Refrigeration type LTCC micro-system based on metal micro-channels and preparation method of refrigeration type LTCC micro-system

A micro-system, refrigeration-type technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of difficulty, precision processing, and filling, and achieve high-efficiency cooling and heat dissipation, and the cooling accuracy is controllable , the effect of fast cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

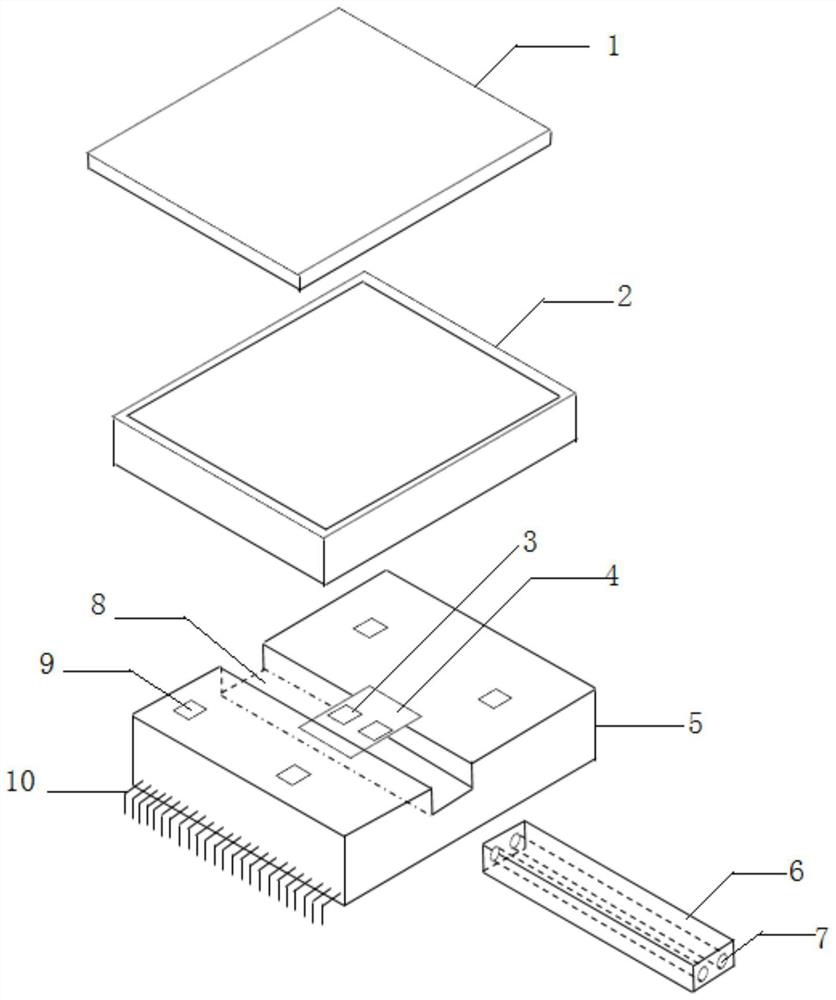

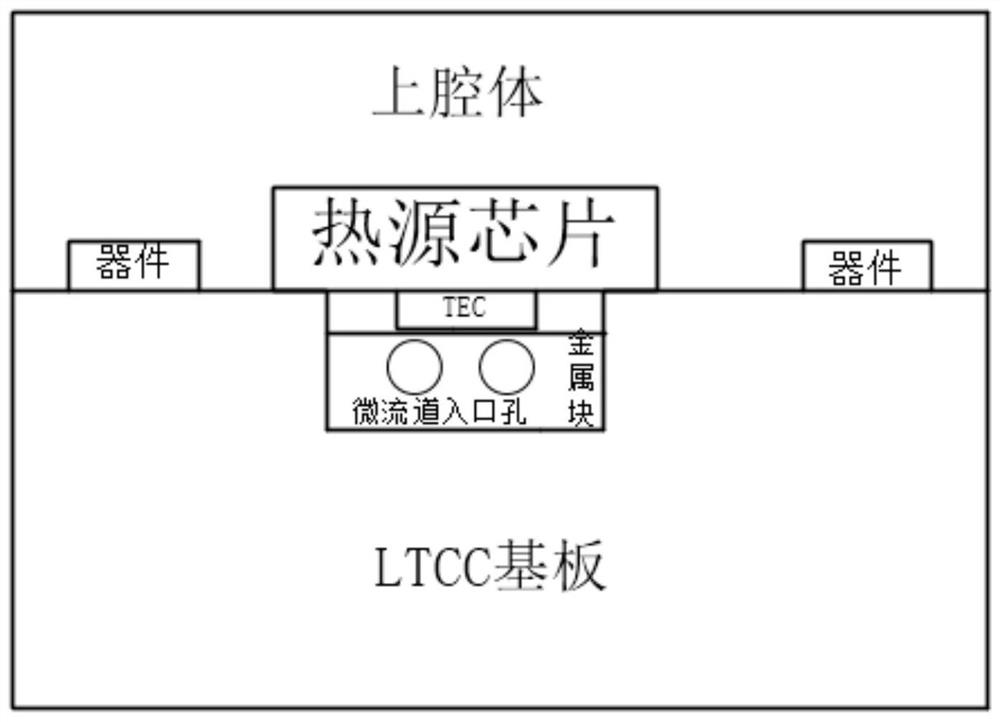

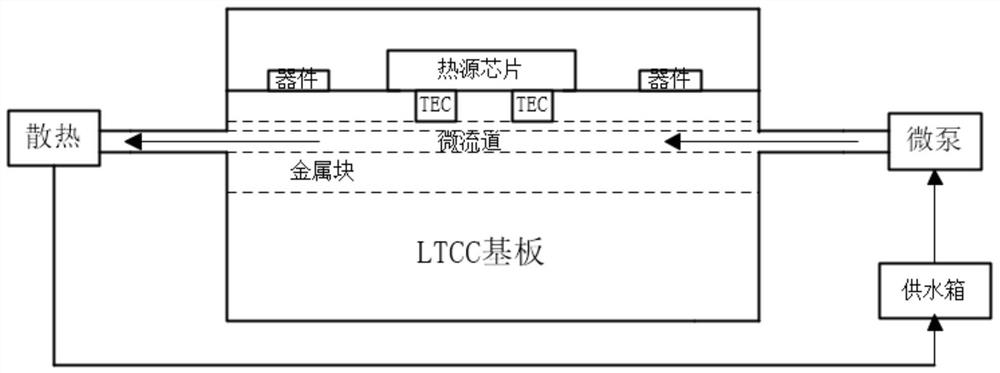

[0060] See figure 1 , figure 2 with image 3 , figure 1 It is a schematic structural diagram of a cooling LTCC microsystem based on metal microchannels provided by an embodiment of the present invention, figure 2 It is a front view of a metal microchannel-based cooling LTCC microsystem provided by an embodiment of the present invention, image 3 It is a left view of a cooling LTCC microsystem based on a metal microchannel provided by an embodiment of the present invention. This embodiment provides a refrigerated LTCC microsystem based on metal microchannels, the refrigerated LTCC microsystem includes: an LTCC substrate 5, a metal block 6 with several microchannels 7, a heat source chip 4, and several TEC chips 3 , a number of devices 9, a surrounding frame 2, a cover plate 1, and a number of pins 10, wherein the LTCC substrate 5 is provided with a groove 8 penetrating the LTCC substrate along a first direction, wherein the first direction is, for example, the length dire...

Embodiment 2

[0063] See Figure 4 , Figure 4 It is a flow chart of a process for preparing a microsystem packaging with TEC and microfluidics provided by the embodiment of the present invention. On the basis of the foregoing embodiments, the present invention also provides a method for preparing a refrigeration type LTCC microsystem based on metal microchannels, the preparation method comprising:

[0064] Step 1, see Figure 5 , the LTCC substrate 5 is prepared, and the LTCC substrate 5 is provided with a groove 8 penetrating the LTCC substrate 5 along the first direction.

[0065] Step 1.1. Select several lower-layer green porcelain sheets and several upper-layer green porcelain sheets.

[0066] Specifically, for example, DuPont951 is selected as the material of the green ceramic sheet, and all the green ceramic sheets are classified, and the green ceramic sheet is divided into a lower layer of green ceramic sheet and an upper layer of green ceramic sheet, wherein the thickness of a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com