Bush bulging shell type self-drilling hollow anchor rod

A self-drilling, hollow technology, which is applied in the direction of installing bolts, earth drilling, mining equipment, etc., can solve the problems that the anchoring position of the end of the bolt cannot be determined, the anchoring effect cannot be achieved, and the bolt cannot be used, etc., to achieve Solve the problem of non-criticism of coal cutting and bolt support, prolong the time of coal cutting, and prevent the effect of rapid layer separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

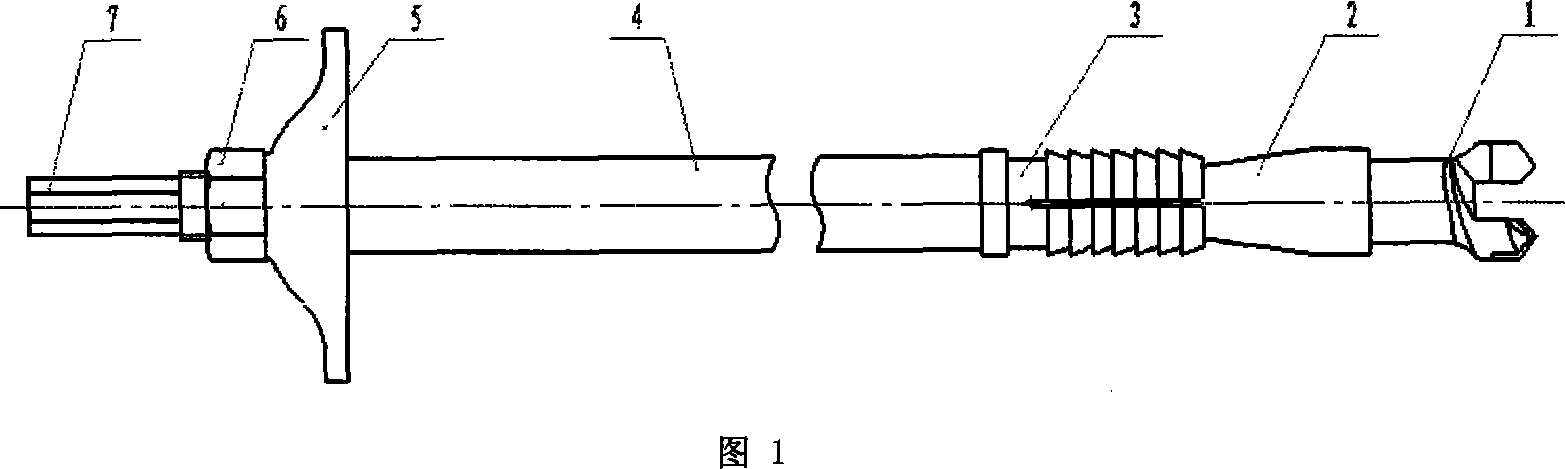

[0030] 1 is a schematic diagram of the structure of the self-drilling anchor of the present invention. The anchor of the present invention is composed of a disposable drill 1, a steel plug 2, an expansion shell 3, a casing 4, a tray 5, a nut 6 and a hollow rod 7. Disposable drill bit 1 is threadedly connected to the front end of hollow rod body 7, steel plug 2 is also connected to hollow rod body 7 through threads, and welded at the same time; expansion shell 3 and casing 4 are empty sleeved on hollow rod body 7, and the lower end of casing 4 is formed by The tray 5 is empty-sleeved on the hollow rod body 7 to support the casing 4, and the bottom end is axially fixed by the nut 6.

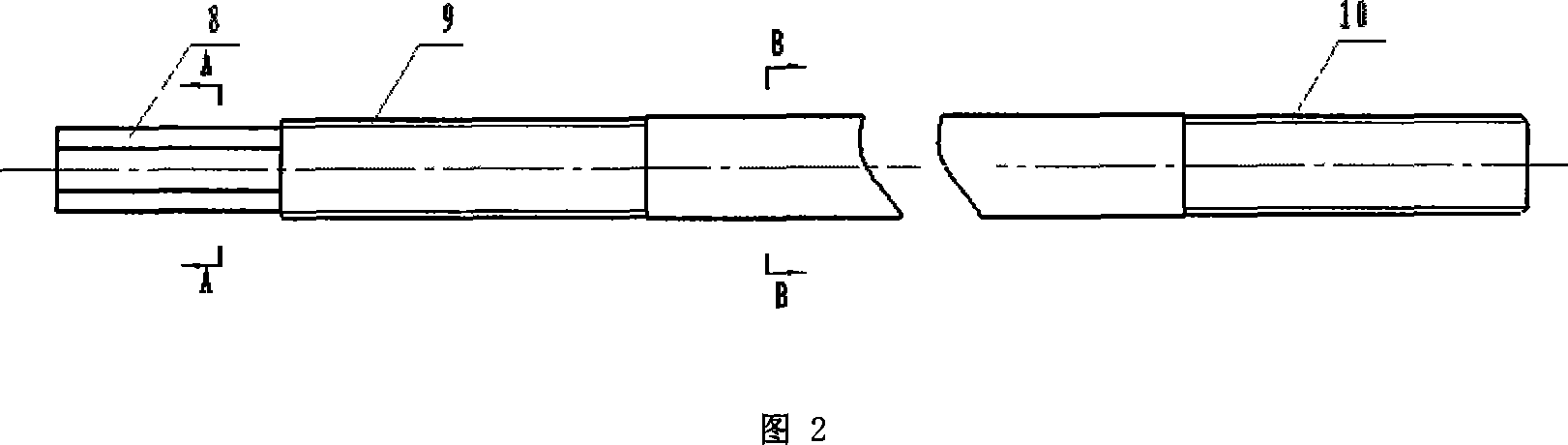

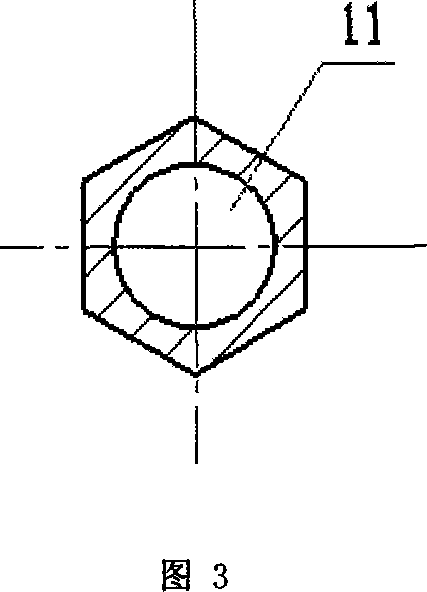

[0031] Figure 2 is the front view of the hollow rod body 7, the connecting part of the rod body and the rock bolt rig is designed as a hexagonal outer surface 8, this design shape can make the anchor rod and the drilling machine directly combined to improve the drilling efficiency; the connecting pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com