Barium slag construction material and preparation method thereof

A technology of building materials and barium slag, which is applied in the field of barium slag building material preparation, can solve the problems of insufficient environmental safety considerations, large barium slag stockpile, high cost of barium slag, etc., achieve low cost, high utilization rate, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

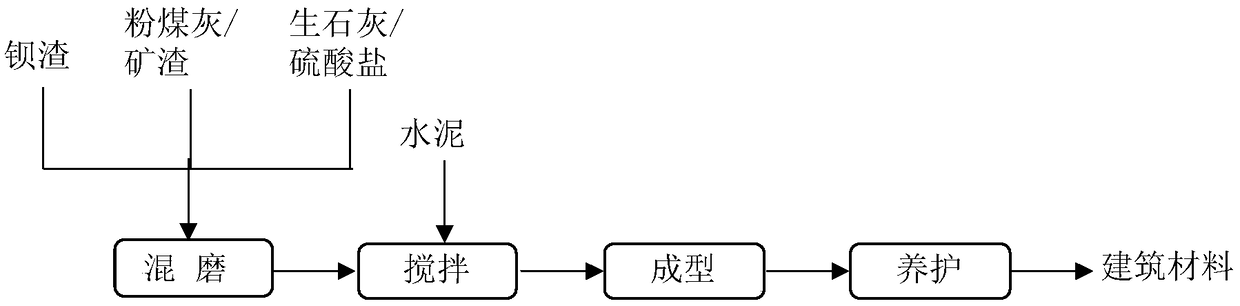

[0043] Such as figure 1 Shown, a kind of preparation method of barium slag building material, the step comprises:

[0044] (1) Stabilization and activation of barium slag: 5000g of barium slag, 800g of fly ash, 1500g of slag, 1500g of quicklime, 200g of calcium sulfate, and 100g of iron sulfate are fully mixed, and placed in a ball mill for 0.5h;

[0045] (2) Fully mix the mixture obtained in step (1) with 900g of cement, add 2000g of water and stir, add 50g of lignosulfonate water reducer, and mix the materials evenly to obtain the barium slag building material slurry;

[0046] (3) Molding: Pour the slurry obtained in step (2) into the mold, fully oscillate for molding, and remove the mold after curing for 12 hours.

[0047] The above formula, after testing, has a 7-day compressive strength of 9.37MPa and a 28-day compressive strength of 20.41MPa, and the leaching toxicity of barium ions is less than 2mg / L.

Embodiment 2

[0049] A preparation method of barium slag building material, the steps comprising:

[0050] (1) Stabilization and activation of barium slag: 3000g of barium slag, 1700g of fly ash, 2500g of slag, 2000g of quicklime, 200g of calcium sulfate, and 100g of aluminum sulfate are fully mixed, and placed in a vertical mill for 1 hour;

[0051] (2) Fully mix the mixture obtained in step (1) with 500g of cement, add 4000g of water and stir, add 100g of polycarboxylate superplasticizer, and mix the materials evenly to obtain the barium slag building material slurry;

[0052] (3) Molding: Pour the slurry obtained in step (2) into the mold, fully oscillate for molding, and remove the mold after curing for 12 hours.

[0053] The above formula, after testing, has a 7-day compressive strength of 4.25 MPa and a 28-day compressive strength of 9.51 MPa, and the leaching toxicity of barium ions is less than 2 mg / L.

Embodiment 3

[0055] A preparation method of barium slag building material, the steps comprising:

[0056] (1) Stabilization of barium slag and activation of activity: After fully mixing 6500g of barium slag, 500g of fly ash, 500g of slag, 2000g of quicklime, 200g of calcium sulfate and 20g of ferrous sulfate, they were placed in a Raymond mill and mixed for 0.2 h;

[0057] (2) Fully mix the mixture obtained in step (1) with 1480g of cement, add 3000g of water and stir, add 100g of polycarboxylate superplasticizer, and mix the materials evenly to obtain the barium slag building material slurry;

[0058] (3) Molding: Pour the slurry obtained in step (2) into the mold, fully oscillate to form, and cure for 6 hours to remove the mold. After demoulding, it is naturally cured without steaming.

[0059] The above formula, after testing, has a 7-day compressive strength of 8.14MPa and a 28-day compressive strength of 18.82MPa, and the leaching toxicity of barium ions is less than 2mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com