Patents

Literature

89results about How to "Avoid cumbersome workmanship" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sparingly soluble active component particle, particle preparation and preparation method thereof

ActiveCN105640890AChange natureChange releaseCosmetic preparationsPowder deliveryPolymer dissolutionActive component

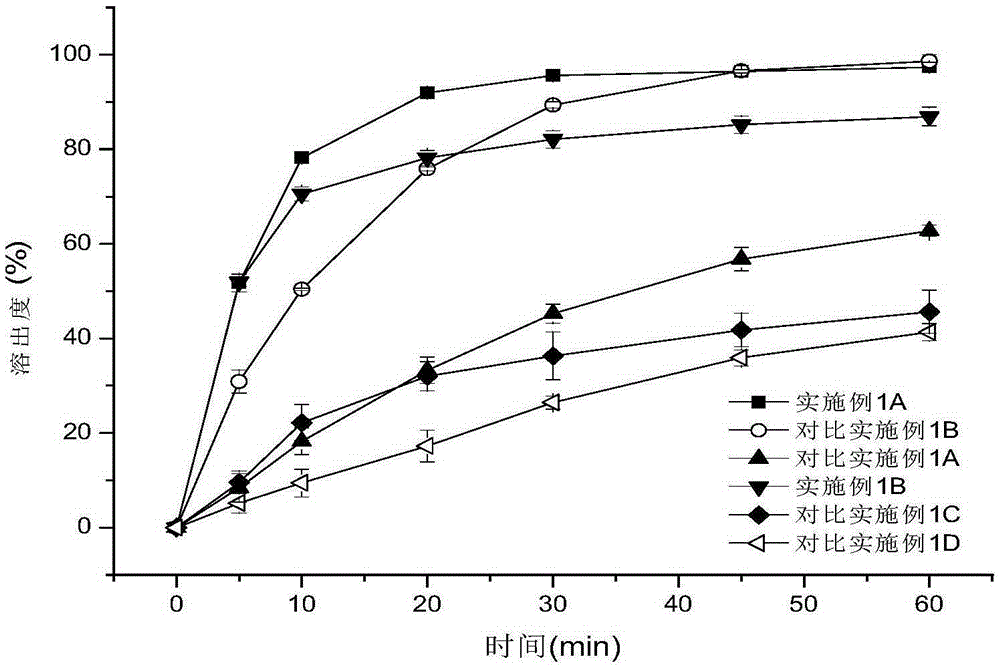

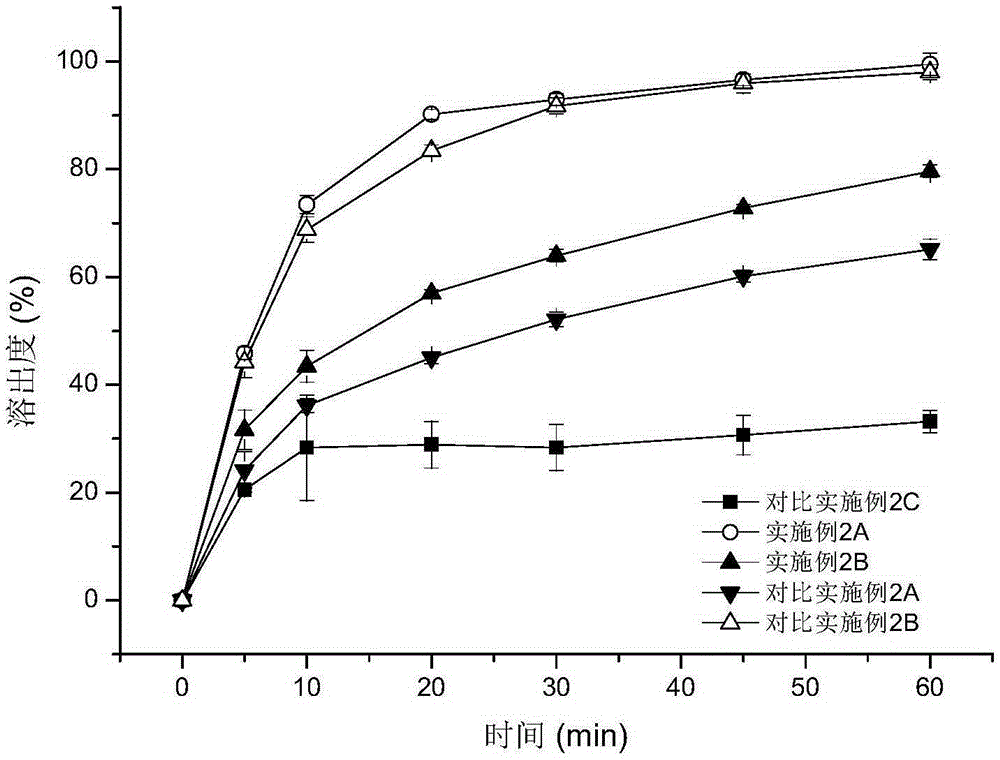

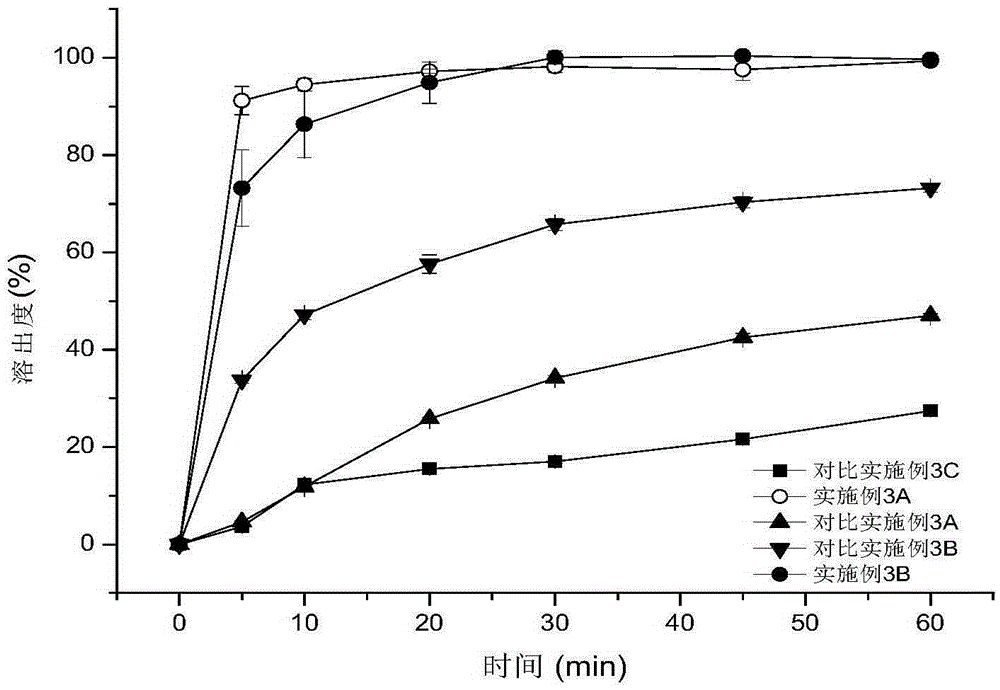

The invention discloses a sparingly soluble active component particle, a particle preparation and a preparation method thereof. The preparation method of the sparingly soluble active component particle comprises the following steps: dissolving sparingly soluble active component and ionic polymer into an alkaline solution or an acidic solution, and then mixing the alkaline solution and acidic solution to change the pH value of solutions so as to precipitate the sparingly soluble active component and ionic polymer from the mixed solution to form particles; and the performance of the sparingly soluble active component particle is improved. According to the preparation method, sparingly soluble active component and ionic polymer are co-precipitated, at the same time, a preparation technology is adopted, and two technologies are tightly combined to prepare the sparingly soluble active component particle preparation. The prepared preparation has the advantages of excellent dissolving-out characteristic, high bioavailability, small individual difference, good stability, and good content uniformity.

Owner:SINOTHERAPEUTICS

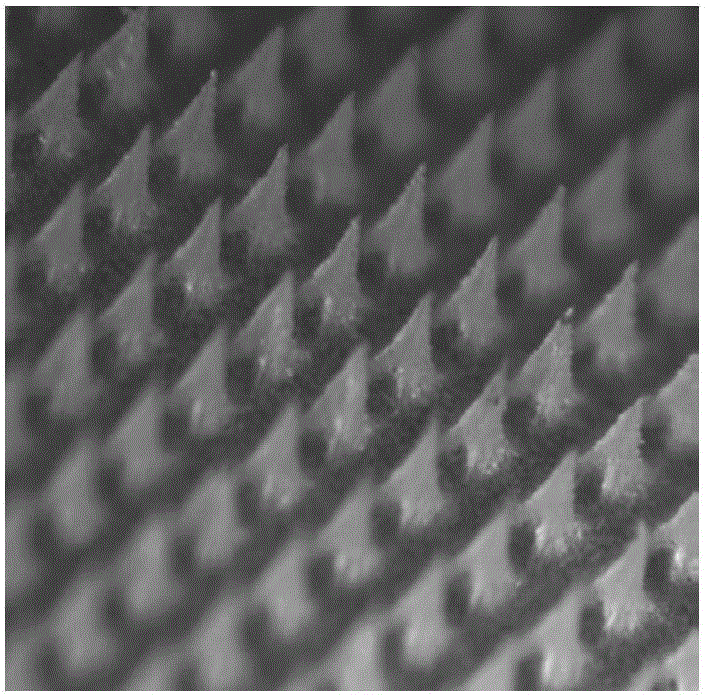

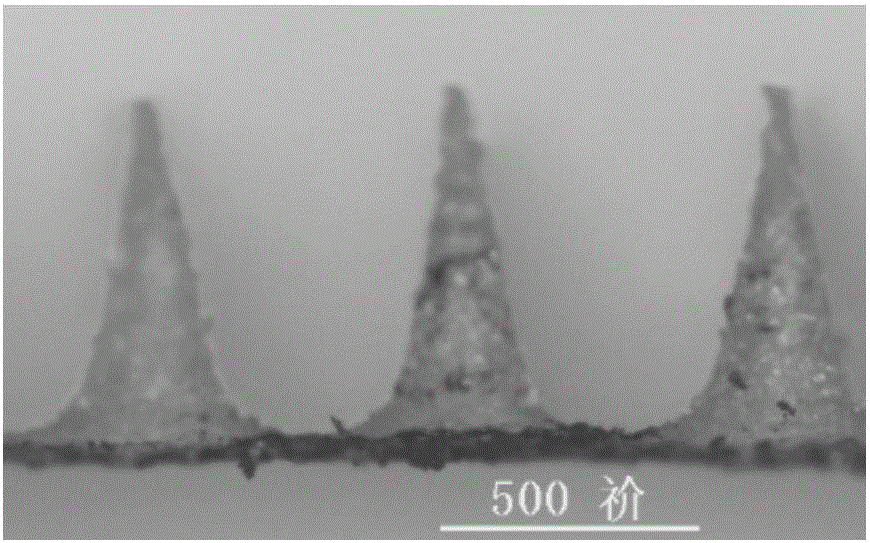

Flexible slow-release micro-needle patch and preparation method thereof

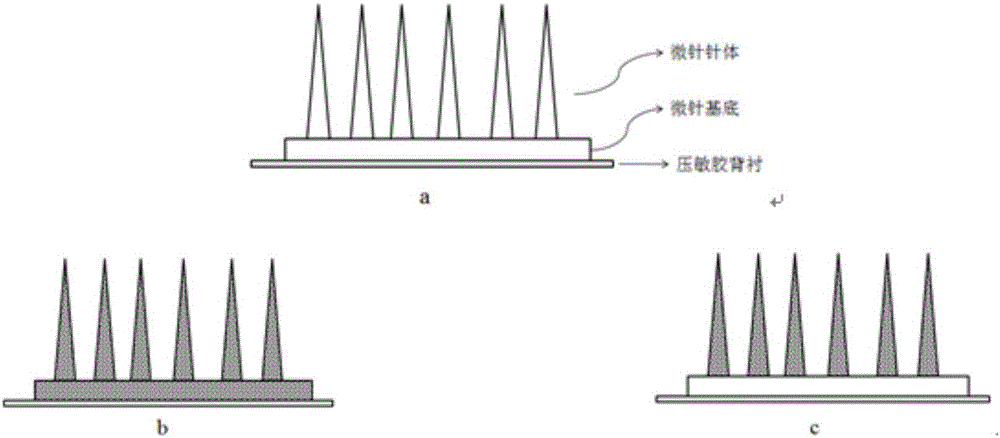

InactiveCN106422045AGood dispersionGood sustained releaseOrganic active ingredientsMicroneedlesSolubilityMedicine

The invention discloses a flexible slow-release micro-needle patch and a preparation method thereof. The micro needle patch comprises a micro-needle, a substrate and a back lining, wherein the micro-needle and the substrate form a micro-needle array; a base material of the micro-needle or a base material of the micro-needle array contains a drug in a crystal form; the solubility of the drug in the crystal form in water is less than 100 microgram / ml. The micro-needle patch has the characteristics of simple process, high preparation safety, low process cost and high drug loading capacity.

Owner:BEIJING CAS MICRONEEDLE TECH LTD

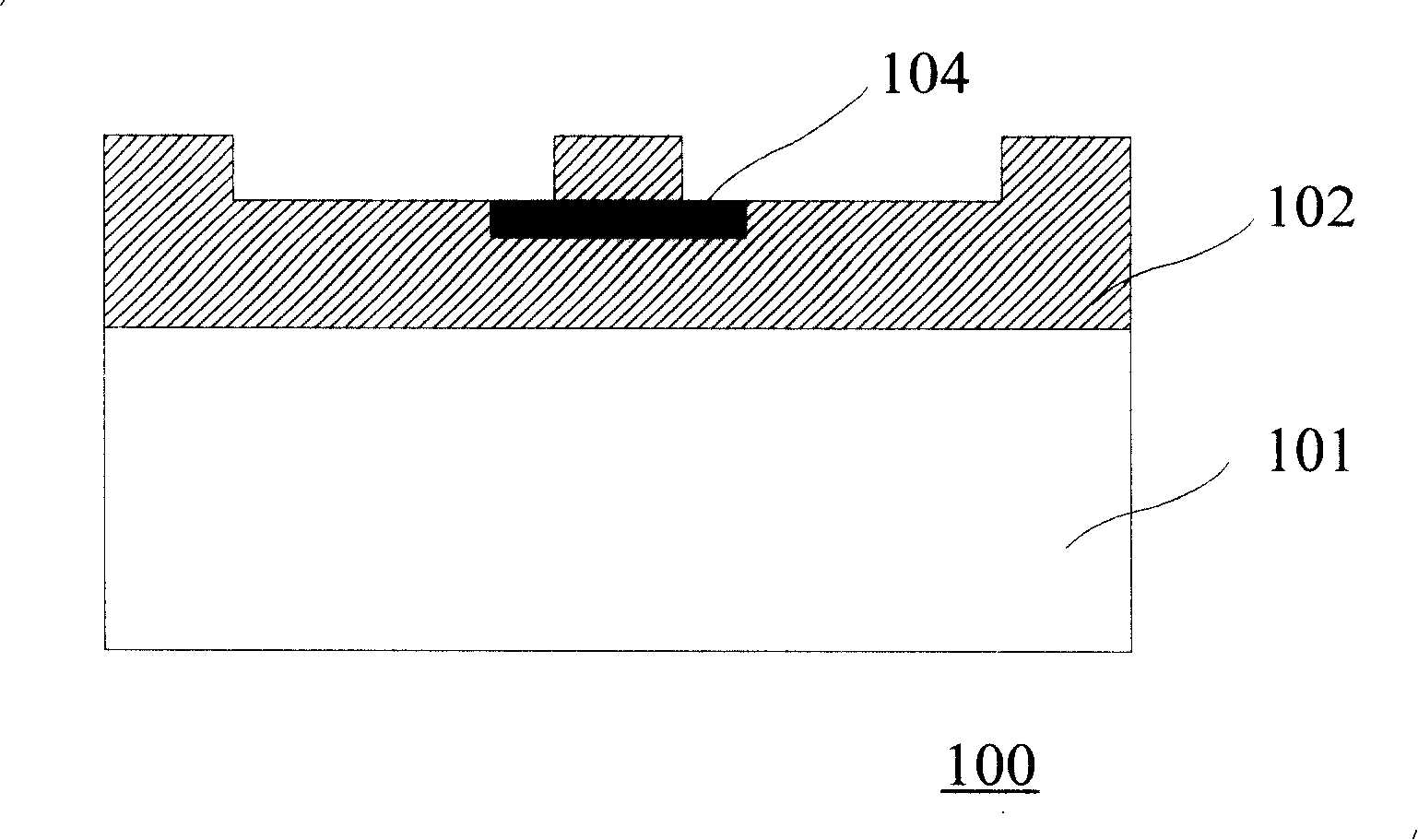

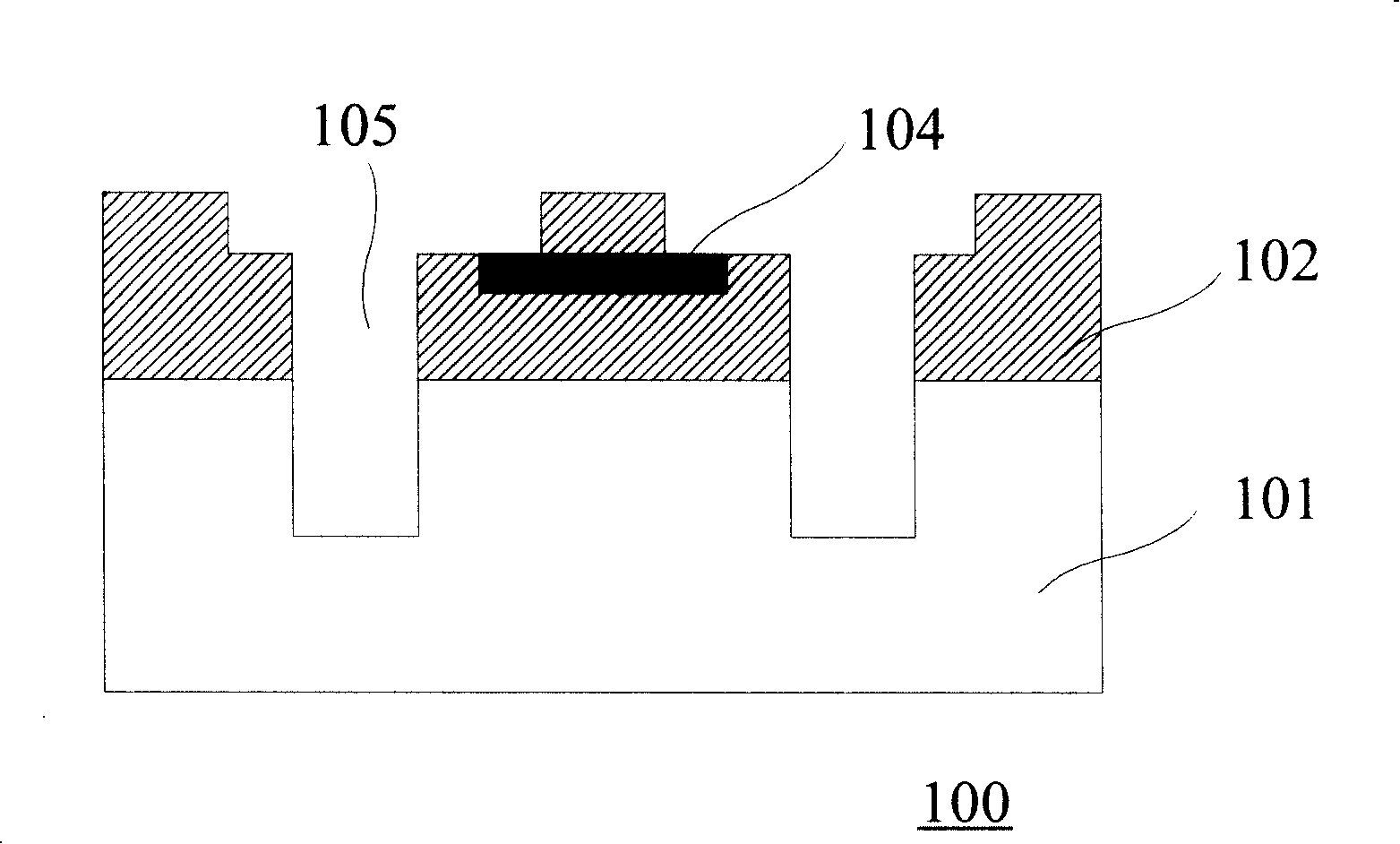

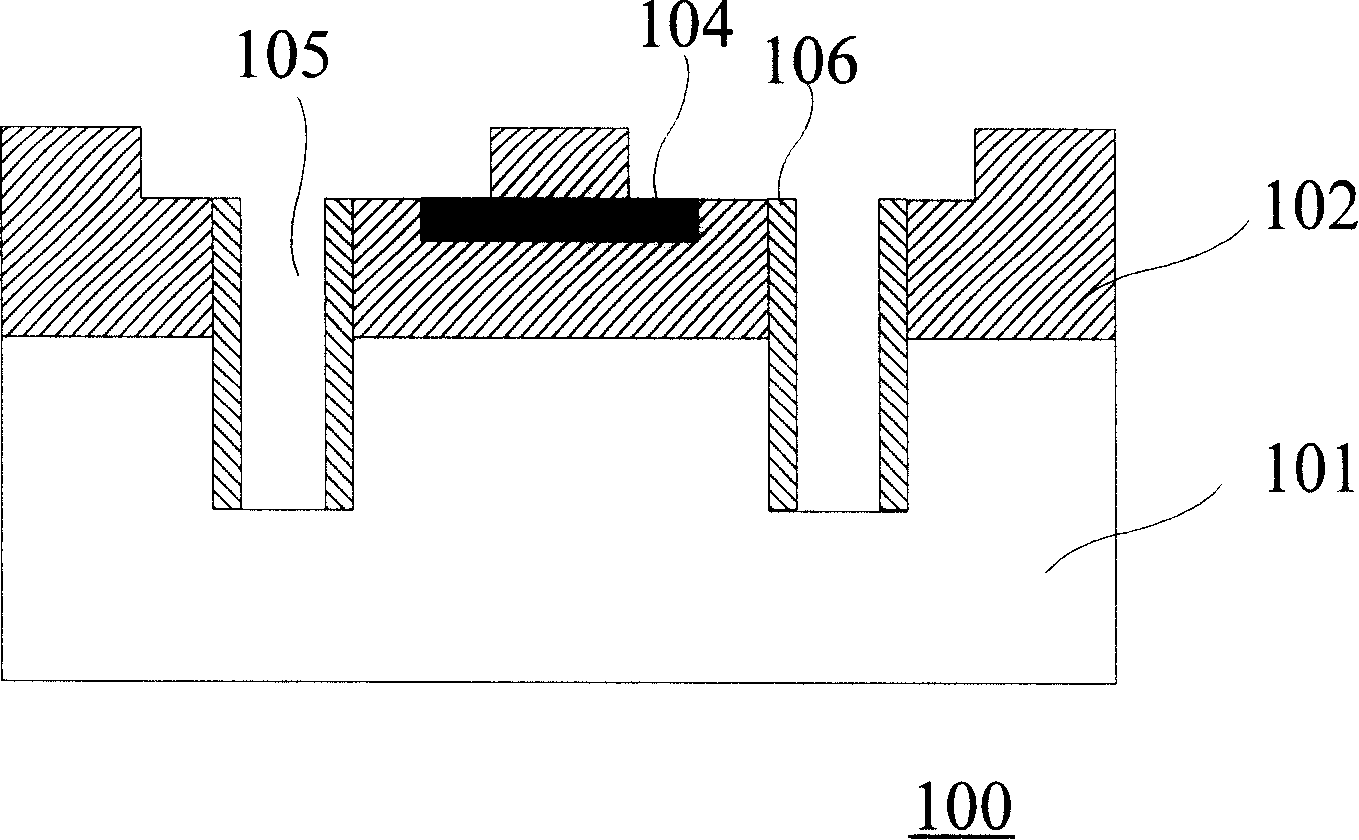

Wafer press welding and bonding method and structure thereof

ActiveCN101197297AWon't breakIncreasing the thicknessSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorBonding process

A three-dimensional interconnection method between wafers comprises the following steps that: firstly, two semiconductor wafers are bonded face to face, secondly the back of one of two semiconductor wafers is thinned to complete the three-dimensional interconnection between the wafers, thirdly the backs of the semiconductor wafers which complete interconnection are bonded spoon-fashion, thinned, and interconnected and the bonding spoon-fashion-thinning-interconnecting technique is repeated; the surfaces of a plurality of semiconductor wafers are overlaid in order. The invention also provides a three-dimensional interconnection structure between the wafers; the surfaces of two semiconductors are bonded face to face; a second connecting welding block is formed on a back underlay of one of the semiconductor wafers; a plurality of semiconductor wafers in order are overlaid on the semiconductor wafer underlay with the second connecting welding block. The method of the invention can not cause the damage to the wafer in a bonding process; a formed semiconductor wafer bonding structure can save the chip area of the semiconductor wafer.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

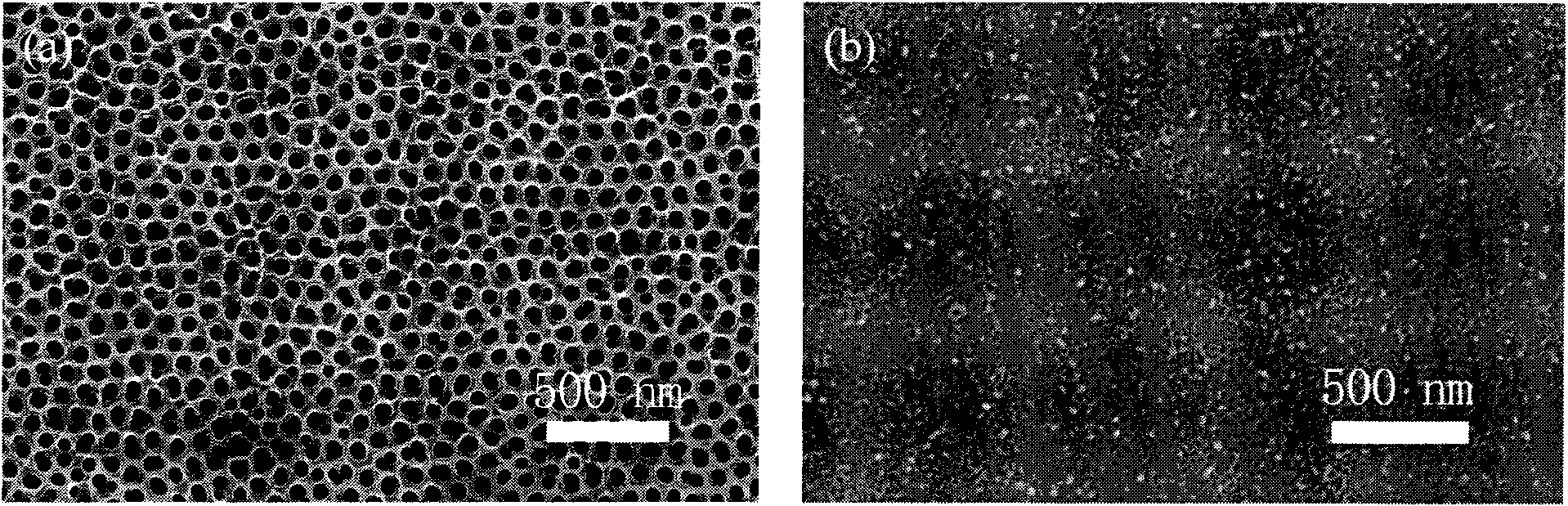

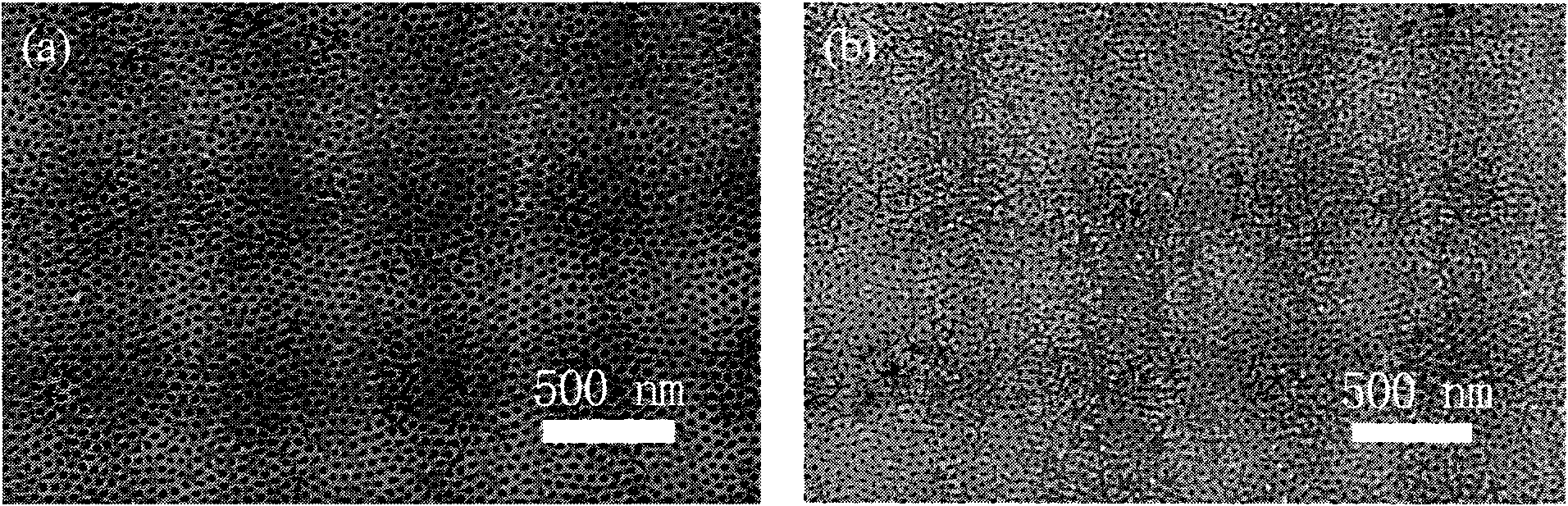

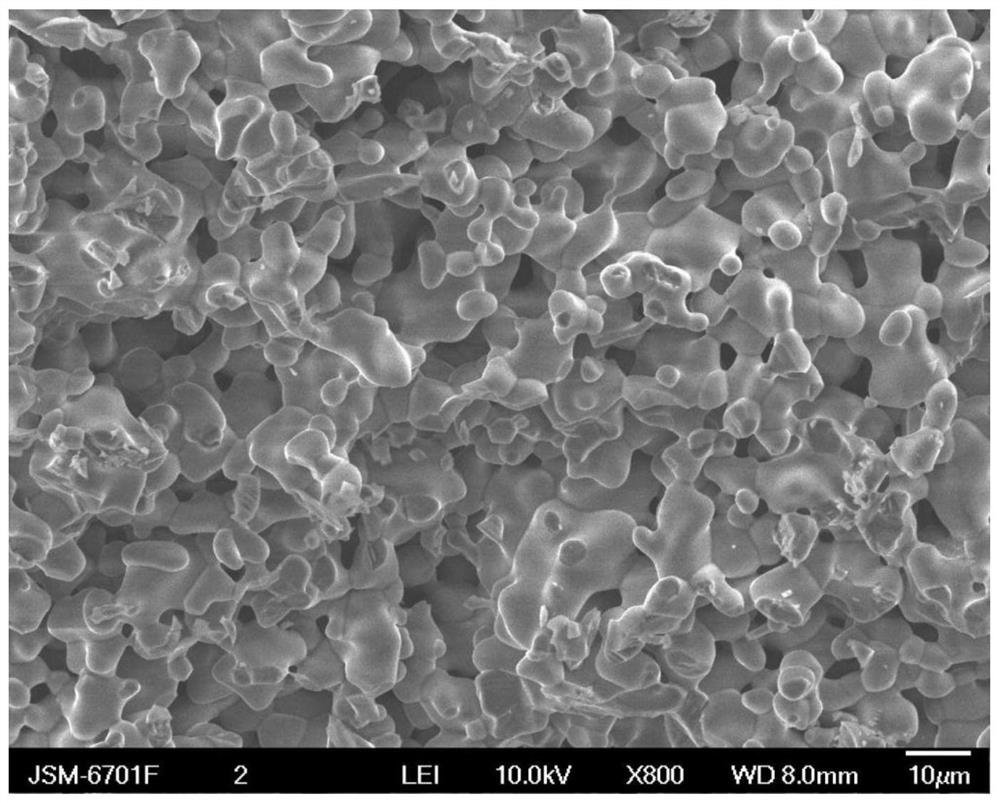

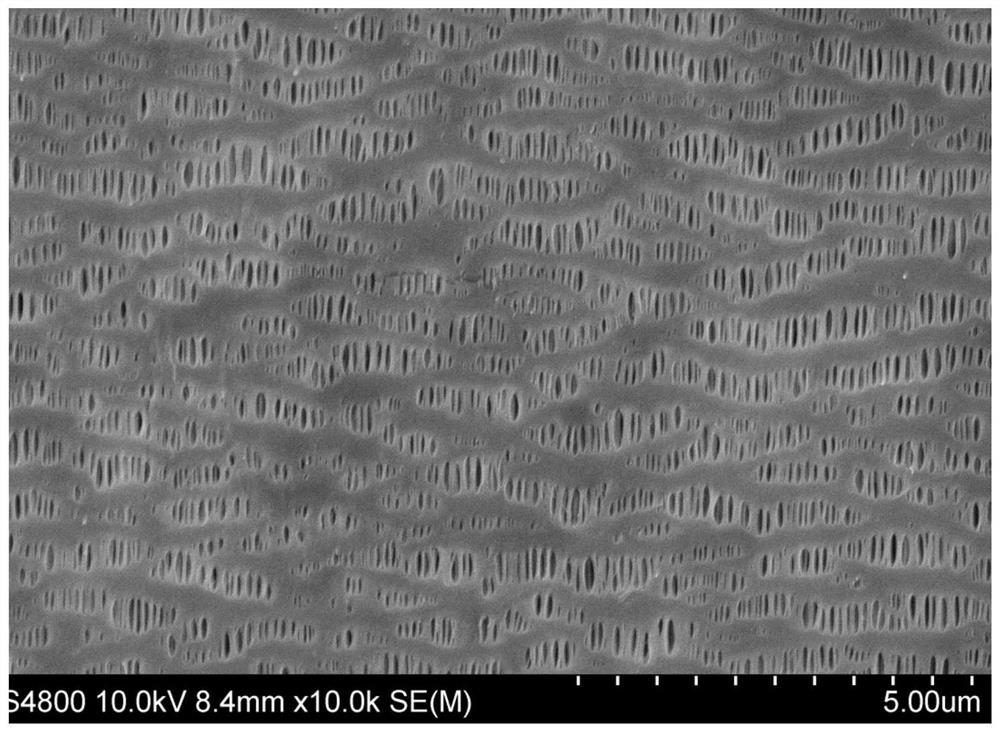

Method for preparing pore diameter controllable through hole anodized aluminum oxide film

The invention relates to technology for preparing an anodized aluminum oxide film, in particular to a method for preparing a pore diameter controllable through hole anodized aluminum oxide film. The method comprises the following steps of: performing anode electrolysis treatment on an anodized aluminum oxide film with an aluminum substrate in mixed solution of perchloric acid and acetone to obtain a pore diameter controllable anodized aluminum oxide film with two open ends in short time (2-300 seconds), wherein the pore diameters at the top end and the bottom end fo the anodized aluminum oxide film are accurately controllable in ranges of between 10 and 100nm and between 5 and 25nm; and putting the aluminum oxide film with the aluminum substrate subjected to stage depressurization-method oxidation into acetone solution of perchloric acid, and applying voltage 5-15V higher than film forming voltage for anode electrolysis treatment to obtain the pore diameter controllable through hole anodized aluminum oxide film. In the method, the pore diameters at the top end and the bottom end of the anodized aluminum oxide film can be respectively controlled, holing and removal of the aluminum substrate are completed by one step, and a plurality of problems of complicated process, time consumption, difficult control of pore diameters and the like in the conventional process for preparing the through hole anodized aluminum oxide film.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

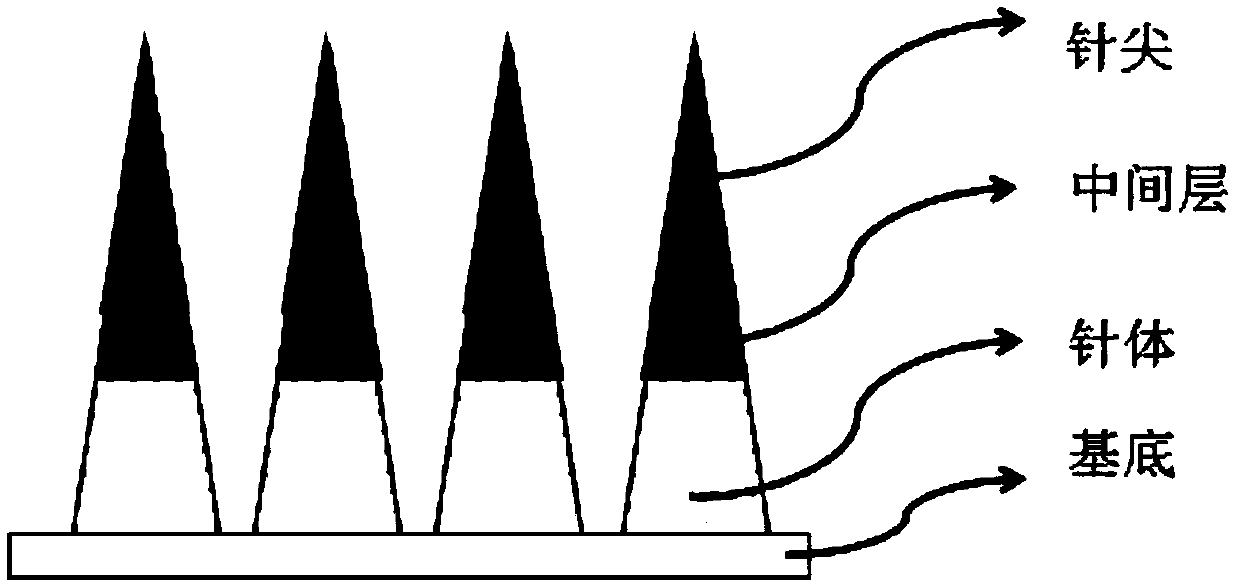

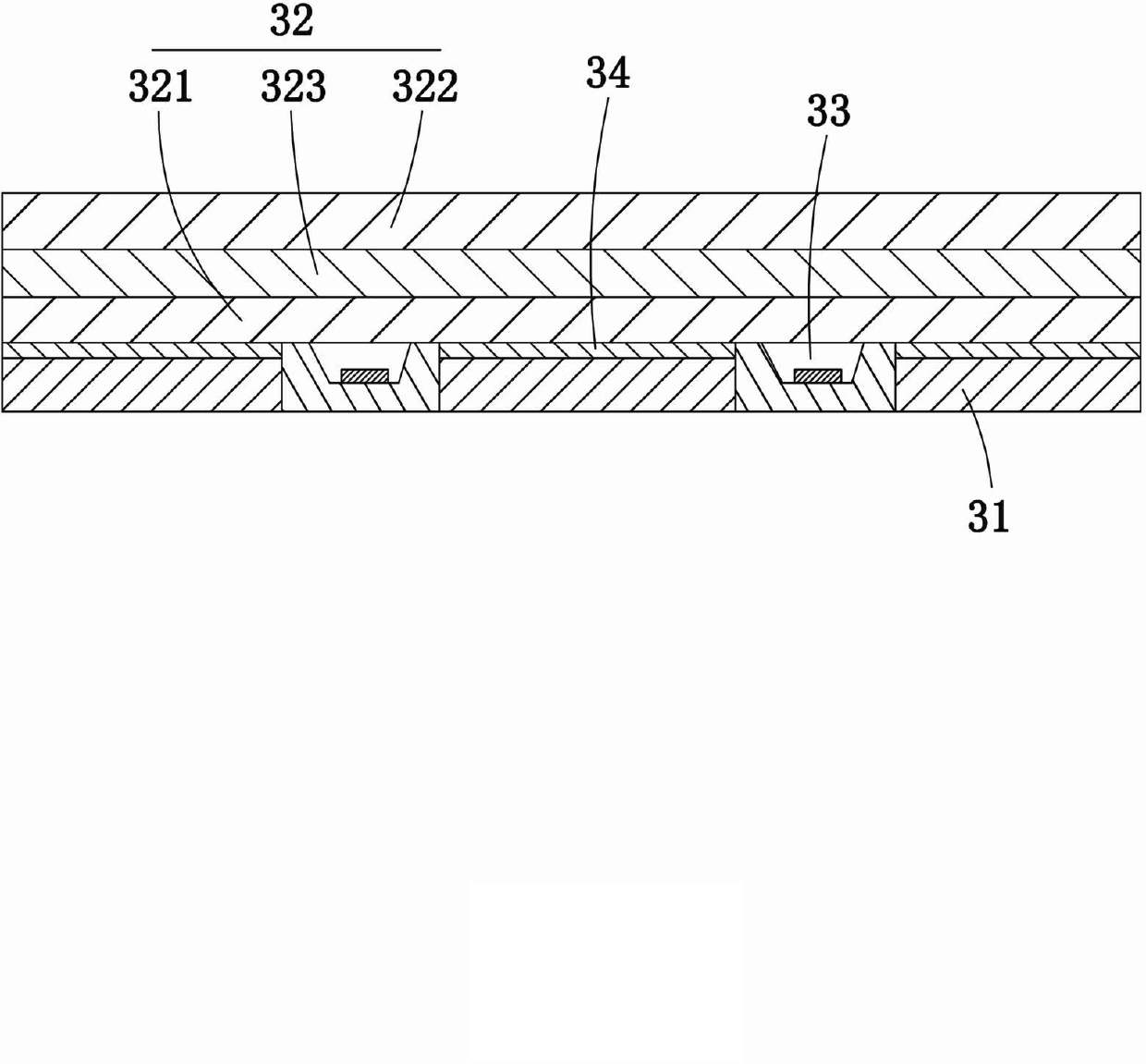

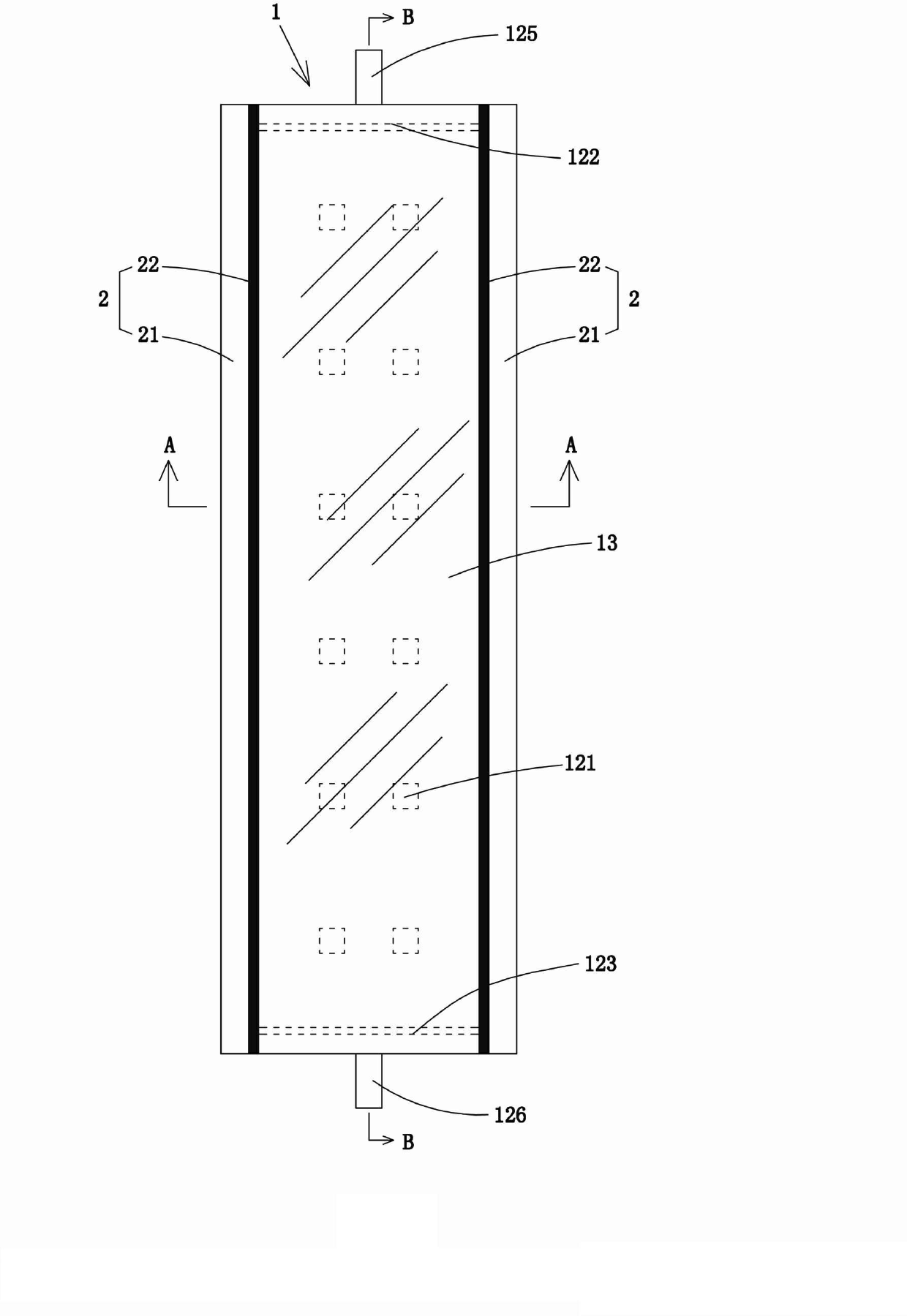

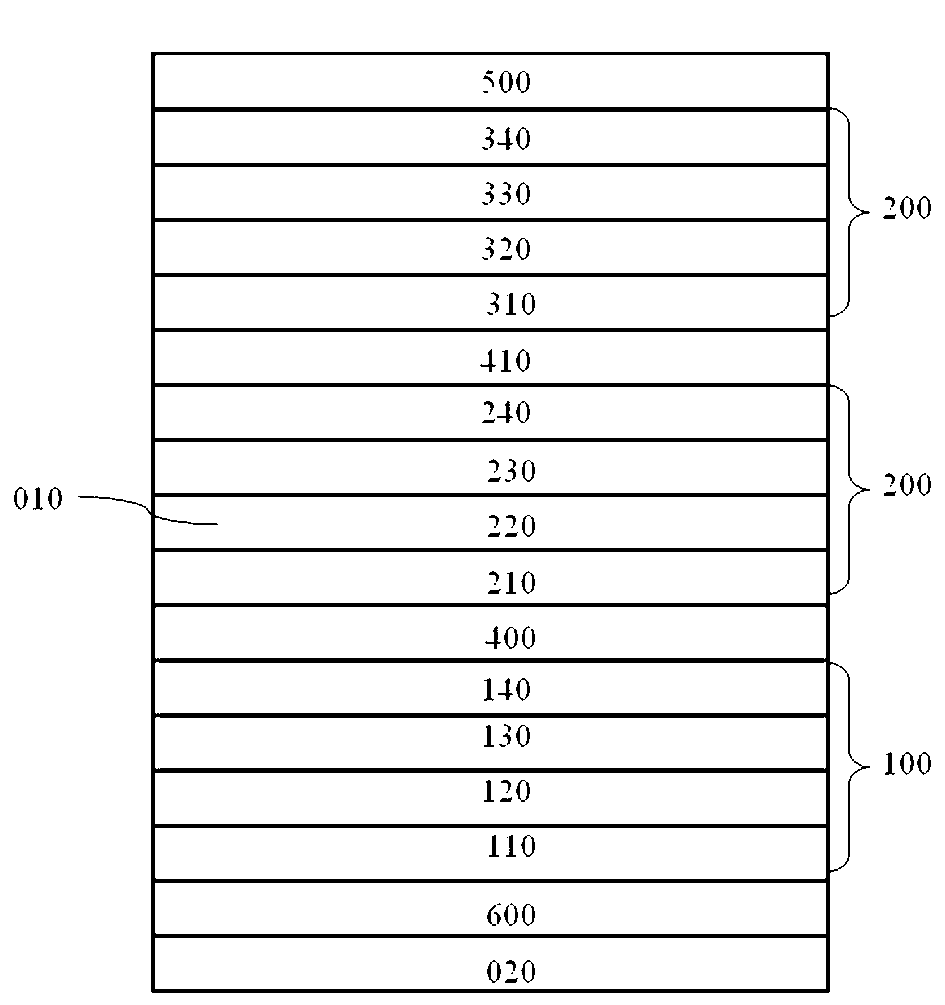

Fast-implantable sustained-release microneedle patch and preparation method of fast-implantable sustained-release microneedle

PendingCN110870846AGuaranteed long-term releaseAvoid cumbersome workmanshipCosmetic preparationsToilet preparationsPharmaceutical SubstancesBiomedical engineering

The invention discloses a fast-implantable sustained-release microneedle patch and a preparation method of a fast-implantable sustained-release microneedle. The invention firstly discloses the fast-implantable sustained-release microneedle, the fast-implantable sustained-release microneedle includes a needle tip, an intermediate layer, a needle body and a base, the needle tip is formed of a substrate containing a biodegradable water-insoluble polymer material, the intermediate layer is formed of a substrate containing a hydrophilic material, and the needle body and the base are formed of a substrate containing a biocompatible polymer material. The invention also discloses the preparation method of the microneedle. According to the microneedle or microneedle patch provided by the invention,the biodegradable water-insoluble polymer material is used to prepare the needle tip, the hydrophilic material is used to prepare the intermediate layer, and the biocompatible polymer material is used to prepare the needle body and the base, so that the multi-layered microneedles with water-insoluble needle tips are formed; and water is absorbed after the microneedles act on skin, the needle tipsand the needle bodies are quickly separated from the base within 1 h, after the base is removed, the needle tips remain in the skin, and the long-term release of a drug in vivo can be ensured withoutapplying the microneedle patch to a user for a long time.

Owner:BEIJING CAS MICRONEEDLE TECH LTD

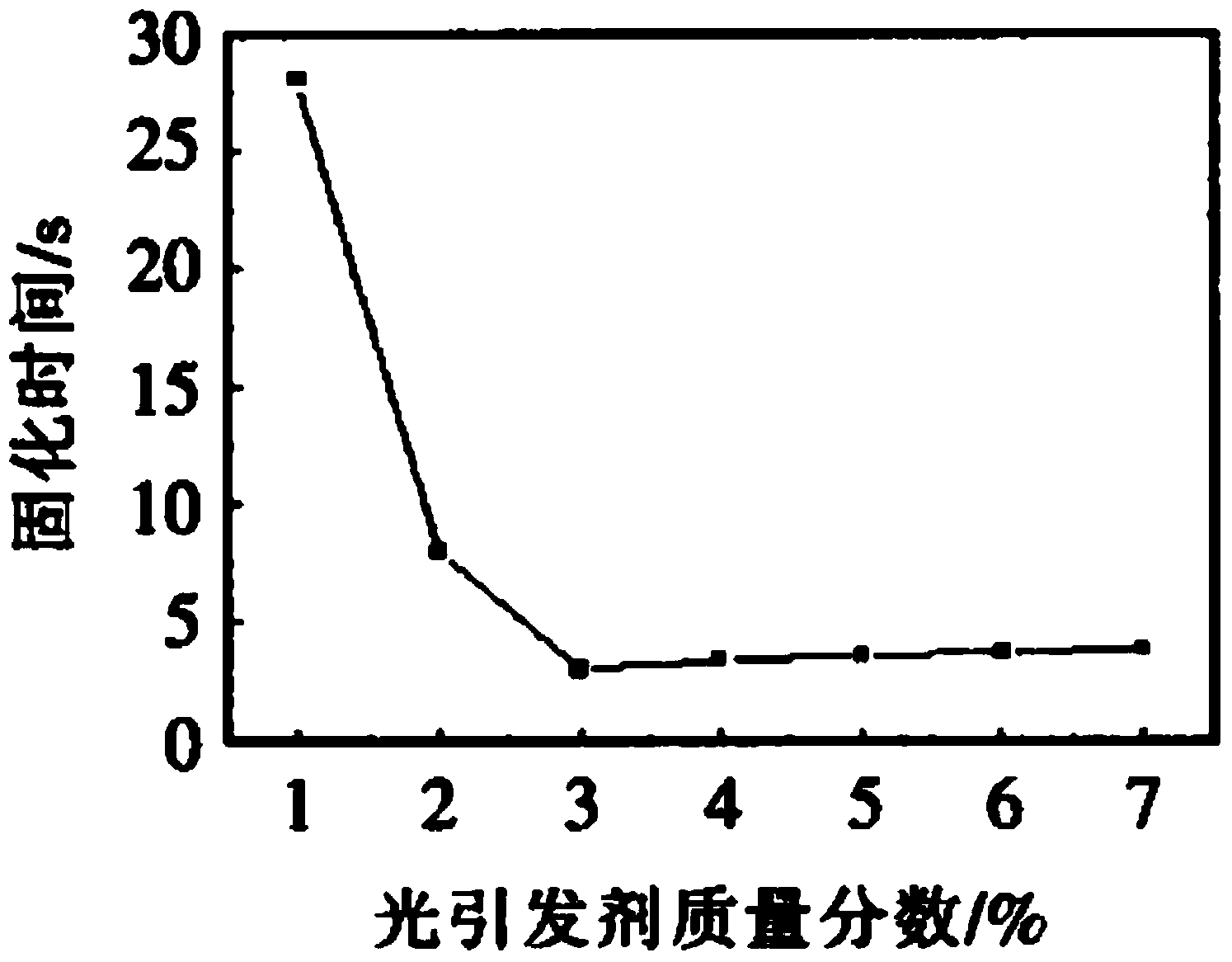

Manufacturing method of complex-structured intelligent material device based on rapid forming technique

InactiveCN104108184AAchieve overlayGet rid of precisionIncreasing energy efficiencyLayered modelDiscretization

The invention relates to a manufacturing method of a complex-structured intelligent material device based on a rapid forming technique. The manufacturing method comprises the following steps: determining the utilized rapid forming technique according to one or multiple requirements including the physicochemical properties and states of a forming raw material and the precision of the complex-structured intelligent material device; establishing a three-dimensional model of the complex-structured intelligent material device, carrying out discretization on the surface of the three-dimensional model of the complex-structured intelligent material device to generate a three-dimensional digital model file of the three-dimensional model of the complex-structured intelligent material device, carrying out support adding, layered model discretization and processing route generation on the three-dimensional digital model file to guide out a processing file capable of being identified by rapid forming equipment, and downloading the processing file to the rapid forming equipment; manufacturing the complex-structured intelligent material device by virtue of the rapid forming equipment according to the processing file. According to the manufacturing method, the problem that different types of the complex-structured intelligent material devices are difficult to manufacture is solved; a forming device has the advantages of high precision, adjustable performance, easiness in manufacturing and the like.

Owner:XI AN JIAOTONG UNIV

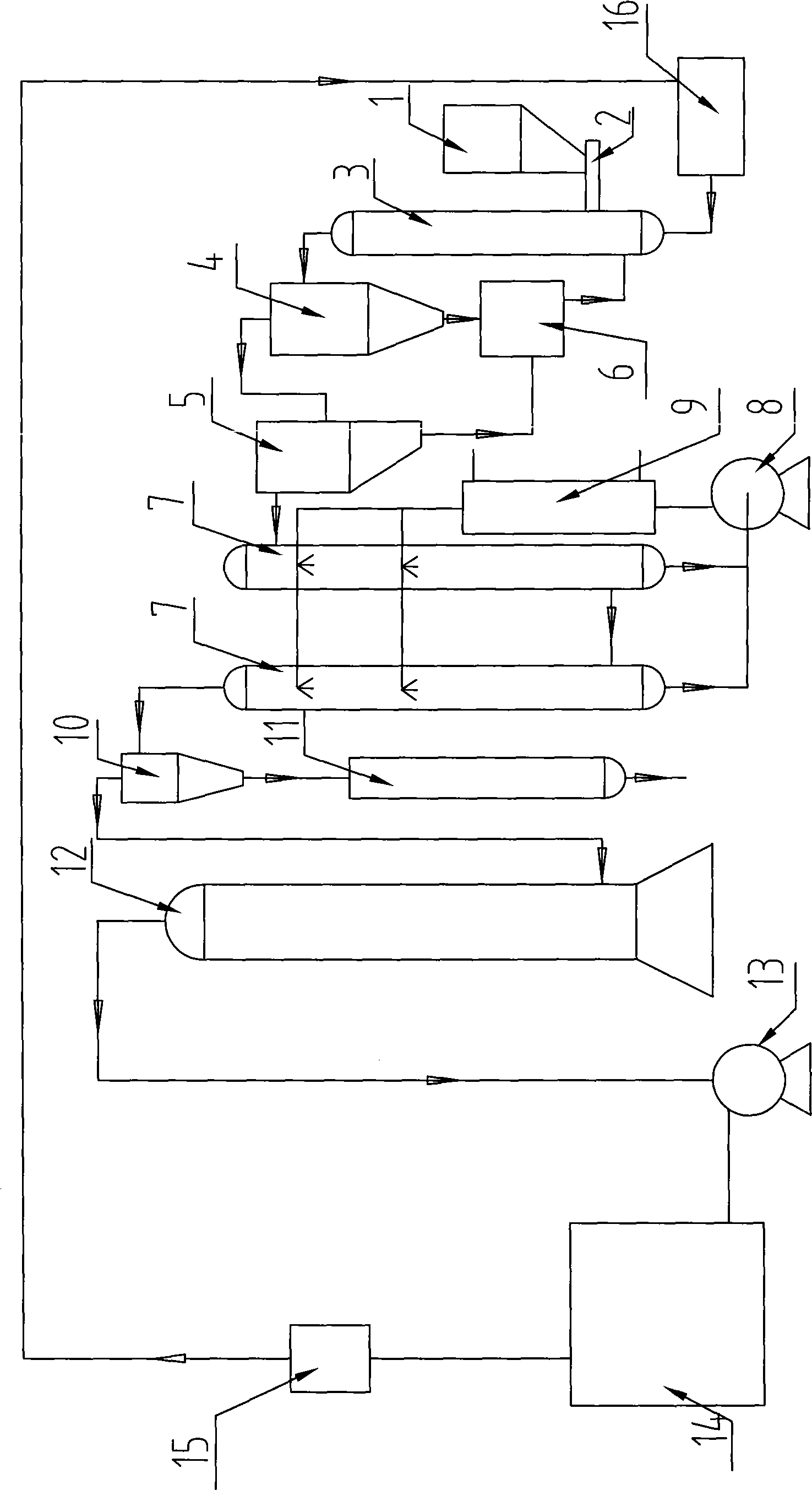

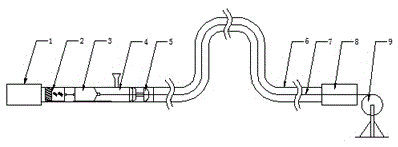

System for rapidly pyrolysing and liquefying biomass

InactiveCN101531910AImprove cleanlinessLow cleanlinessLiquid hydrocarbon mixture productionProcess engineeringBiomass

The invention discloses a system for rapidly pyrolysing and liquefying biomass, which comprises a pyrolysis reactor, a feeding device connected with a biomass material inlet of the pyrolysis reactor, a reaction starter connected with a circulating heat supporting gas inlet, a gas-solid separation sub-system connected with a pyrolysis gas outlet of the pyrolysis reactor, a bio-oil condensing and reserving sub-system connected with a gas outlet of the gas-solid separation sub-system, and a thermal circulation medium heating and separating sub-system connected with a solid outlet of the gas-solid separation sub-system. The thermal circulation medium outlet of the thermal circulation medium heating and separating sub-system is connected with the thermal circulation medium inlet of the pyrolysis reactor, wherein the bio-oil condensing and reserving sub-system includes at least one heat exchanger that is applied for cooling partial obtained bio-oil to be used as a condensed medium of the bio-oil condensing and reserving sub-system. The system for rapidly pyrolysing and liquefying biomass can fully improve the utilization rate of biomass energy and reduce the operation cost thereof to the maximum degree.

Owner:GUANGZHOU DEVOTION THERMAL TECH

Food grade biodegradable polylactic acid-based composite material and application thereof

The invention relates to a food grade biodegradable polylactic acid-based composite material which is prepared by drying, mixing and performing one-step melt blending modification and extrusion pelleting on four components, namely, 55-85wt% of polylactic acid, 2-10wt% of biodegradable polyester, 3-10wt% of food grade plasticizer and 10-30wt% of inorganic packing, in a double-screw extruder, wherein the inorganic packing is inorganic packing without surface treatment, and the average particle size of the inorganic packing is 2.7-19 micrometers; the weight-average molecular weight of the polylactic acid is 100000-180000, and the molecular weight distribution index is 1.2-2.0. All components of the composite material are non-toxic food grade materials, the content of the inorganic packing is high, the mechanic property and the thermal resistance of the composite material are remarkably improved, and thus the composite material can be used as a resin universal for sucking molding, injection modeling and blowing injection, a one-step mixing process is adopted, tediousness in the conventional inorganic powder pretreatment is avoided, continuous production is achieved, and the production cost is greatly lowered.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

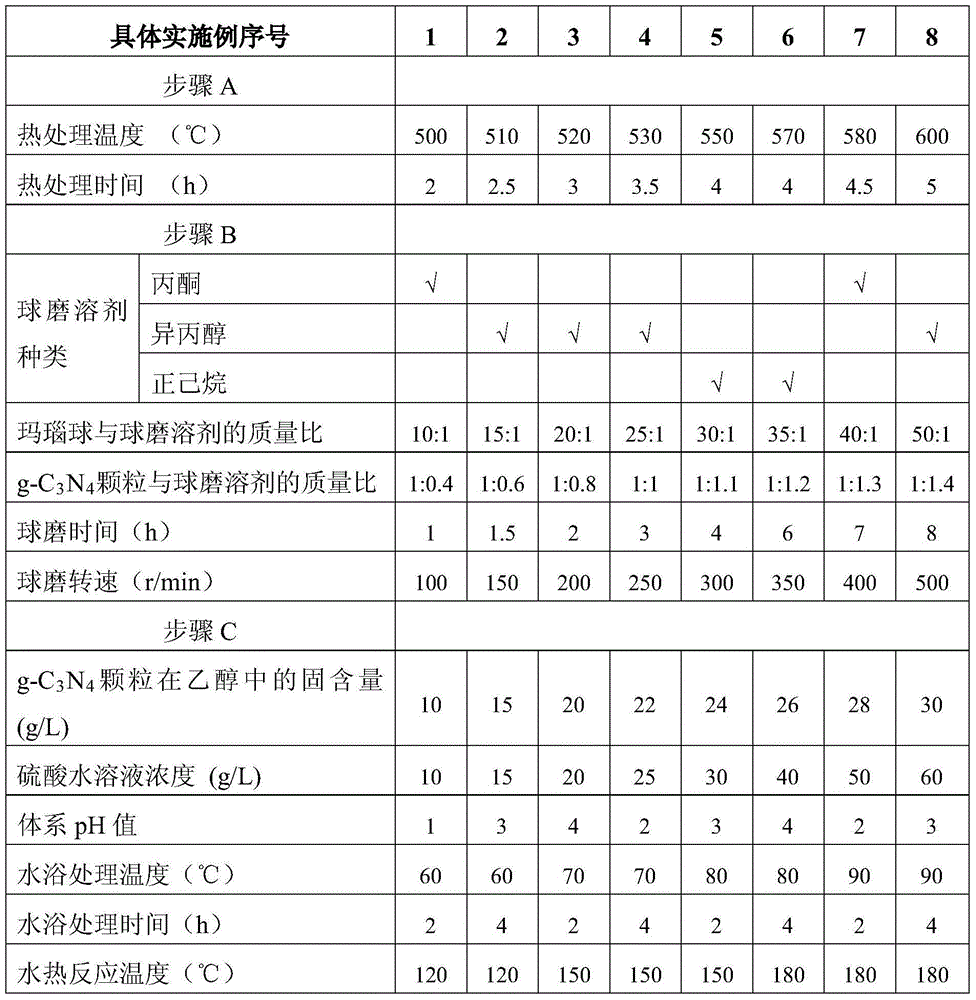

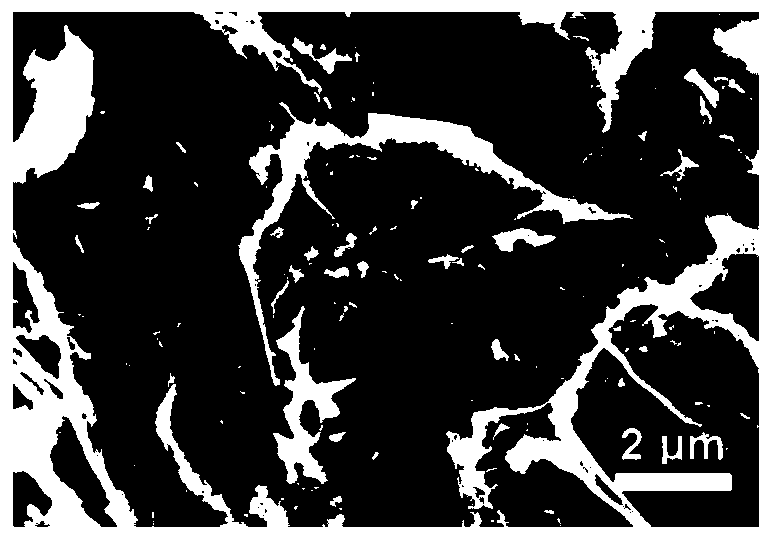

Preparation method of porous g-C3N4 semi-conducting material

InactiveCN104310321AAvoid cumbersome workmanshipExcellent photocatalytic performanceNitrogen and non-metal compoundsSolventPre treatment

The invention relates to the field of semi-conducting materials and provides a preparation method of a porous g-C3N4 semi-conducting material. The preparation method comprises the following steps of putting melamine powder into a crucible boat, putting the crucible boat with melamine powder into a tubular furnace, carrying out heating treatment, carrying out cooling to obtain yellow blocky g-C3N4 solids, carrying out grinding, putting the g-C3N4 particles into a ball milling tank, carrying out ball milling pretreatment, adding the slurry obtained by ball milling with a same ball milling solvent, carrying out drying to obtain g-C3N4 particles, dispersing the g-C3N4 particles into ethanol, carrying out ultrasonic treatment for dispersion, adding sulfuric acid into the ethanol dispersion solution of g-C3N4 to adjust a pH value of the ethanol dispersion solution, and carrying out a hydro-thermal reaction process to obtain the porous g-C3N4. Through combination of a ball milling technology and protonation effects, the preparation method conveniently prepares the porous g-C3N4 and solves the problem that the traditional method produces g-C3N4 having a small specific surface area and low efficiency.

Owner:ZHEJIANG UNIV

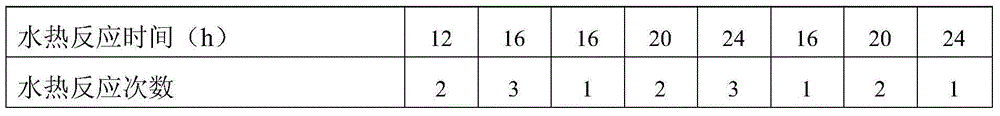

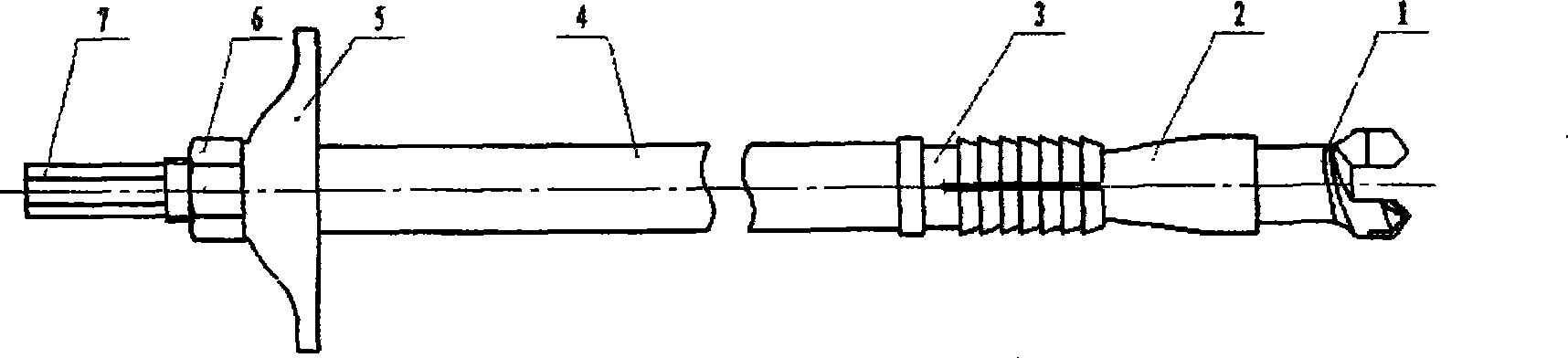

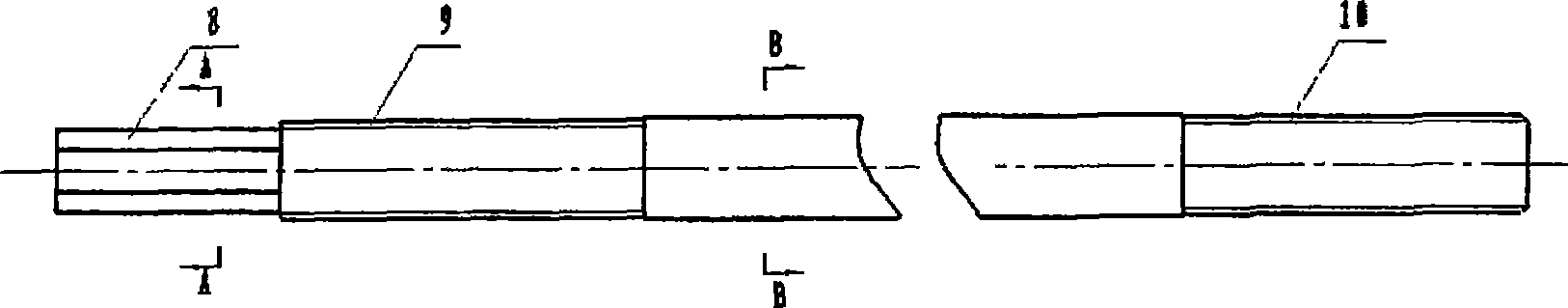

Bush bulging shell type self-drilling hollow anchor rod

InactiveCN101054901APlay the role of mechanical advanced anchoringPermanent supportAnchoring boltsCement slurryRock bolt

The invention relates to a casing pipe rising shell type self-drilling hollow anchor bar, belonging to project supporting field, which comprises a one-off drill bit, a steel plug, a rising shell, a casing pipe, a hollow bar body, a tray and a nut. The one-off drill bit is connected at the most front end of the hollow bar body, the life design is to drill a hole; the steel plug is scyewed joint and welded together with the hollow bar body, the lower end of the steel plug is in turn hollow housed the rising shell and the casing pipe; four slots are opened on the upper of the rising shell, and tilted teeth are machined in outside; the casing pipe is held on the lower end of the tray and is fixed by the nut. The invention is applied to the supporting of coal mine back, at first the quick load-bearing requirement is reached by mechanical rising shell ahead anchoring, then the whole length anchoring is realized by injecting sand-cement slurry. The invention has convenient drilling and mounting in the construction and changes construction process of the traditional anchor bar, and realizes integration of the drilling and anchoring of the coal drift supporting and is help to safe and quick supporting of the coal drift.

Owner:郑晓雯 +2

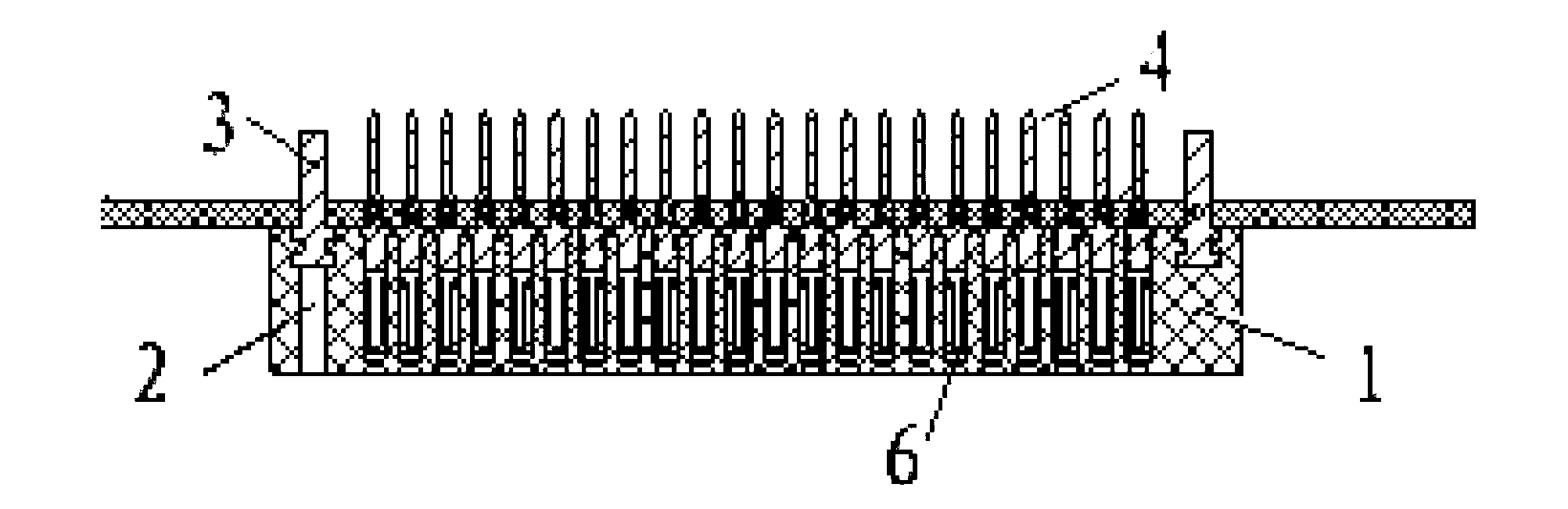

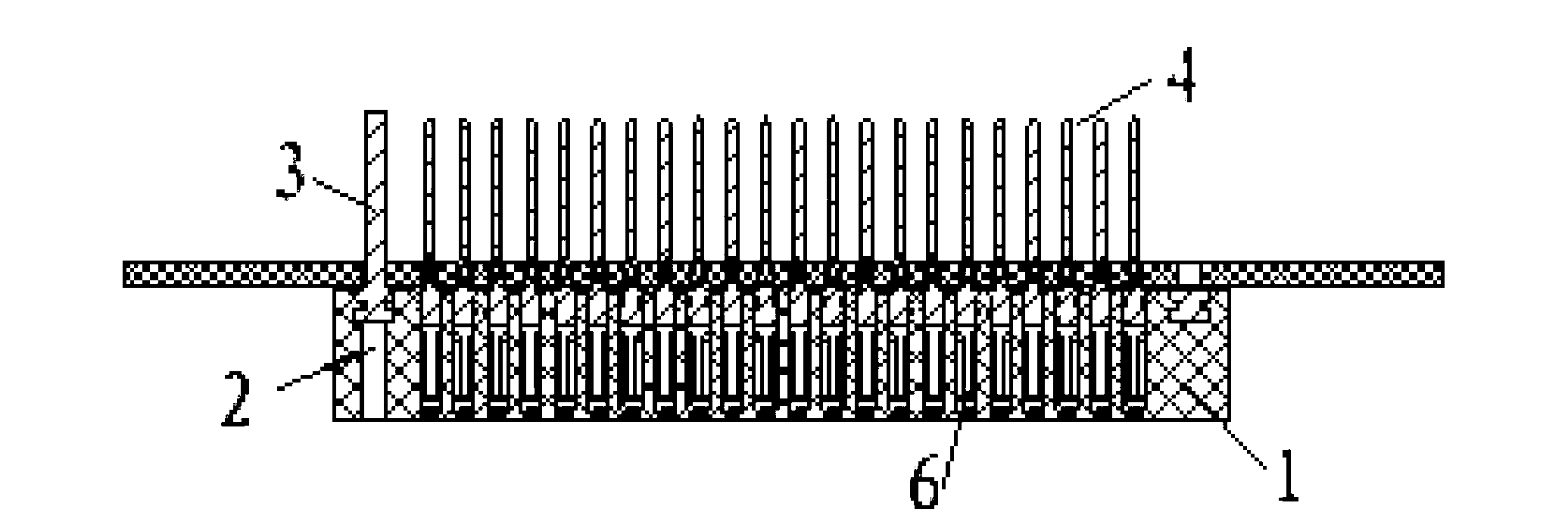

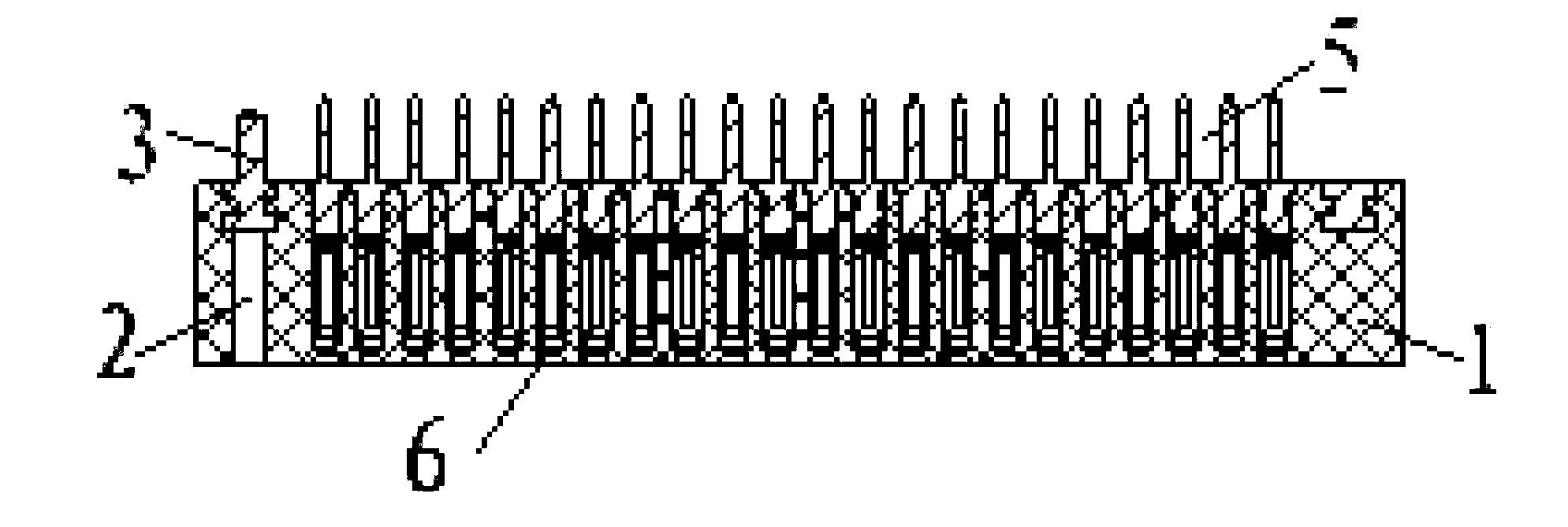

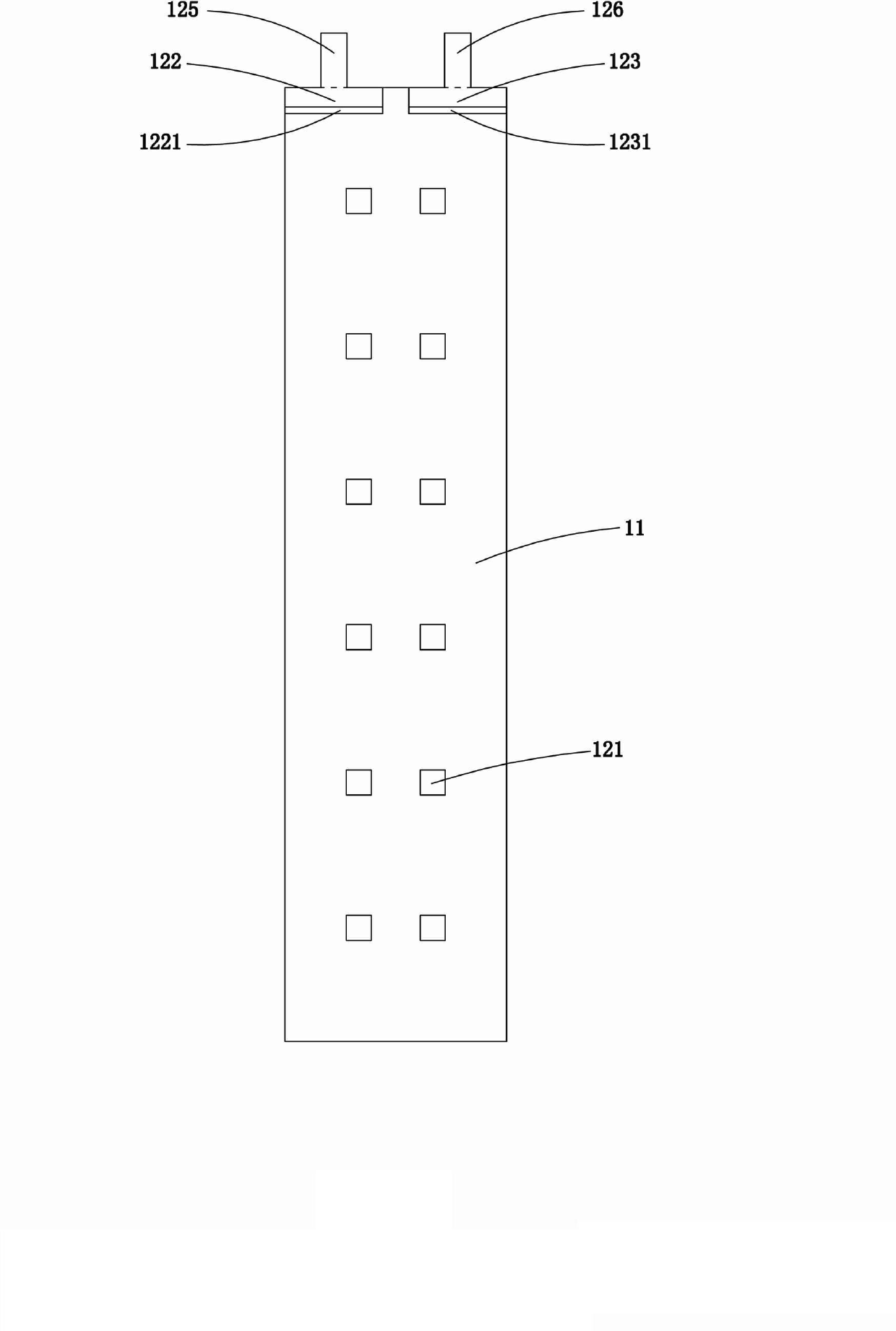

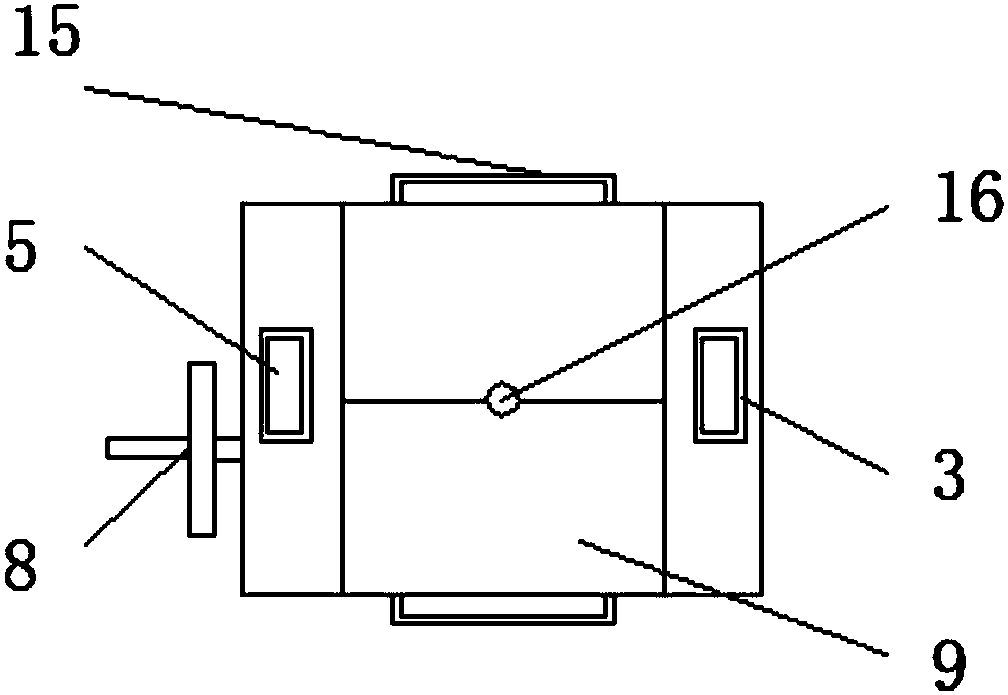

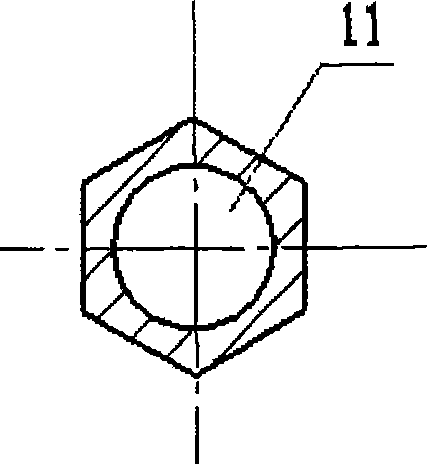

Printed circuit board press-in connection-type rectangular connector

InactiveCN103227372ASuitable for cascade installationAvoid cumbersome workmanshipCoupling device detailsFixed connectionsInterference fitConnection type

A printed circuit board press-in connection-type rectangular connector comprises an insulator (1), wherein guide sleeves (2) or guide pins (3) that are used for mutual connection in a positioning manner are arranged on the insulator (1); and in addition, one or a plurality of insertion holes (4), inserting needles (5) and slots (6) used for connecting a printed circuit board are also formed in the insulator (1). The printed circuit board press-in connection-type rectangular connector is characterized in that the insertion holes (4), the inserting needles (5) and the slots (6) are fixed in the insulator (1) in a barb interference fit fixing manner, and the connector and the printed circuit board are in interference fit in a press-in manner, so that the contact is reliable, the installation space is saved, the cumbersome dip soldering-type process of the common connector for the printed circuit board is also avoided, the printed circuit board press-in connection-type rectangular connector is very convenient to operate and is very suitable for stacking installation and use of the printed circuit boards, and signals among the printed circuit boards can be managed in a unified and integrated manner.

Owner:沈阳兴华航空电器有限责任公司

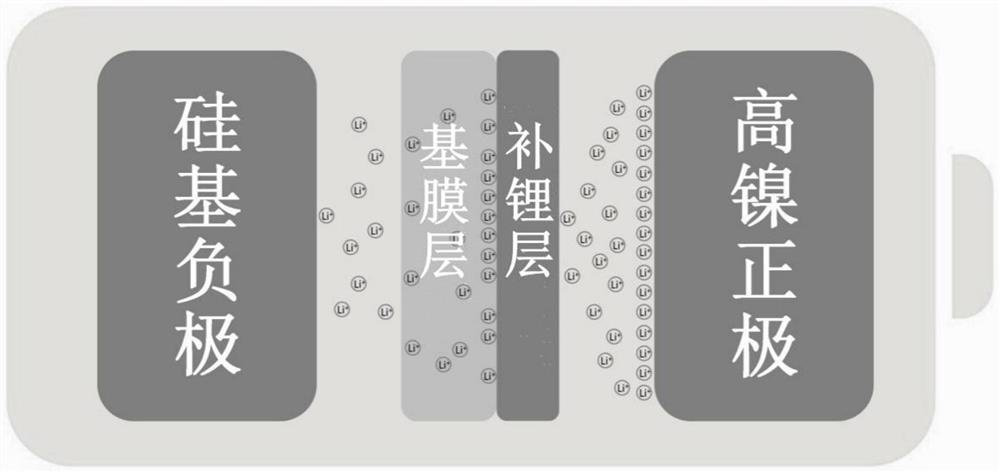

Functionalized lithium supplementing diaphragm and preparation method thereof

ActiveCN111816822AImprove performanceWill not harmSecondary cellsCell component detailsElectrolytic agentPolymer substrate

The invention provides a functionalized lithium supplementing diaphragm and a preparation method, the functionalized lithium supplementing diaphragm is composed of a lithium supplementing layer and abase film layer, and the lithium supplementing layer comprises a lithium-containing compound, a polymer substrate and a flexibilizer; the base film layer comprises a polymer base material; and the lithium supplementing layer and the base film layer are prepared through melting double-layer co-extrusion. The functionalized lithium supplementing diaphragm replaces a traditional lithium ion battery diaphragm, lithium ions can be supplemented for the first circle after the battery is assembled, the performance of the battery is improved, and the performance of the battery cannot be damaged after the charging of the first circle. The inventor unexpectedly finds that the lithium supplementing agent and the polymer base material are matched according to a proper ratio, and a proper thickness is extruded in a double-layer co-extrusion manner, so that the formed three-dimensional porous composite structure can realize good lithium supplementing, and can prevent the lithium supplementing agent from falling into an electrolyte to cause reduction of the lithium supplementing efficiency.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Light emitting diode light source structure

InactiveCN102664229ASolve the technical problem of luminous dead angleMoisture-proofSolid-state devicesSemiconductor devicesFluorescenceSilica gel

The invention discloses a light emitting diode light source structure, which comprises a packaging main body, wherein the packaging main body is composed of a light transmitting substrate, a light emitting diode device fixed on the upper surface of the light transmitting substrate and a light transmitting top plate correspondingly packaged on the light emitting diode device; the light emitting diode device comprises an LED (Light Emitting Diode) light emitting chip, a positive light emitting electrode slice and a negative light emitting electrode slice; the LED light emitting chip and the light emitting electrode slices are connected; a transparent silica gel layer for sealing the LED light emitting chip is injected between the light transmitting substrate and the light transmitting top plate; the side surface of at least one packaging main body is fixedly stuck with a light transmitting side plate; the light transmitting substrate and the light transmitting top plate respectively comprise a first transparent sheet and a second transparent sheet which are fixedly overlapped; a fluorescence rubber layer is evenly coated between the opposite surfaces of the first transparent sheet and the second transparent sheet; and the light transmitting side plate comprises a transparent sheet and the fluorescence rubber layer coated on the inner surface of the transparent sheet. According to the light emitting diode light source structure, no dead corner four-direction lighting illumination is realized, fluorescent powder and the light emitting diode are completely sealed to protect the safety of the light source device, and the light emitting diode light source structure has the advantages of long service life, high lighting effect, energy conservation and environment protection.

Owner:厦门宝晨照明科技有限公司

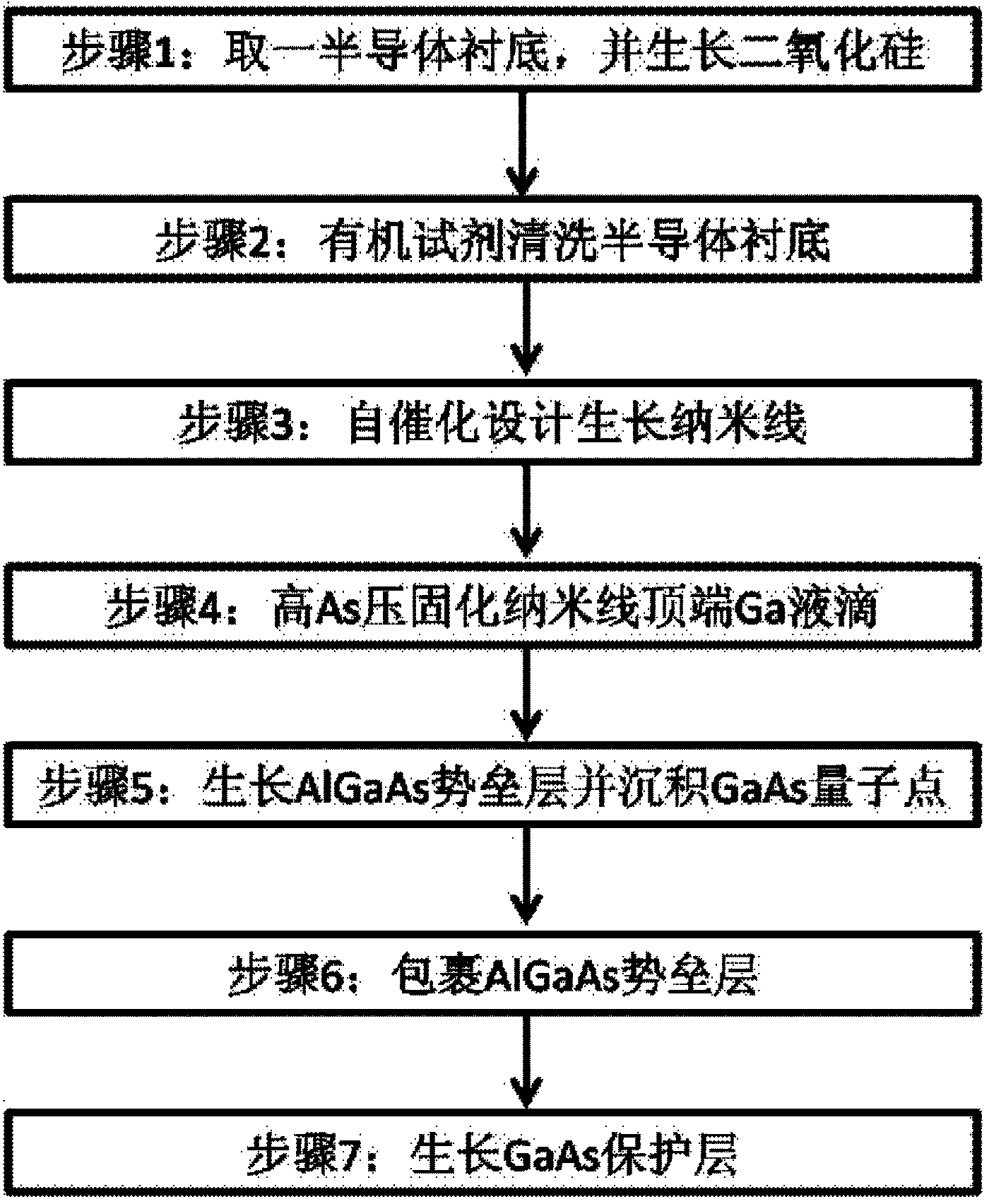

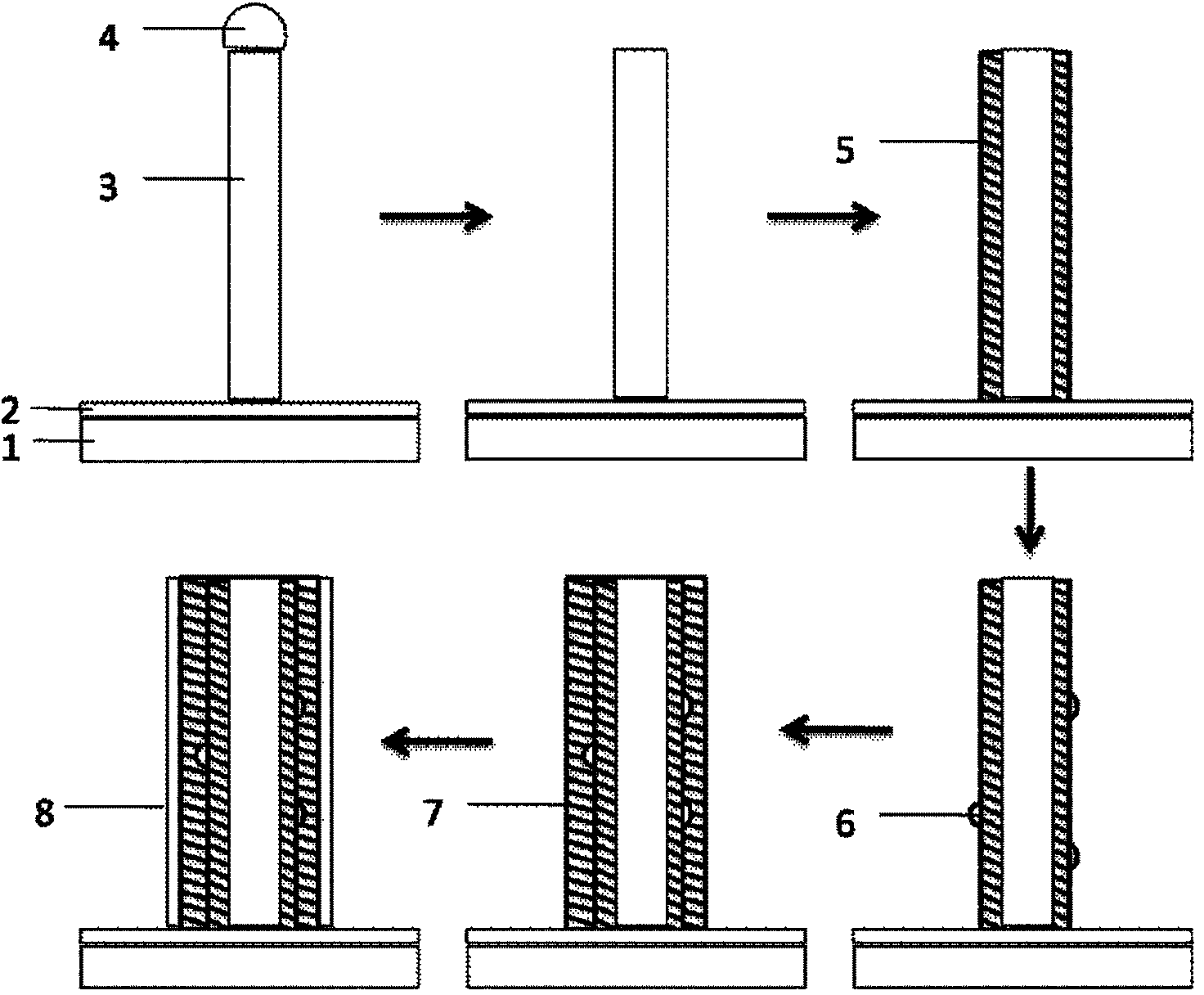

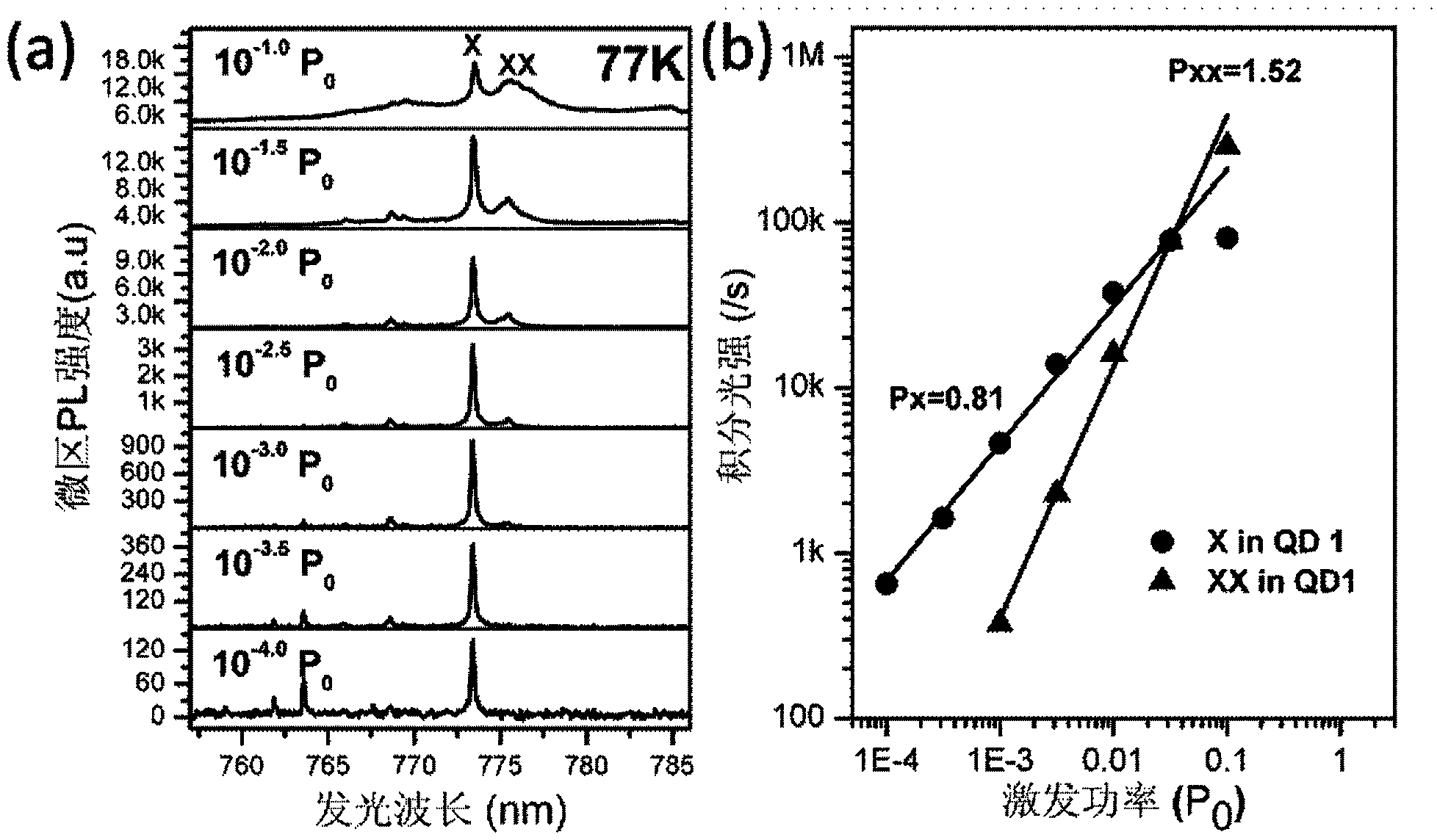

Method for preparing quantum-dot single photon source in hexagonal-prism nano microcavity

ActiveCN103531679AAvoid cumbersome workmanshipTwo-dimensional confinement works wellNanoinformaticsSemiconductor devicesElectrical conductorAutocatalysis

The invention provides a method for preparing a quantum-dot single photon source in a hexagonal-prism nano microcavity. The method comprises the steps as follows: step 1, taking a semiconductor substrate, and growing a silicon dioxide layer containing oxidation holes on the semiconductor substrate; step 2, washing the semiconductor substrate, where the silicon dioxide layer grows; step 3, adopting an autocatalysis method to grow a GaAs nanowire on the silicon dioxide layer, and forming a Ga droplet at the top of the GaAs nanowire; step 4, adopting high As pressure processing to consume the Ga droplet at the top of the GaAs nanowire, restraining axial VLS (vapor-liquid-solid method) growth of the GaAs nanowire, and forming a prismatic shaped structure; step 5, depositing a first AlGaAs barrier layer on the side wall of the prismatic shaped structure, and depositing GaAs quantum dots at a low speed on the surface of the AlGaAs barrier layer; step 6, covering the GaAs quantum dots with a second AlGaAs barrier layer; and step 7, growing a GaAs protective layer on the surface of the second AlGaAs barrier layer to finish the preparation.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Peanut nutrition milk and preparation method thereof

InactiveCN101176487AAvoid preprocessingAvoid cumbersome processes such as extractionMilk preparationFood preparationBiotechnologySucrose

The invention relates to a peanut nutritional milk and the preparation method, belonging to the technical field of food drink processing. The ingredients and the weight percentage of the invention are as follows: the protein 2.0 to 4.0 percent, sucrose 5.0 to 8.0 percent, emulsification stabilizing agent 0.15 to 0.25 percent, and remainder is the water. Compared with the prior art, the invention has the advantages that: (1) using the peanut butter protein directly to avoid the complicated crafts of pretreatment of peanut kernel, the protein extraction and other crafts, thus the production equipment disposition is simplified. (2) the nutritional milk prepared according to the invention has a protein content as high as 2.0 to 4.0 percent. (3) the nutritional milk presents cream color and has the unique fragrance and the taste of peanut and milk, taste is pure without burnt taste. During the guarantee of six months, the milk presents the uniform shape of the emulsion without lamination, flocculation phenomena and obvious deposit layer. Only by slightly shaking, the deposit can restore to the original condition.

Owner:广州合诚实业有限公司

Efficient triple-junction solar cell and manufacturing method thereof

InactiveCN103258872AHigh mechanical strengthImprove lattice qualityPhotovoltaic energy generationSemiconductor devicesEngineeringSolar battery

The invention discloses an efficient triple-junction solar cell and a manufacturing method thereof. The efficient triple-junction solar cell comprises a growth substrate, a bottom cell, an intermediate cell and a top cell, wherein the growth substrate is provided with two polished surfaces; the bottom cell is formed by a strain compensation superlattice structure, grows on the reverse side of the growth substrate in an inverted mode, and is provided with a first band gap, and the equivalent lattice constant of the bottom cell is matched with that of the growth substrate; the intermediate cell is formed on the obverse side of the growth substrate and is provided with a second band gap larger than the first band gap, and the lattice constant of the intermediate cell is matched with that of the growth substrate; the top cell is formed on the intermediate cell and provided with a third bang gap larger than the second band gap, and the lattice constant of the top cell is matched with that of the intermediate cell. Distribution of energy band gaps of the triple-junction solar cell meets an optimal choice for capturing a solar energy spectrum, and current matching and lattice matching are achieved, so photoelectric conversion efficiency of the triple-junction solar cell is effectively improved; according to the manufacturing method of the triple-junction solar cell, a mode of double-faced growth on the growth substrate is adopted, so growth cockamamie processes brought in the later stage of inverted growth are eliminated, and the yield of products is improved.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

Method for immobilizing effective microorganisms (EM) during solid fermentation

InactiveCN103146672ASolve the problem of easy falling offAvoid cumbersome workmanshipOn/in organic carrierBiological water/sewage treatmentFiberEffective microorganism

The invention discloses a method for immobilizing effective microorganisms (EM) during solid fermentation. The method is used for preparing immobilized EM through four steps including (1) preparation of a carrier, (2) preparation of fermented materials, (3) preparation of EM microbial inoculum through fermentation, and (4) preparation of immobilized solid EM microbial inoculum. Compared with the prior art, the method has the advantages that 1 operation time is shortened, work efficiency is improved, production cost is saved, effects are better than those of the mode that single adsorption immobilization is used in the prior art, and a problem that adsorption immobilization bacteria are easy to drop in the prior art is solved; and 2 EM preparation prepared by combining the adsorption of the carrier and bonding of a culture medium enables the bacteria to be tightly fixed on carrier fibers, and partial population superiority can be formed in a water body, so that action time of water quality is long, and effects are obvious.

Owner:GUANGXI INST OF FISHERIES

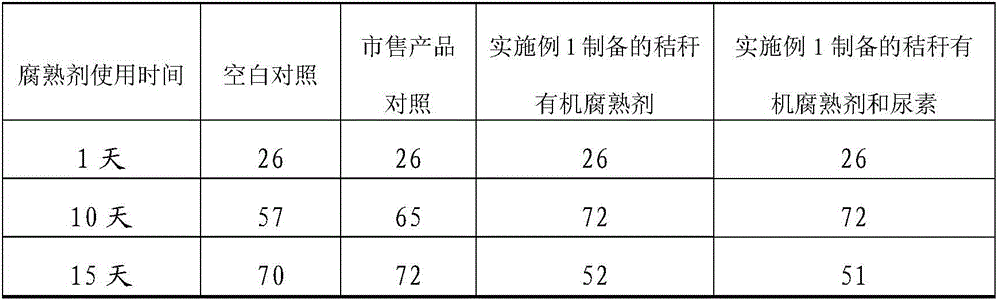

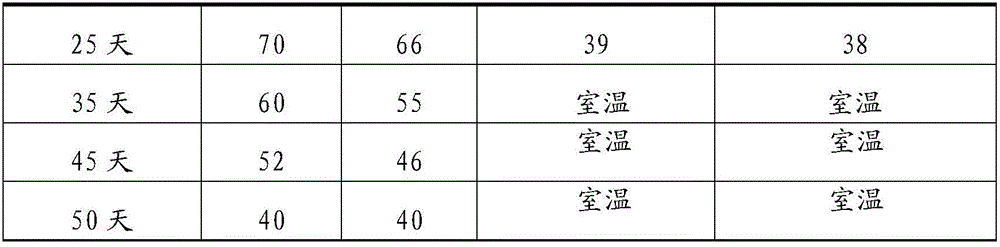

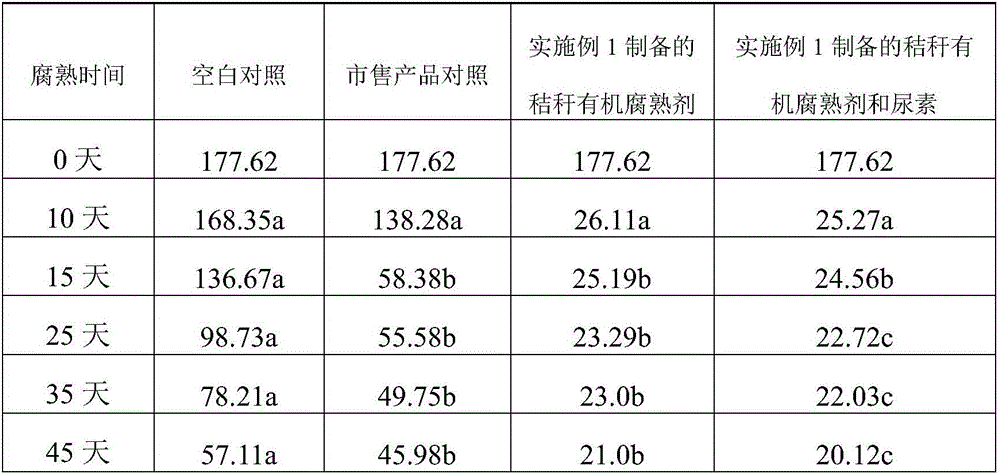

Straw organic decomposition agent and preparation method thereof

InactiveCN106318884AEasy to useThe use effect is more effective than similar products in the marketFungiBacteriaAdditive ingredientDecomposition

A straw organic decomposition agent is prepared from bacillus subtilis, brewer's yeast and aspergillus oryzae, the content of bacillus subtilis is larger than or equal to 15 billion cfu / g, the content of the brewer's yeast is larger than or equal to 20 billion cfu / g, the content of aspergillus oryzae is larger than or equal to 500 million cfu / g, and the number of effective living bacteria in the decomposition agent is larger than or equal to 265 million per gram. In the straw organic decomposition agent, only three original strains exist, bacteria, fungus living bacteria and an enzymic preparation are compounded, multiple components achieve a synergistic effect in the decomposition process, a cellulase preparation is cultured by mixing bacillus subtilis, brewer's yeast, aspergillus oryzae and the like, multiple kinds of cellulase systems are generated, good applicability is achieved, lignin ingredients in straw can be damaged fast, cellulose and hemicellulose in organic materials are exposed, and the decomposition time of the straw is shortened. A method for screening strains is efficient and practical, the production and fermentation process is simple, the production period is short, the number of the living bacteria and the enzyme activity level are high and stable, the use effect of the prepared decomposition agent is superior to that of an existing product, and wide industrialization prospects are achieved.

Owner:JIANGSU ZHIFENG BIOLOGICAL TECH CO LTD

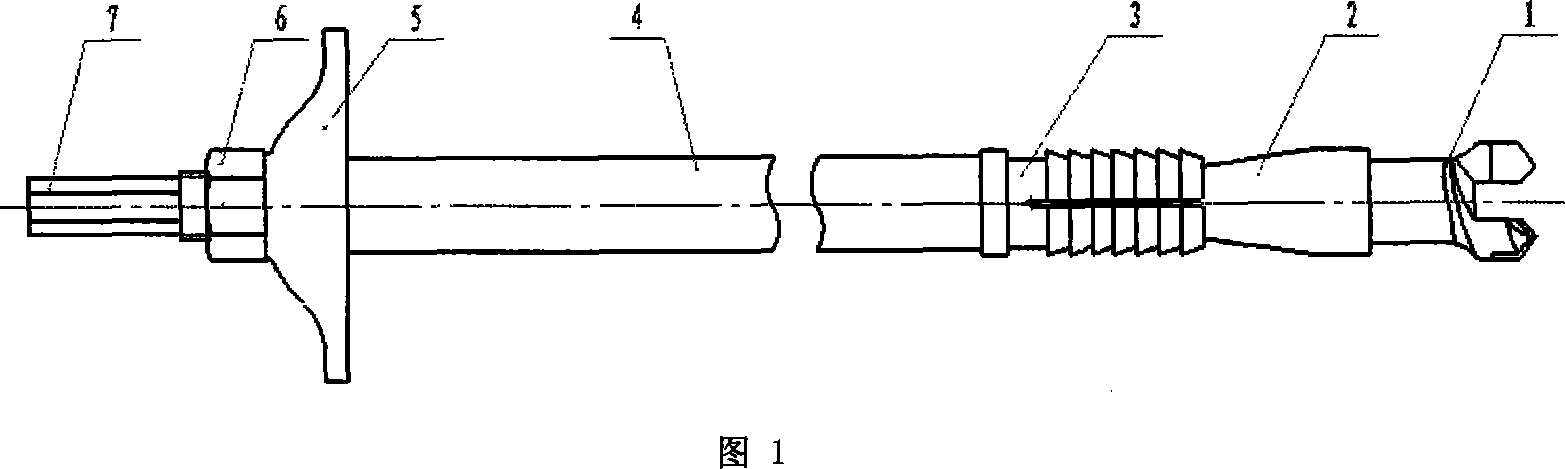

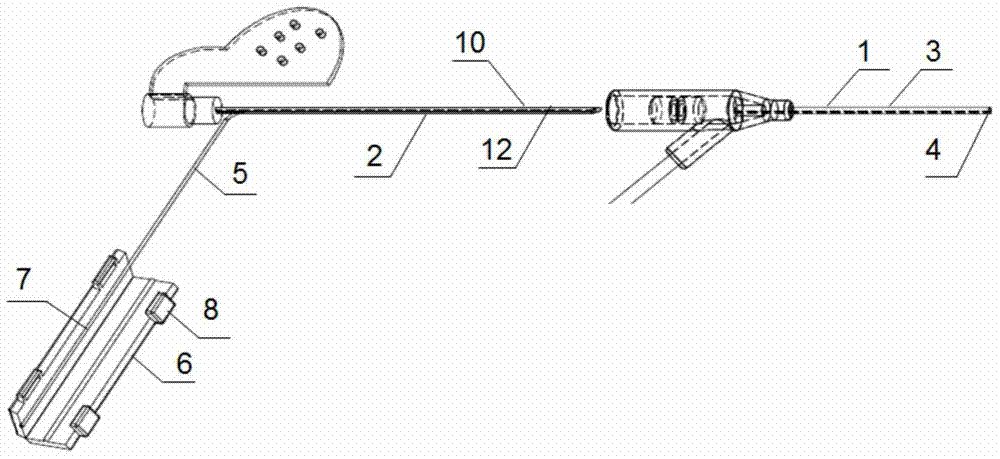

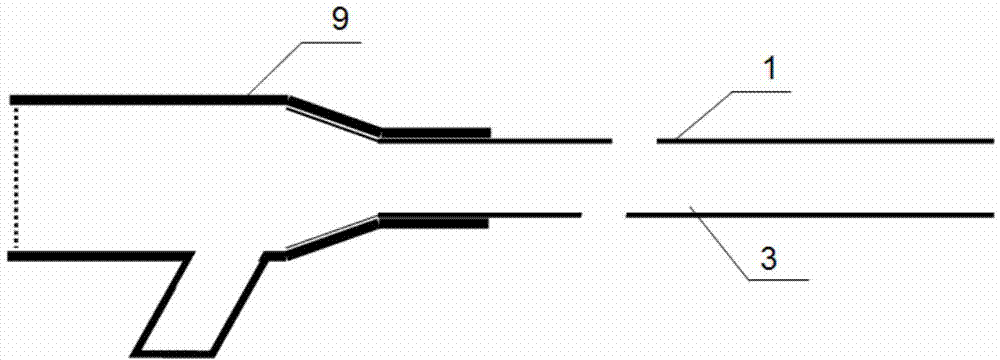

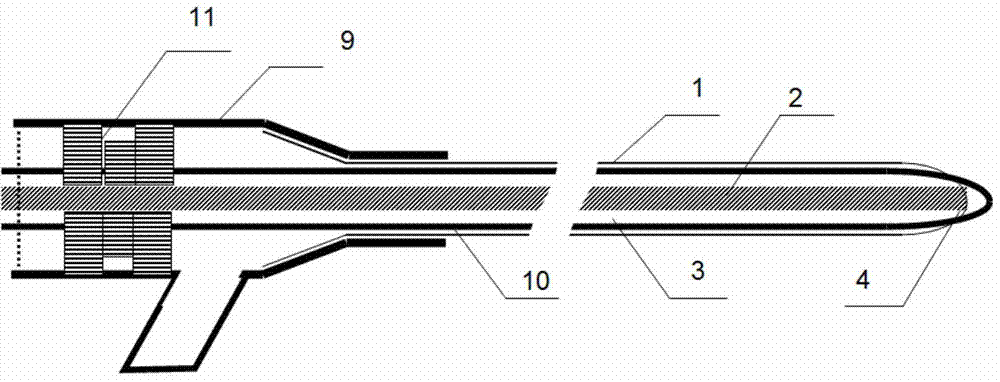

Self-sealing type venous indwelling needle and production method thereof

InactiveCN104721913AAvoid disadvantagesAvoid cumbersome workmanshipInfusion needlesIndwelling catheterVenipuncture

The invention relates to a self-sealing type venous indwelling needle and a production method thereof. The self-sealing venous indwelling needle is composed of an indwelling guide tube 1, an as-received basis bladder tube 2, an infusion tube cavity 3, a needle point groove 4, a flexible connecting tube 5, a pressurization block 6, a pressure proof bladder 7, a lock catch 8, a needle seat 9, a steel needle core 10 and a steel core isolating plug 11. The as-received basis bladder tube 2 of the self-sealing type venous indwelling needle enters into the needle seat 9 through the steel core isolating plug 11, the continuity and completeness of the guide tube are maintained, an as-received basis bladder, the steel needle core and the steel core isolating plug can be installed automatically, it is avoided that an openings is formed in the side wall of the indwelling guide tube or in the needle seat for installing the as-received basis bladder tube, complex and petty procedures are omitted, and the welding or bonding at the guide tube or at the needle seat is omitted; by means of a C-shaped groove structure of the steel needle core, it is convenient to contain and convey the as-received basis bladder tube to reach the tip of the as-received basis bladder tube, the steel needle core can be drawn out easily, and meanwhile the rigidity and sharpness of the indwelling needle in the process of venipuncture are maintained.

Owner:邓杜娟

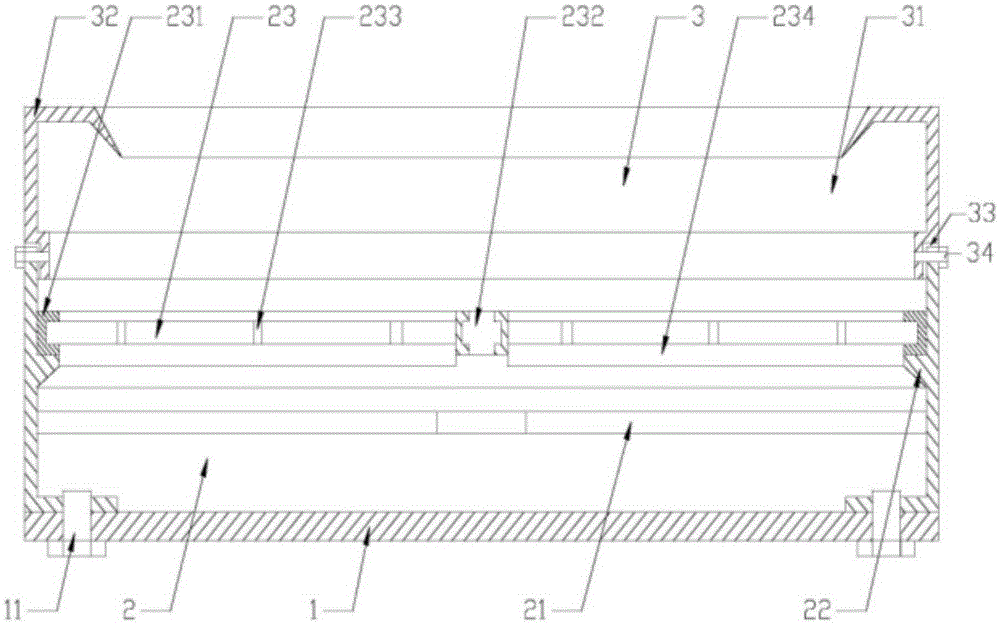

One-time forming device for corrosion preventing of interior of steel pipeline

InactiveCN105618336ASolve a series of problems of anti-corrosionExtended service lifeLiquid surface applicatorsCorrosion preventionSocial benefitsEngineering

The invention discloses a one-time forming device for corrosion preventing of the interior of a steel pipeline. The one-time forming device comprises a coating mechanism and a traction mechanism. The coating mechanism comprises a charging pipe, a coating and extruding ball and a painting limiting ball, and the coating and extruding ball and the painting limiting ball are arranged in the charging pipe and connected. A charging cavity is formed between the coating and extruding ball and the painting limiting ball. The charging pipe is connected to one end of a coated pipeline and is consistent to the coated pipeline in inner diameter. The traction mechanism penetrates the other port of the coated pipeline through a traction rope till the traction mechanism is connected with the painting limiting ball. The coating mechanism further comprises an even coating device arranged in the charging pipe, and the even coating device is a rotating brushwork device connected to the coating and extruding ball. The one-time forming device is short in construction period, the technology is easy to achieve, cost is low, and the defects that according to an original corrosion preventing technology, repaired mouths are excessive, and the overall corrosion preventing effect of the pipeline is hard to guarantee are avoided. The service life of the pipeline is prolonged, the construction efficiency is improved, and economic and social benefits are obvious.

Owner:CHINA PETROLEUM & CHEM CORP +1

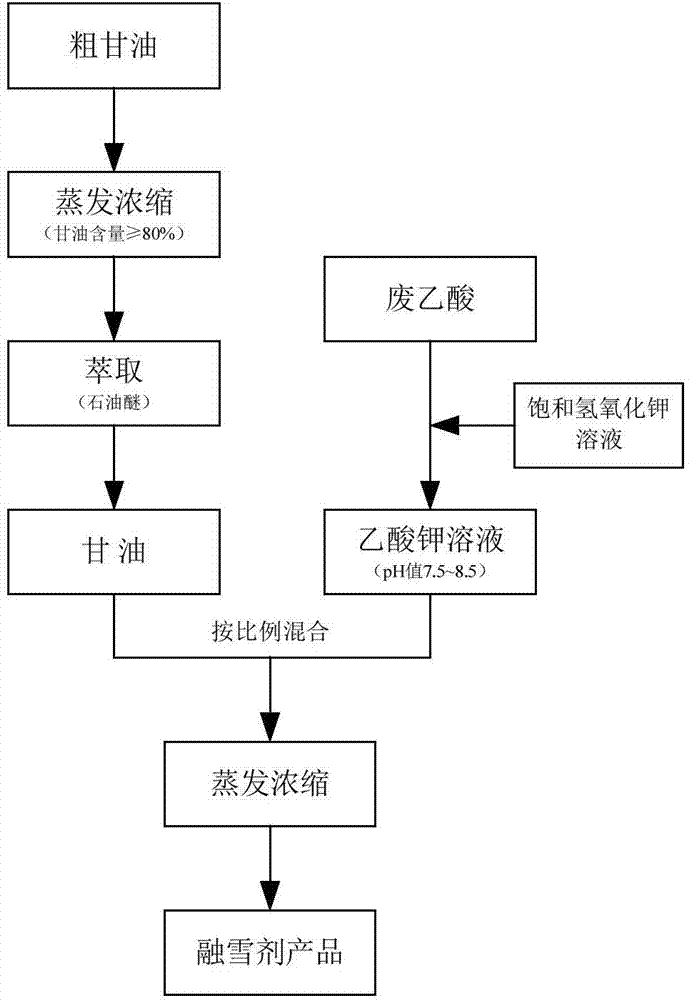

Method for preparing environment-friendly snow-melting agent by using byproduct crude glycerol and waste acetic acid

InactiveCN104762063AImproved snow melting and deicing performanceIncrease viscosityOther chemical processesAcetic acidGlycerol

The invention discloses a method for preparing an environment-friendly snow-melting agent by using a byproduct crude glycerol and waste acetic acid. The preparation process comprises the following steps: (1) pretreating the crude glycerol; (2) preparing acetate; (3) preparing a snow-melting agent; and (4) concentrating the product. According to the method disclosed by the invention, an industrial byproduct and a waste are used as raw materials to prepare the environment-friendly snow-melting agent which is good in snow-melting and deicing performances, easy to use, and easy to degrade biologically, so that wastes are changed into valuable, and a good resource is provided for the development of the snow-melting agent.

Owner:淮南新能源研究中心

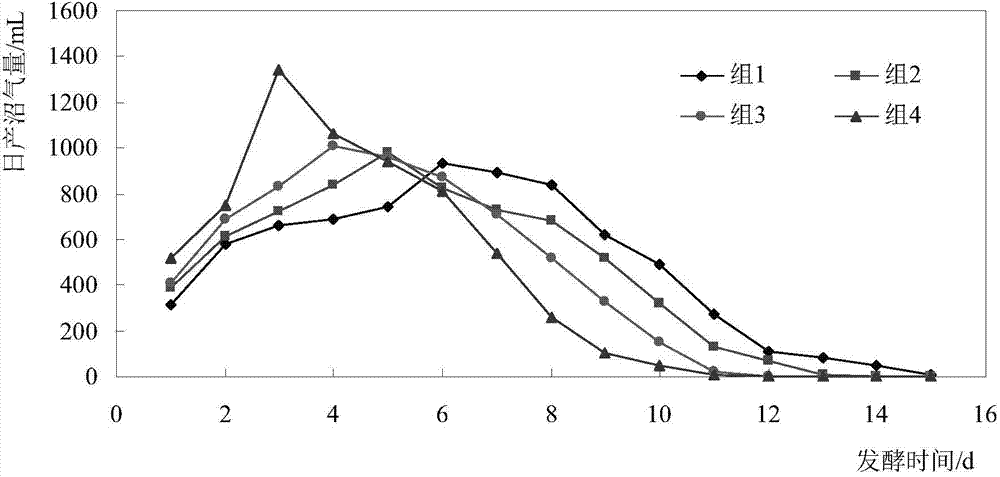

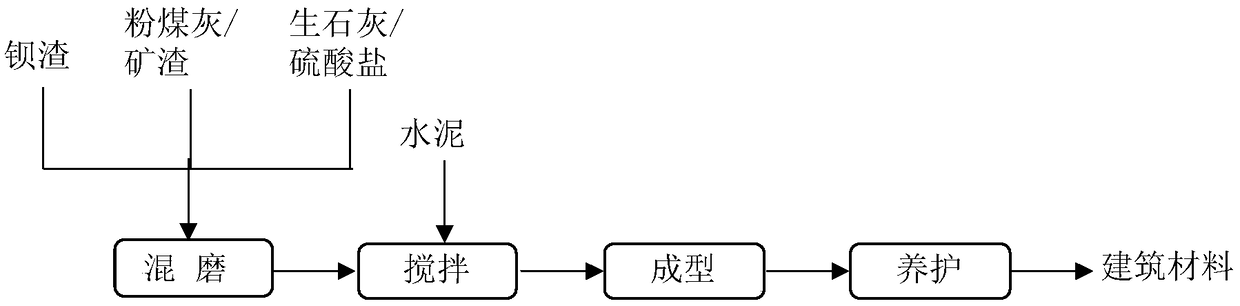

Barium slag construction material and preparation method thereof

The invention provides a barium slag construction material. The barium slag construction material is prepared from, in parts by weight: 30-65% of barium slag, 4-20% of coal ash, 4-25% of mineral wasteresidue, 8-20% of quick lime, 2-5% of calcium sulfate, 0.2-1% of sulfate, 5-15% of cement and 0.2-1.5% of water reducing agent. Barium slag, coal ash, mineral waste residue, quick lime, calcium sulfate and sulfate are subjected to mixing grinding after being blended, the mixture obtained after mixing grinding is sufficiently mixed with water, the water reducing agent and cement to be uniform, slurry is obtained, then slurry is poured into a mold, the mold is sufficiently vibrated and formed, then demolding is conducted after maintenance is conducted for 6-24 hours, and the barium slag construction material is obtained through natural non-steam curing after demolding is completed. The barium slag utilization rate is high, the cost is low, the technology is simple, the construction materialand the preparation method provided by the invention solve the difficult problems that the strength of barium slag is low and the safety is poor when barium slag serves as the construction material,and meanwhile solves the problems that the storage volume of existing barium slag is large, the environment is polluted, the cost is high in the recycling process, and the environmental safety is notsufficiently considered.

Owner:DONGGUAN UNIV OF TECH +1

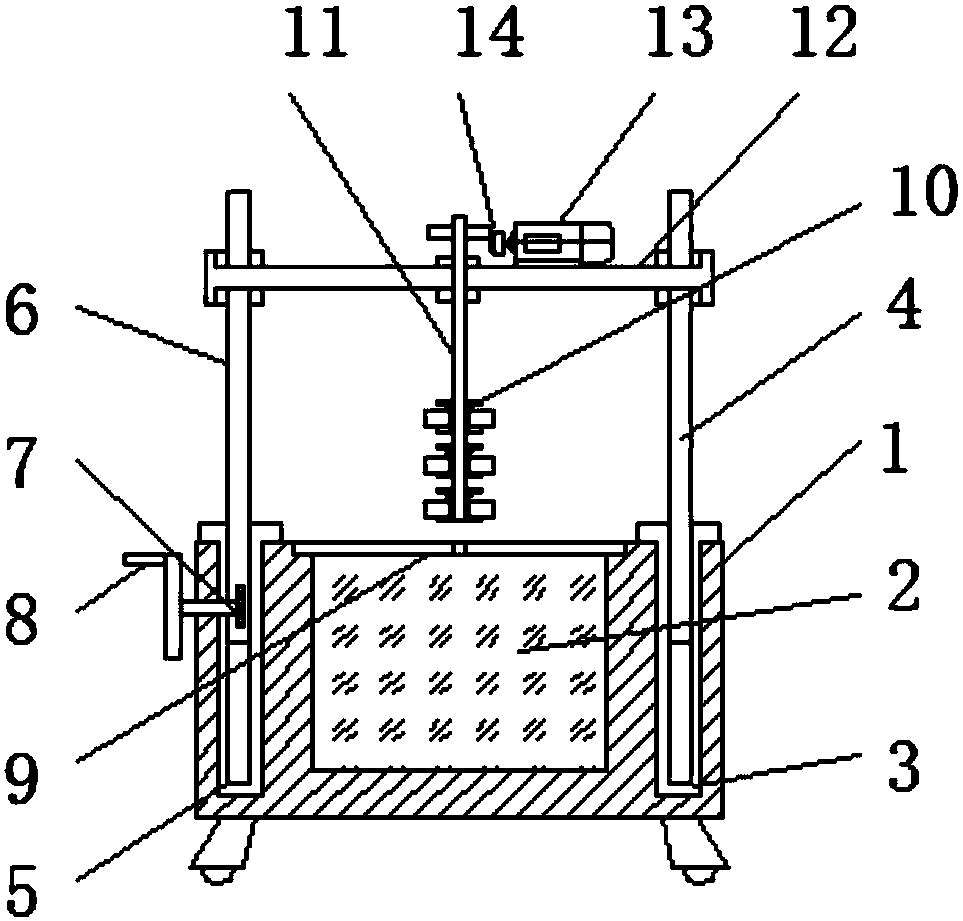

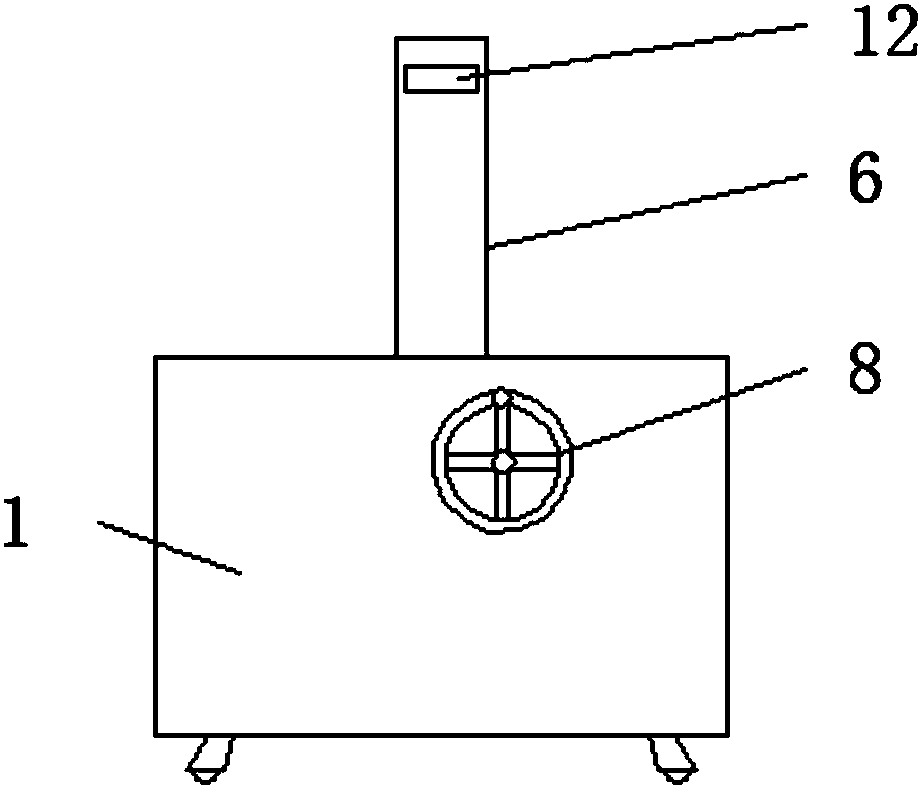

Gear grinding and polishing device

InactiveCN109015324AImprove efficiencySmall footprintEdge grinding machinesPolishing machinesAgricultural engineeringMechanical equipment

The invention discloses a gear grinding and polishing device. The gear grinding and polishing device comprises a frame and a hand wheel. A sand barrel is arranged in the middle of the frame. A first height adjusting hole is formed in the left side of the sand barrel. A second height adjusting hole is formed in the left side of the frame. A second height adjusting rod is embedded in the middle of the second height adjusting hole. The upper part of the first height adjusting rod and the upper part of the second height adjusting rod are connected by a fixing frame. A motor is fixed on the upper right side of the fixing frame. A rotating shaft is embedded in the middle of the fixing frame. Gear fixing clamps are arranged at the lower end of the rotating shaft. According to the gear grinding and polishing device, the sand barrel is arranged, a gear to be polished is put into carborundum and polished, and the surface of the gear is coated with the carborundum, so that the grinding of the gear is more uniform; and the grinding and polishing are carried out together, so that the complicated process of polishing by using a grinding machine first and then a polishing machine in a traditionaltechnology is avoided, the occupied area of mechanical equipment is reduced, and the cost of purchasing machines is saved.

Owner:TIANJIN HAOYAN TECH DEV

Method using weak magnetic iron ore for producing fine iron powder and cement

InactiveCN101603121AEfficient enrichmentReduce moisture contentMagnetic separationIronstoneCalcination

The invention relates to a method using weak magnetic iron ore for producing fine iron powder and cement. The technical scheme thereof is as follows: firstly, 55 to 88 percent of weak magnetic iron ore, 10 to 25 percent of reducing agent and 10 to 20 percent of fusing agent by weight are mixed; secondly, the mixture is agglomerated and then is calcinated, the calcination temperature ranges from 1250 to 1450 DEG C, the calcination time ranges from 0.5 to 2.5 hours, and the calcinated mixture is sealed and cooled to room temperature; thirdly, the calcinated material is crushed and then is drily ground to be less than 25 micrometers; and finally, a micro powder dry magnetic separator is used for dry magnetic separation so as to obtain fine iron powder and cement clinker. The weak magnetic iron ore includes the following chemical components by weight: 20 to 55 percent of TFe, no more than 5 percent of FeO, 0.1 to 5.5 percent of P, 10 to 40 percent of SiO2, 1 to 15 percent of Al2O3, 0.5 to 15 percent of CaO and 0.1 to 10 percent of MgO. The TFe grade of the fine iron powder produced by the invention is higher than 70 percent, and the metal recovery rate is higher than 85 percent; therefore, the invention has the advantages of simple process, high concentrate grade, and high recovery ratio of metallic iron, besides, weak magnetic tailings can be used as cement clinker.

Owner:WUHAN UNIV OF SCI & TECH

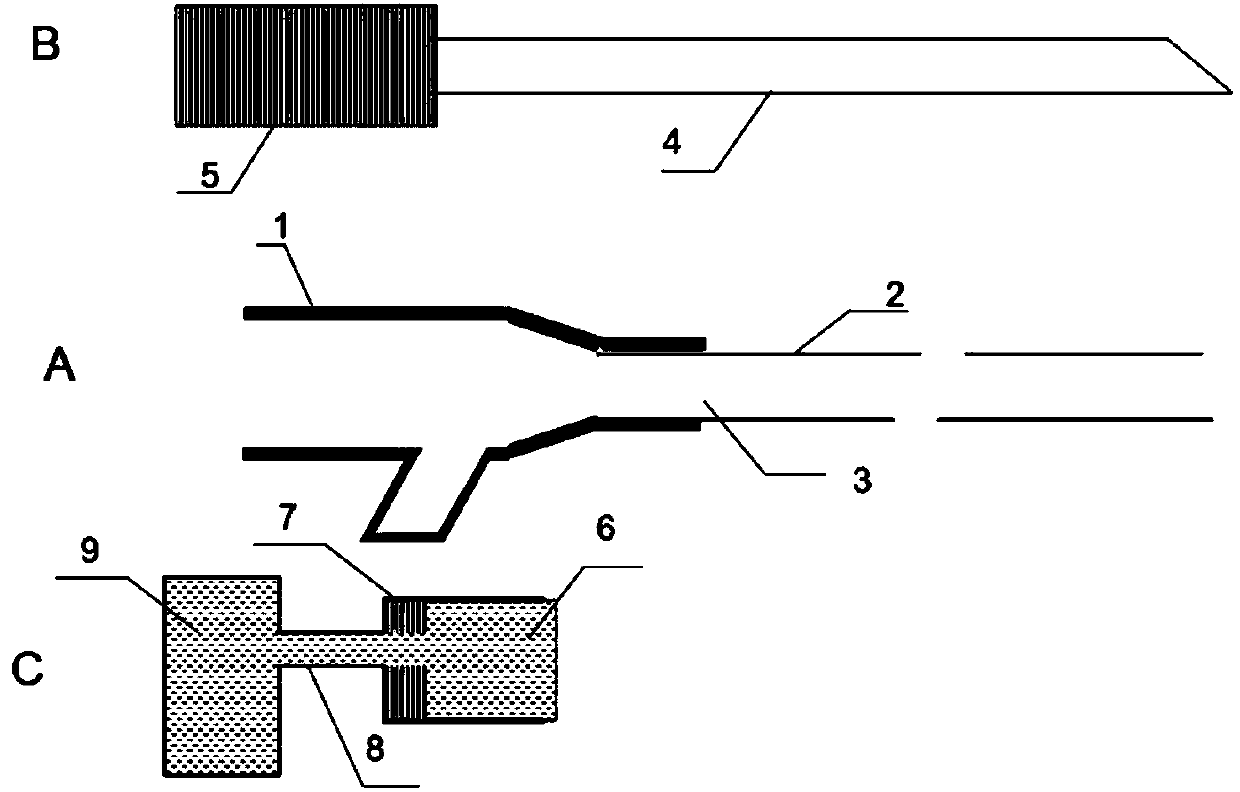

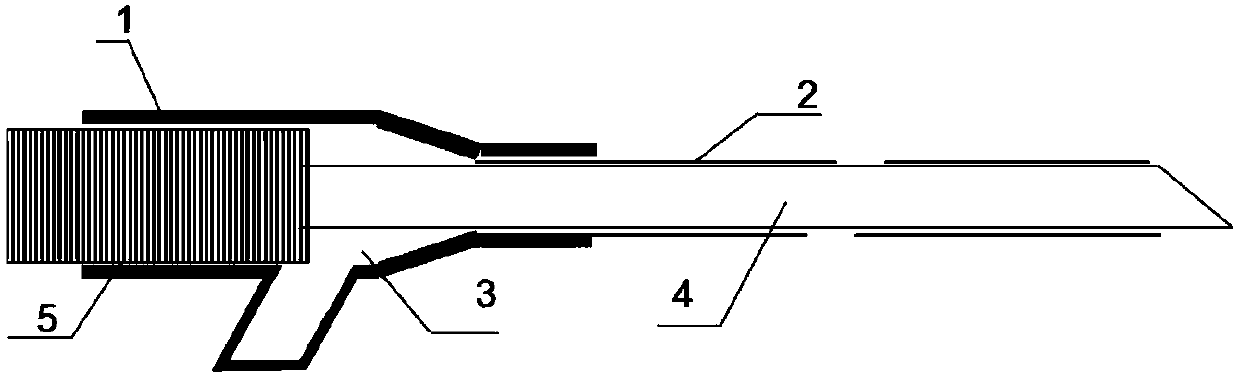

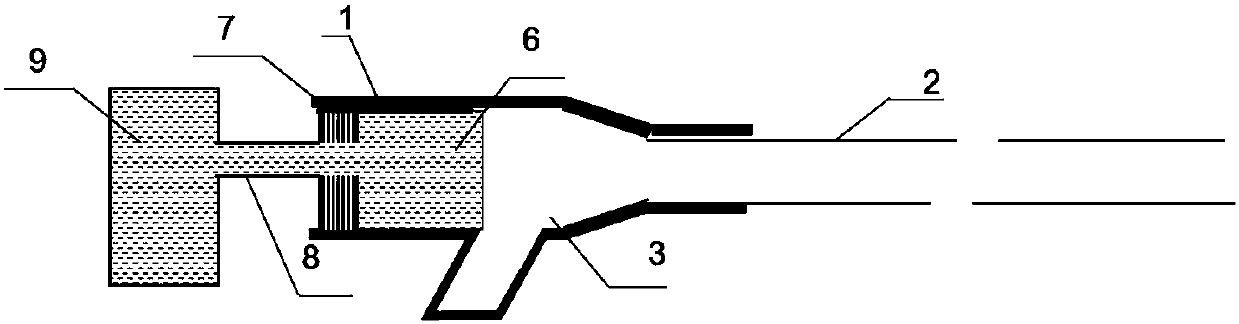

Positive-pressure liquid bag self-sealing type intravascular indwelling needle

PendingCN107890595AEasy to operateEasy to masterInfusion needlesOther medical devicesThrombusNursing care

The invention provides a positive-pressure liquid bag self-sealing type intravascular indwelling needle. The positive-pressure liquid bag self-sealing type intravascular indwelling needle is mainly composed of a main body part A, a part I B and a part II C. For the positive-pressure liquid bag self-sealing type intravascular indwelling needle, the operation is extremely simple, a working medium liquid bag seals an infusion channel and provides continuous positive pressure, and the effects in sealing a tube, preventing backflow and resisting thrombus are reliable; the operation is easy to master when the indwelling needle is placed through puncture, during the nursing operation, the operations of pumping liquid medicine and preparing tube sealing liquid are not needed, the operation can becompleted through one movement of one hand, a disposable syringe and a flusher do not need to be consumed, thus the step of the nursing operation is saved, and the nursing efficiency and quality are improved.

Owner:西藏多欣健康科技有限公司

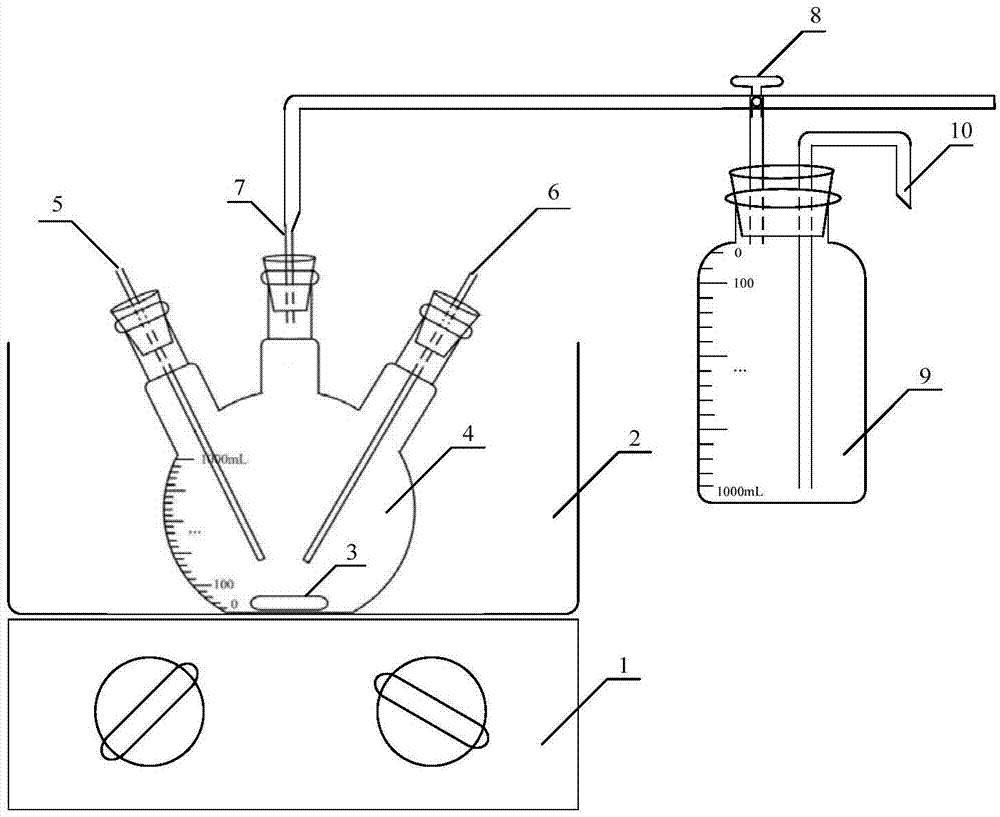

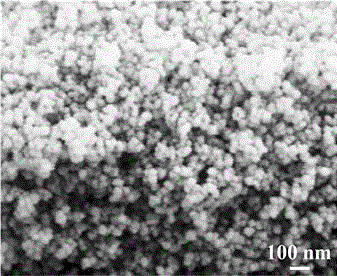

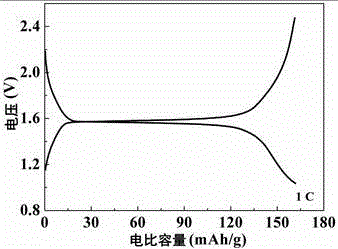

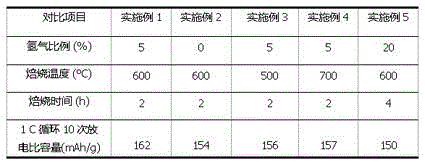

Preparation method of hydrogenated lithium titanate nano-material

InactiveCN103332735AMild responseUniform responseMaterial nanotechnologyCell electrodesAqueous solubilityCapacitor

The invention discloses a preparation method of a hydrogenated lithium titanate nano-material. The method comprises the specific steps of: adding titanium dioxide into an aqueous solution of a water-soluble lithium salt, uniformly stirring, then placing the mixture in an enclosed environment and insulating; stopping heating, cooling, conducting pumping the mixture, conducting filtration and washing, and drying to obtain a lithium titanate precursor powder; and calcining the precursor powder in a mixed atmosphere of hydrogen and protection gas to obtain hydrogenated lithium titanate nanometer particles. The hydrogenated lithium titanate nanometer powder electrode material prepared by the method of the invention can be used as a cathode material for preparation of a super capacitor or a lithium battery.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Bush bulging shell type self-drilling hollow anchor rod

InactiveCN100497887CPlay the role of mechanical advanced anchoringPermanent supportAnchoring boltsCement slurryRock bolt

The invention relates to a casing pipe rising shell type self-drilling hollow anchor bar, belonging to project supporting field, which comprises a one-off drill bit, a steel plug, a rising shell, a casing pipe, a hollow bar body, a tray and a nut. The one-off drill bit is connected at the most front end of the hollow bar body, the life design is to drill a hole; the steel plug is scyewed joint and welded together with the hollow bar body, the lower end of the steel plug is in turn hollow housed the rising shell and the casing pipe; four slots are opened on the upper of the rising shell, and tilted teeth are machined in outside; the casing pipe is held on the lower end of the tray and is fixed by the nut. The invention is applied to the supporting of coal mine back, at first the quick load-bearing requirement is reached by mechanical rising shell ahead anchoring, then the whole length anchoring is realized by injecting sand-cement slurry. The invention has convenient drilling and mounting in the construction and changes construction process of the traditional anchor bar, and realizes integration of the drilling and anchoring of the coal drift supporting and is help to safe and quick supporting of the coal drift.

Owner:郑晓雯 +2

Sealed type automobile anti-fog instrument

InactiveCN105329103AEliminate the temperature difference inside and outside the instrumentAvoid cumbersome workmanshipVehicle componentsWall plateEngineering

The invention relates to a sealed type automobile anti-fog instrument. The sealed type automobile anti-fog instrument comprises a bottom plate, a shell body and an upper cover plate, wherein the bottom plate is fixedly connected with the shell body through a first bolt; the shell body comprises a heat conducting net, a graduated disc, an annular lug boss, a sealing ring, an oil sealing ring, a plurality of through holes and a drying cabin; the graduated disc and the sealing ring are mutually clamped; the heat conducting net comprises an annular wall plate, a supporting pillar arranged in the middle of the annular wall plate, a metal net arranged on the supporting pillar and a through hole through which a pointer rotary shaft passes; the upper cover plate comprises a glass panel and a metal ring for fixing the glass panel; the lower end of the upper cover plate and the upper end of the shell body are mutually connected through a second bolt. The sealed type automobile anti-fog instrument provided by the invention has a reasonable structure and has the advantages of high structure strength, good waterproof performance and rapid heat transferring speed; the problem of fogging of an automobile cab instrument is effectively solved.

Owner:CHONGQING DACHENG GRACE NC TECH CO LTD

Preparation method of methylated melamine-formaldehyde resin

The invention discloses a preparation method of methylated melamine-formaldehyde resin , relates to the technical field of fine chemical engineering, and in particular relates to a preparation method of methylated melamine-formaldehyde resin. The method comprises the steps of 1, adding formaldehyde, melamine and caustic soda liquid into a pipeline, heating to 60-70 DEG C, and carrying out heat preservation reaction for 10-12 minutes, wherein the molar ratio of the formaldehyde to the melamine is (6.9-7.1): 1; 2, adjusting the pH value to 3-4, and carrying out a heat preservation reaction for 5-7 min, wherein the molar ratio of melamine to methanol is 1: (15-17), and carrying out negative pressure distillation at 65-70 DEG C; and 3, adjusting the pH value to 3-4, and carrying out a heat preservation reaction for 4-6 min, wherein the molar ratio of melamine to methanol is 1: (5-7), and then carrying out negative pressure distillation to 115-120 DEG C, and filtering to obtain the methylated melamine-formaldehyde resin. The method disclosed by the invention has the positive effects of avoiding the problem of quality difference of products among batches, and being easy to operate, good in product stability and high in yield.

Owner:SHANDONG YANGGU HUATAI CHEM

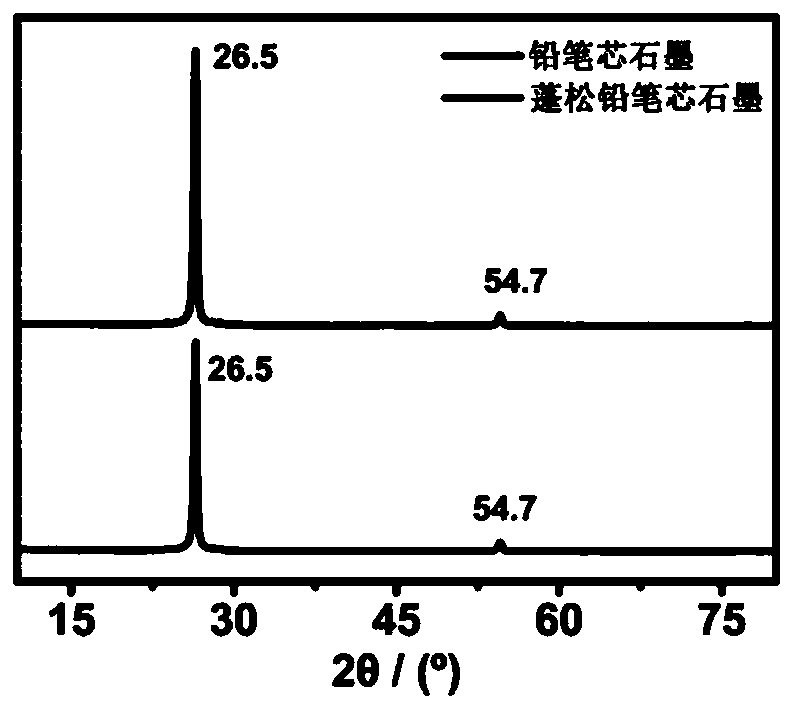

Preparation method and application of dual function expanded graphite/nanogold composite electrode

ActiveCN109765209AImprove electrocatalytic performanceImprove featuresMaterial nanotechnologyMaterial analysis by electric/magnetic meansBinding siteMaterials science

The invention belongs to the technical field of nanogold sensors, in particular to a preparation method and application of a dual function expanded lead refill graphite / nanogold composite electrode. Amild voltage is applied to graphite, so that the edge of the graphite is expanded without stripping to obtain a netlike puffy graphite structure; and then metal nanoparticles are electrically deposited in situ to obtain a composite electrode. A puffed graphene like structure can provide a large specific surface area and a large quantity of binding sites; and the high electrocatalytic capability and plasma characteristic of the gold nanoparticles show excellent performance on the aspects of glucose catalyzation and SERS (Surface Enhanced Raman Scattering) application. The prepared composite electrode solves the problems of poor response stability, low sensitivity and poor reproducibility caused by offline synthesis and later material fixing. The composite electrode has a relatively wide linear range, relatively low detection limit and high reproducibility specific to glucose catalyzation, and has very high SERS response, high sensitivity and high stability specific to probe molecules.

Owner:ZHEJIANG NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com