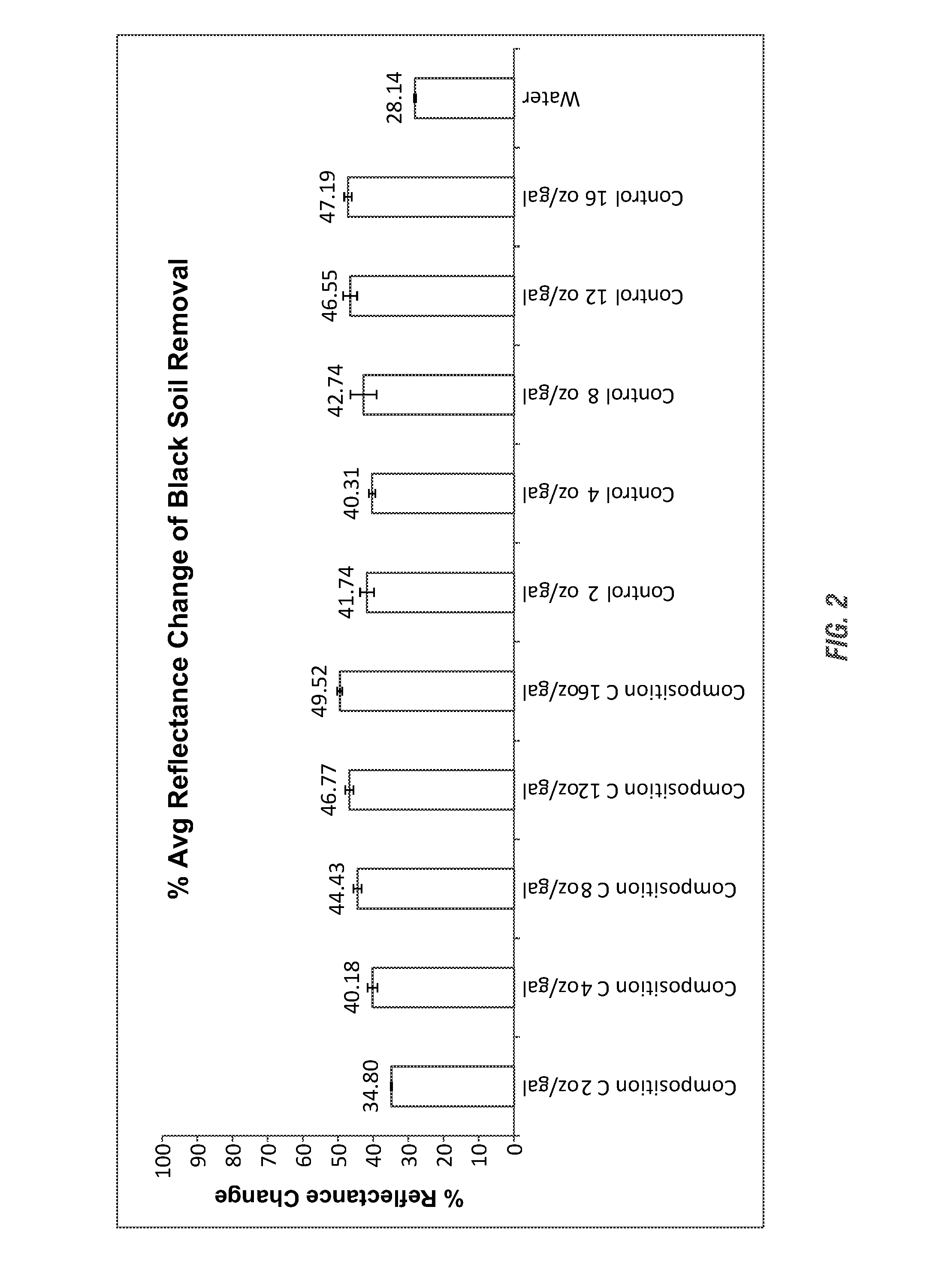

All-purpose cleaners with natural, non-volatile solvent

ActiveUS8617317B1Good effectLow cleanlinessPowder deliveryCosmetic preparationsAlcoholAlkyl polyglycoside

Renewable, non-volatile cleaning compositions incorporating ethyl ester solvents are disclosed. Preferred compositions employ non-volatile C8-16 ethyl ester solvents. All-purpose cleaning compositions incorporating the non-volatile C8-16 ethyl ester solvents, further include an alkyl polyglycoside surfactant, an alcohol ethoxylate surfactant, and water. Preferably the compositions are free of anionic, cationic and amphoteric surfactants and / or co-solvents. The invention also discloses methods employing the non-volatile solvent all-purpose cleaning compositions.

Owner:ECOLAB USA INC

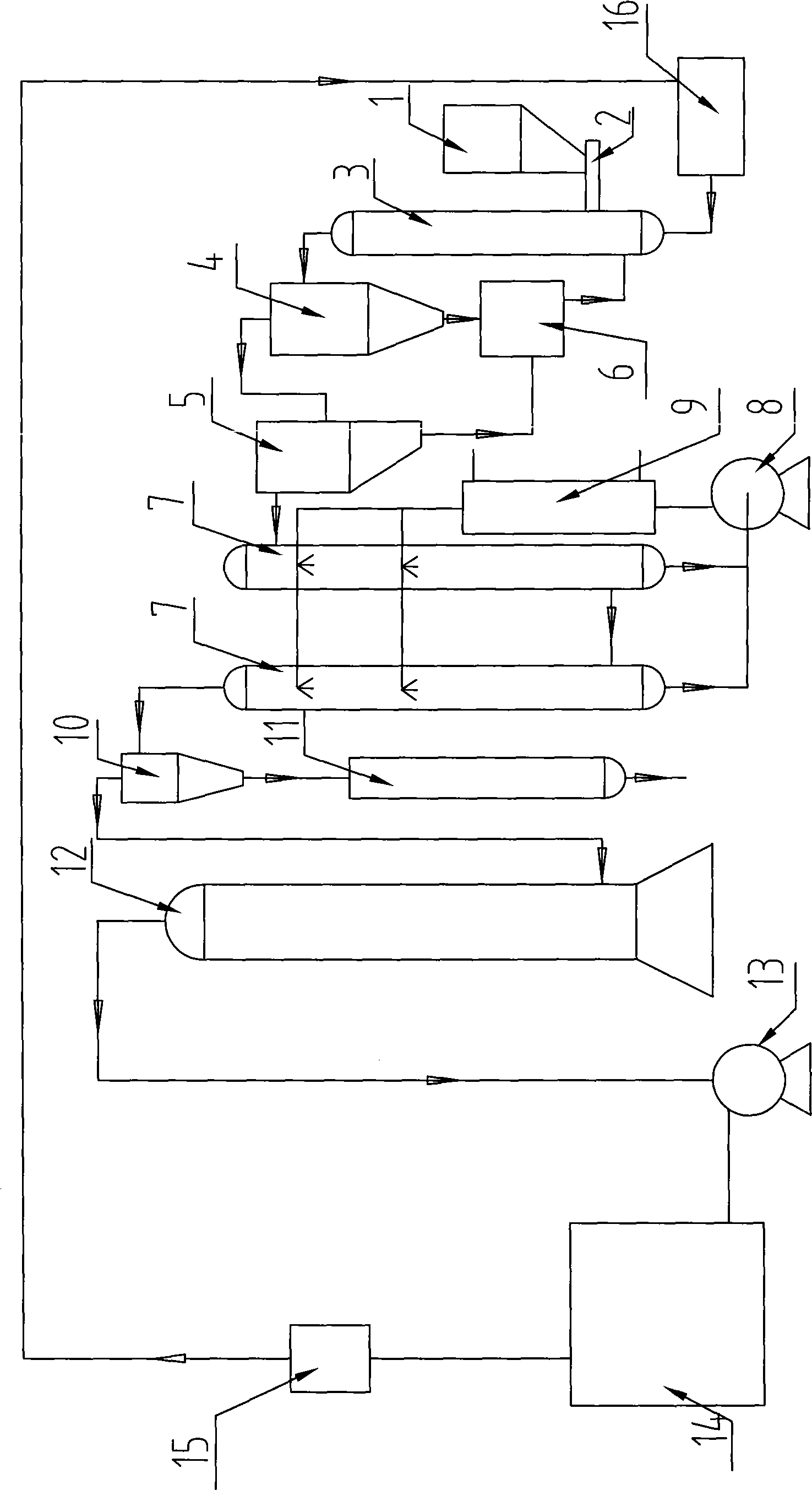

System for rapidly pyrolysing and liquefying biomass

InactiveCN101531910AImprove cleanlinessLow cleanlinessLiquid hydrocarbon mixture productionProcess engineeringBiomass

The invention discloses a system for rapidly pyrolysing and liquefying biomass, which comprises a pyrolysis reactor, a feeding device connected with a biomass material inlet of the pyrolysis reactor, a reaction starter connected with a circulating heat supporting gas inlet, a gas-solid separation sub-system connected with a pyrolysis gas outlet of the pyrolysis reactor, a bio-oil condensing and reserving sub-system connected with a gas outlet of the gas-solid separation sub-system, and a thermal circulation medium heating and separating sub-system connected with a solid outlet of the gas-solid separation sub-system. The thermal circulation medium outlet of the thermal circulation medium heating and separating sub-system is connected with the thermal circulation medium inlet of the pyrolysis reactor, wherein the bio-oil condensing and reserving sub-system includes at least one heat exchanger that is applied for cooling partial obtained bio-oil to be used as a condensed medium of the bio-oil condensing and reserving sub-system. The system for rapidly pyrolysing and liquefying biomass can fully improve the utilization rate of biomass energy and reduce the operation cost thereof to the maximum degree.

Owner:GUANGZHOU DEVOTION THERMAL TECH

Tinning substrate for deep-punching food can and production method thereof

The invention relates to a steel metallurgical material, in particular to a tinning substrate for deep-punching food cans and a production method thereof. The tinning substrate comprises the following chemical element compositions in percentage by weight: less than or equal to 0.04% of C; less than or equal to 0.02% of Si, 0.20-0.25% of Mn, less than or equal to 0.02% of P, less than or equal to 0.018% of S, 0.005-0.040% of Als, and the balance iron and unavoidable inclusion. The production method comprises the following processes: smelting, continuous casting, heating, hot rolling, cooling and reeling, pickling and cold rolling, and annealing and leveling, wherein the heating temperature is 1210 DEG C, the primary rolling temperature is 1100-1150 DEG C, the final rolling temperature is 890+ / -10 DEG C, the reeling temperature is 560+ / -15 DEG C, the annealing temperature is 670-690 DEG C, and others are performed as conventional processes. The invention has small production control difficulty, low cost, stable performance and high can manufacturing percent of pass, and is suitable for manufacturing deep-punching food cans and can covers with more complex transformation.

Owner:TANGSHAN GUOFENG IRON & STEEL

Micro gas generator with automatic ignition function

ActiveUS20060162607A1Low cleanlinessImprove stabilityBlasting cartridgesPedestrian/occupant safety arrangementEngineeringGas generator

A micro gas generator with an automatic ignition function operated before being weakened by heat without impairing the cleanliness of exhaust gas, comprising gas generating agent, a cup body for filling the gas generating agent therein, and a holder formed integrally with squibs and fixedly sealing the squibs in the cup body, wherein an automatic igniting agent layer is put on the inner surface of the cup body.

Owner:NIPPON KAYAKU CO LTD

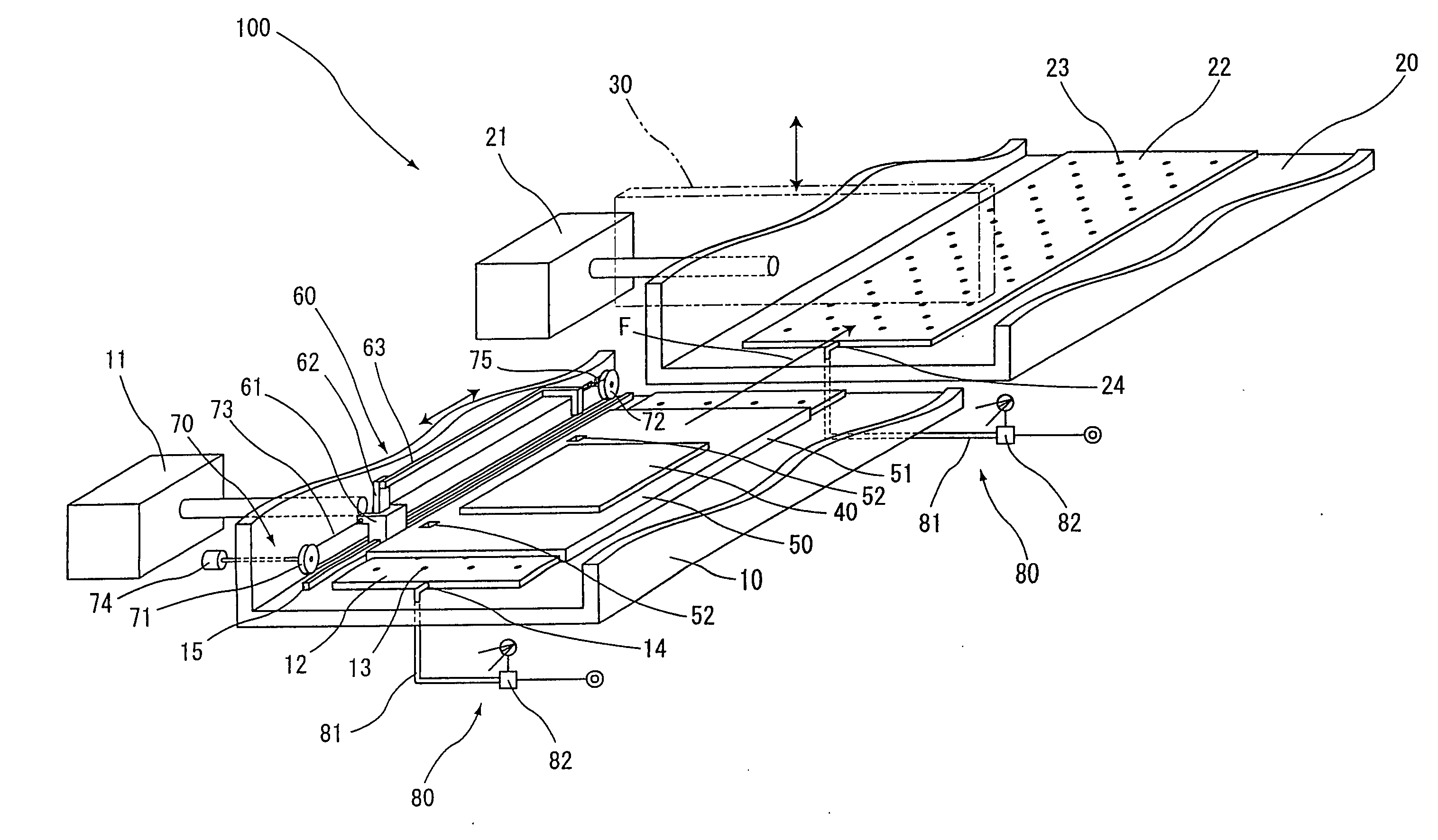

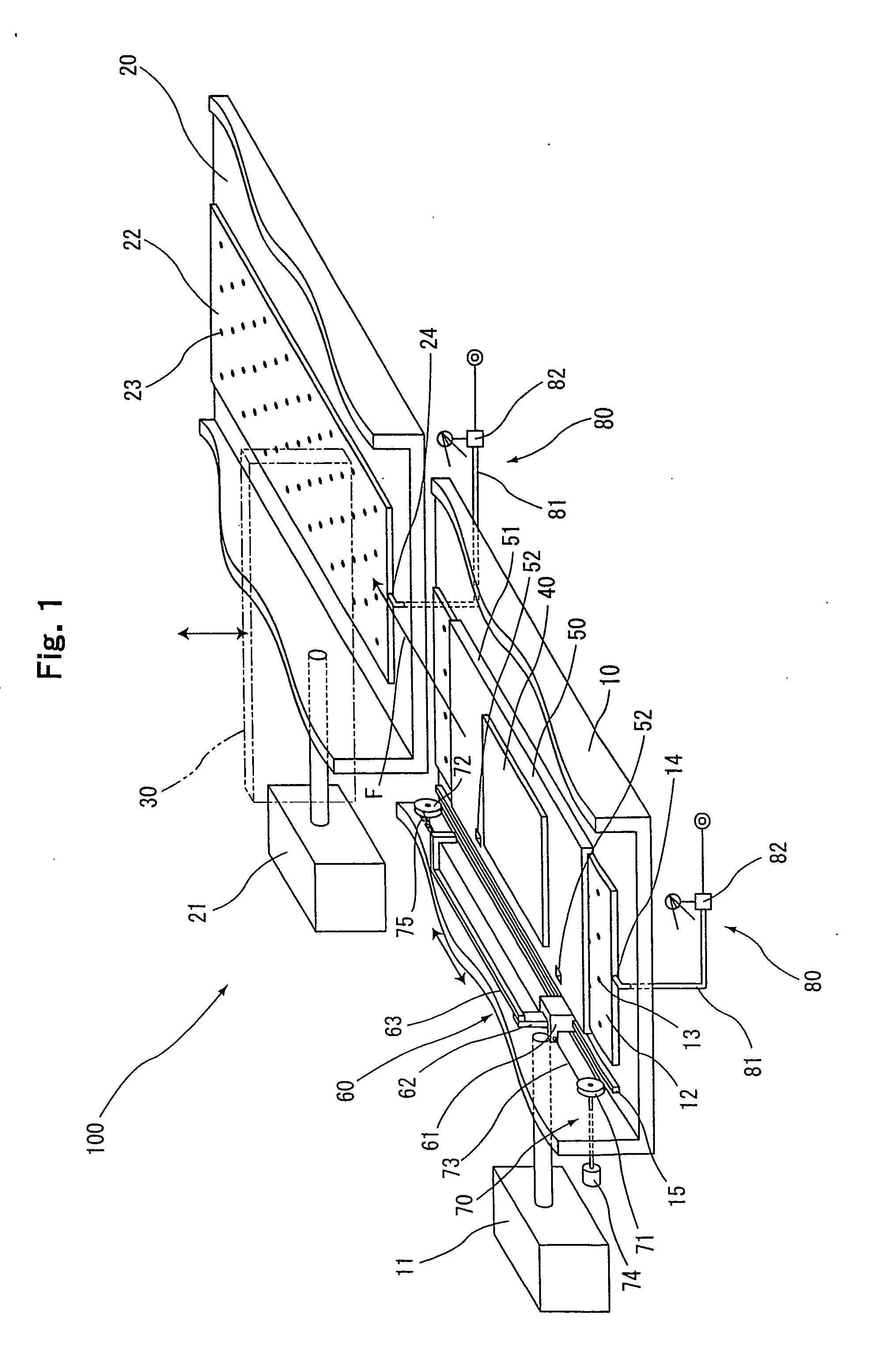

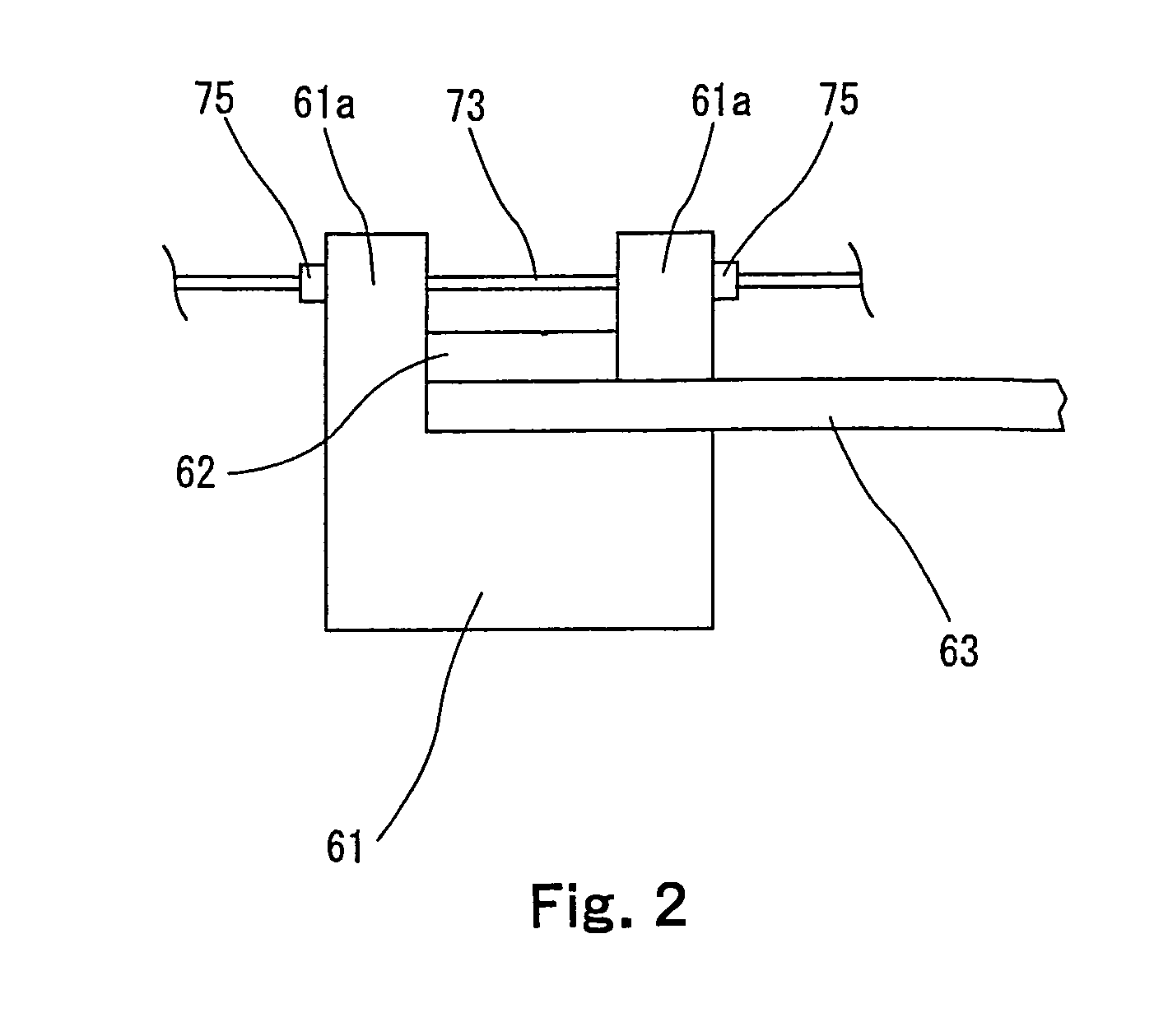

Semiconductor manufacturing apparatus and semiconductor manufacturing method using the same

InactiveUS20070137570A1Satisfied with precisionSimple configurationConveyorsSemiconductor/solid-state device manufacturingManufactured apparatusEngineering

A semiconductor manufacturing apparatus comprising: a plurality of vacuum chambers corresponding to a plurality of processing sections necessary for manufacturing a semiconductor device; an exhaust device connected to each vacuum chamber; a plate shaped guide plate arranged at the bottom of each vacuum chamber and having a plurality of gas emission holes; and a gas supply source for supplying gas to the gas emission holes, wherein the plurality of vacuum chambers are adjacent to each other by way of a shutter, one of the two adjacent vacuum chambers includes a tray mounted on the guide plate for mounting a substrate to be performed with a predetermined process, a conveying function section having a conveying arm for moving the tray from one vacuum chamber to the other vacuum chamber along the guide plate, and a controlling function section, the controlling function section performing the control so as to open the shutter to communicate the two adjacent vacuum chambers, emit gas from the gas emission holes of the guide plate of the vacuum chambers, and move the tray in one vacuum chamber, which is floated by the emitted gas, from the guide plate of one vacuum chamber to the guide plate of the other vacuum chamber along the guide plate by means of the conveying arm.

Owner:SHARP KK

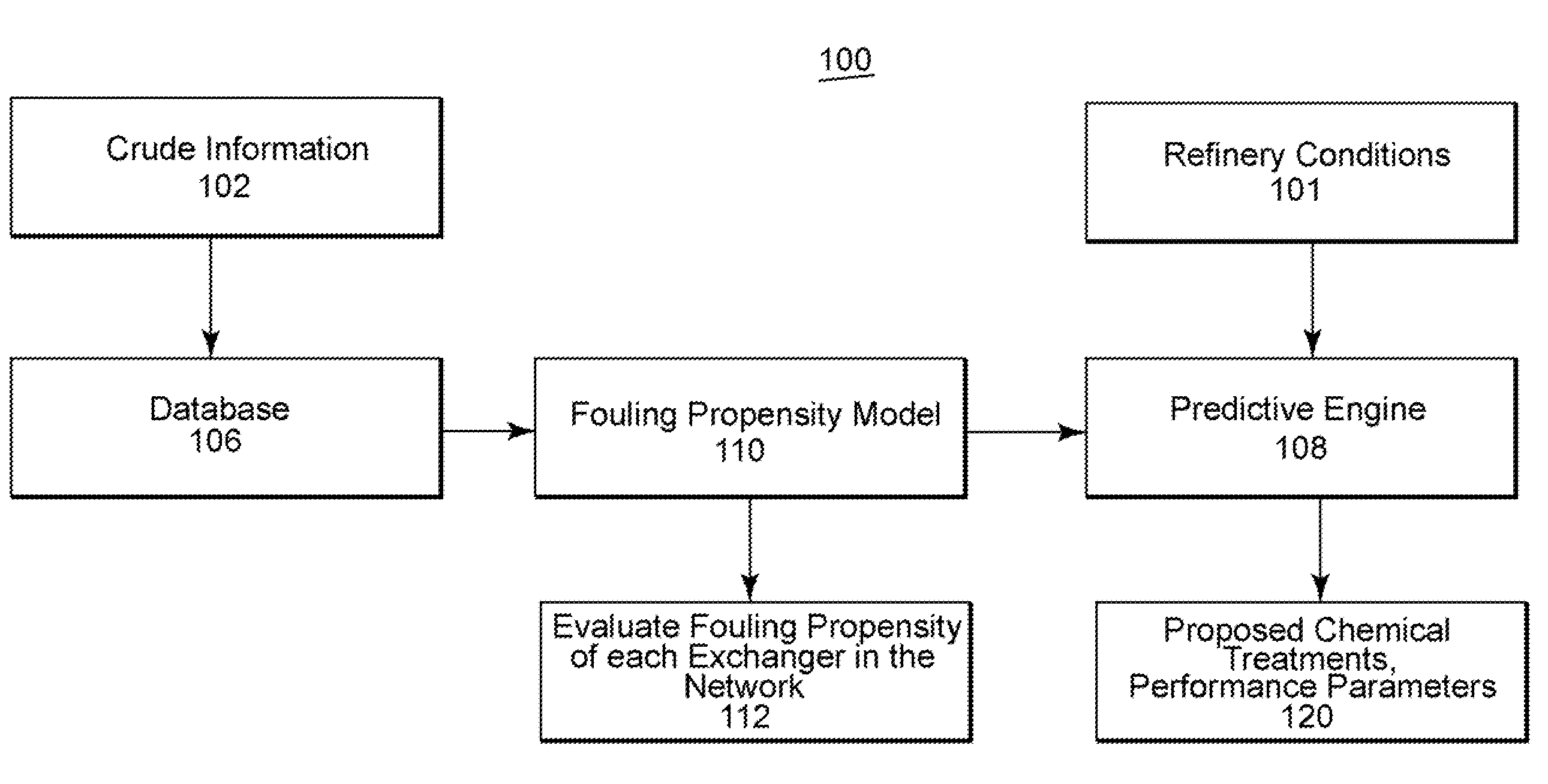

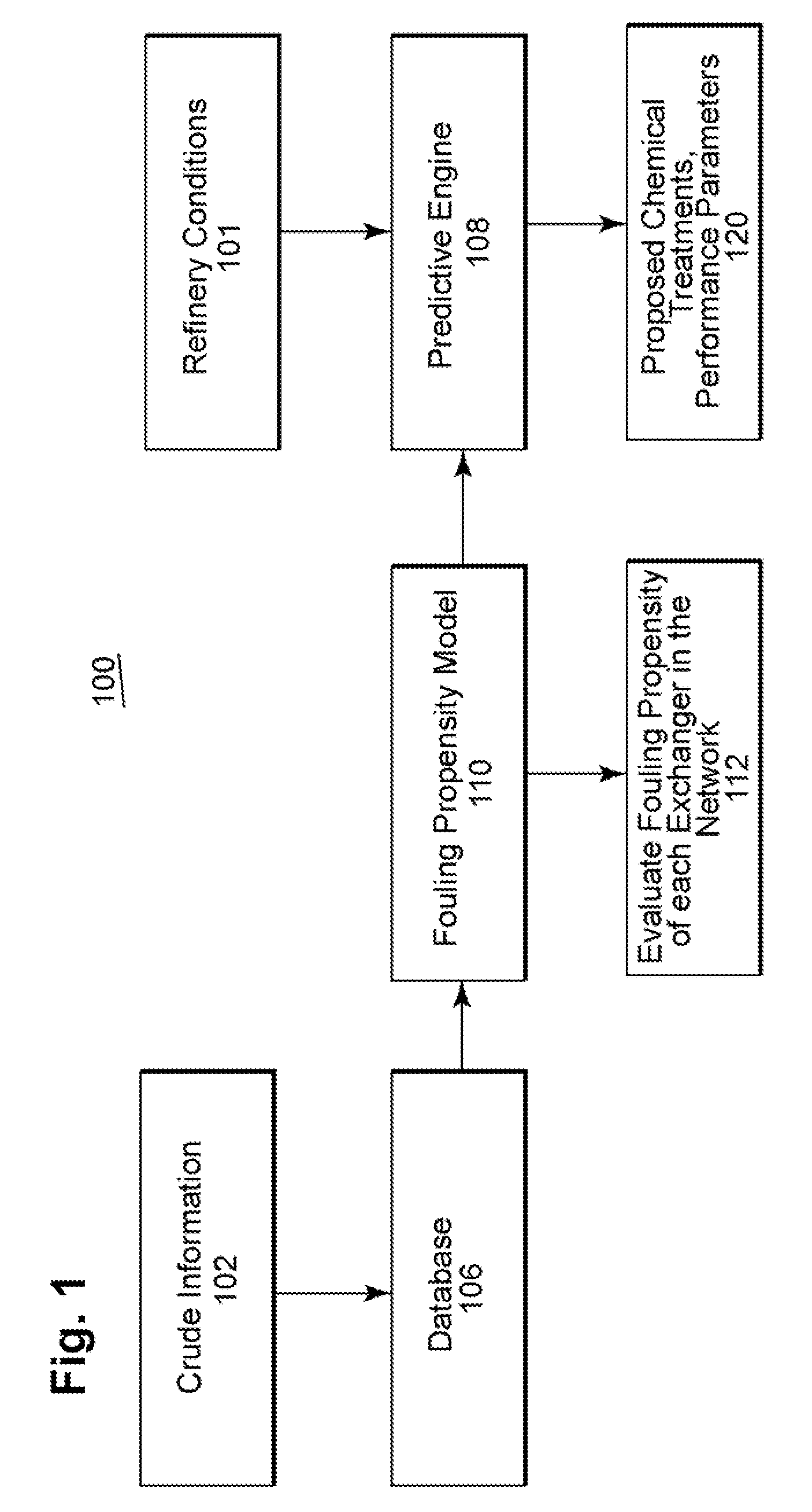

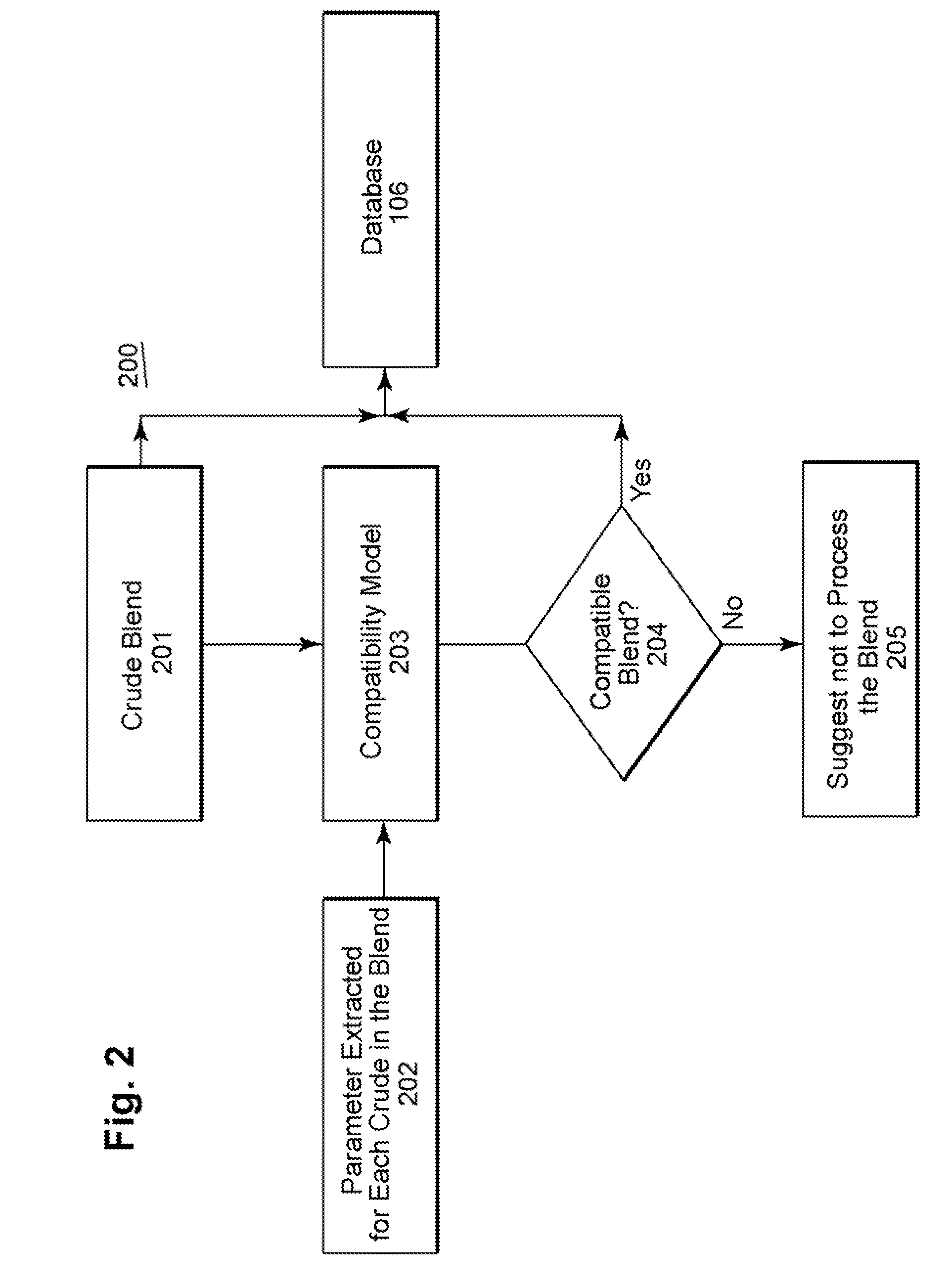

Method and system for assessing the performance of crude oils

ActiveUS20080147365A1Performance degradationImprove performanceDigital computer detailsNuclear monitoringQualitative propertyModel parameters

A methodology and system is disclosed which addresses outstanding needs of refiners to process cheaper crudes or blends of crudes. This method and system comprises a number of steps, including characterizing the impact of various constituents in the crude which result in fouling of heat exchangers; estimating model parameters; monitoring and predicting qualitative and quantitative performance; and determining optimal dosage of chemical treatments.

Owner:BL TECH INC

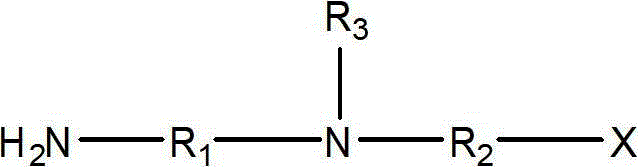

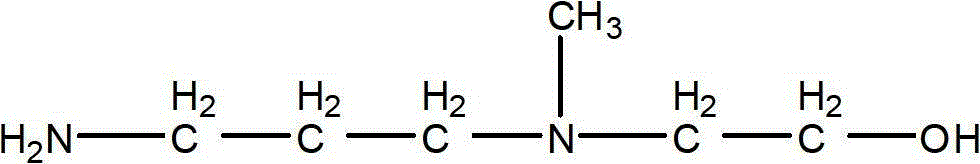

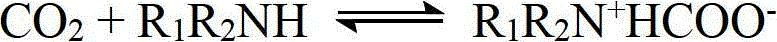

Novel absorbent for capturing and separating carbon dioxide

ActiveCN102974203AReduce heat of reactionImprove stabilityDispersed particle separationBy chemical separationAbsorption capacityDesorption

The invention belongs to the technical field of gas separation and purification and relates to a novel absorbent for capturing and separating CO2 in mixed gas. An active amine compound aqueous solution with a special structure is used as an absorbent; two functional groups, namely a primary amine functional group and a tertiary amine functional group, are contained in the active amine molecules; primary amine is mainly used for improving the absorption rate, and tertiary amine is mainly used for increasing the absorption amount and reducing the desorption temperature; and the two types of amine can promote activation. The active amine compound aqueous solution comes into contact with treated gas to purify gas; and the concentration of the absorbent is 5-80wt%. The absorbent provided by the invention is wide in amine concentration range, high in CO2 absorption rate, large in absorption capacity and low in desorption temperature and causes little corrosion to equipment. The novel absorbent can be widely applied to separation and purification of CO2 in natural gas, transformation gas, flue gas and synthesized gas.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

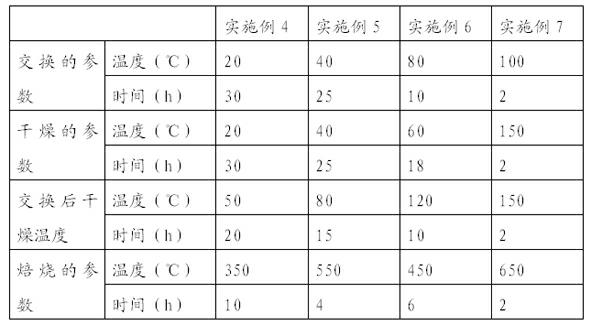

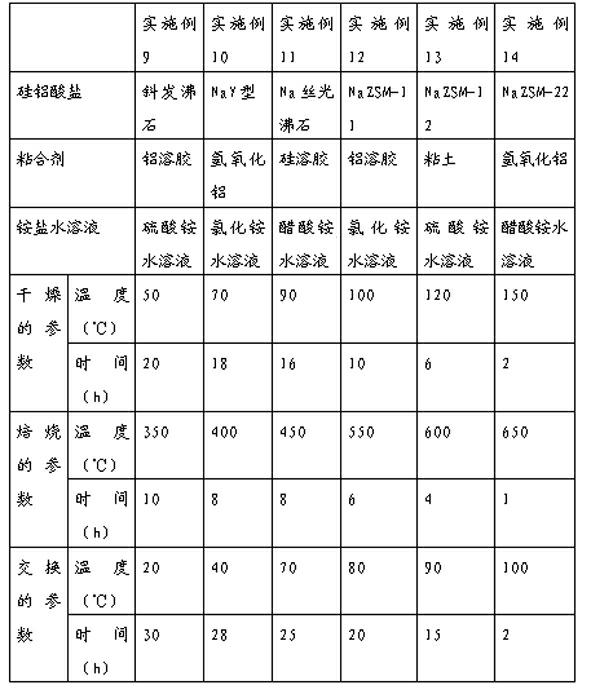

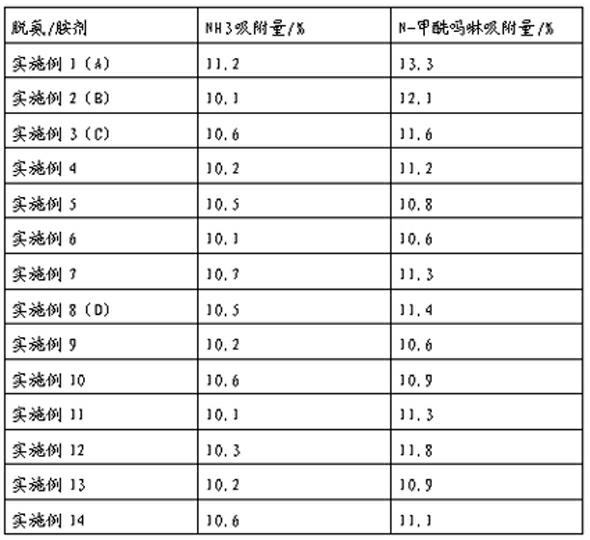

Deaminizing agent and preparation method thereof

InactiveCN101982232AIncreased ammonia capacityLow cleanlinessOther chemical processesAluminium silicatesAdhesiveIon exchange

The invention relates to a deaminizing agent and a preparation method thereof. The preparation method comprises the following steps: mixing and molding aluminosilicate and adhesive in the dry basis weight ratio of 90:10-70:30, and carrying out ion exchange with ammonium salt water solution to obtain the deaminizing agent. The deaminizing agent comprises the following raw materials in percentage by weight: 10-90% of SiO2, 5-10% of Al2O3 and 0.5-10% of MxO. The content of ammonia is greatly increased to higher than 10%, the degree of purification is lower than 0.3 ppm, the strength of adsorbentis very high, the phenomenon of efflorescence does not occur in the use process, and in addition, the adsorbent is reproducible and can be used for a long time.

Owner:YANTAI UNIV

Flexible ultrasonic glue dipping device

The invention discloses a flexible ultrasonic glue dipping device. The flexible ultrasonic glue dipping device comprises a tank body, wherein the tank body is provided with an inner concave chamber for containing liquid resin, is of a two-layer structure and comprises an inner tank body and an outer tank body; a space for storing cycling medium is formed between the inner tank body and the outer tank body; the outer tank body is respectively provided with a liquid inlet and a liquid outlet which are respectively communicated with the space; and the outer wall of the outer tank body is provided with a flexible ultrasonic device with adjustable parameters such as frequency and power. The flexible ultrasonic glue dipping device disclosed by the invention has the advantages that ultrasonic waves produced by the ultrasonic device act on fiber and the liquid resin uniformly by means of the cycling medium to realize glue dipping, and after the glue dipping procedure is finished, when a glue dipping tank is cleaned, the ultrasonic waves also act on sewage in the tank body, therefore, for the glue dipping and cleaning processes, a physical means is adopted in the flexible ultrasonic glue dipping device, and on the basis of realizing glue dipping, the cleaning effect is improved, the cleaning process is simplified, and the influence on the reuse effect of the glue dipping tank is avoided.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

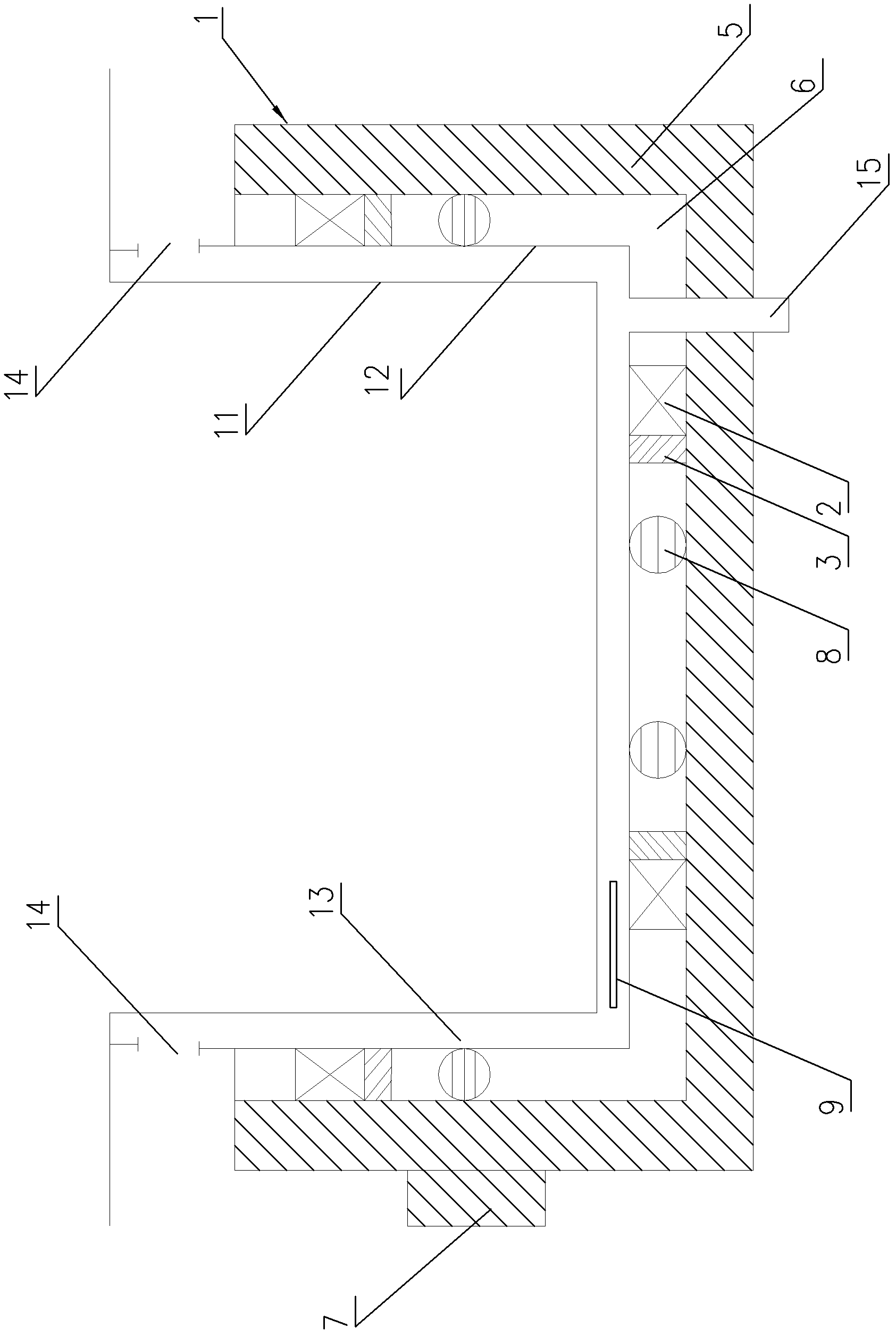

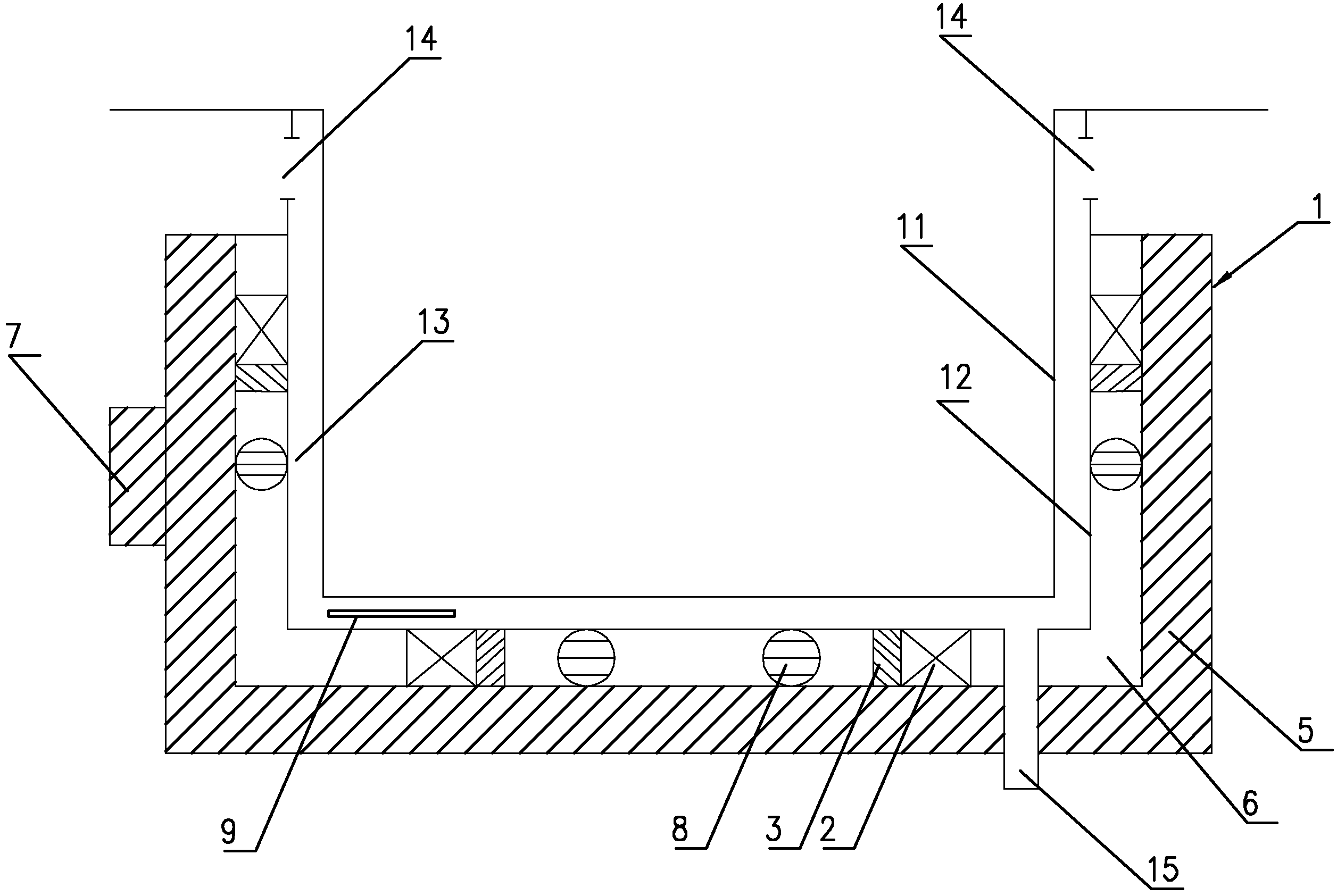

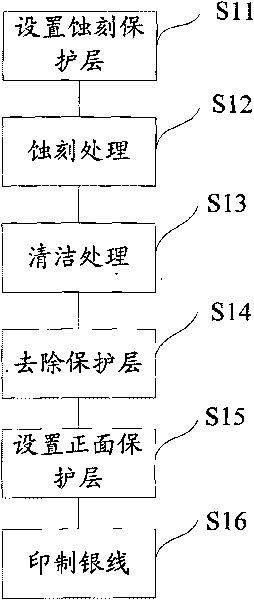

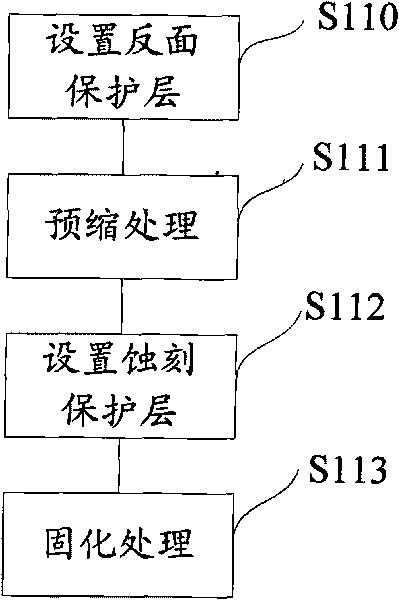

Manufacturing method of ITO film for touch screen

InactiveCN101739160AImprove cleanlinessLow cleanlinessInput/output processes for data processingEngineeringProtection layer

The invention discloses a manufacturing method of an ITO film for a touch screen, which comprises the following steps: arrangement of etching protection layer: arranging an etching protection layer on the front surface of the ITO film; etching treatment: etching the front surface of the ITO film; cleaning treatment: cleaning the etched ITO film; stripping of the etching protection layer: removing the etching protection layer of the cleaned ITO film; arrangement of protection layer on front surface: arranging a protection layer in the visible area on the front surface of the ITO film; and printing of silver wires: printing silver wires around the front surface of the ITO film. As the etching protection layer on the front surface of the ITO film protects the ITO film after the etching treatment step, higher cleanness can be provided when the ITO film is cleaned; and simultaneously, the ITO film can be prevented from being scratched or oxidized, thus the yield of the touch screen can be improved.

Owner:深圳市航泰光电有限公司

Wide-recognition-range monitoring equipment based on face recognition technology

InactiveCN108361501AImprove practicalityImprove operational efficiencyCharacter and pattern recognitionClosed circuit television systemsDrive wheelEngineering

The invention relates to wide-recognition-range monitoring equipment based on the face recognition technology. The wide-recognition-range monitoring equipment comprises a sliding rail, a movable block, an adjusting mechanism, a camera and a clearing mechanism. The adjusting mechanism comprises a rotary block, a rotary shaft, a movable assembly, a rotary assembly, a swing assembly and two supporting plates. The rotary assembly comprises a first motor, a conveying belt, two driving wheels, two driving units and two driven units. Each driving unit comprises a connecting shaft, a first gear, a first gear rack and a limiting unit. According to the wide-recognition-range monitoring equipment based on the face recognition technology, the angle of the camera is adjusted through the adjusting mechanism, and therefore the monitoring recognition range is widened. The practicality of the monitoring equipment can be improved. Dust accumulated on a lens of the camera is cleared away through the clearing mechanism, it is avoided that the cleanliness degree of the camera is reduced as the use time of the camera is increased, and therefore the recognition precision of the monitoring equipment is improved.

Owner:MAANSHAN BEIYITONG INTELLIGENT TECH CO LTD

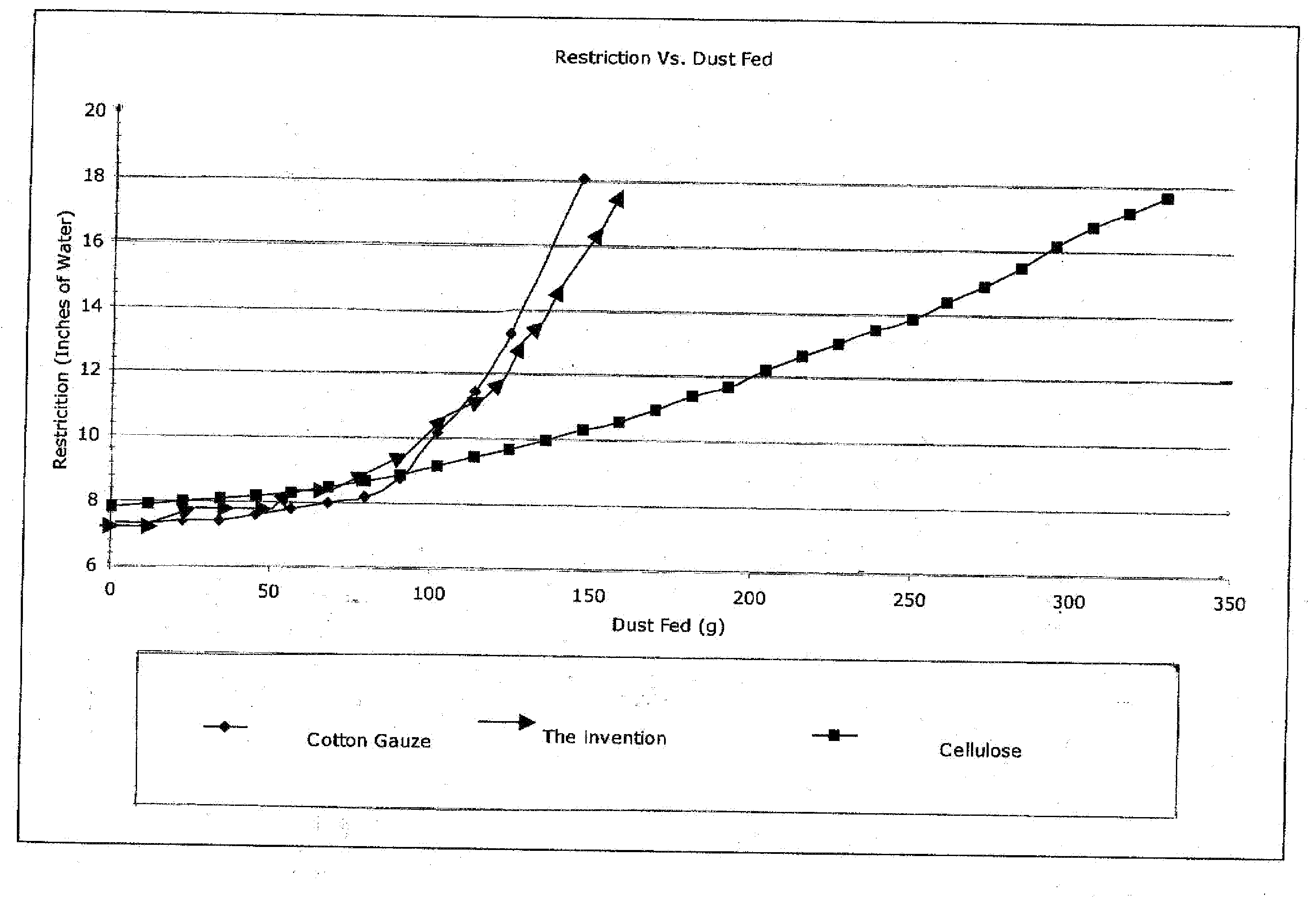

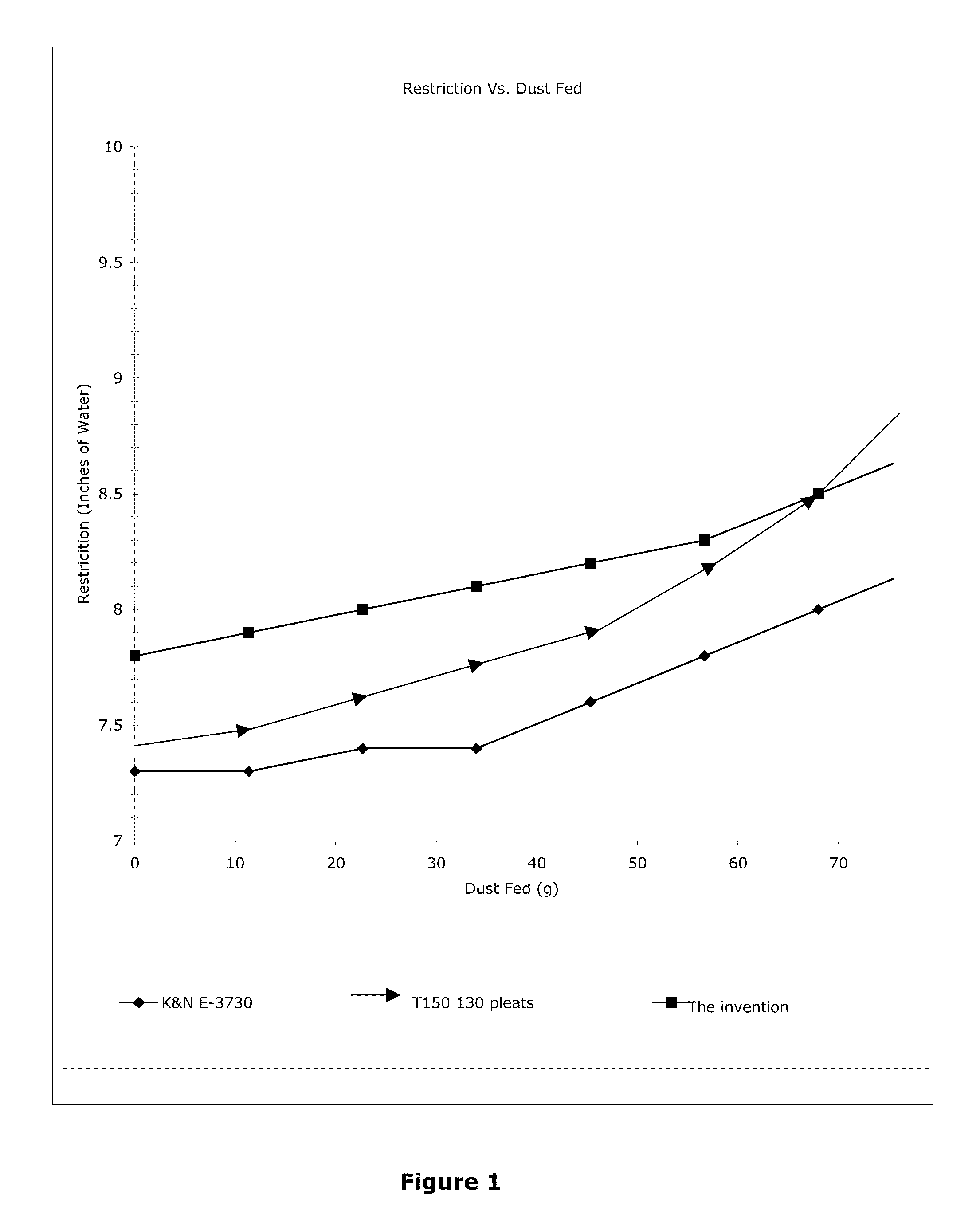

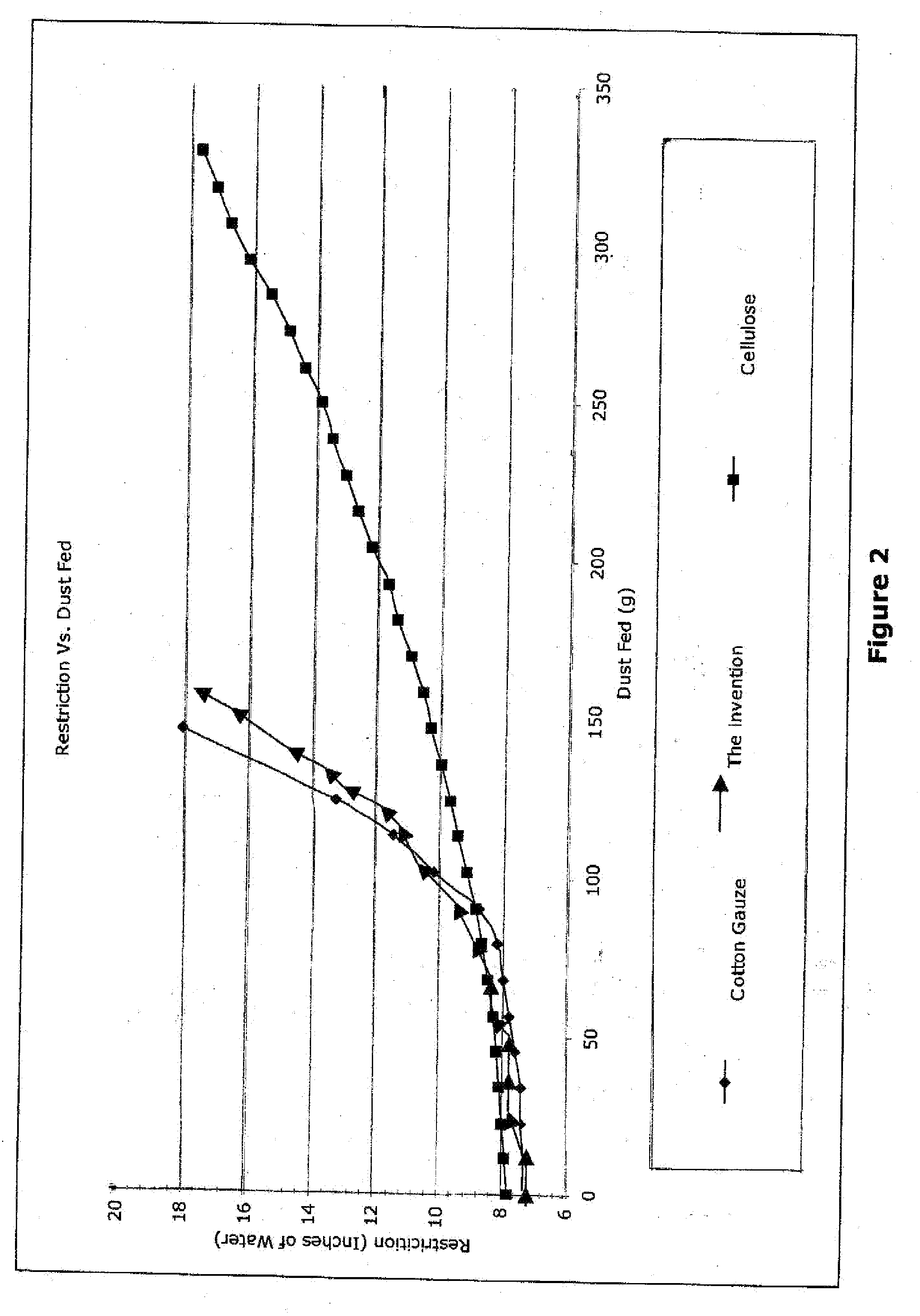

Gradient density engine intake filter media

InactiveUS20090301042A1Control flowLow dust holding capacityCombination devicesGas treatmentAir filtrationFilter media

A filter for internal combustion engine air intake comprised of a synthetic fiber media uniquely enhanced with a gradient density configuration. The media described in this application is a low restriction synthetic fiber media enhanced with gradient density configuration to greatly improve efficiency and dust holding capacity. The invention is for use and configuration for use in engine intake air filtration.

Owner:R2C PERFORMANCE PRODS

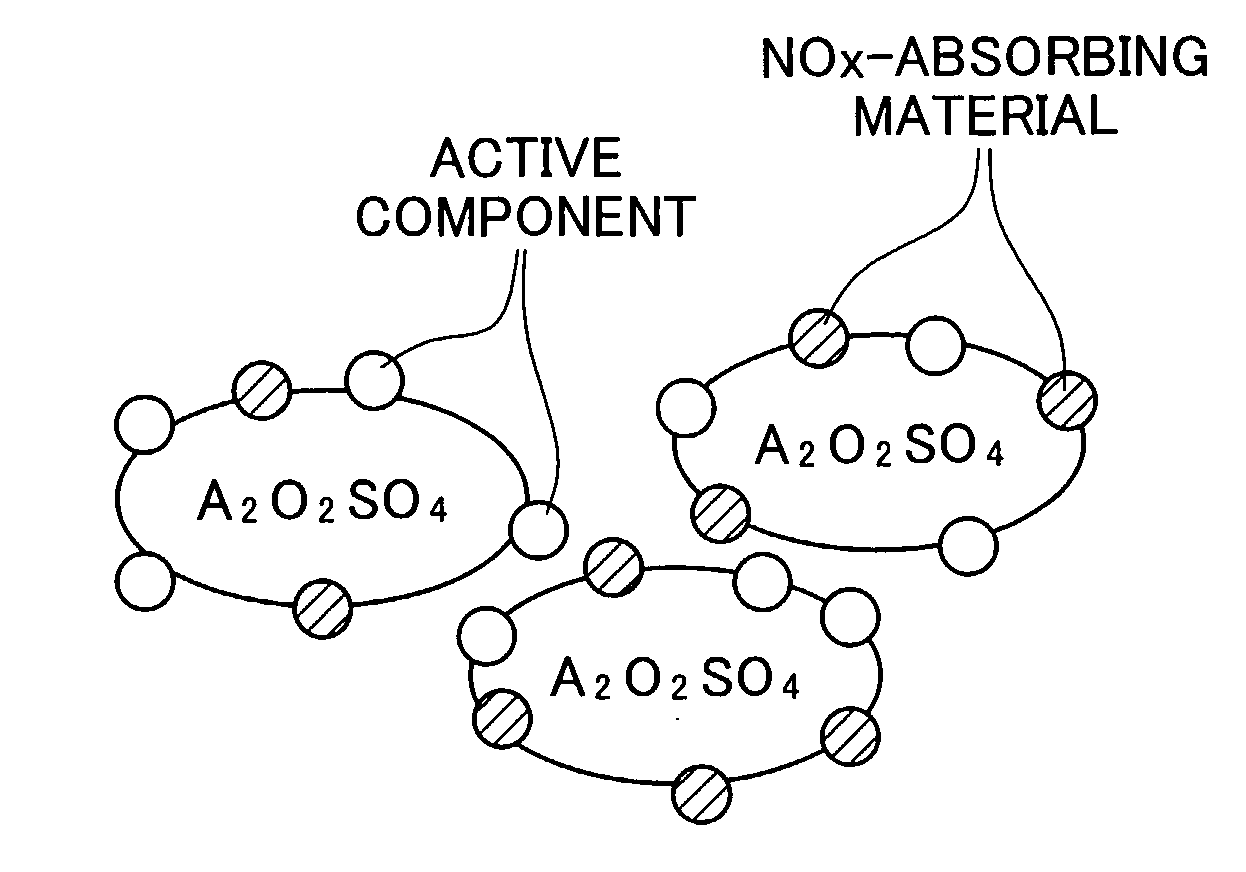

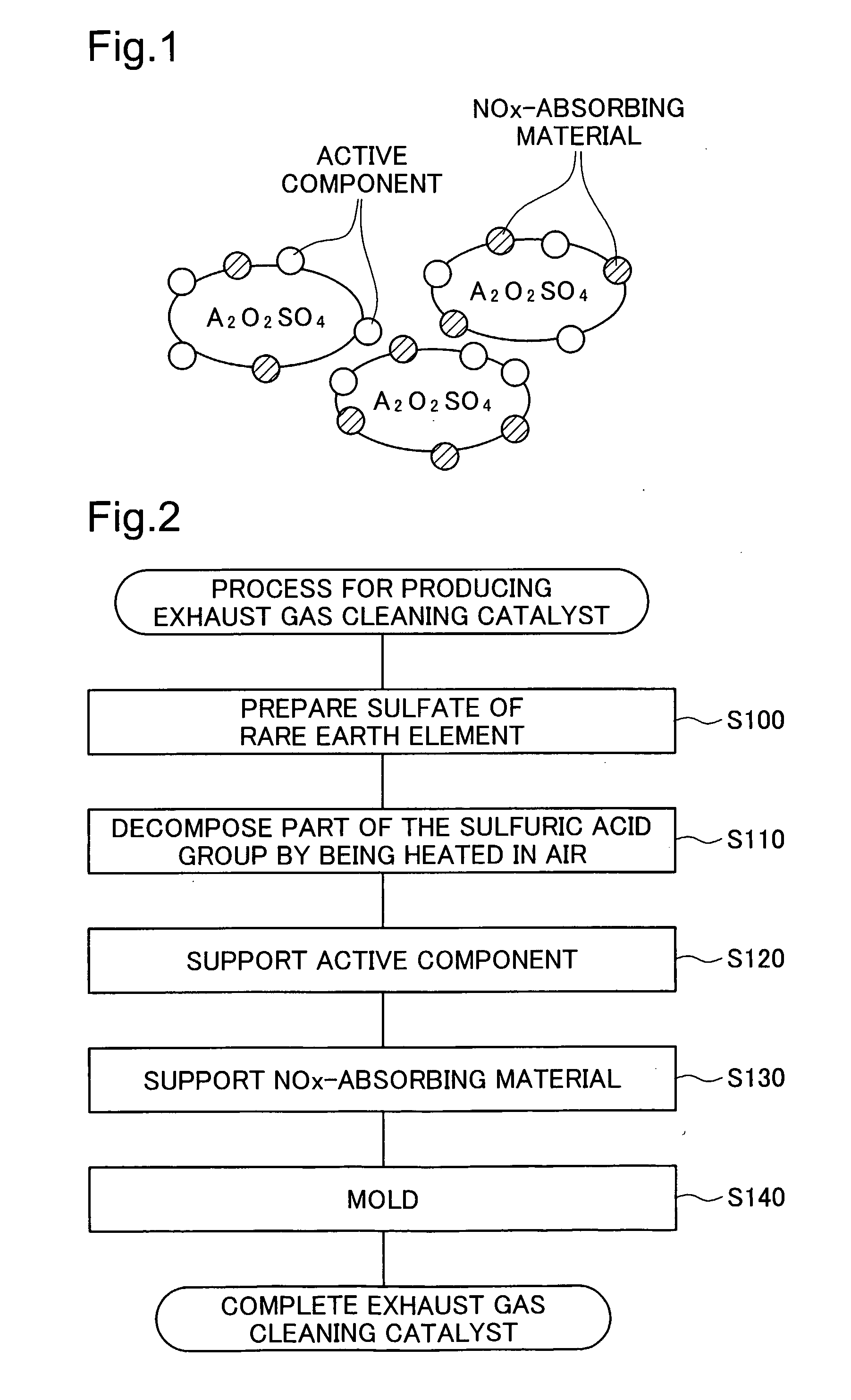

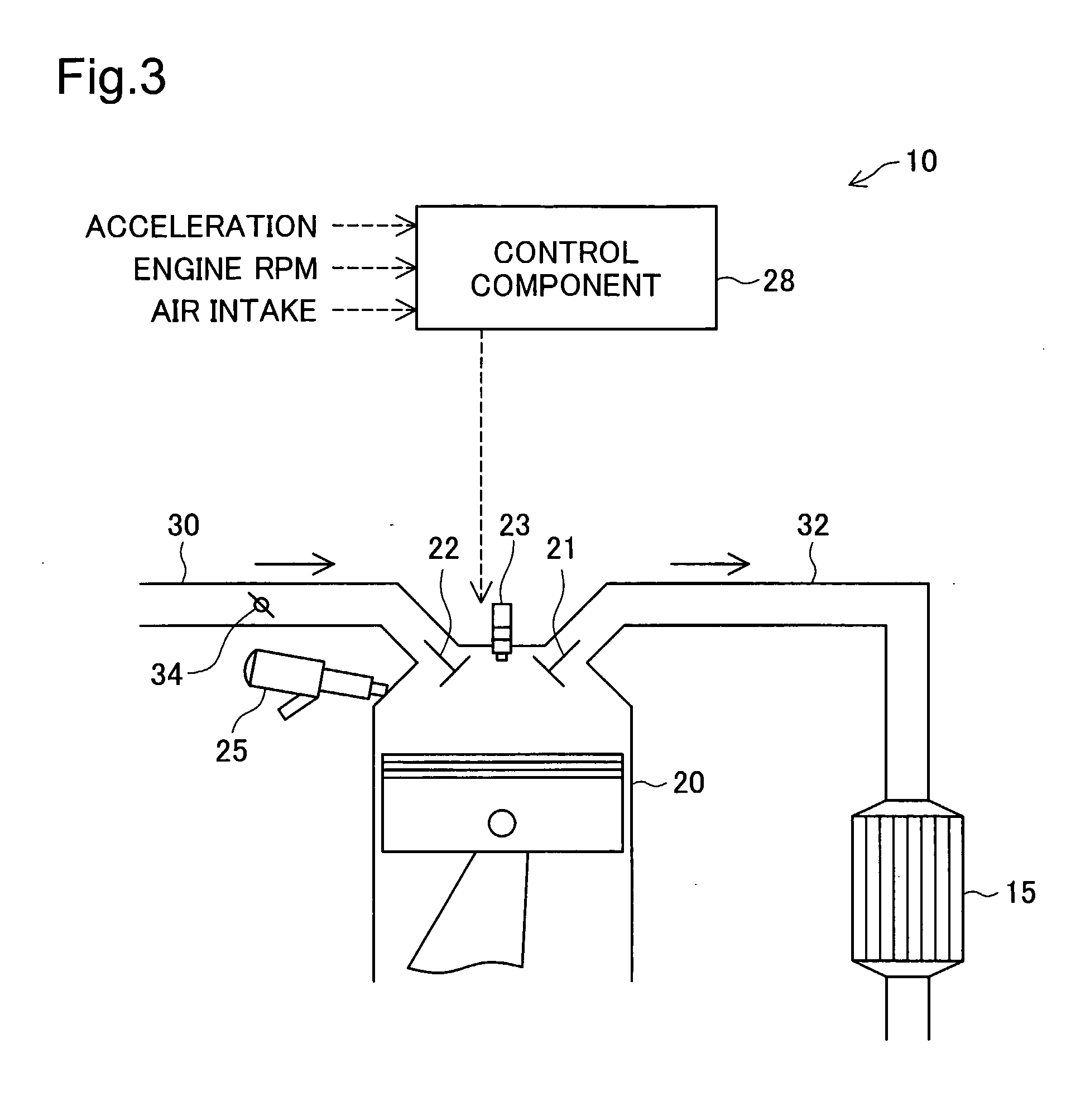

Exhaust Gas Cleaning Catalyst, Exhaust Gas Cleaning Device, and System Comprising Internal Combustion Engine

ActiveUS20080000222A1Easy to cleanReduce cleaningCombination devicesInternal combustion piston enginesRare-earth elementActive component

The invention makes use of an exhaust gas catalyst, comprising an active component comprising at least one type of metal from noble metals and transition metals; NOx-absorbing material for absorbing and releasing nitrogen oxides according to the surrounding nitrogen oxide concentration; and compounds represented by A2O2SO4 and / or A2O2S (A is a rare earth element).

Owner:TOYOTA JIDOSHA KK

Narrow pore size distribution cordierite ceramic honeycomb articles and methods for manufacturing same

ActiveUS7648550B2Low cleanlinessLow pressureCombination devicesDispersed particle filtrationFiltrationHeat resistance

Disclosed are ceramic honeycomb articles, which are composed predominately of a crystalline phase cordierite composition. The ceramic honeycomb articles possess a microstructure characterized by a unique combination of relatively high total porosity of less than 54%, and relatively narrow pore size distribution having a d10 pore diameter of not less than 8 μm, a d90 pore diameter of not greater than 35 μm, and a value of df=(d50−d10) / d50 of less than 0.50. The articles exhibit high thermal durability and high filtration efficiency coupled with low pressure drop across the filter. Such ceramic articles are particularly well suited for filtration applications, such as diesel exhaust filters or DPFs. Also disclosed are methods for manufacturing the ceramic articles of the present invention.

Owner:CORNING INC

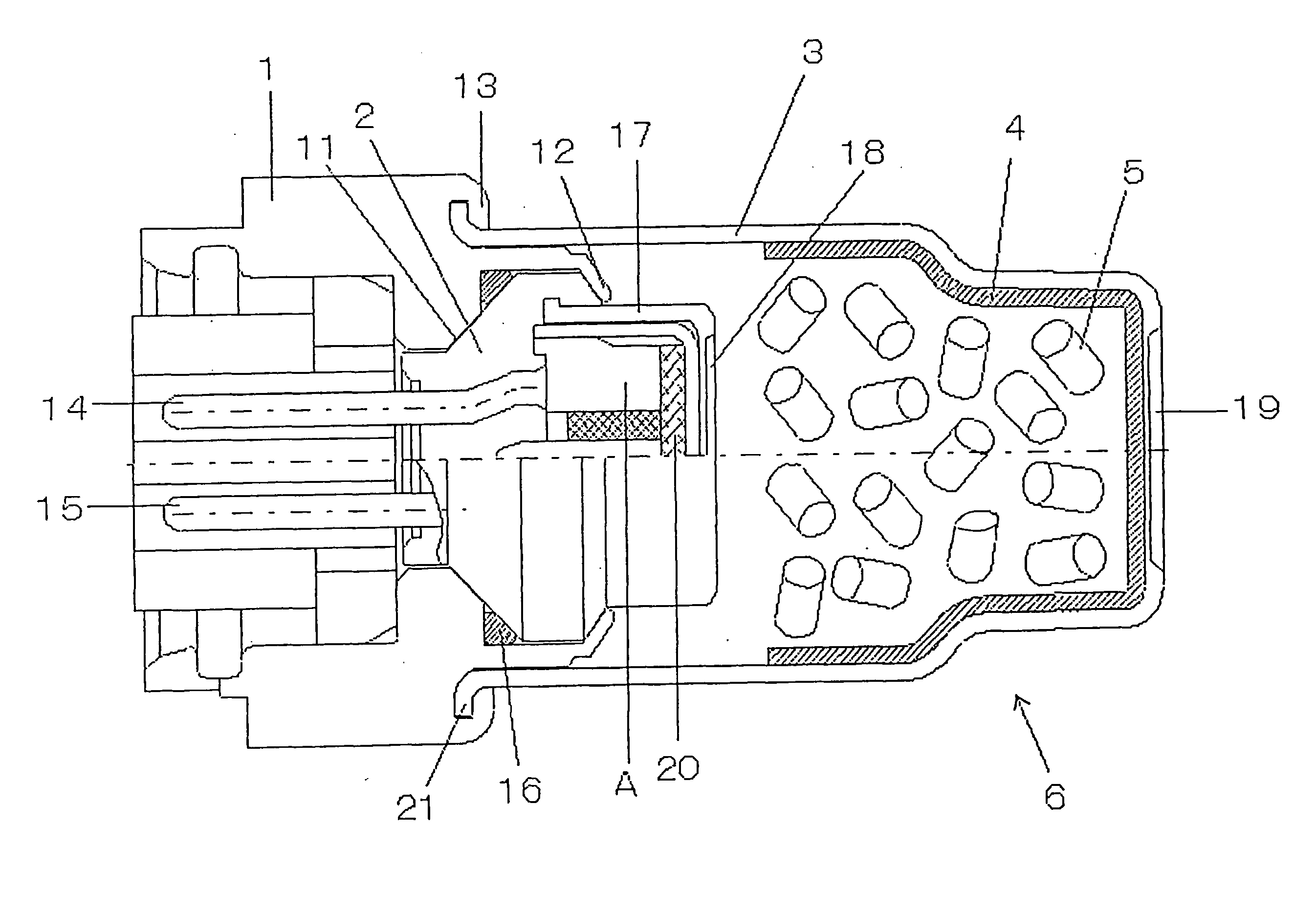

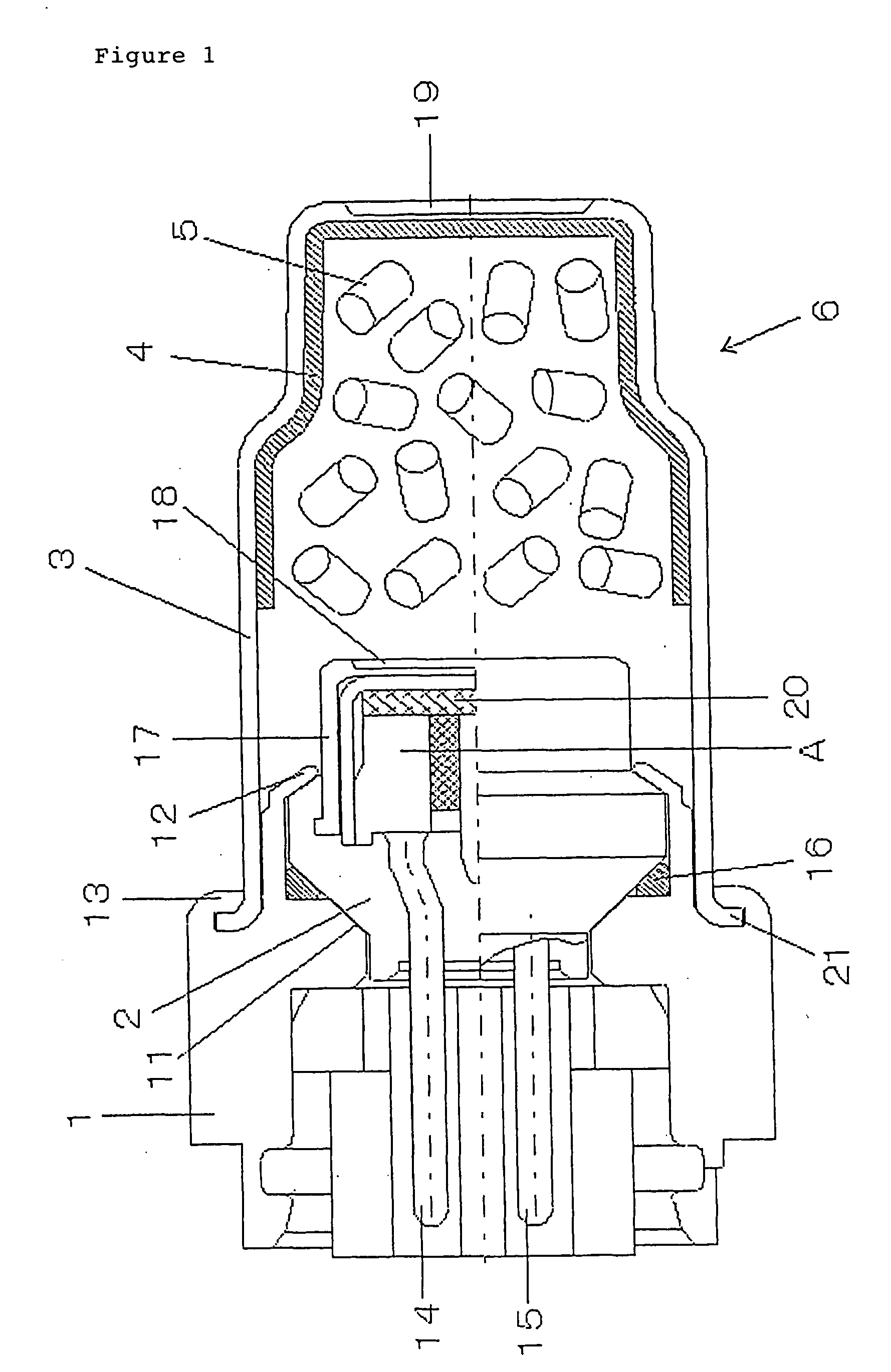

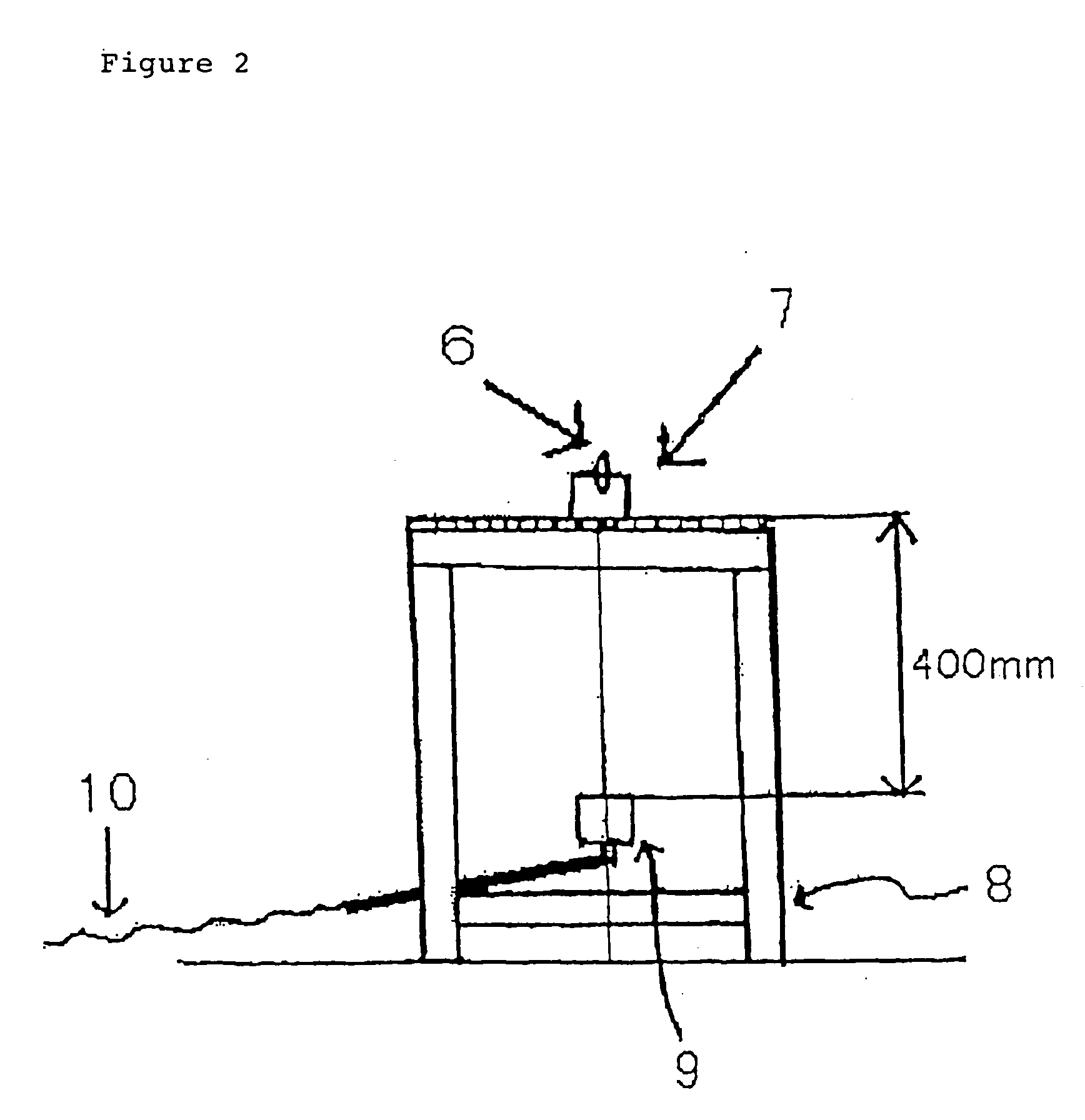

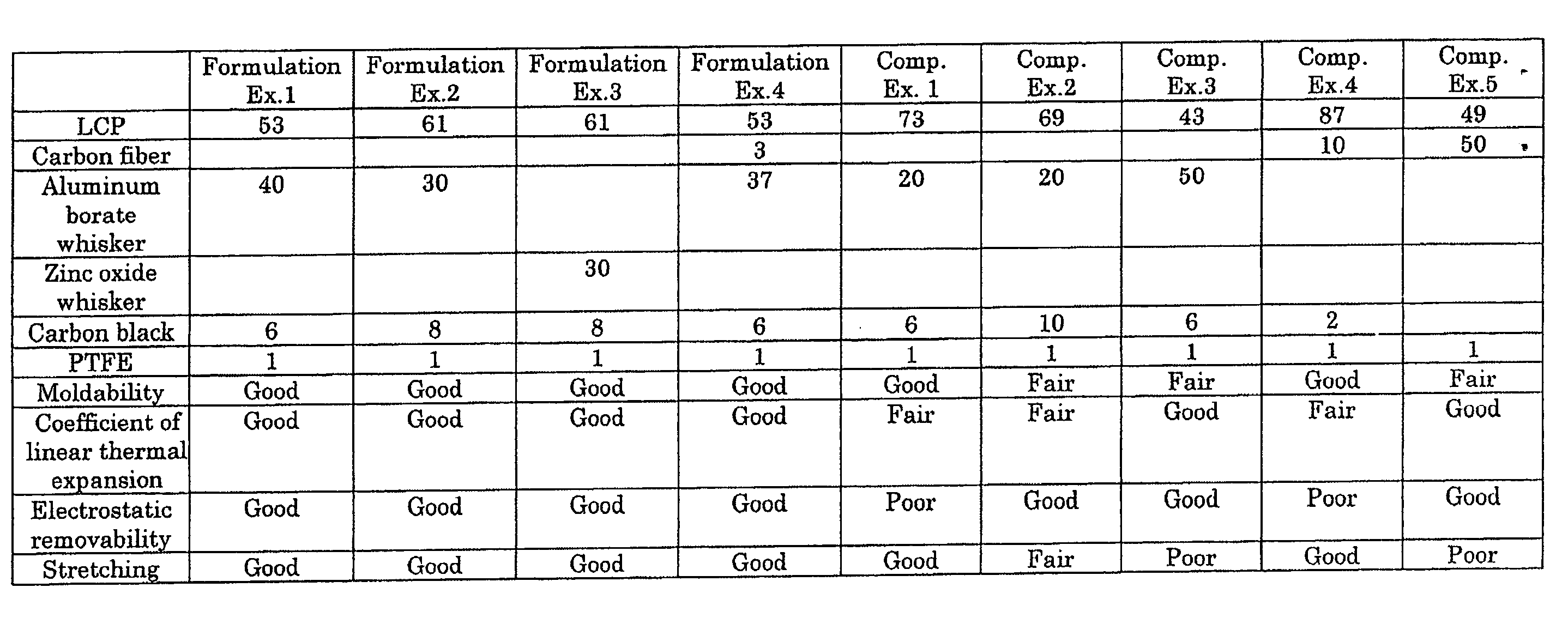

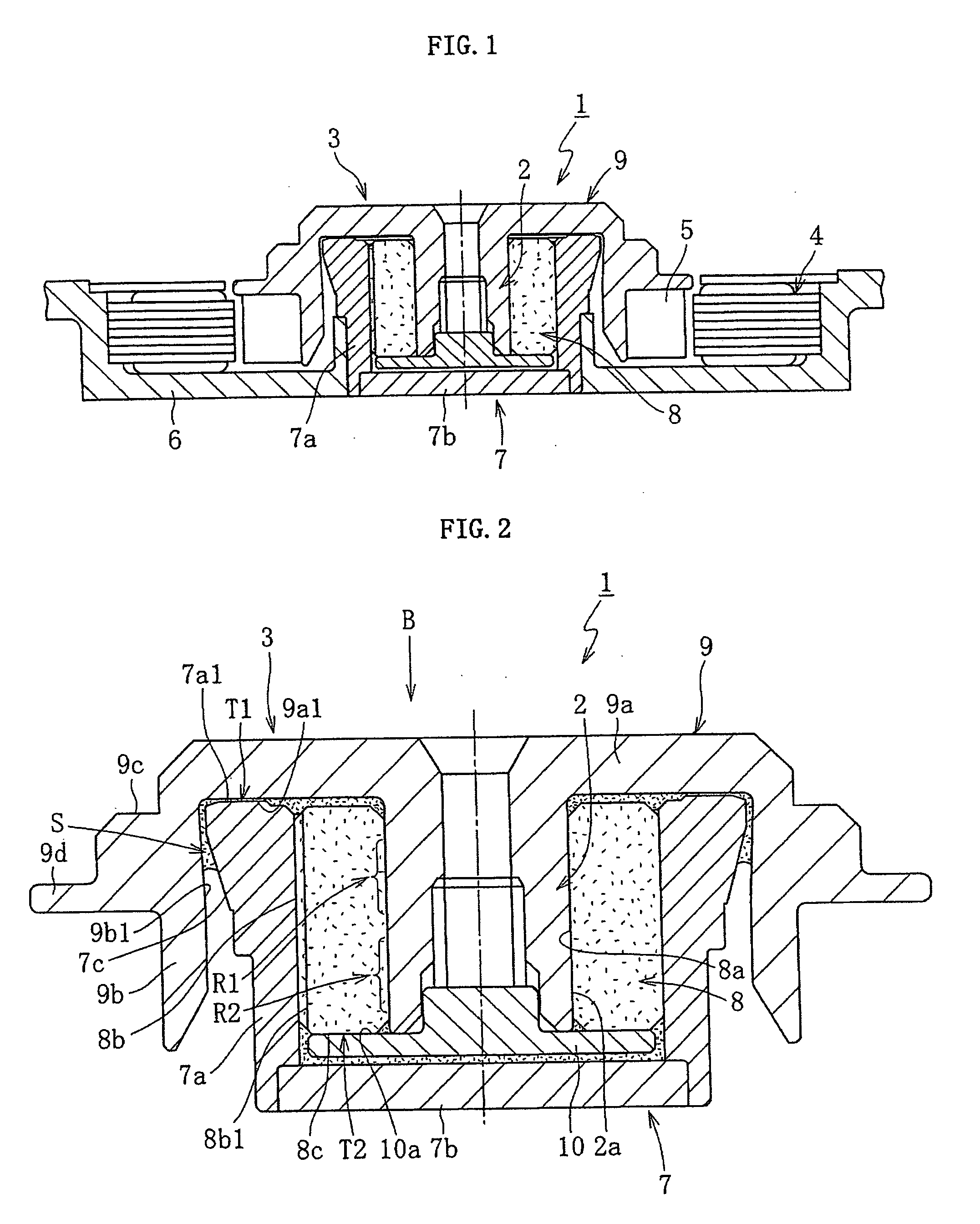

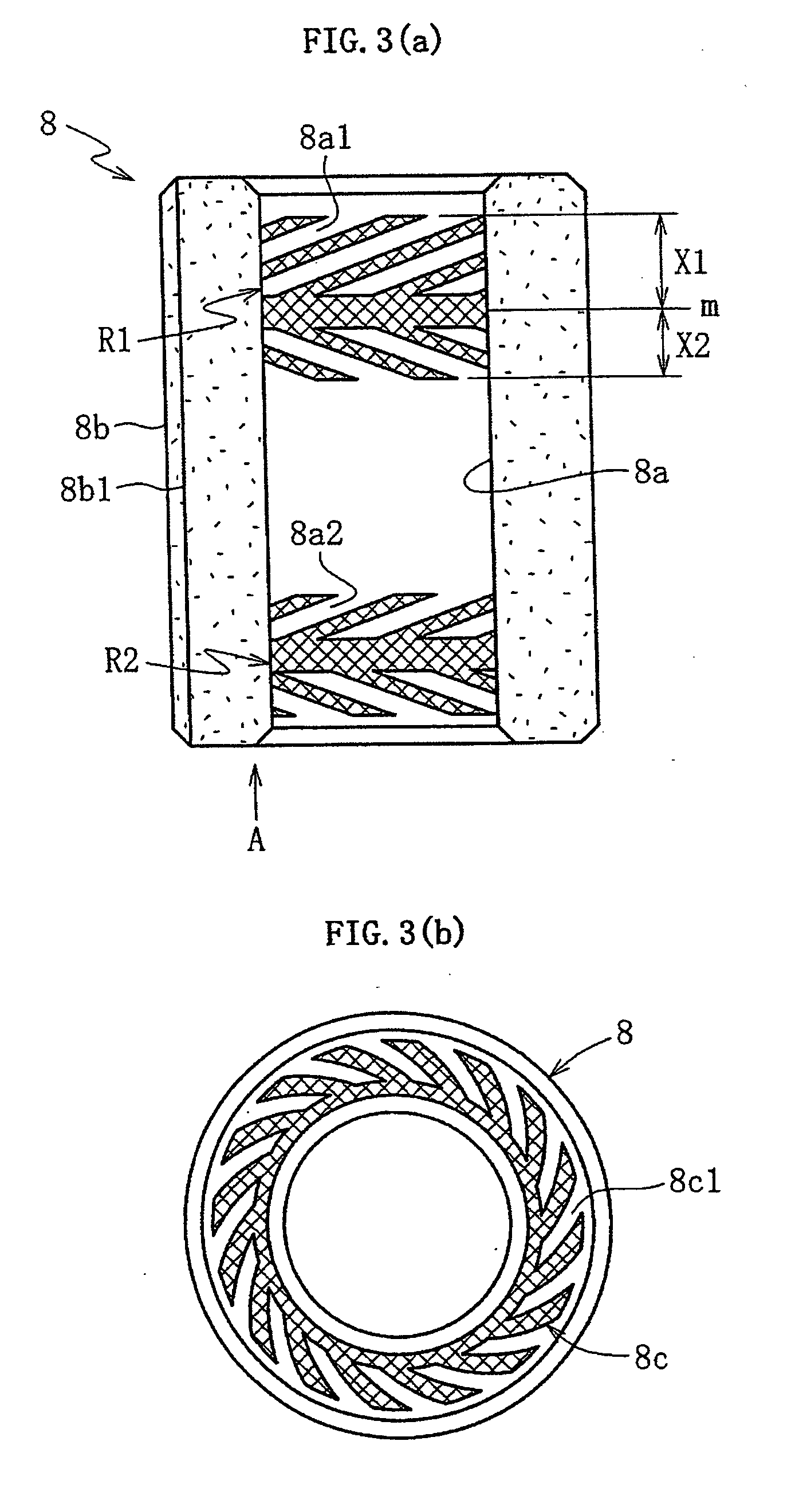

Hydrodynamic bearing unit

ActiveUS20090034888A1High oil resistanceLow outgassing propertyShaftsRecord information storageEngineeringHigh resistance

A housing for a hydrodynamic bearing unit of this type is formed from a resin material having high oil resistance and low outgassing property to ensure the cleanliness of the bearing unit. An ester-based lubricating oil is used as a lubricating oil filled inside the hydrodynamic bearing unit 1, and the housing 7 is formed from an LCP-based resin material.

Owner:NTN CORP +1

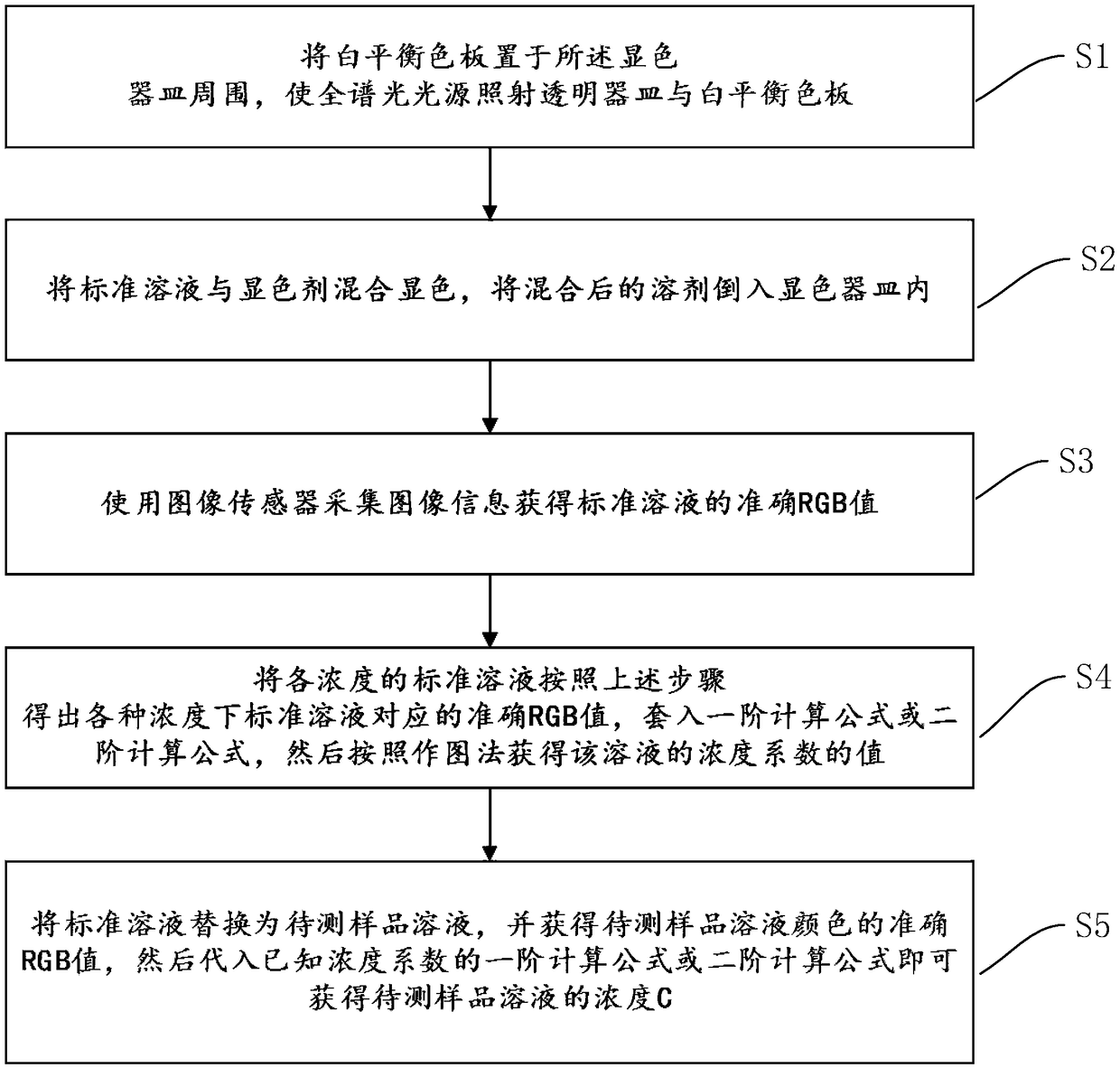

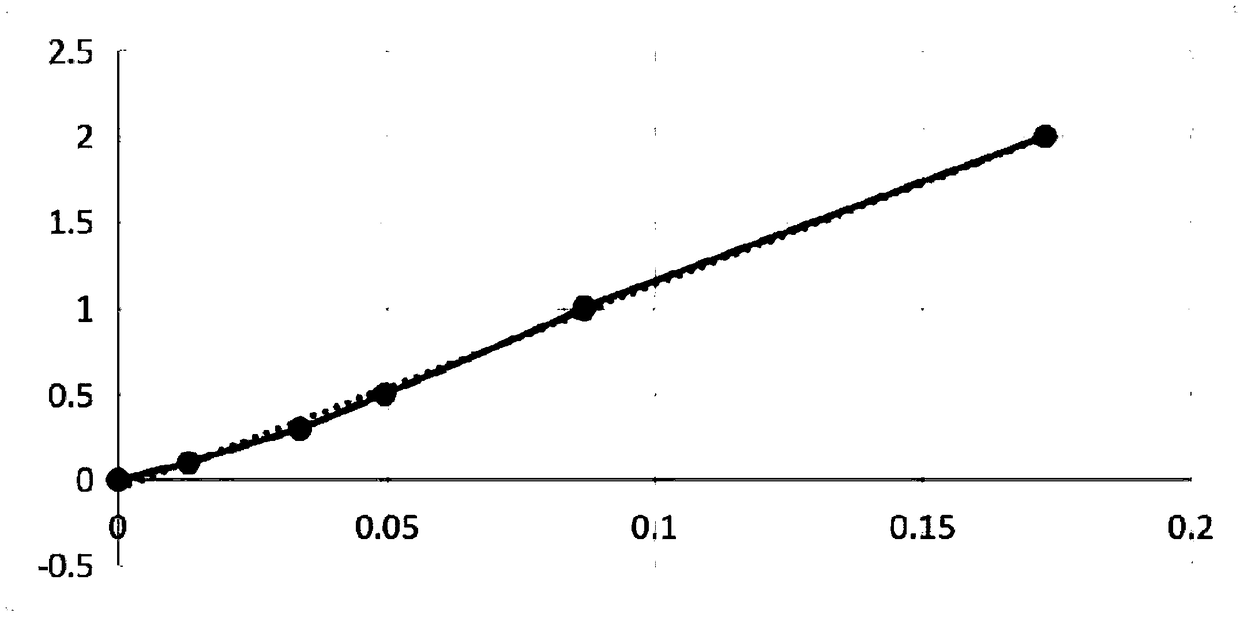

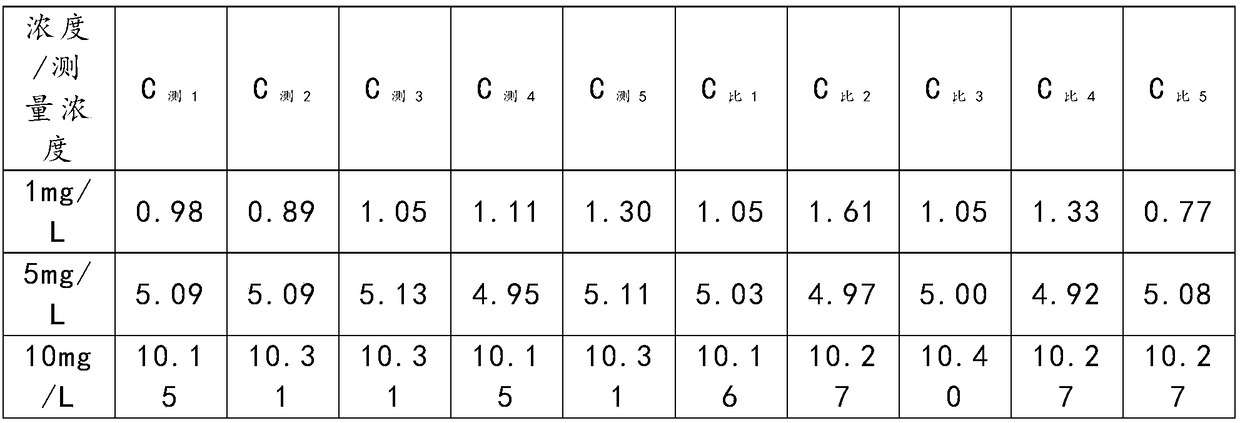

Spectral analysis method for replacing visible spectrophotometer

ActiveCN108776107ANot affectedEliminate distractionsMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsFull-spectrum lightTest sample

The invention discloses a spectral analysis method for replacing a visible spectrophotometer. The method comprises the steps of: selecting a full spectrum light source, a color developing vessel, a white balance color plate, and placing the white balance color plate around the color developing vessel containing a color developing standard solution, using an image sensor to align the standard solution and the white balance color plate, and collecting image information to obtain an accurate RGB value of solution color of the standard solution; putting the accurate RGB value corresponding to thestandard solution into a first-order calculation formula or a second-order calculation formula, and then obtaining a value of a concentration coefficient of the solution according to a mapping method;then replacing the standard solution with a to-be-tested sample solution, obtaining an accurate RGB value of the color of the to-be-tested sample solution, and substituting into the first-order calculation formula or the second-order calculation formula known the concentration coefficient to obtain a concentration C of a to-be-tested sample. The method does not need to be isolated from an external light environment, the cleanliness requirements of the to-be-tested sample solution and a device are low, and experimental steps are simple, easy to operate, and high in accuracy.

Owner:侯延辉

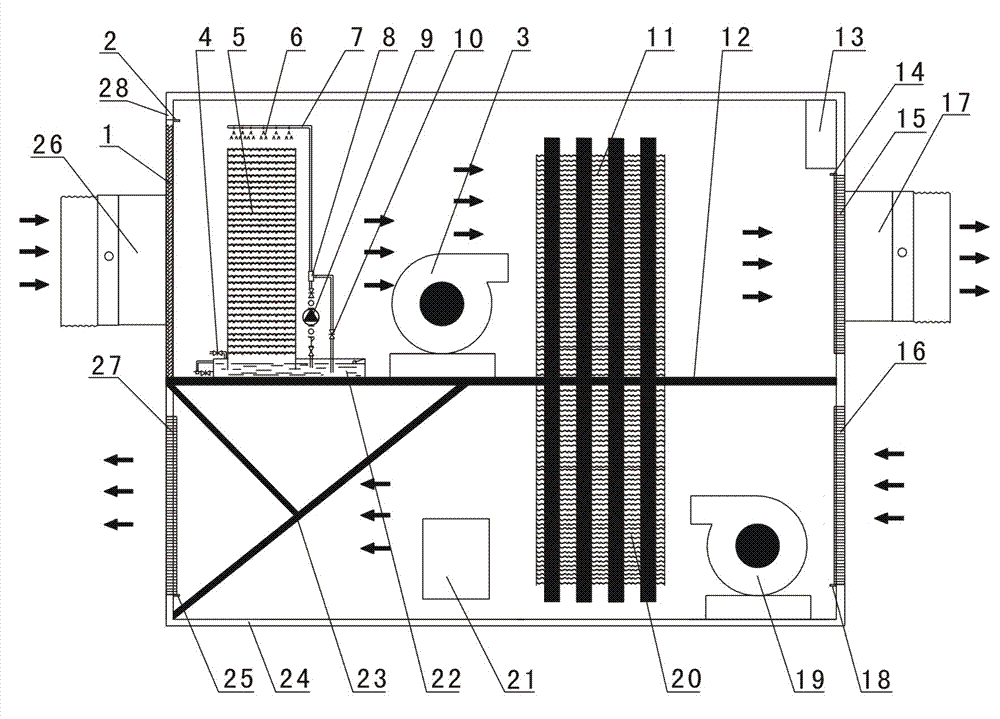

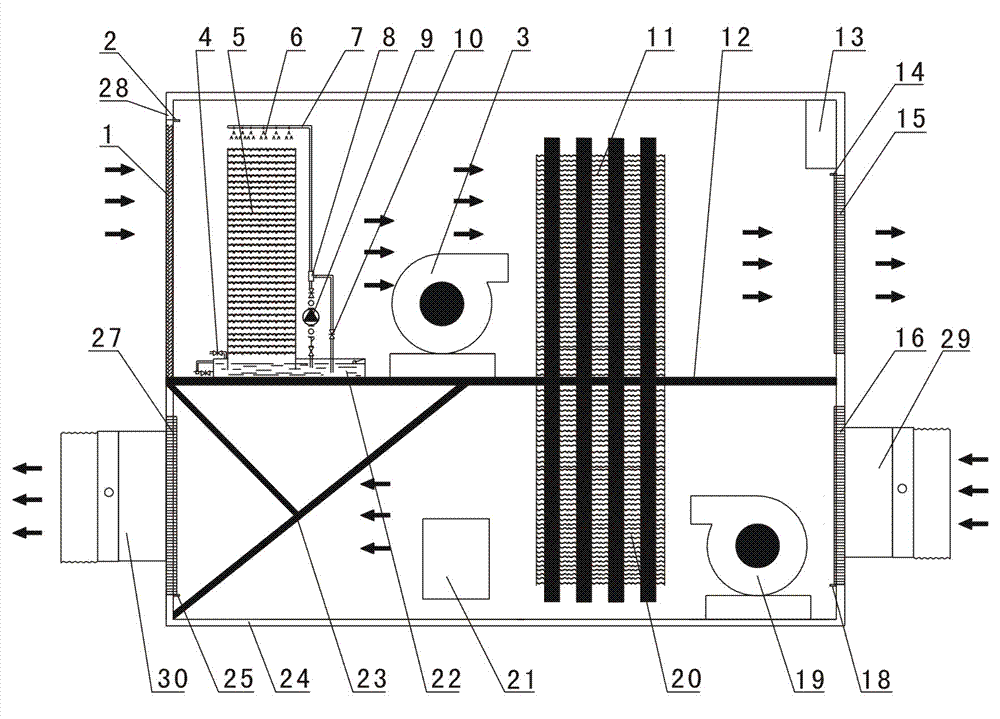

Direct evaporation integral heat pipe exchanger

InactiveCN102967019AEfficient refrigerationEnergy efficientLighting and heating apparatusSpace heating and ventilation detailsSprayerThermal insulation

The invention discloses a direct evaporation integral heat pipe exchanger, which comprises a condensation end and an evaporation end, wherein the condensation end and the evaporation end are combined and mounted into a whole; the condensation end comprises a wet film, a sprayer, a water tank, an intake air fan and a condensing working medium coil; the intake air fan is positioned between the wet film and the condensing working medium coil; the sprayer is positioned above the wet film; a water inlet of the sprayer is connected with a water outlet of the water tank through a water pipe; the evaporation end comprises an outtake air fan and an evaporating working medium coil; the evaporating working medium coil is positioned on the air outlet side of the outtake air fan; and the condensing working medium coil and the evaporating working medium coil are connected through a connection working medium pipe and are separated through a thermal insulation separation plate. According to the invention, the efficient direct evaporation integral heat pipe exchanger is formed by applying the direct evaporation cooling mode, which has a cooling effect similar to that of the traditional water cooling mode, to a heat pipe system, in this way, air cooled through direct evaporation efficiently cools the condensing working medium coil, and the efficient cooling effect and the high energy saving rate of the integral heat pipe exchanger for indoor air are ensured.

Owner:四川澄观节能环保科技有限公司

Self-cleaning animal watering device

Owner:KANSAS STATE UNIV RES FOUND

Fluoro-rubber composite, rubber material using the same, and a method of manufacturing a fluoro-rubber molded product

InactiveCN1743370AReduce incidenceLow cleanlinessSemiconductor/solid-state device manufacturingRubber materialTetrafluoroethylene

The present invention provides a fluororubber composition that is less likely to reduce the cleanliness of the manufacturing environment and is less prone to cracks, a rubber material using the composition, and a method for producing a fluororubber molded body. The fluororubber, tetrafluoroethylene / propylene copolymerized Compound or tetrafluoroethylene / propylene / vinylidene fluoride copolymer mixed with fluorine-containing thermoplastic resin, and added peroxide crosslinking agent, co-crosslinking agent and other necessary fillers to form a fluororubber composition, through crosslinking The fluororubber composition is used to obtain a fluororubber molded body. As a crosslinking method, for example, a mold having a desired shape is filled with a certain amount of the fluororubber composition, and primary crosslinking is performed through a heating step. Then, secondary crosslinking can be performed in an oven at 150° C. to 250° C. for 1 hour to 32 hours as needed. The shape of the fluororubber molded article may be, for example, a sheet shape, a rod shape, a ring shape, various complicated block shapes, etc., and it can be formed into any shape according to its use.

Owner:NICHIAS CORP

Preparation of hydrodesulfurization catalyst for coking benzene and using method of the catalyst

ActiveCN104258900AGood catalytic hydrogenation performanceReduce the temperatureMolecular sieve catalystsHydrocarbonsHydrodesulfurizationReaction temperature

A hydrodesulfurization method of coking benzene is provided. A preparation process of a hydrodesulfurization catalyst used in a hydrodesulfurization reaction includes: respectively dipping an aluminium oxide-titanium dioxide mixed power carrier into solutions containing active metal elements comprising molybdenum, nickel, cobalt and tungsten, with the solutions containing citric acid; dipping a NaZSM-5 molecular sieve into a solution containing copper and / or zinc; drying; calcinating; mixing the dipped aluminium oxide-titanium dioxide mixed power carrier and the dipped NaZSM-5 molecular sieve; processing the coking benzene by a rectifying tower before hydrodesulfurization; and performing pre-hydrogenation, main hydrogenation and removal of inorganic sulfur to finish sulfur removal. The NaZSM-5 molecular sieve loaded with an active component has an effect of selective adsorption for thiophene. The aluminium oxide-titanium dioxide mixed power carrier loaded with the active metals has good catalytic hydrogenation effects for the thiophene. By cooperation of the NaZSM-5 molecular sieve loaded with the active component and the aluminium oxide-titanium dioxide mixed power carrier loaded with the active metals, good removing effects can be achieved even at a low reaction temperature. The citric acid promotes formation of an active phase, improves hydrogenation activity of the catalyst and prolongs maintaining time of the activity of the catalyst.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Solar water heater

InactiveCN107655218AAchieve cleaningAchieve protectionSolar heating energySolar heat collectors with working fluidsMicroorganismUv disinfection

The invention discloses a solar water heater which comprises a protecting plate, a base, a protecting frame, heat collecting pies, a supporting plate, a control panel, a heat preservation layer and ultraviolet sterilizing lamps. The supporting plate is arranged at the upper ends of supporting rods, the heat collecting pipes are embedded into one end of a water tank, the heat preservation layer isarranged on the inner wall of the water tank, and the ultraviolet sterilizing lamps are arranged in a protecting hood; and the protecting frame is arranged on one side of the heat collecting pipes, the protecting plate is arranged on the other side of the heat collecting pipes, and the control panel is arranged on the front surface of an outer end cover. The solar water heater is scientific and reasonable in structure and safe and convenient to use, the ultraviolet sterilizing lamps can be conveniently used by a user for killing harmful microorganisms in the water tank, the protecting plate can be conveniently used by the user to protect the heat collecting pipes, the supporting plate can be conveniently used by the user to protect and disassemble the bottom of the water tank, and convenience is brought to normal using for the user.

Owner:山东久固太阳能有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com