Direct evaporation integral heat pipe exchanger

A heat pipe heat exchanger, an integrated technology, applied in the direction of household heating, heating methods, household heating, etc., can solve the conditions of no large-scale promotion and application, not suitable for energy-saving renovation of old computer rooms, and high investment in water-cooled heat pipe systems. and other problems, to achieve the effect of convenient application, increase temperature difference, and prolong running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

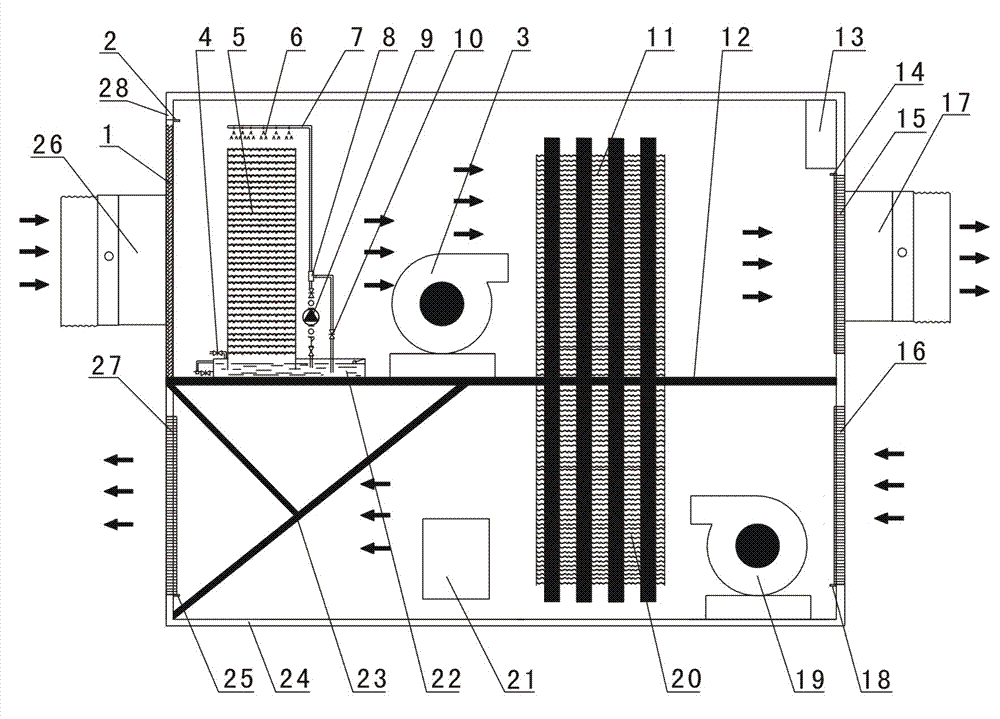

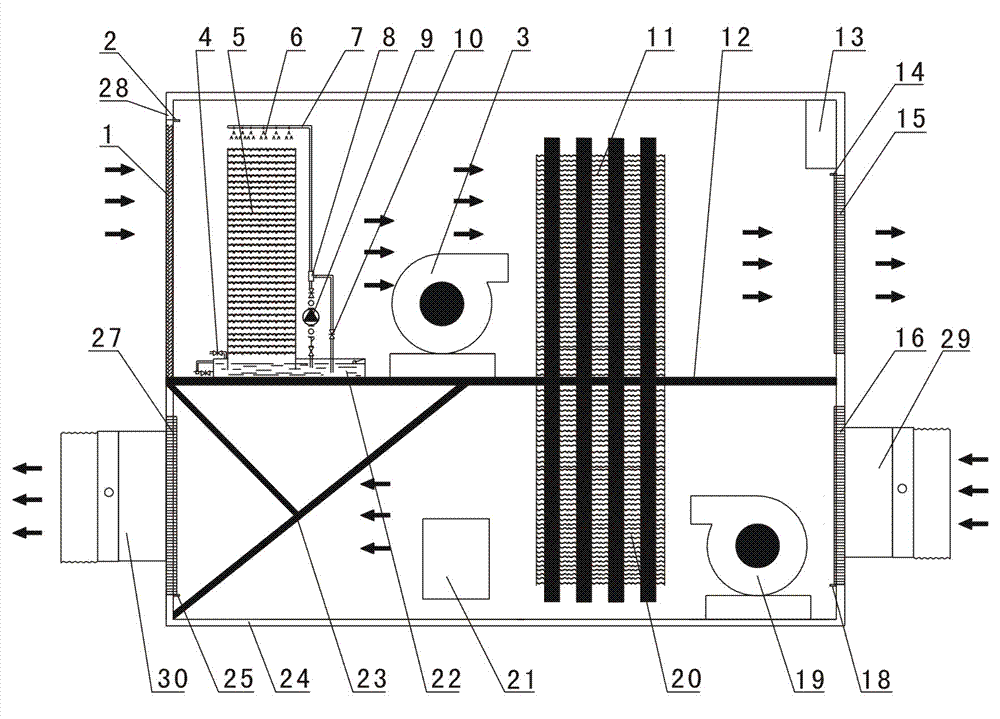

[0040] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0041] Such as figure 1 As shown, the direct evaporation integrated heat pipe heat exchanger of the present invention includes a condensing end 28 located above and an evaporating end 24 located below. Wet film 5, sprinkler 6, water tank 22, air intake fan 3 and condensing medium coil 11, air intake fan 3 is located between wet film 5 and condensing medium coil 11, sprayer 6 is placed in wet film 5, the water inlet of the sprinkler 6 is connected to the water outlet of the water tank 22 through the water pipe 7; On the air outlet side: the condensing working medium coil 11 and the evaporating working medium coil 20 are connected by a connecting working medium pipe (not shown in the figure) and separated by a thermal insulation board 12. and the evaporation end 24.

[0042] Such as figure 1 As shown, in the detailed structure of the condensing end 28, the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com