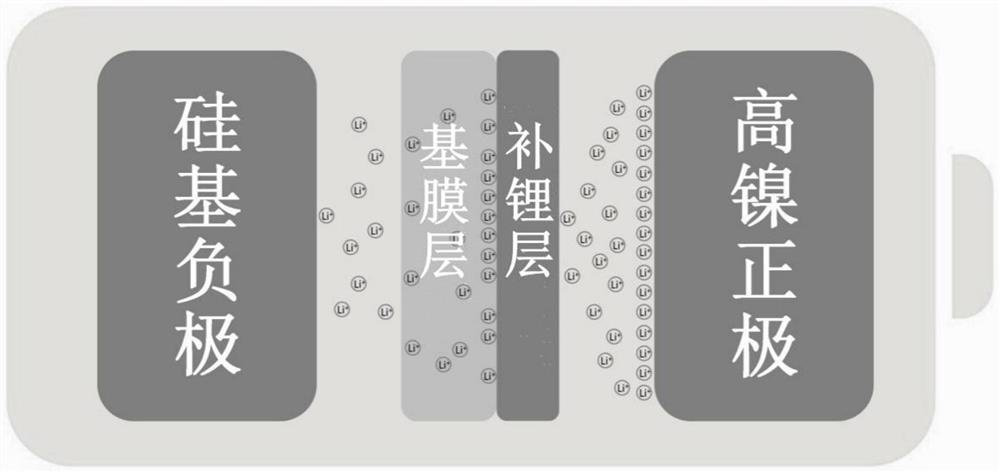

Functionalized lithium supplementing diaphragm and preparation method thereof

A functional and lithium-supplementing technology, applied in the field of lithium-ion batteries, can solve problems such as cumbersome process, unfavorable commercialization, and operator safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

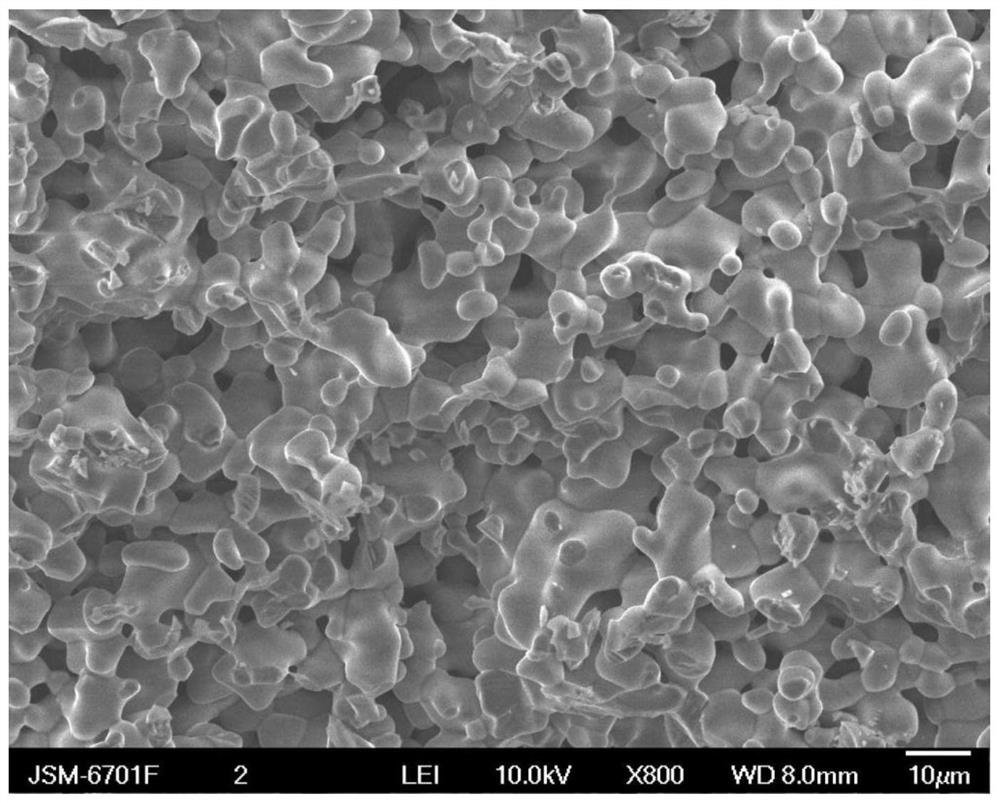

[0049] 1) 40 parts of Li with an average particle size of 200nm 5 FeO 4 , 45 parts of polypropylene with a melting point of 3.1g / 10min, 15 parts of toughening agent EVA in a high-speed mixer at a speed of 600r / min, and stirred for 40min to pre-mix until uniform;

[0050] 2) Add the mixture obtained in step 1) and polypropylene with a melt index of 3.1g / 10min to the extruder A and extruder B of the double-layer co-extrusion diaphragm device at the same time, and carry out melt co-extrusion, wherein, the first The extrusion temperature of one extruder is 170-220°C, the extrusion temperature of the second extruder is 160-210°C, and the final double-layer co-extruded film is cooled by a cooling roller with a temperature of 25°C to obtain a thickness of 30μm composite membrane substrate;

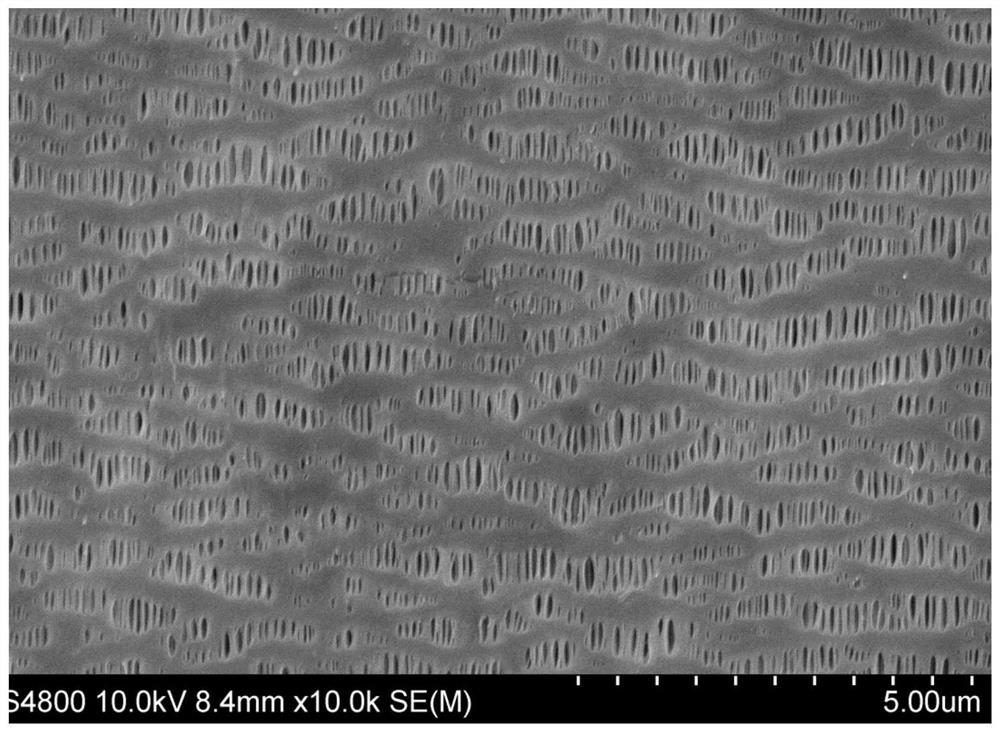

[0051] 3) The composite film substrate obtained in step 2) is uniaxially stretched at a temperature of 20°C, a stretch ratio of 2, and a stretching speed of 0.08m / min, until the cold-drawn film...

preparation example 2

[0055] The rest are the same as Preparation Example 1, except that the amount of Li5FeO4 in step 1) is 20 parts.

preparation example 3

[0057] The rest are the same as Preparation Example 1, except that the amount of Li5FeO4 in step 1) is 60 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com