System for rapidly pyrolysing and liquefying biomass

A liquefaction system and biomass technology, applied in the field of biomass rapid pyrolysis liquefaction system, can solve the problems of increasing system complexity and manufacturing cost, increasing process difficulty and cost, reducing biomass conversion rate, etc., to achieve product improvement value, avoiding equipment investment, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

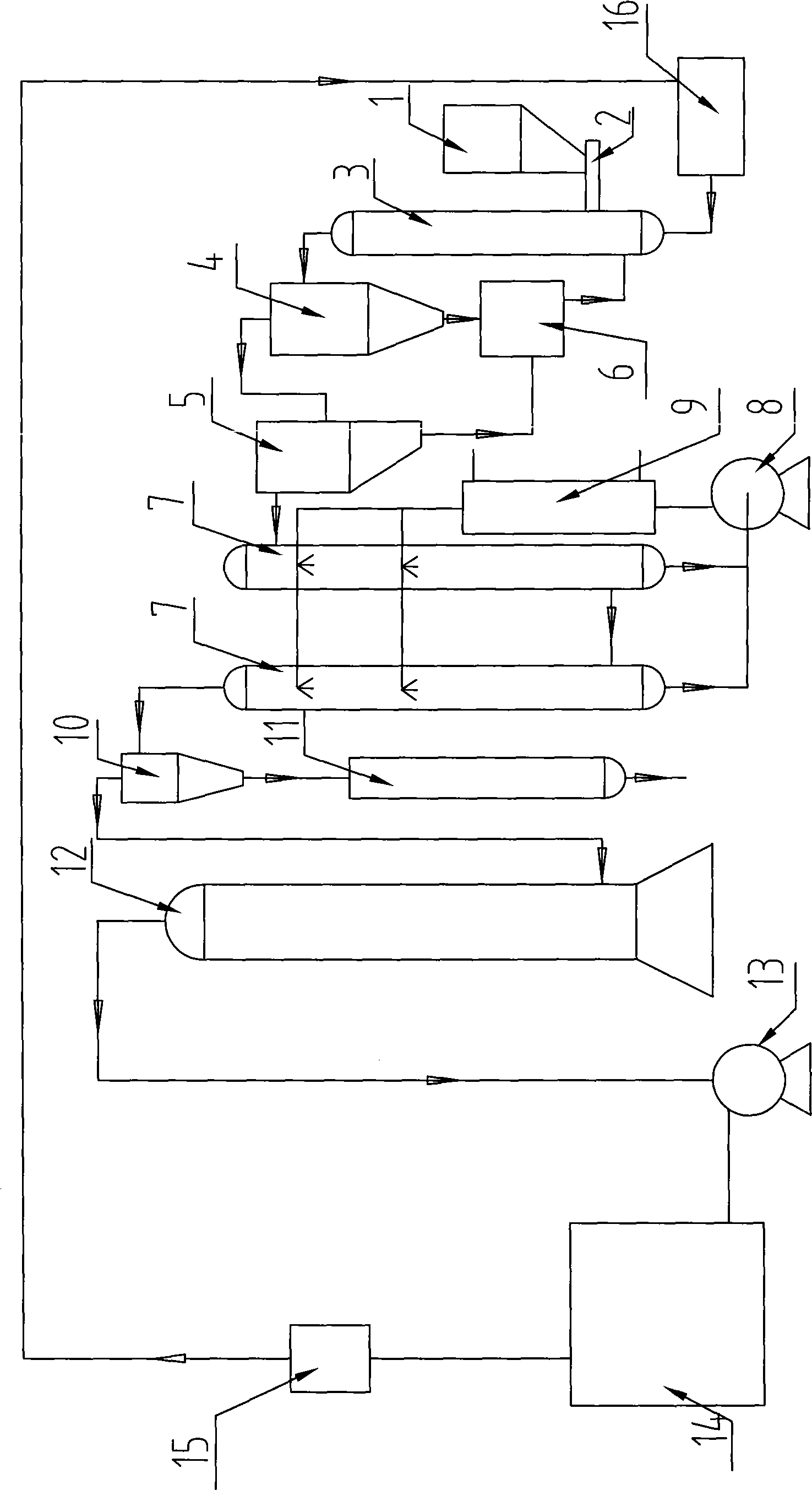

[0026] Please refer to figure 1 , the biomass rapid pyrolysis liquefaction system of the present invention comprises a pyrolysis reactor 3, a feeder connected to the biomass material inlet of the pyrolysis reactor 3 (comprising a storage bin 1 and a screw feeder 2 in this embodiment ), the reaction starter 16 connected to the thermal carrier gas inlet of the pyrolysis reactor 3, the gas-solid separation subsystem connected to the pyrolysis gas outlet of the pyrolysis reactor 3 (comprising a high-temperature cyclone separation device in this embodiment 4 and high-temperature gas-solid separation device 5), the bio-oil condensation reserve subsystem (comprising two condensing towers 7 in this embodiment, connected to the bio-oil outlet of the condensing tower 7) with the gas outlet of the gas-solid separation subsystem The oil storage tank 8, and the circulating bio-oil bypass) connected between the oil storage tank 8 and the condensing medium inlet of the condensation tower 7 a...

Embodiment 2

[0032] As another kind of scheme of the present invention, other parts are identical with embodiment 1, and difference is:

[0033] The biomass rapid pyrolysis liquefaction system of the present invention may also include a raw material pretreatment subsystem for pulverizing and drying biomass materials, a gas power generation sub-system for using the generated gas for a gas-fired generator set to generate electricity for the entire system, and An automatic operation monitoring subsystem used to control the orderly work of the entire system.

[0034] Only one condensing tower 7 may be provided and spray devices divided into three or more groups in the height direction of the condensing tower 7 may be used.

[0035] The thermal cycle medium heating and separation subsystem may include two independent thermal cycle medium heating devices and thermal cycle medium separation devices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com