Light emitting diode light source structure

A technology of light-emitting diodes and light-emitting diodes, which is applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve problems such as unsafe hidden dangers, unsatisfactory, low light efficiency, etc., to achieve safety protection, product cost reduction, and light emission high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

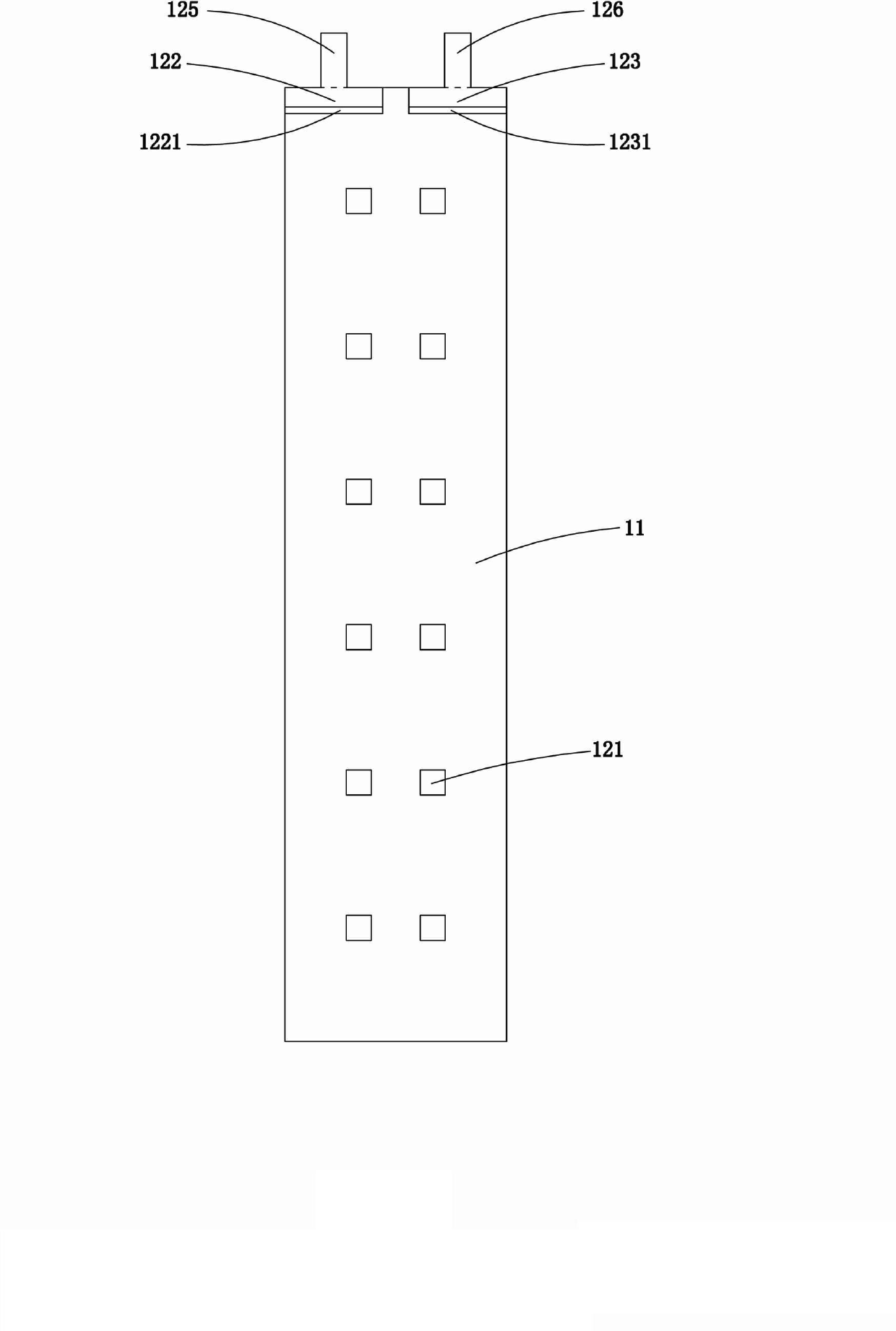

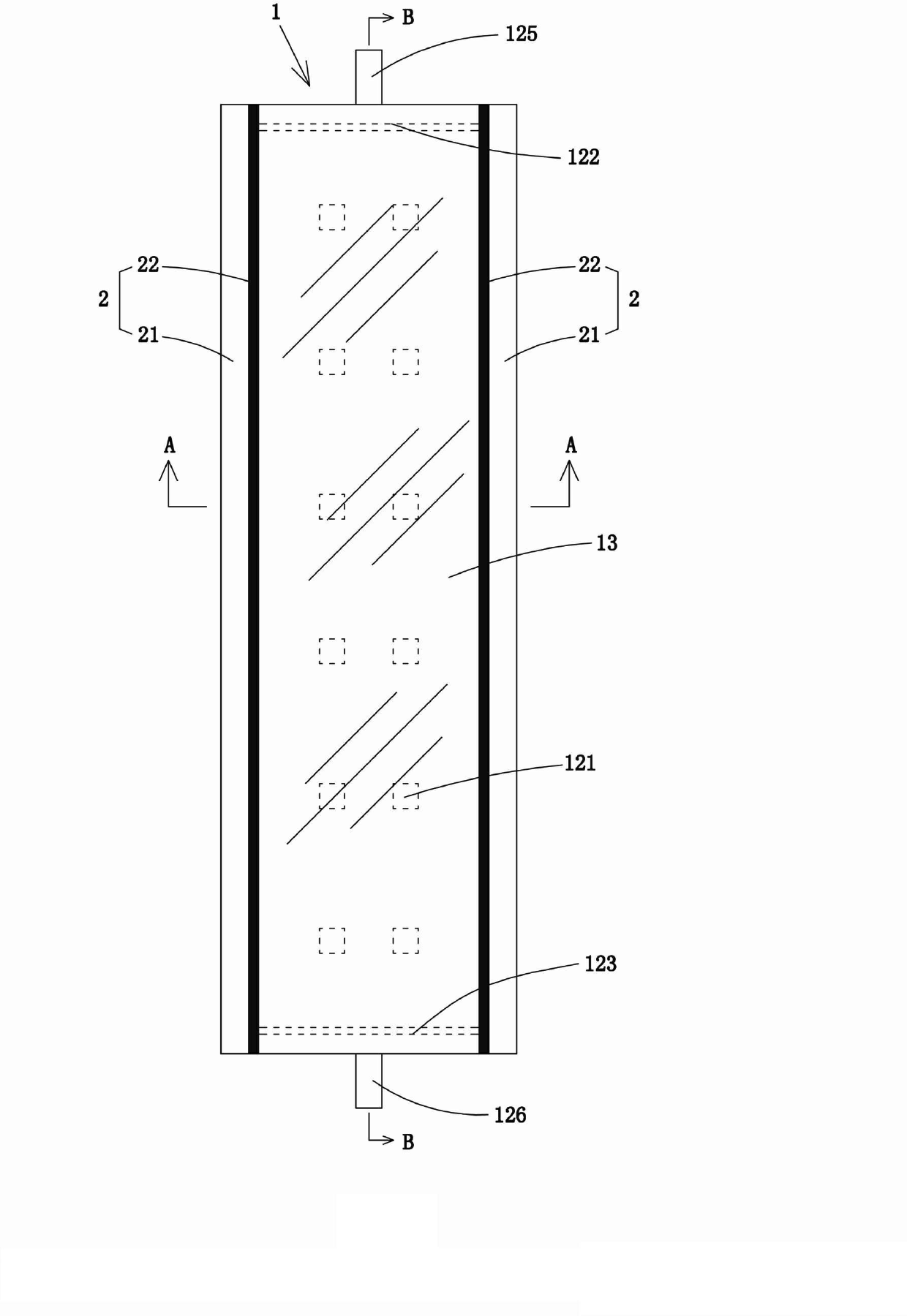

[0029] refer to Figure 2 to Figure 4 . A light-emitting diode light source structure, including a cuboid package body 1 composed of a light-transmitting substrate 11, a light-emitting diode device, and a light-transmitting top plate 13, and the light-emitting diode device is fixed and packaged on the opposite surface of the light-transmitting substrate 11 and the light-transmitting top plate 13 Between; the package main body 1 is a strip-shaped structure, and the light-transmitting side panels 2 are fixedly attached to the sides of the two lengthwise directions.

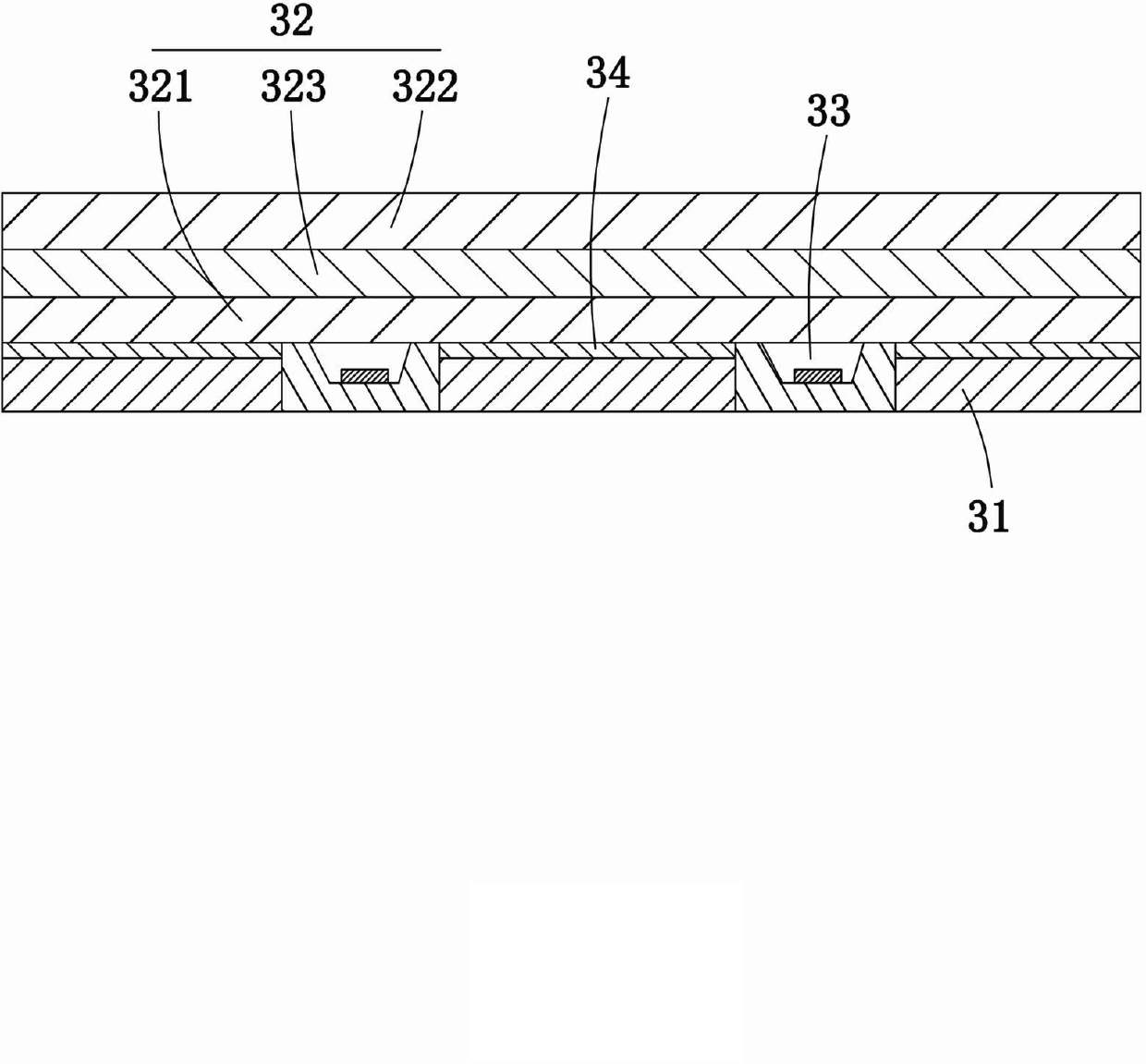

[0030] refer to Figure 2 to Figure 4 . The light-transmitting substrate 11 and the light-transmitting top plate 13 are rectangular transparent sheets of equal specifications. The light-transmitting substrate 11 and the light-transmitting top plate 13 respectively include a first transparent sheet 101 and a second transparent sheet 103 fixedly stacked together, and fluorescent glue is evenly coated between the op...

Embodiment 2

[0040] The difference between this embodiment and the first embodiment above is that: refer to Figure 6 and Figure 7 . Positive and negative light-emitting electrode sheets 122, 123 are spaced at the side edges of the same width side of the light-transmitting substrate 11, and the positive and negative connection electrodes 125, 126 protrude from the width side of the package body 1; preferably, the positive and negative light emitting The electrode sheets 122 and 123 are fixed and glued to the light-transmitting substrate 11 and the light-transmitting top plate 13 by insulating glue. The other width side of the package body 1 is also fixedly attached with a transparent side plate 2'. The two longitudinal sides of the package body 1 are packaged with light-transmitting side panels 2 , and the other width side of the package body 1 is also packaged with a light-transmitting side panel 2 ′. The light side plate 2 is similar, and it includes a transparent sheet 21' and a fluor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com