Self-sealing type venous indwelling needle and production method thereof

A technology for intravenous indwelling needles and production methods, which is applied to needles and devices introduced into the body, and can solve problems such as blood coagulation blockage and uncertain effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

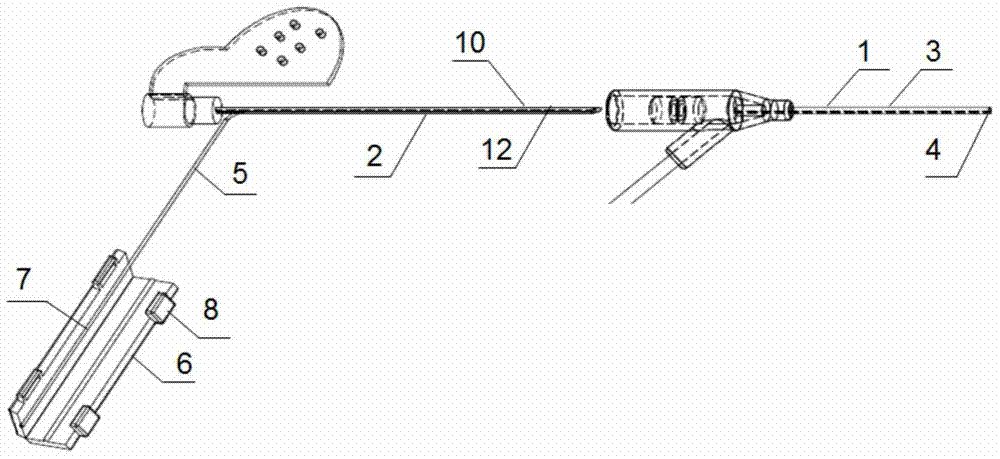

[0085] Embodiment 1: self-sealing venous indwelling needle of the present invention

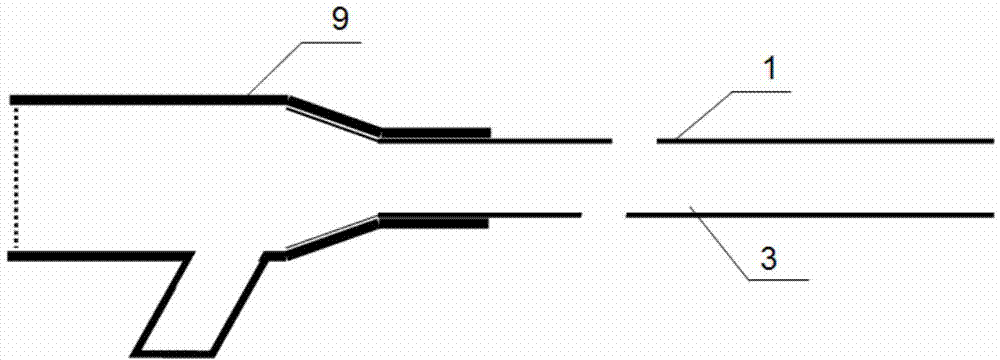

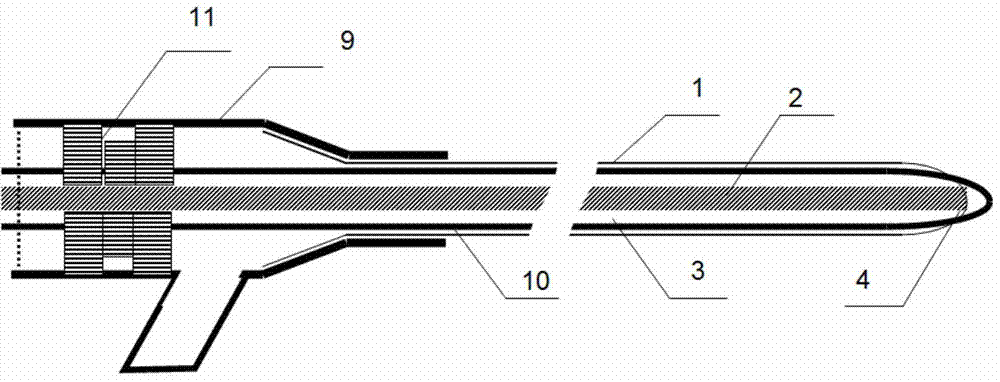

[0086] The self-sealing venous indwelling needle of the present invention is composed of an indwelling catheter 1, a working liquid sac tube 2, an infusion lumen 3, a needle point groove 4, a flexible connecting tube 5, a pressurizing block 6, a pressure-resistant liquid sac 7, a lock 8, and a needle seat 9. Composition of steel needle core 10 and steel core isolation plug 11;

[0087] Wherein, an indwelling catheter 1 is installed at the end of the needle holder 9, and the indwelling catheter is an infusion tube lumen 3, and a steel core isolation plug 11 is arranged in the needle holder 9, and the steel core isolation plug 11 provides the access needle for the working fluid sac tube 2. The channel and seal of the seat 9, and the steel core isolation plug 11 will seal the inner cavity of the needle seat 9 on the side close to the needle tip with the outside world;

[0088] The steel needle ...

Embodiment 2

[0092] Embodiment 2: Self-sealing venous indwelling needle of the present invention

[0093] This embodiment is the same as that of Example 1, except that distilled water is used as the working fluid, the cuboid pressure-resistant liquid bag 7 and the V-shaped groove 12 of the steel needle core 10, the indwelling catheter 1 is provided with an end hole and is 1.0 away from its end. mm side holes, the hole diameter of these holes is 0.1mm.

[0094] Use the self-sealing venous indwelling of this embodiment to perform indwelling needle infusion and lock tube for patients with "intracranial hypertension, high blood pressure, heart failure, kidney disease". Such patients limit saline input, and routine flushing and lock tube will be infused Extra sodium salt and fluid enter the body, and patients who use the catheter lock of the present invention avoid inputting too much salt and water. The operation of the present invention is extremely simple, and the sealing of the tube is comp...

Embodiment 3

[0095] Embodiment 3: Self-sealing venous indwelling needle of the present invention

[0096] This embodiment is the same as that of Example 1, except that normal saline is used as the working fluid, the oval pressure-resistant liquid bag 7 and the rectangular groove 12 of the steel needle core 10, the indwelling catheter 1 is provided with an end hole and is 3.0 away from its end. mm side holes, these holes have a diameter of 1.0mm.

[0097] Use the self-sealing double-lumen tube indwelling vein of this embodiment to perform indwelling needle infusion and seal tube for patients with "long-term infusion" or "difficult venipuncture". Repeated puncture has been denatured, each venipuncture is extremely difficult, and the patient is extremely painful, so each venous infusion channel should be kept unobstructed, and the use of the present invention can prolong the service time of the infusion channel as much as possible. The operation of the present invention is extremely simple, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com