Fully mechanized excavation face automatic anchor protection, slide rail type stepping temporary support bracket

A technology of temporary support and fully mechanized excavation surface, which is applied in the direction of mine roof support, mining equipment, earthwork drilling, etc. to achieve the effect of improving stability, reducing repeated support and improving space safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

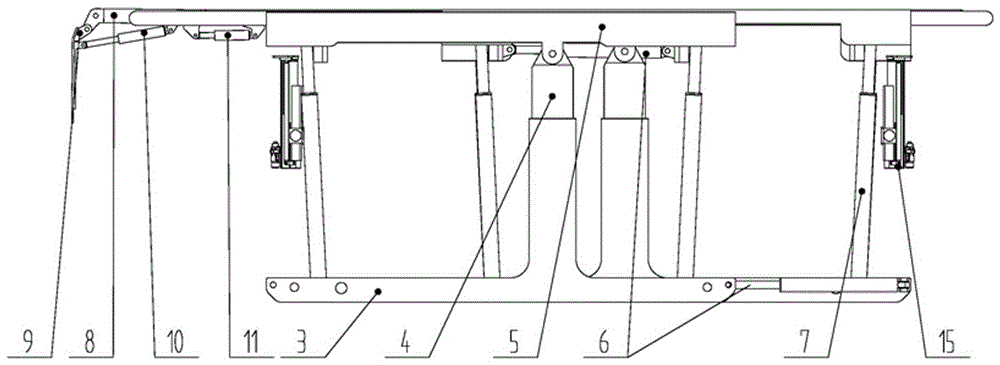

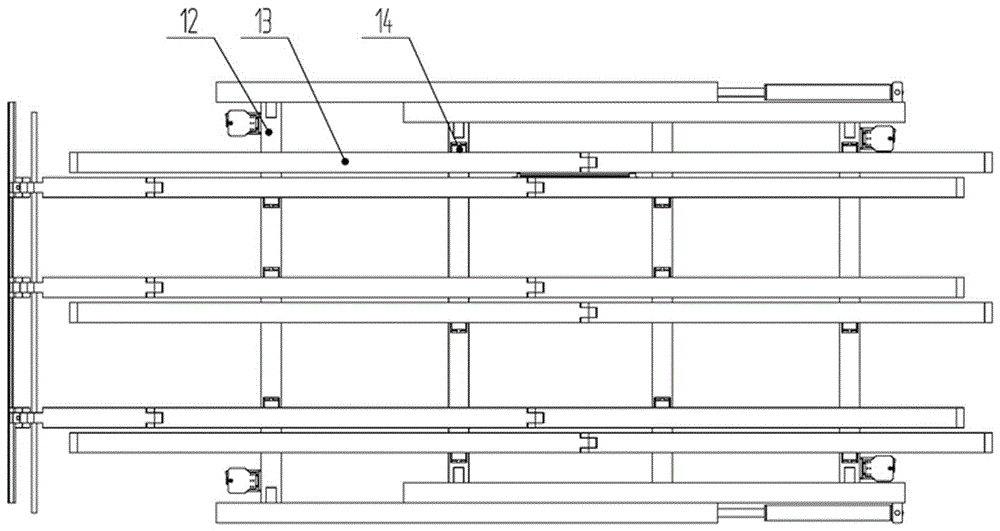

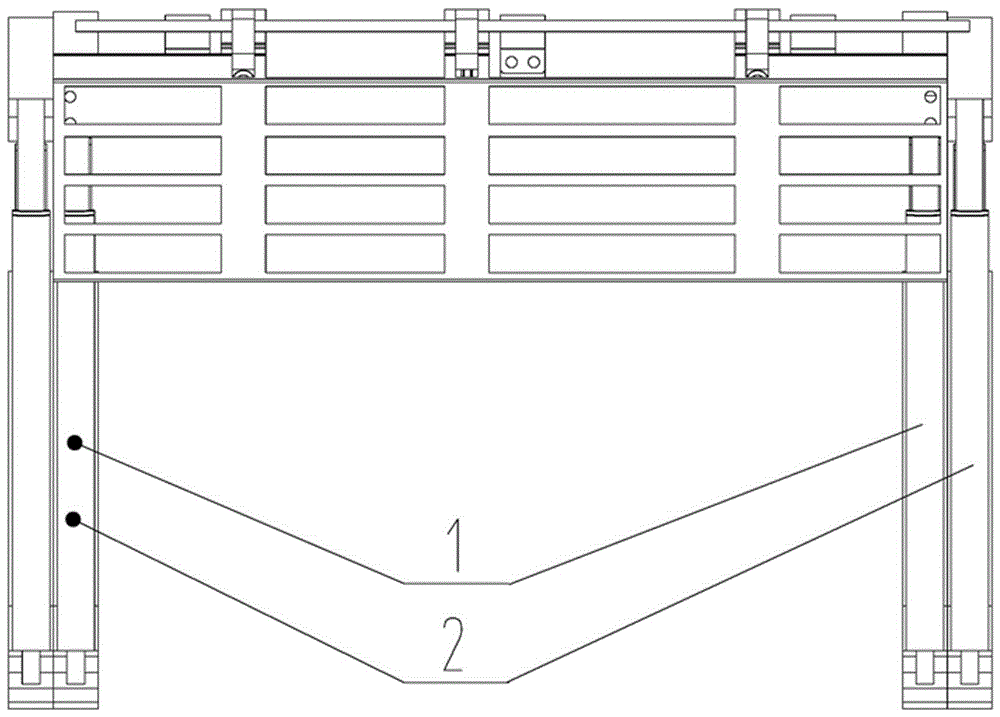

[0030] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0031] The automatic anchoring and protection of the fully mechanized excavation surface, the sliding rail type stepping temporary support bracket and the roadheader are reasonably matched, which can realize the full section support in time, simplify the support procedure, and realize the simultaneous continuous operation of excavation, temporary support and permanent anchoring The method prevents operators from working in the empty roof area, improves the degree of mechanized support operations, reduces the labor intensity of operators, improves the tunneling efficiency, and provides a strong guarantee for the safety of operators. Fully-mechanized excavation surface automatic anchor protection, slide rail type stepping temporary support bracket, mainly composed of two sets of brackets inside and outside, the two sets of brackets are respectively co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com