Stepping type tunneling support device suitable for tunneling in hard rock

A supporting device, stepping technology, applied in the field of stepping tunneling support device, can solve problems such as poor safety of roadheader, difficulty in backing operation, narrow application range, etc., to reduce strength, avoid insufficient forward force, and avoid equipment loss big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

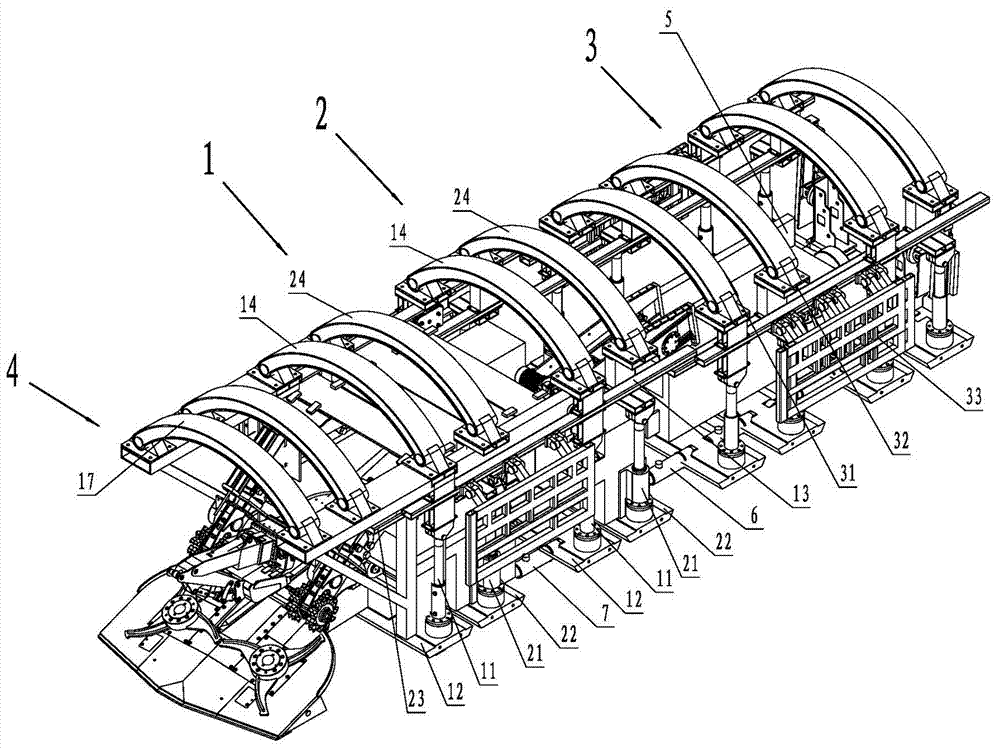

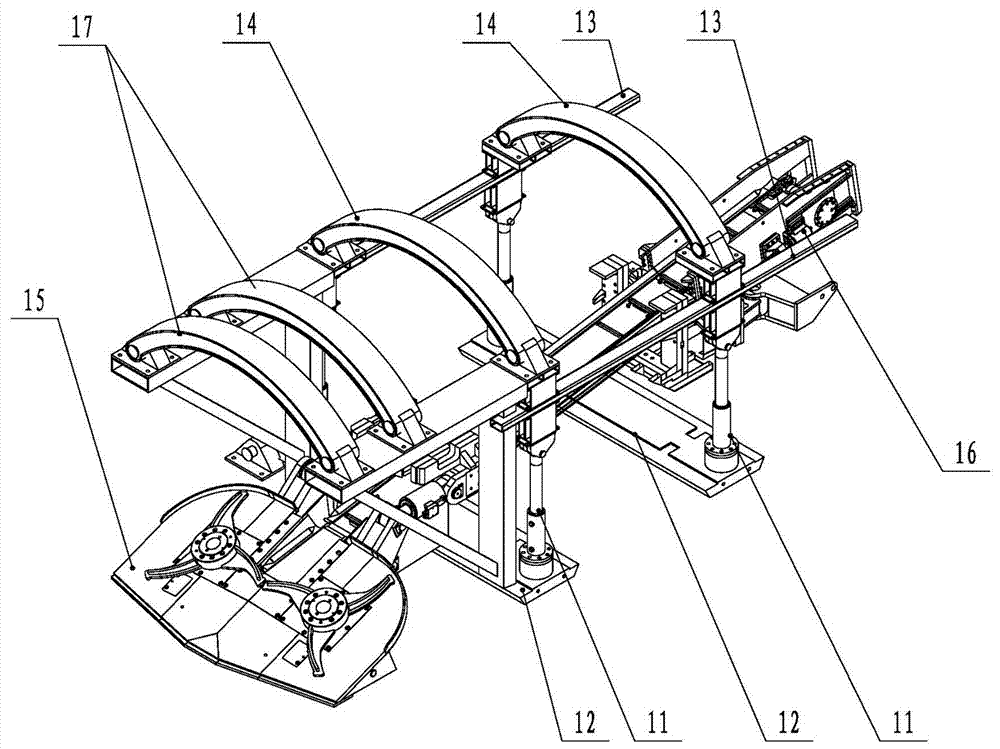

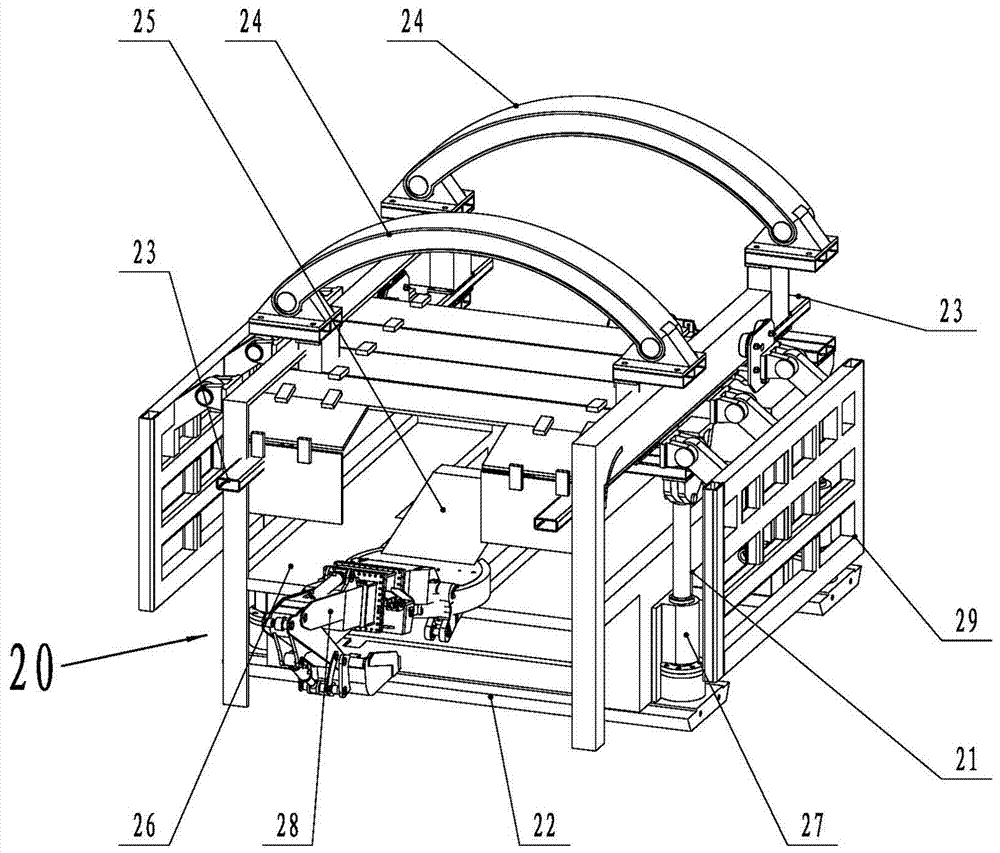

[0034] The following combination Figure 1~7 , the content of the present invention will be described in detail through specific embodiments. The walking-type excavation support device suitable for tunneling in hard rock includes a tail unit 3, a main unit, a cutting unit 4, a shutter assembly and a conveying device. Among them, the main unit includes the main support group 2 of the main unit and the auxiliary support group 1 of the main unit, which are arranged staggered from back to front:

[0035] The main support group of the main unit includes two horizontally arranged connecting plates I22 at the front and rear, two pairs of vertically supporting oil cylinders I21 respectively fixed on the two connecting plates I at the front and rear, and a pair of vertically arranged between the two supporting oil cylinders I at the front and rear. The longitudinal beam I 23 between the longitudinal beams 1, a pair of top beams I 24 respectively located on the support cylinder 1 spann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com