Preparation method of porous g-C3N4 semi-conducting material

A g-c3n4, semiconductor technology, applied in the direction of nitrogen and non-metallic compounds, can solve the problems of high environmental hazards, cumbersome preparation process of hard template method, carbon residue, etc., and achieve the effect of avoiding cumbersome process and excellent photocatalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

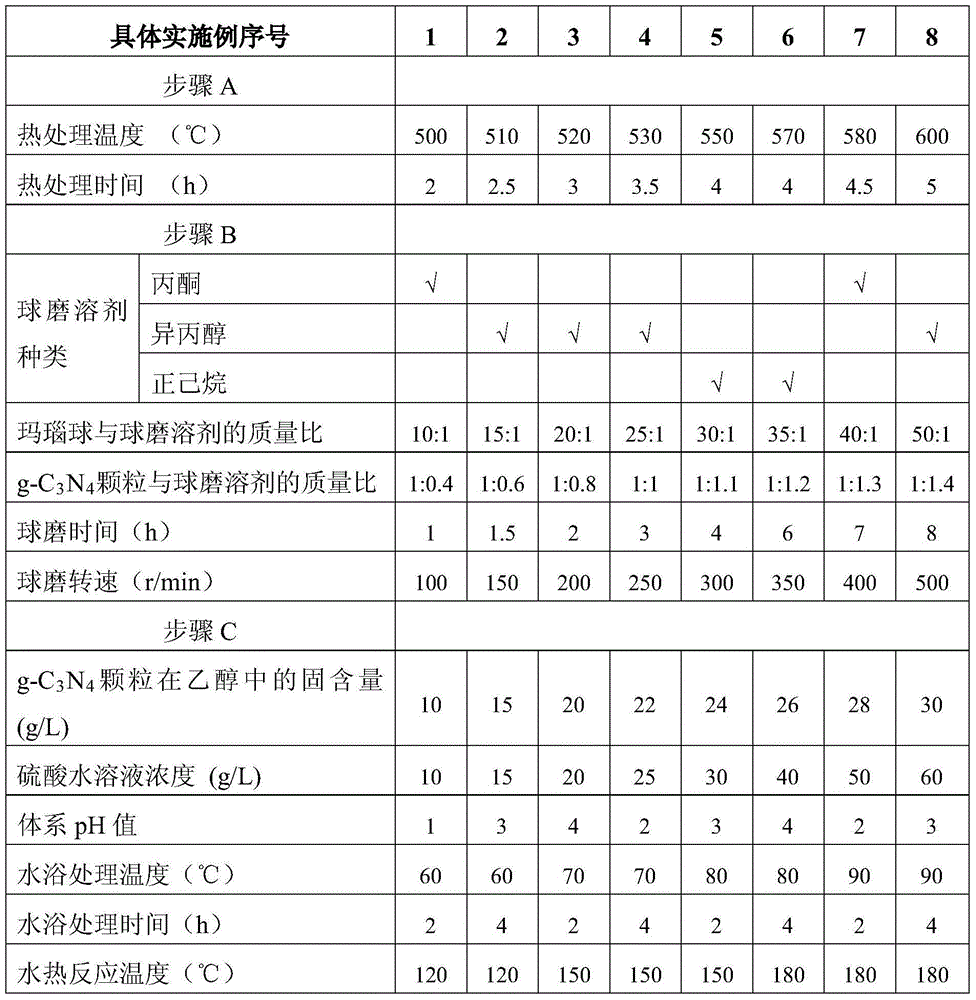

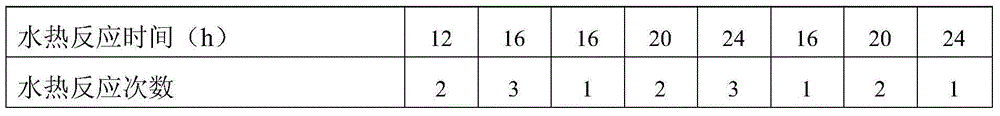

[0019] Porous g-C 3 N 4 A method for preparing a semiconductor material, comprising the steps of:

[0020] Step A: First, take the melamine powder and put it evenly in the corundum crucible boat, put it into the tube furnace, pass in argon to exhaust the air in the tube furnace, and under the protective atmosphere of argon, within 10 minutes Raise the temperature to 380°C, and then raise the temperature to the heat treatment temperature at a rate of 5°C / min. After heat treatment for a certain period of time, cool to room temperature to obtain a yellow block g-C 3 N 4 solid; block g-C 3 N 4 The solid was ground in an agate mortar to give g-C 3 N 4 particles;

[0021] Among them, the heat treatment temperature in the tube furnace is 500°C to 600°C; the heat treatment time is 2h to 5h;

[0022] Step B: Change g-C 3 N 4 Put the particles into the agate ball mill tank, then add agate balls and ball milling solvent in turn, and put them into a planetary ball mill for ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com