Method for preparing environment-friendly snow-melting agent by using byproduct crude glycerol and waste acetic acid

A technology of crude glycerol and waste acetic acid, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of limited large-scale promotion and high cost, and achieve improved snow melting and deicing performance, long action time, and easy biodegradation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

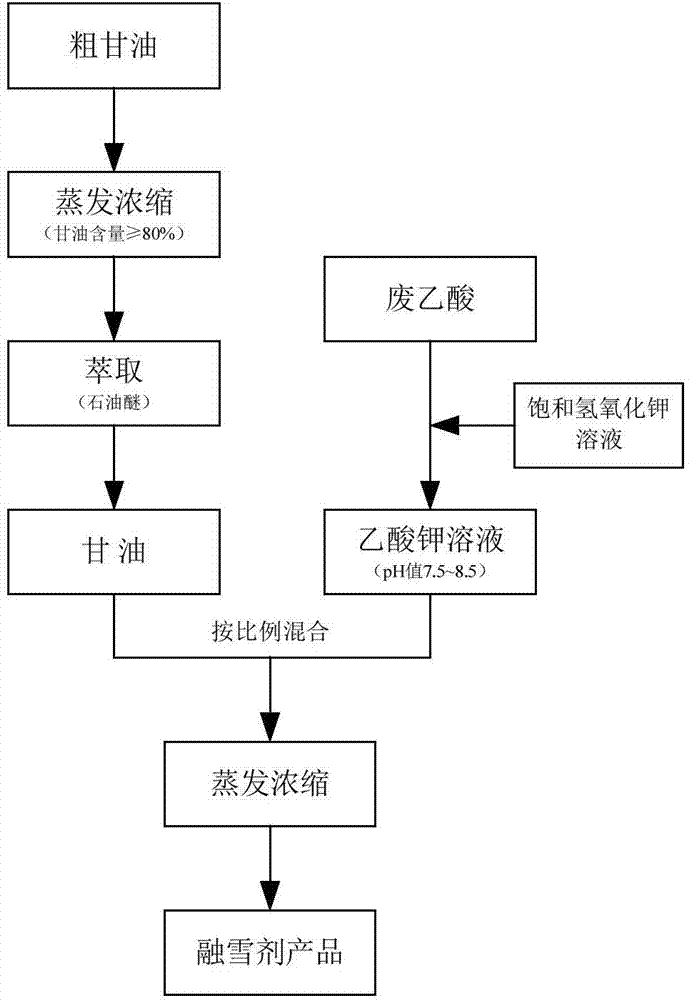

[0030] Embodiment 1: preparation of deicing agent

[0031] The deicing agent was prepared by using crude glycerin and waste acetic acid as raw materials from different sources, and the following two sets of experiments were carried out:

[0032] Test group 1: Take 100g of crude glycerin (about 83% glycerol content) produced by biodiesel, which contains a small amount of potassium hydroxide, which does not affect the performance of the snow-melting agent; first add 50g of ether to it, mix well, let stand for 1h, divide 93g of the glycerol phase of the lower layer is taken after the layer, and its glycerol content is about 90% after measuring, and the ether phase adopts a rotary evaporator at 95°C to reclaim the solvent; get 100g of waste acetic acid (about 82% of the acetic acid content) produced by the fermentation production process of N-acetylneuraminic acid , which contains a small amount of organic matter, which does not affect the performance of the snow-melting agent pro...

Embodiment 2

[0034] Example 2: Detection of freezing point and snow-melting and ice-melting ability of different formula deicing agents

[0035] The deicing agents obtained from the two sets of tests carried out in Example 1 are all configured according to the ratio of glycerin and potassium acetate 4:1 to 1:4, and the preparation raw materials do not contain mercury (Hg), cadmium (Cd), chromium (Cr) , lead (Pb), and arsenic (As), so the resulting deicing agent has the same composition and does not contain the above metal ions. According to the method specified in GB / T 23851-2009 "Road Deicing and Snow Melting Agent", the results of testing the freezing point and snow melting and ice melting ability of different formulas of snow melting agents are shown in Table 1.

[0036] The test results in Table 1 show that the snow-melting and ice-melting ability of the snow-melting agent obtained according to the formula adopted in the invention is significantly higher than the relevant regulations o...

Embodiment 3

[0038] Embodiment 3: The actual use effect of different formula deicing agents

[0039] From January 27th to 29th, 2015, the weather in Hefei City was from moderate snow to heavy snow, and the lowest temperature was -3°C. The snowmelting agent obtained by the present invention was diluted 5 times with water, and evenly sprayed on the snow-falling concrete floor. The result was It shows that there is no snow accumulation on the ground where the deicing agent is sprayed within 3 days, indicating that the actual use effect of the deicing agent is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com