Patents

Literature

86results about How to "Reduce heat of reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

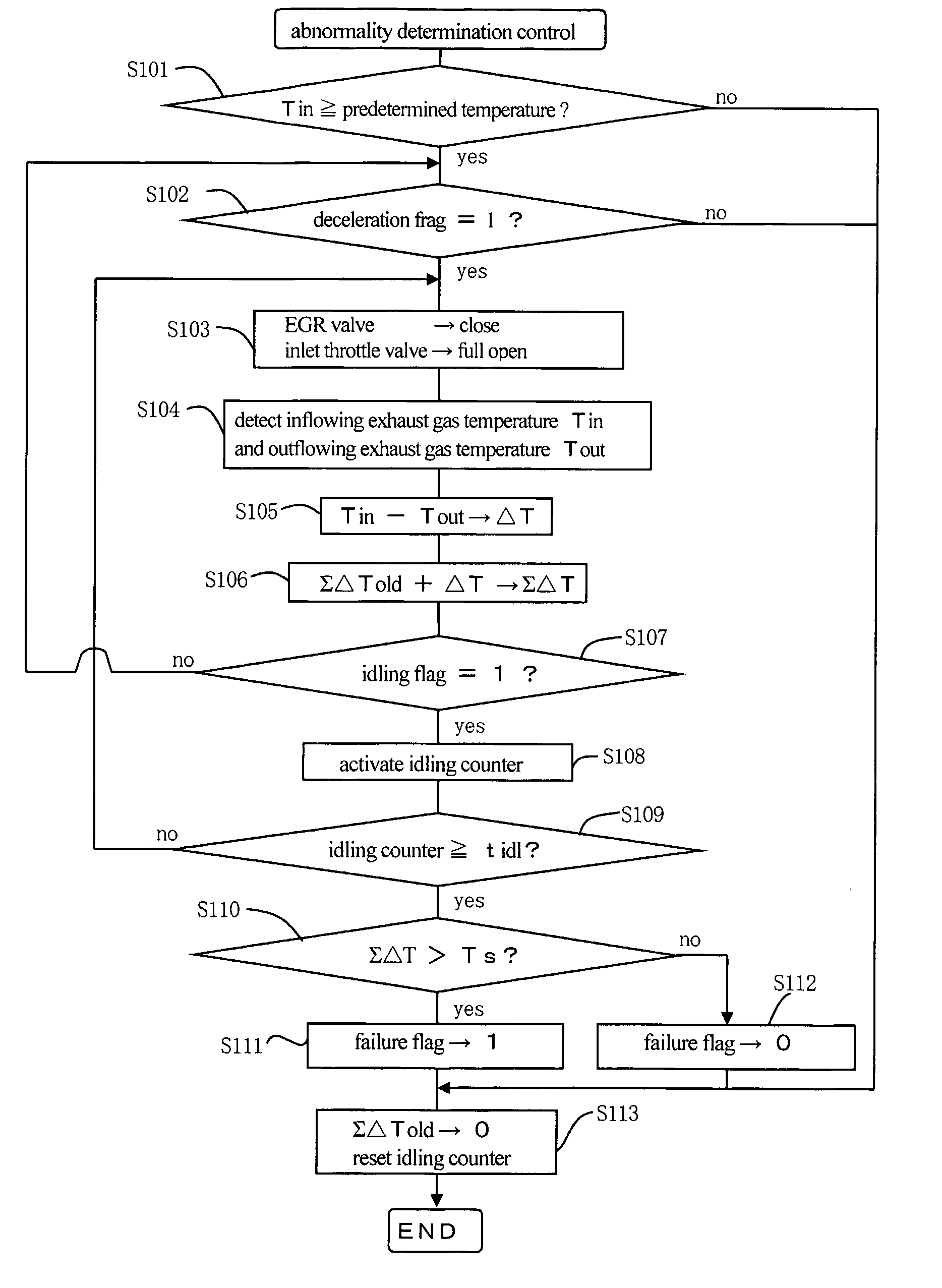

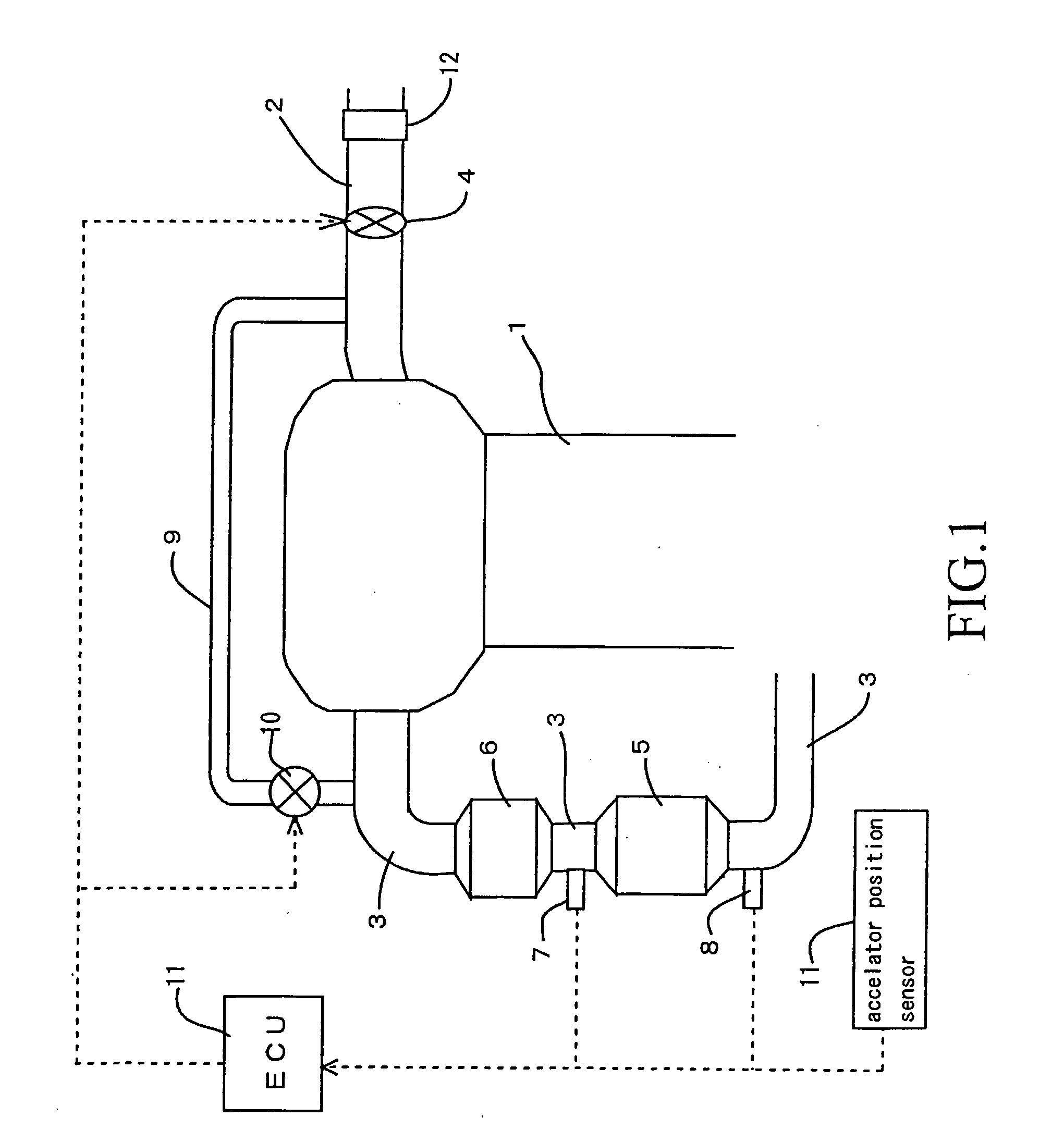

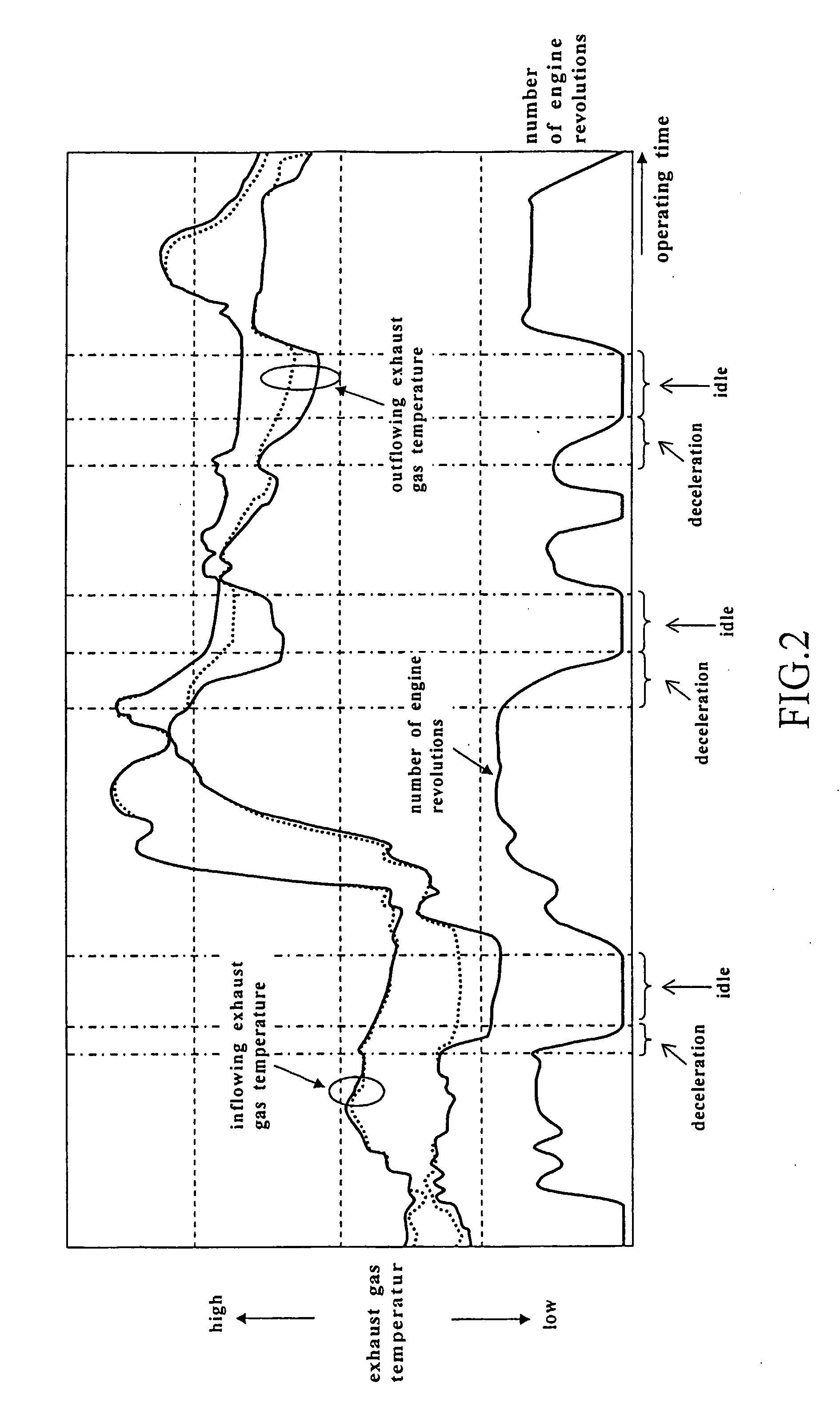

Method of Determining Abnormality in Particulate Filter

InactiveUS20080041035A1Easy to implementShort timeElectrical controlInternal combustion piston enginesParticulatesProcess engineering

An object of the invention is to realize a method of determining an abnormality in a particulate filter (5) capable of trapping and oxidizing particulate matter contained in exhaust gas in which even a minor abnormality in which small quantity of particulate matter can pass through the particulate filter (5) can be determined with a high degree of accuracy. To achieve this object, the abnormality determination method according to the invention, the transition of the inflowing exhaust gas temperature in and the outflowing exhaust gas temperature out of the particulate filter (5) during deceleration operating, and the degree of decrease in the outflowing exhaust gas temperature relative to the inflowing exhaust gas temperature is computed based on the transition. If the degree of decrease exceeds a threshold value, it is determined that the particulate filter (5) is abnormal.

Owner:TOYOTA JIDOSHA KK

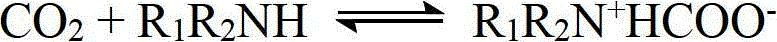

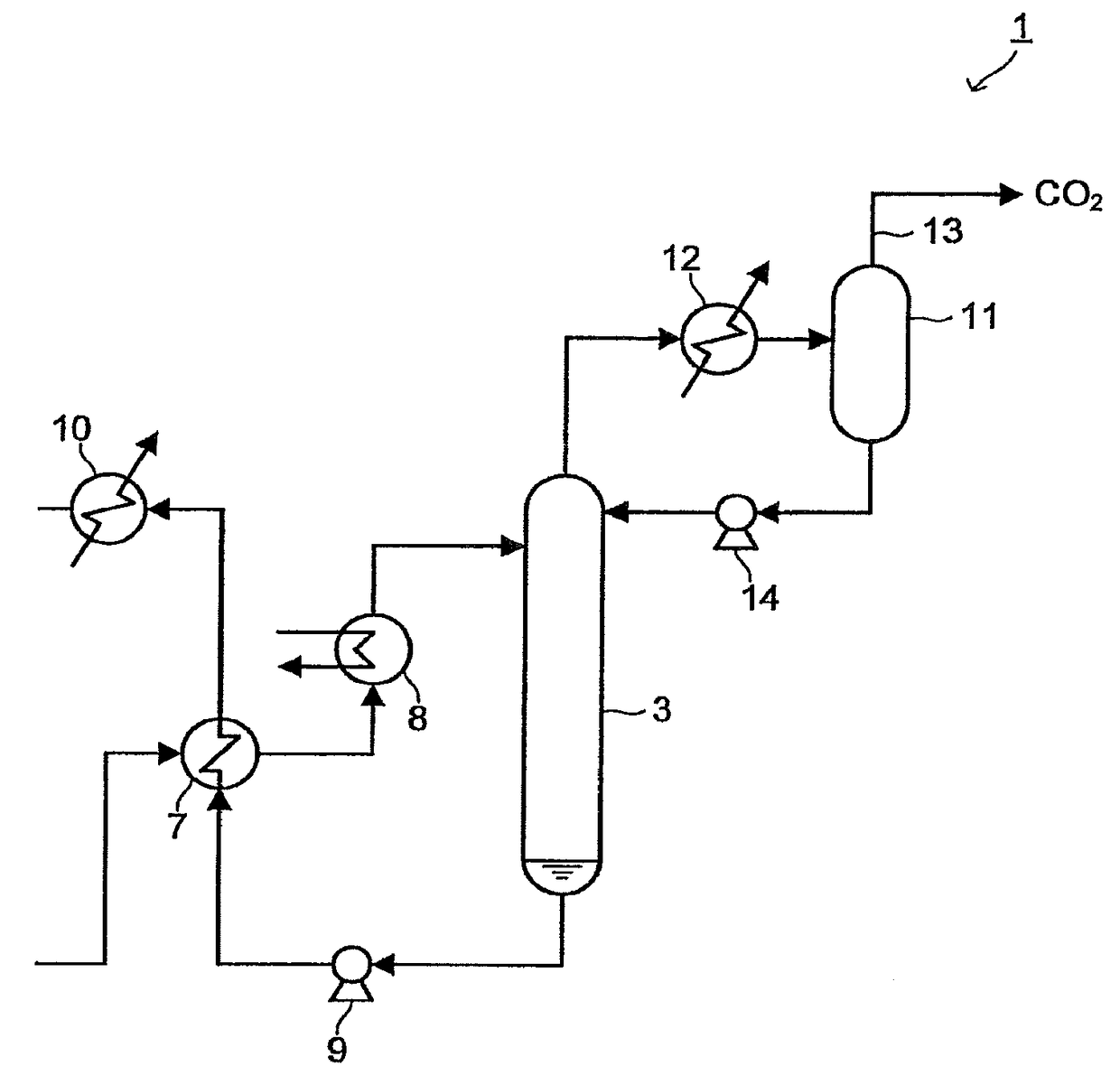

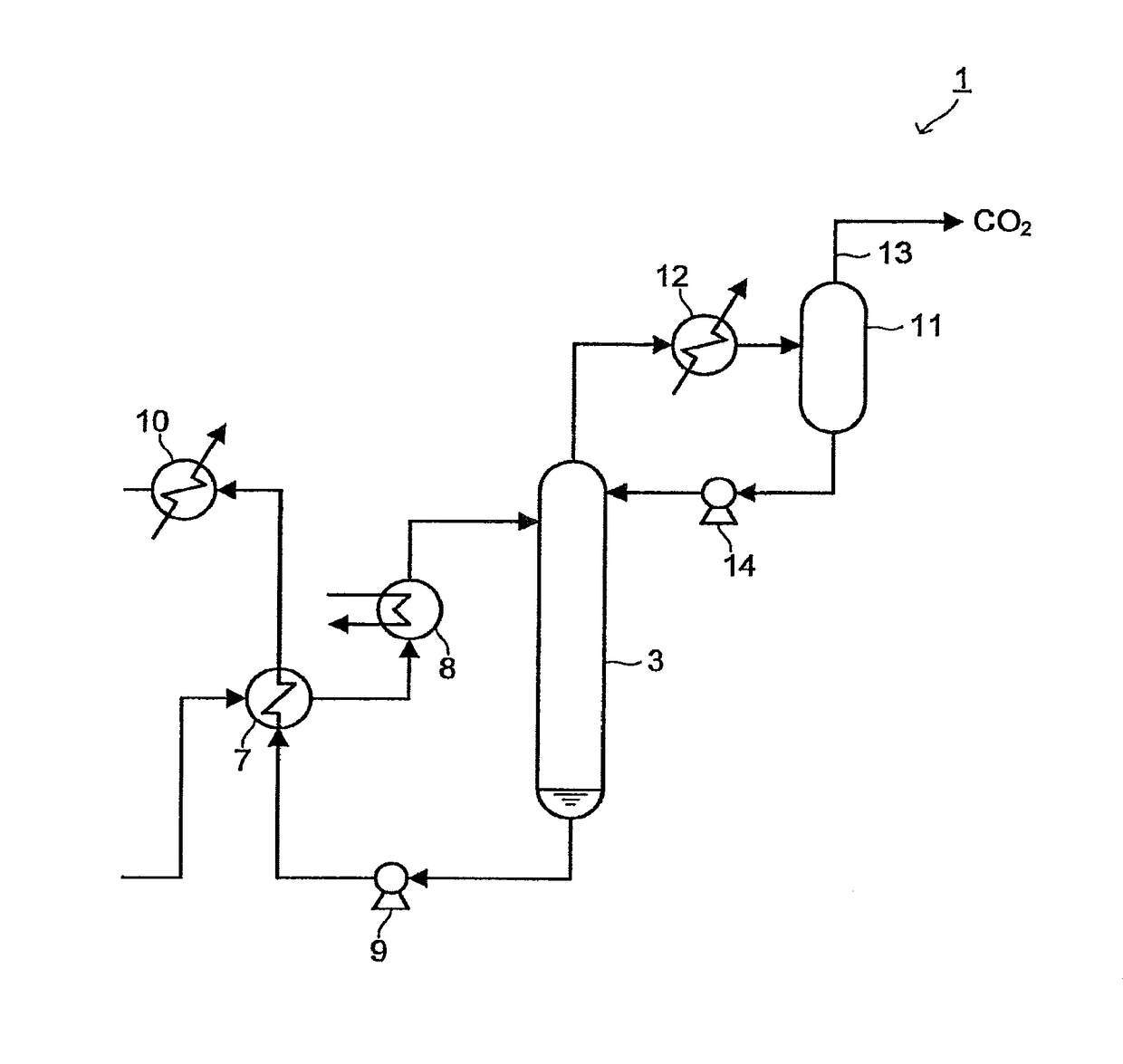

Carbon dioxide absorber and carbon dioxide separation/recovery method using the absorber

InactiveUS20140127119A1Efficient and stable removalSave energyCombination devicesCarbon compoundsRecovery methodCo2 absorption

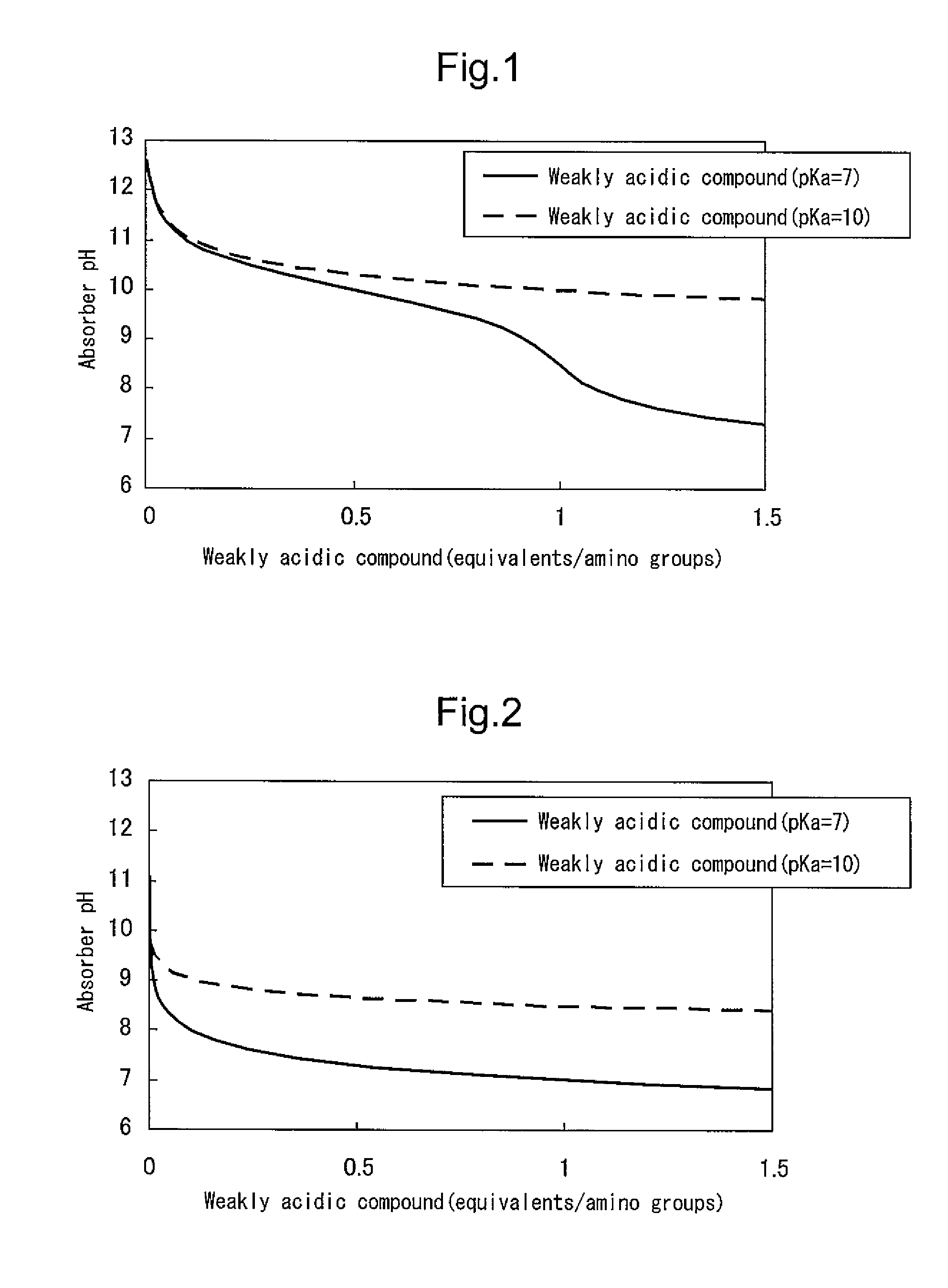

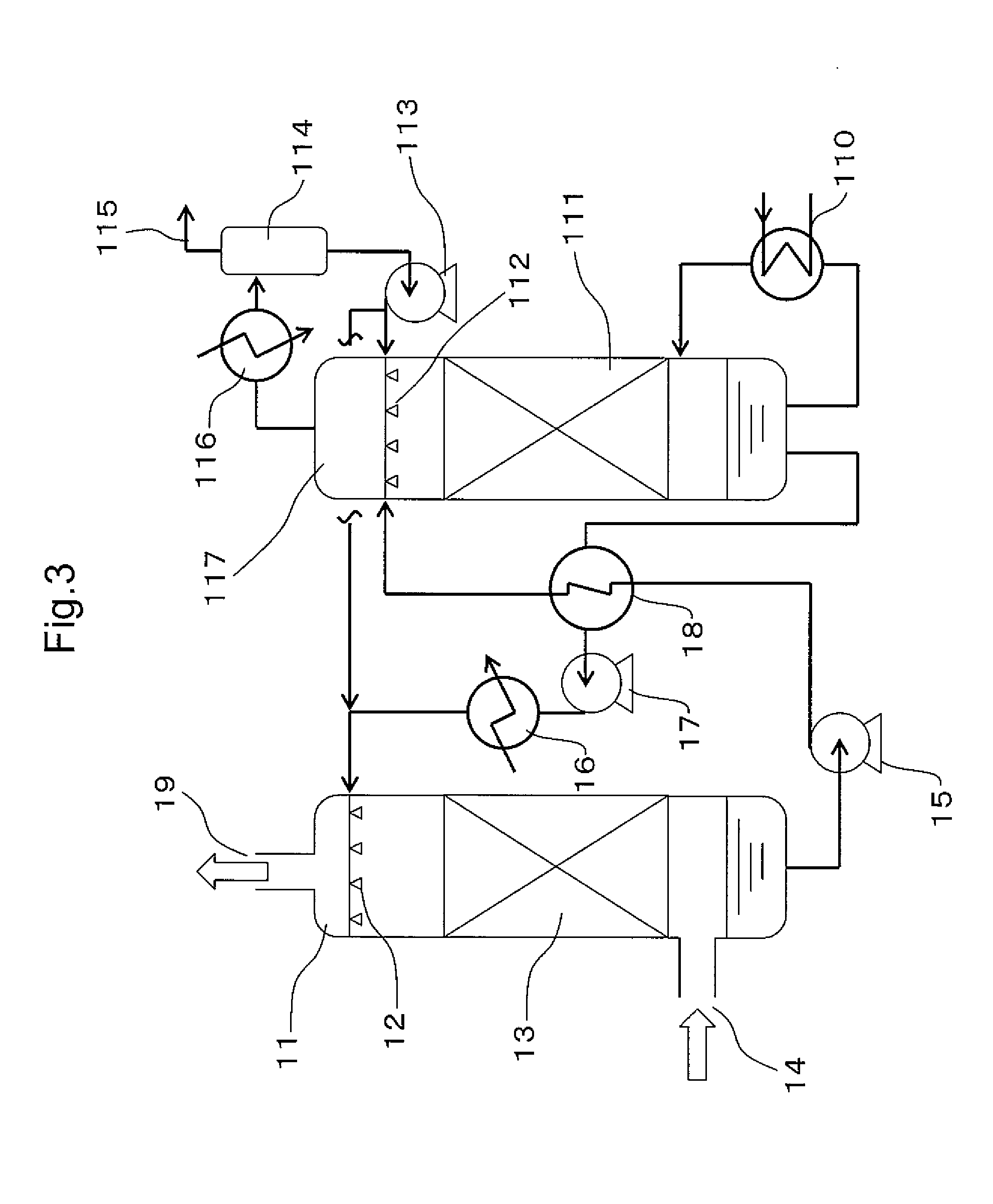

The present invention provides a carbon dioxide absorber capable of efficiently and stably removing carbon dioxide in a gas or solution. This carbon dioxide absorber contains an amine compound, a weakly acidic compound and water, the pKb value of the amine compound in an aqueous solution at 30° C. is 4.0 to 7.0, the pKa value of the weakly acidic compound in an aqueous solution at 30° C. is 7.0 to 10.0, and the weakly acidic compound is present in an amount within the range of 0.01 equivalents to 1.50 equivalents with respect to amino groups of the amine compound.

Owner:ASAHI KASEI KK

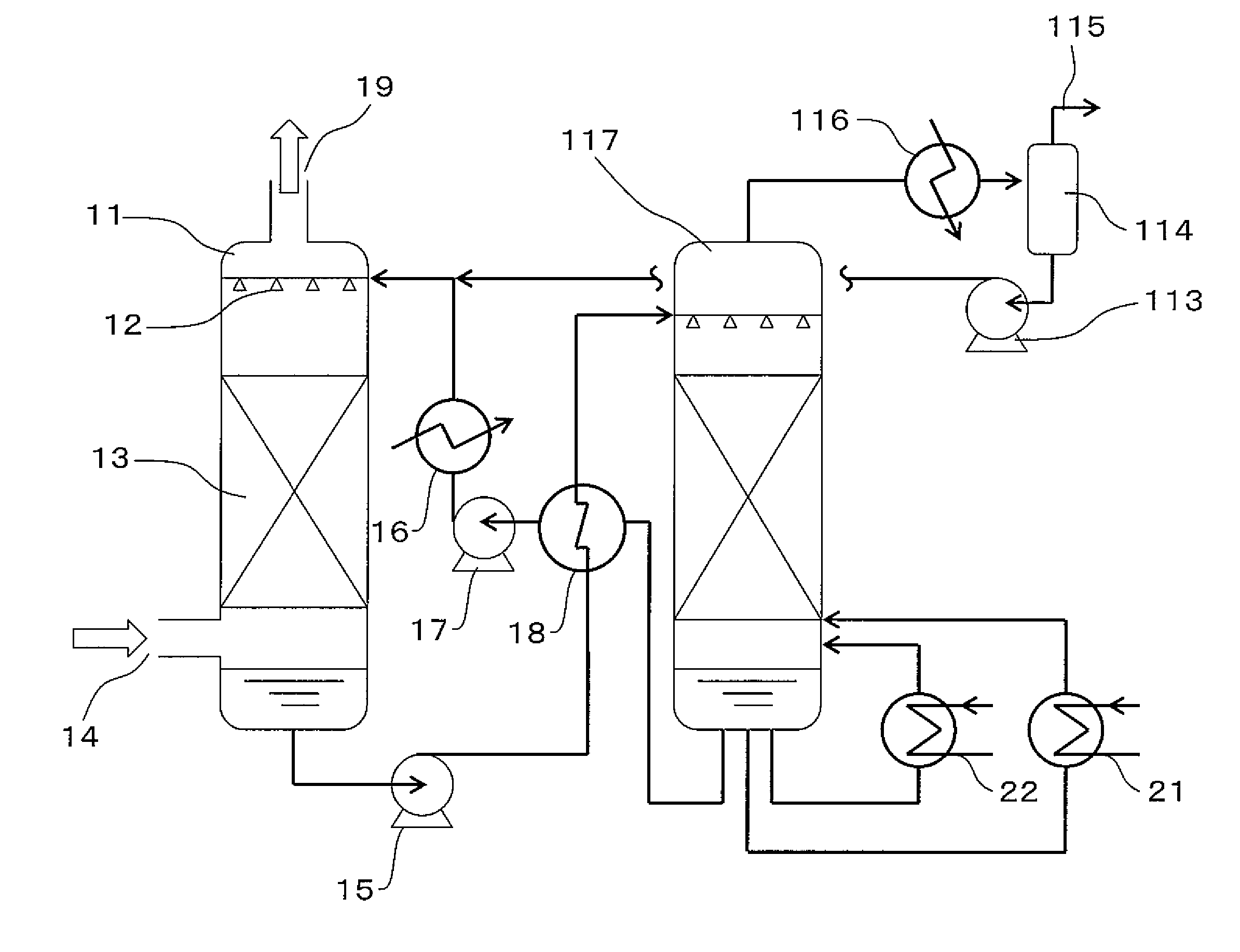

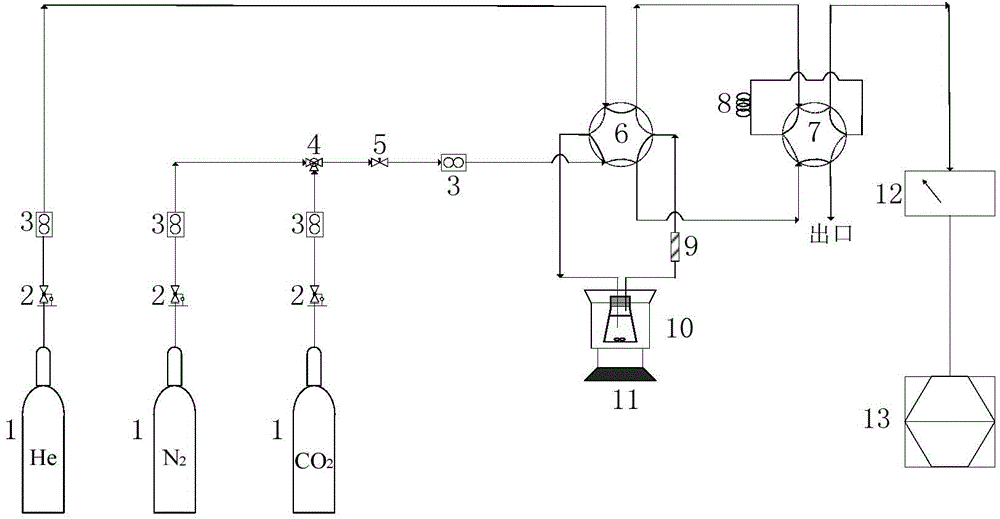

Circulating fluidized bed gas generator system

ActiveCN101063053AEfficient recyclingReduce heat of reactionEnergy inputGranular/pulverulent flues gasificationFluidized bedEngineering

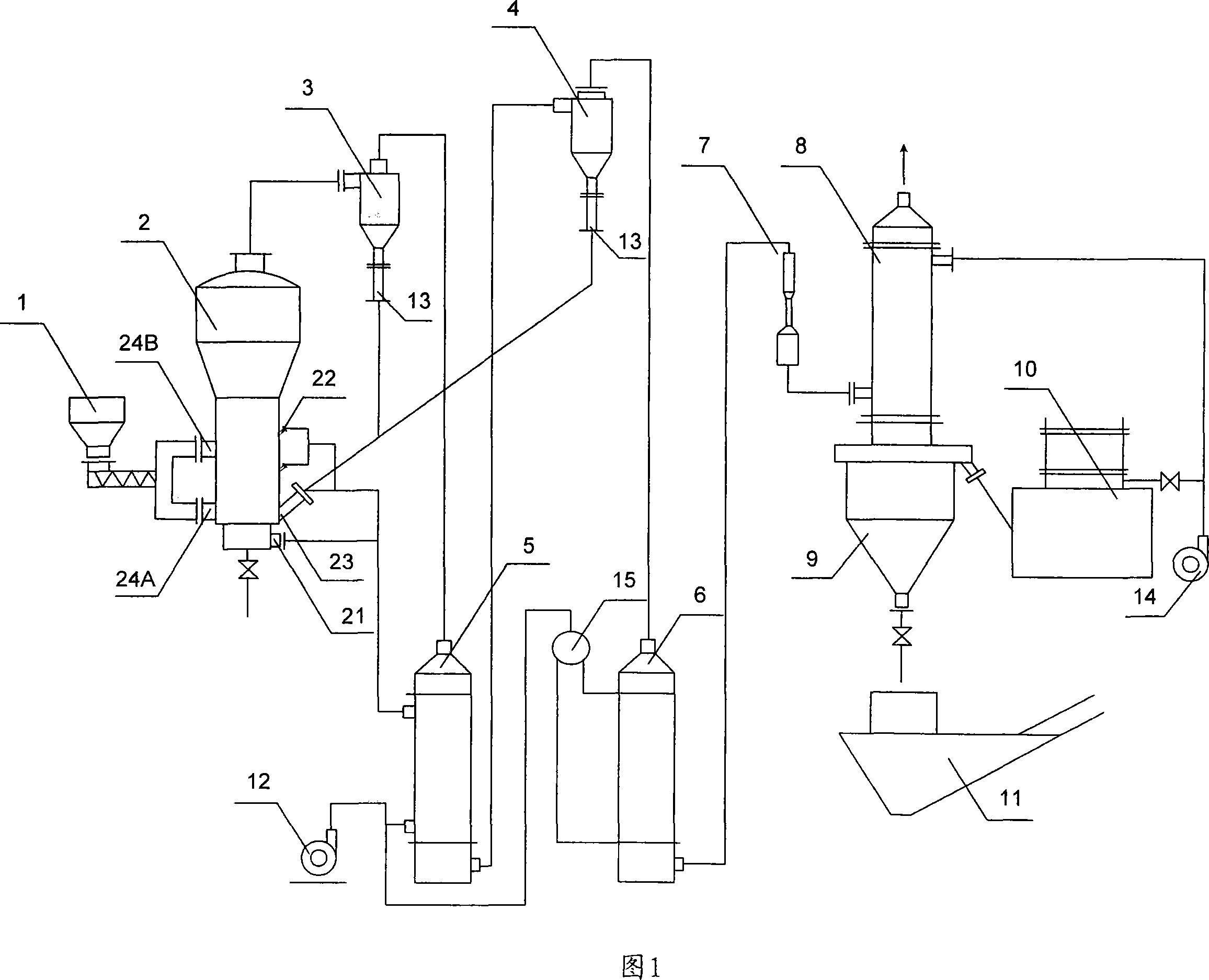

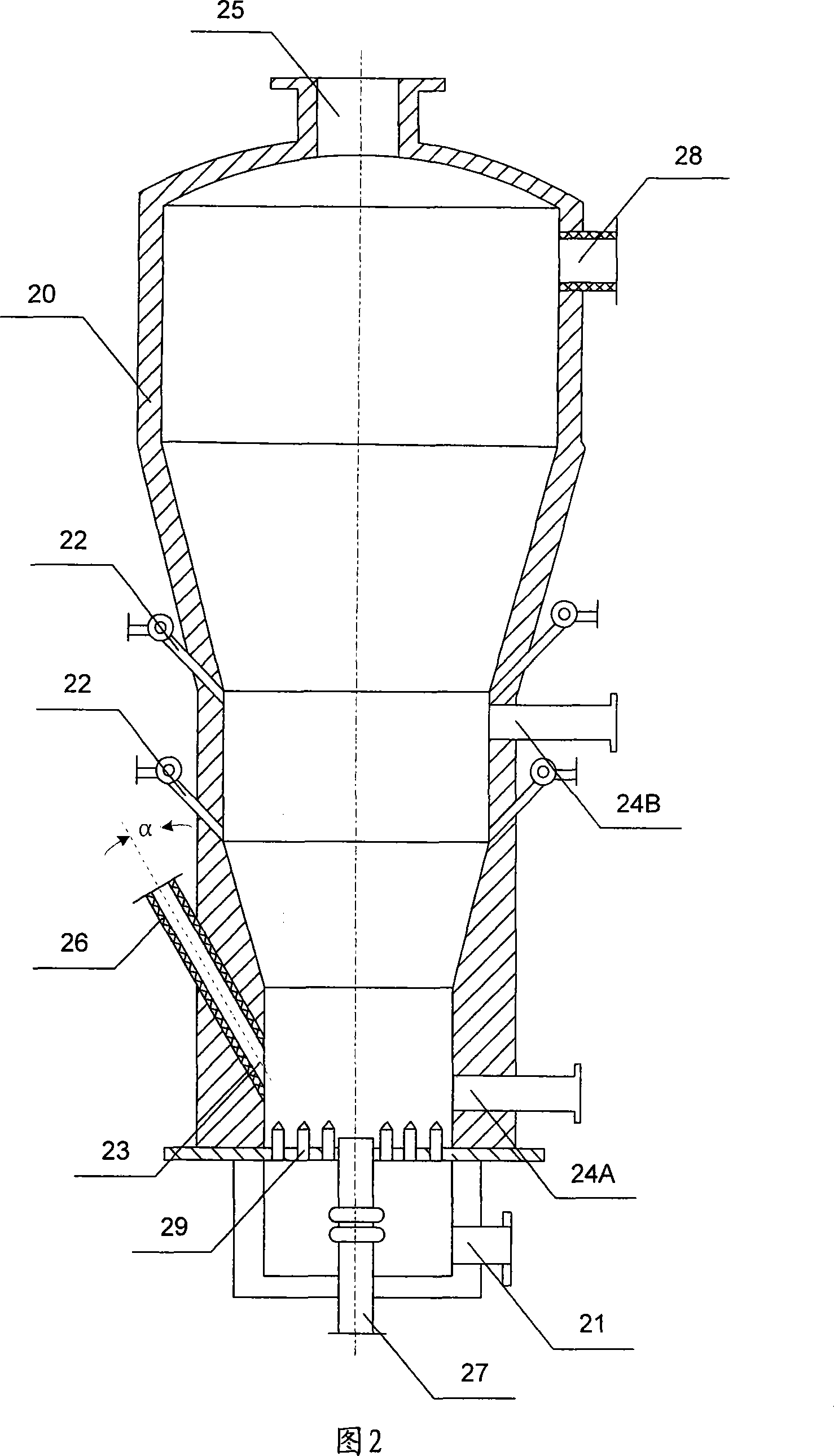

The invention discloses a circulating coal fluidized bed coal gas producer system, which is characterized by the following: comprising coal-gas producer, high temperature segregator, heat exchanger, low temperature segregator and exhaust heat boiler; arranging primary air port entered high temperature gasifying agents into the burner and at least a overfire air port on coal-gas producer; equipping circling coal inlet to enter circling coal into burner; connecting the primary air port and overfire air port with heat exchanger; connecting circulating coal inlet with high temperature segregator, low temperature segregator and heat exchange; proceeding twice air intake, twice coal intake and twice separation. This invention possesses low coal consumption, high heat value, high productive efficiency and low cost, which can make the temperature of gasifying agents reach 750-850 deg. c.

Owner:KEDA INDUSTRIAL GROUP CO LTD +1

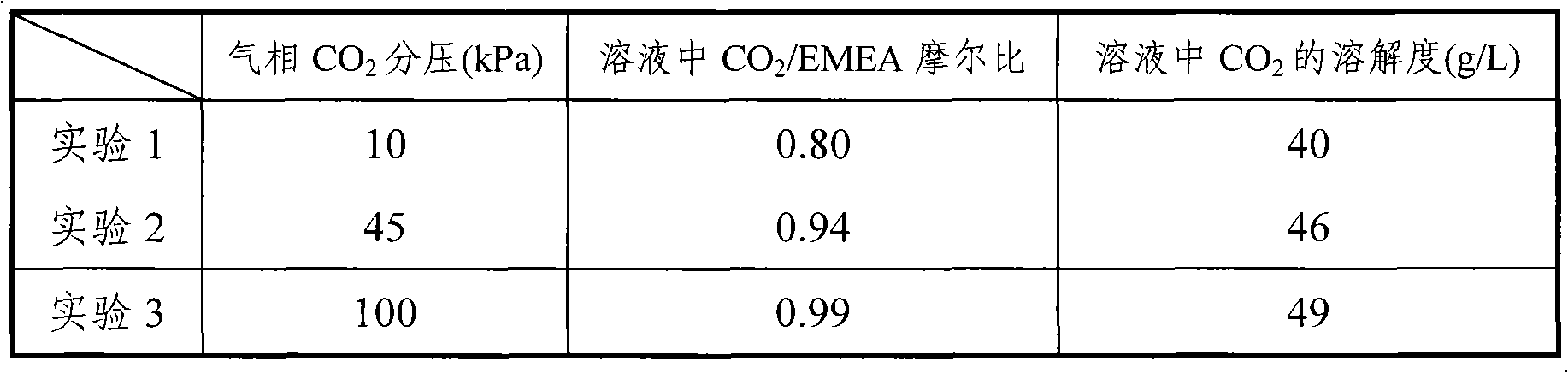

Absorbing agent for catching or separating carbon dioxide

The invention relates to an absorbing agent for catching or separating carbon dioxide from gas mixture, which mainly comprises the components by weight percent: 10-50wt% of N-ethylethanolamine, 10-40wt% of tetramethylene sulfone and balance water. The absorbing agent adopts the N-ethylethanolamine as effective component, and the N-ethylethanolamine has high solubility for low-pressure carbon dioxide, good desorbing effect, lower reaction heat of absorption reaction and lower energy consumption for catching or separating the carbon dioxide; and as the 3-dimethyl amino-1-propyl alcohol has the functions of improving the desorbing effect and reducing the volatilization of water, so that the energy consumption of desorbing is further reduced. The absorbing agent can be used for catching or separating the carbon dioxide in various gas mixtures such as flue gas, refinery gas, natural gas, synthesis gas, shift gas, hydrogen preparation gas and the like.

Owner:TSINGHUA UNIV

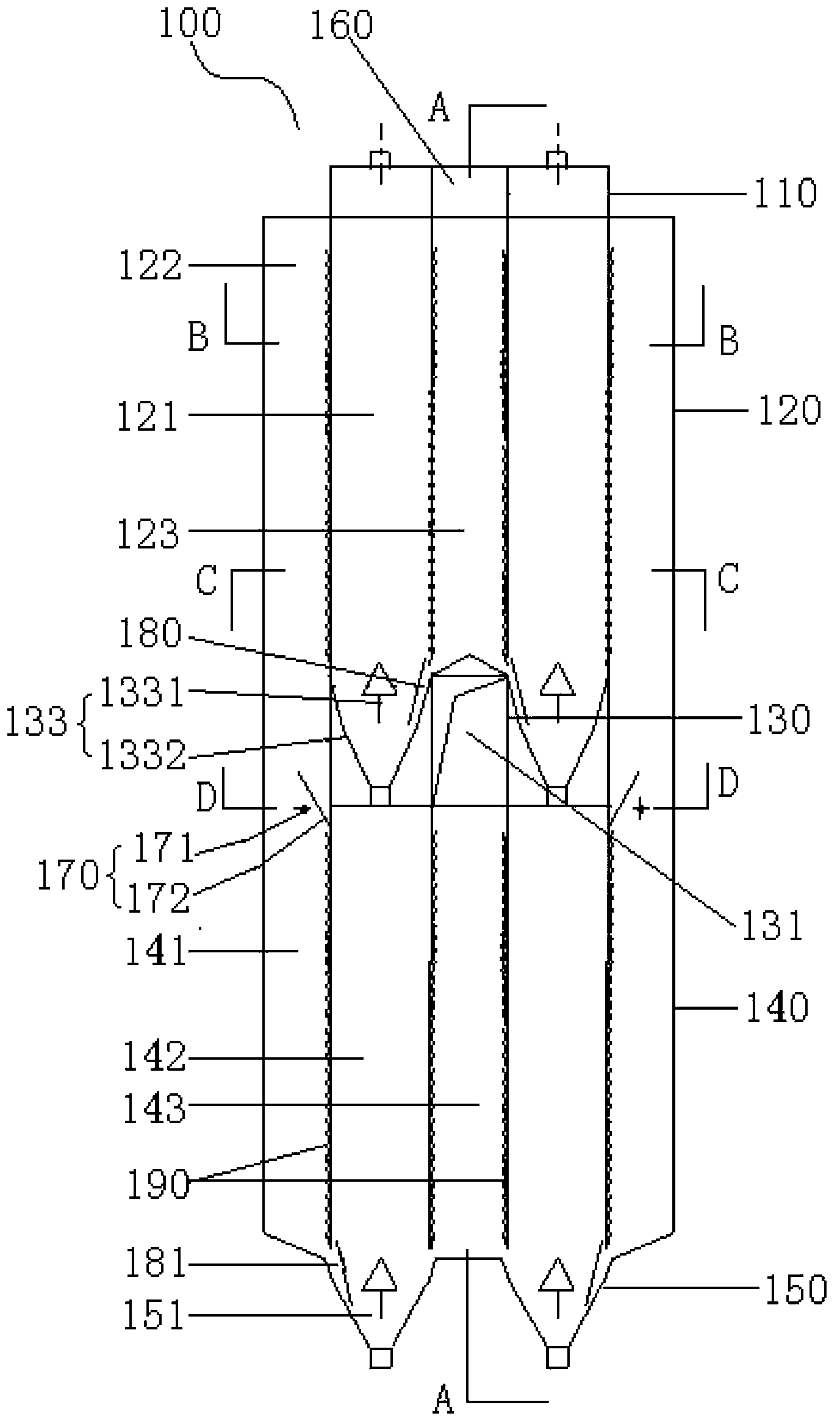

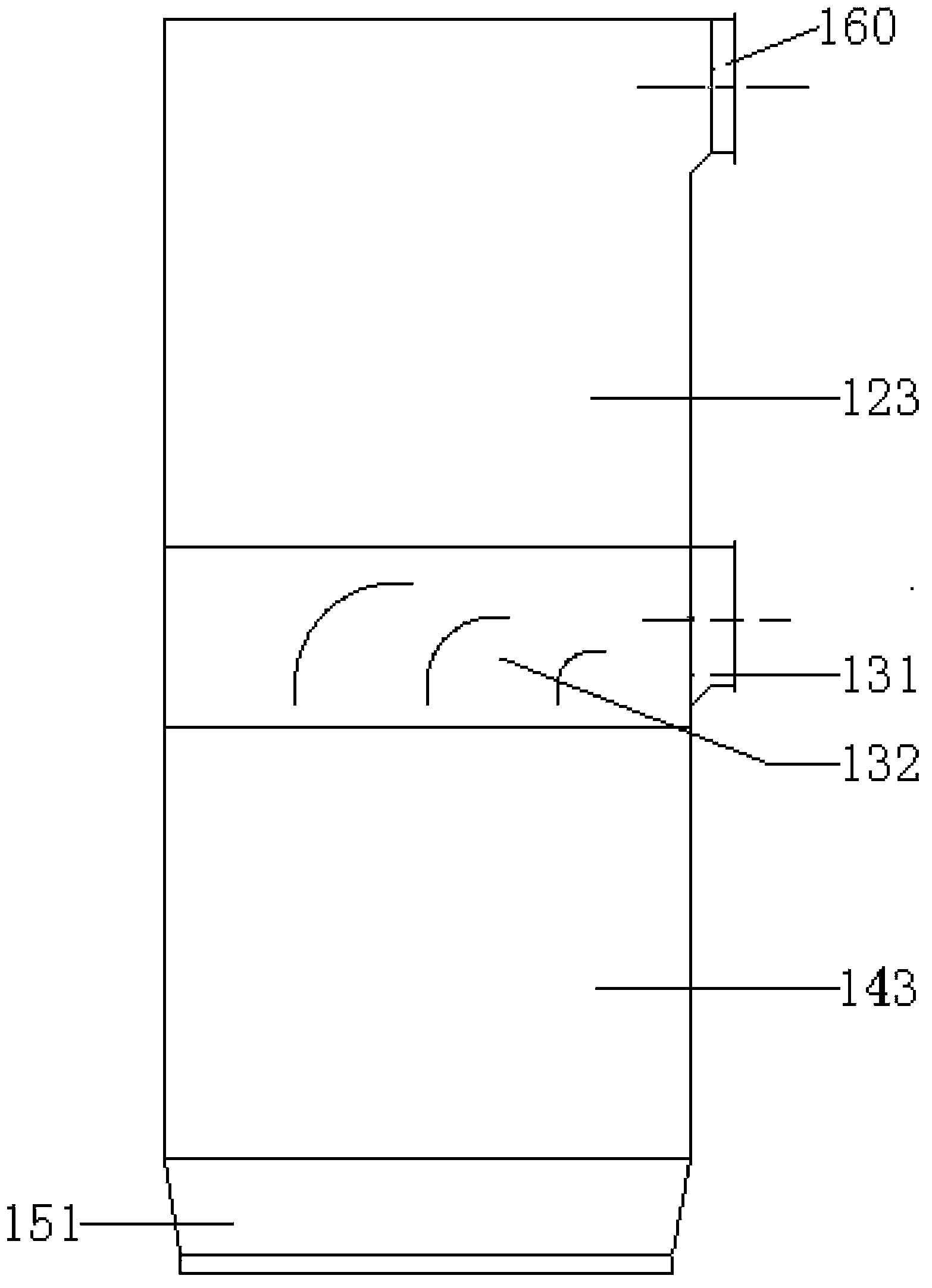

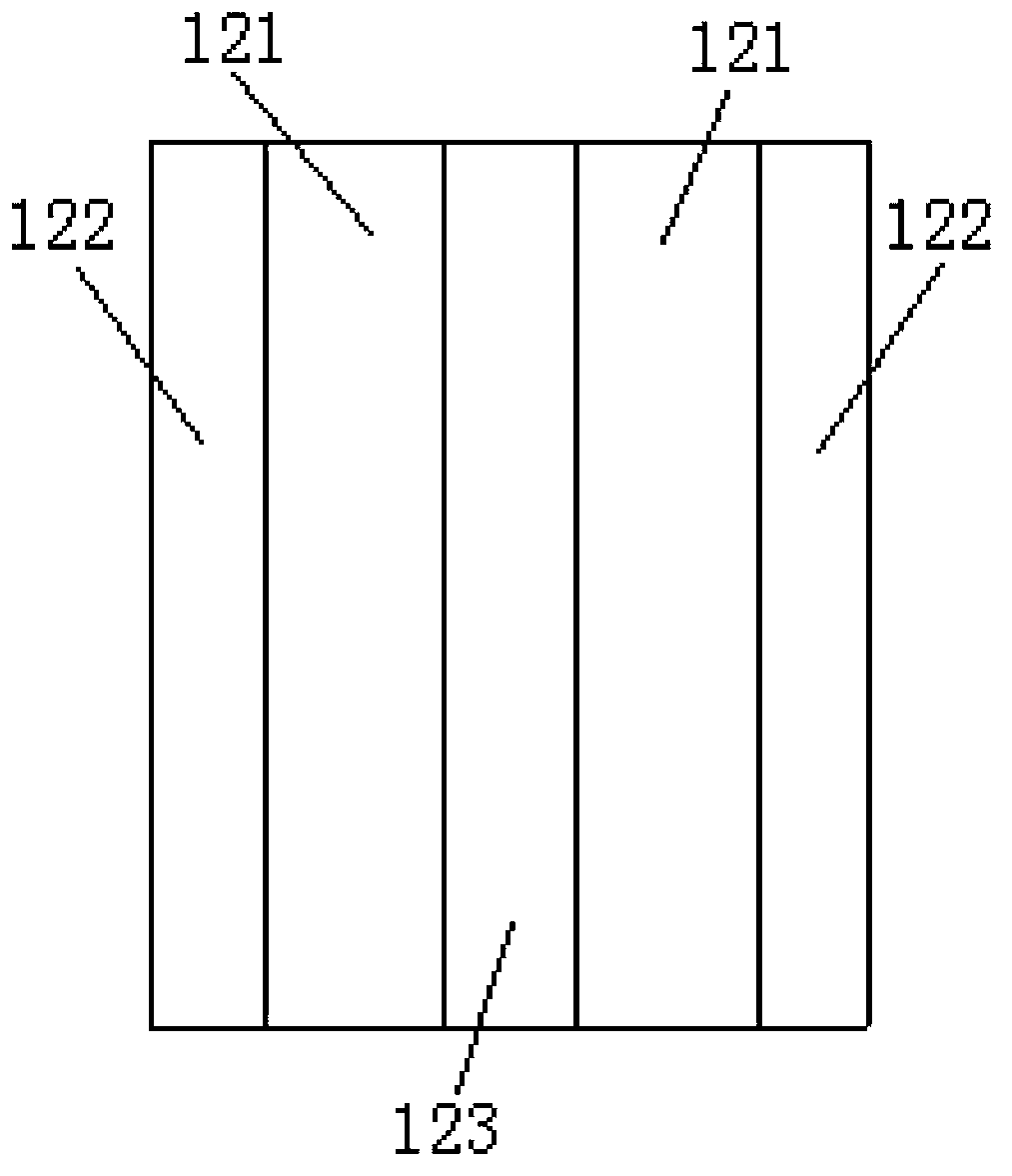

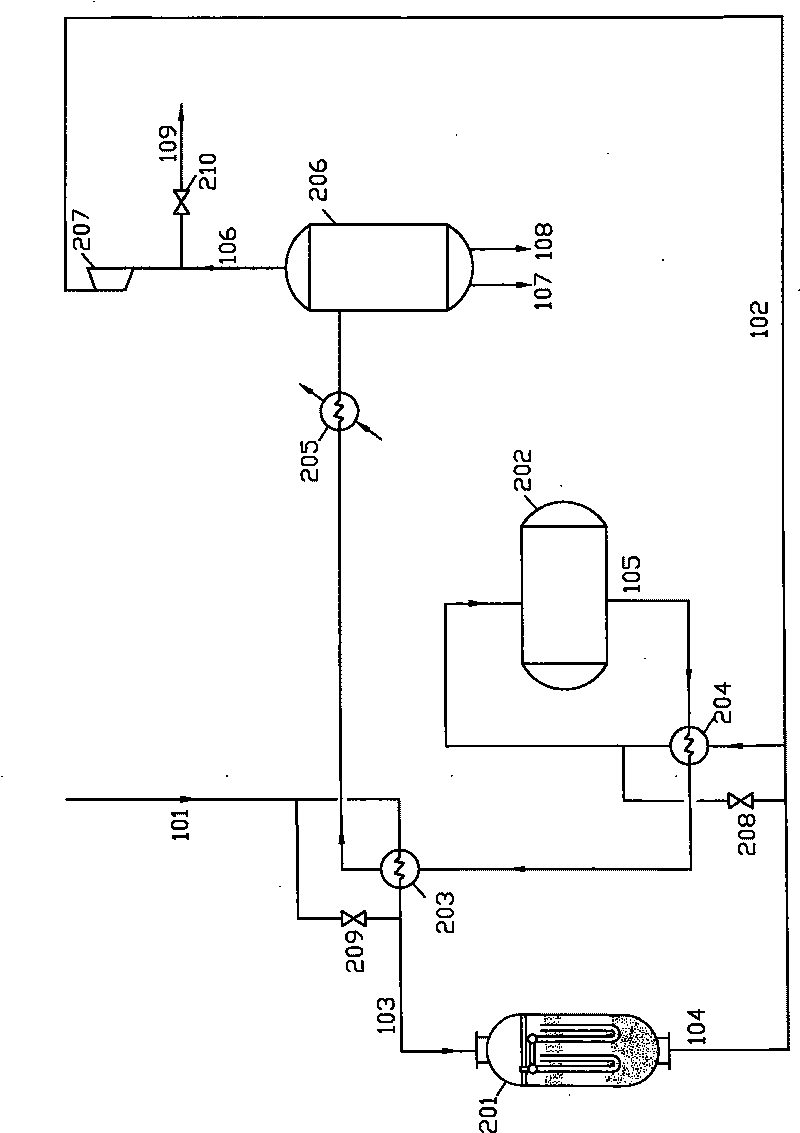

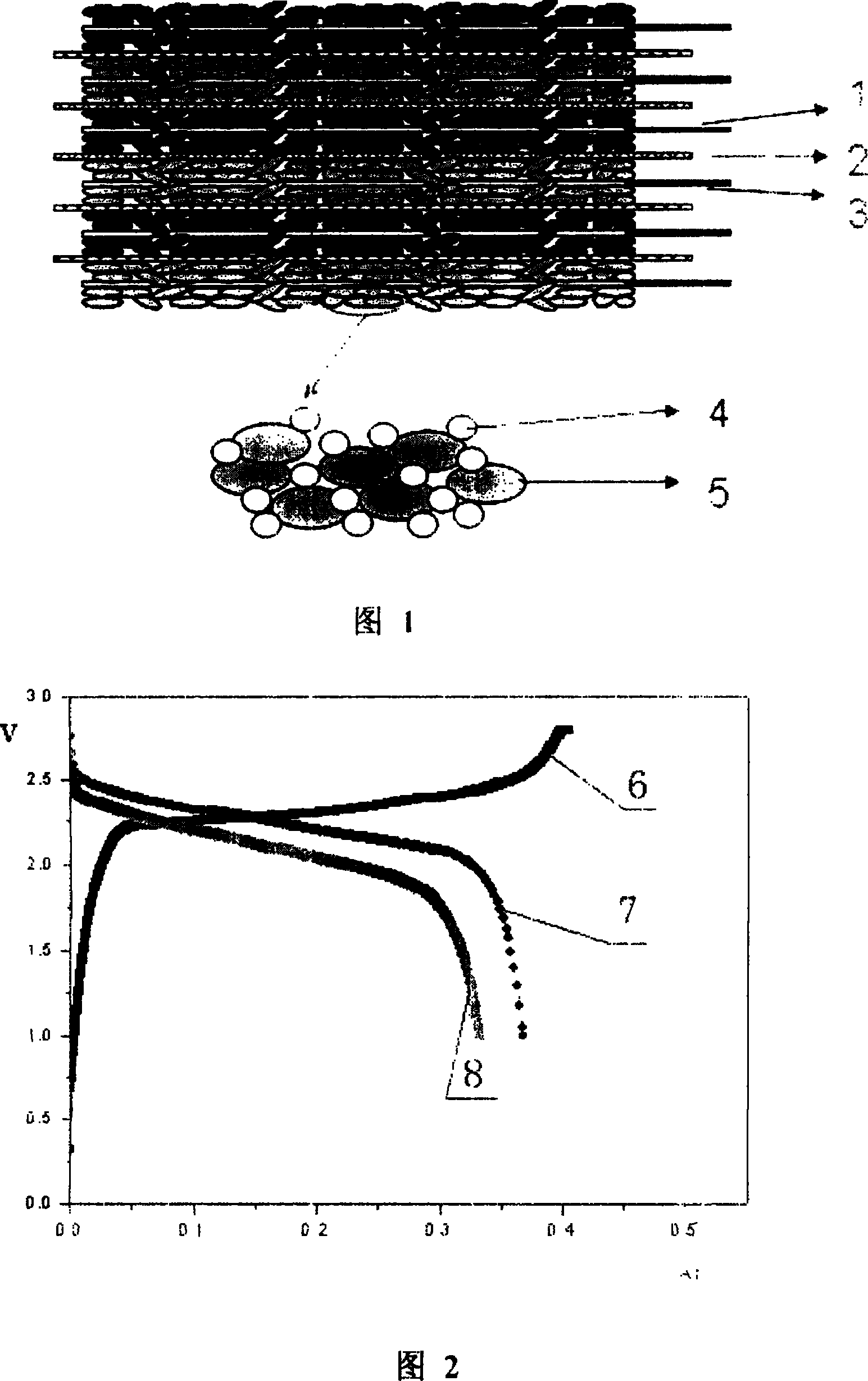

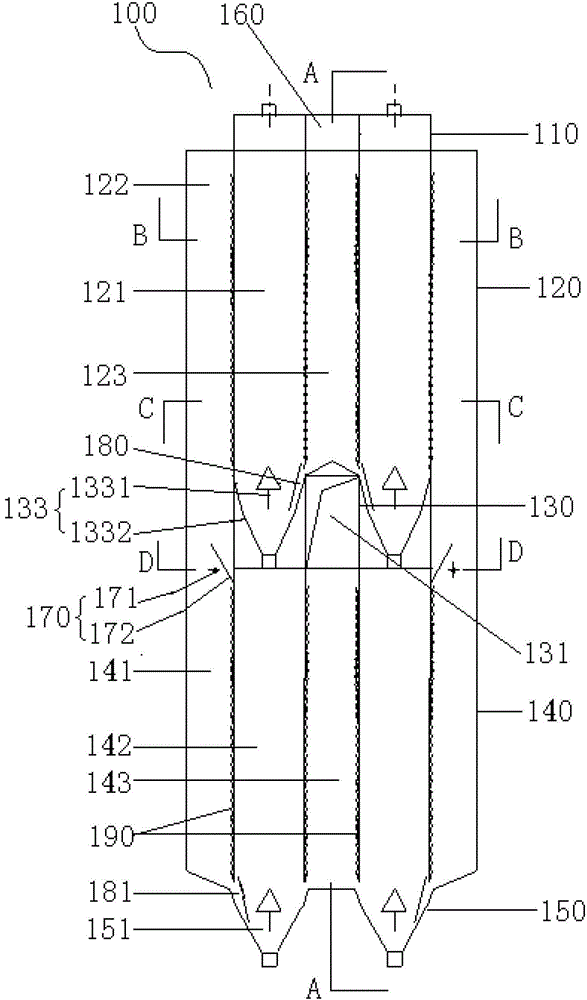

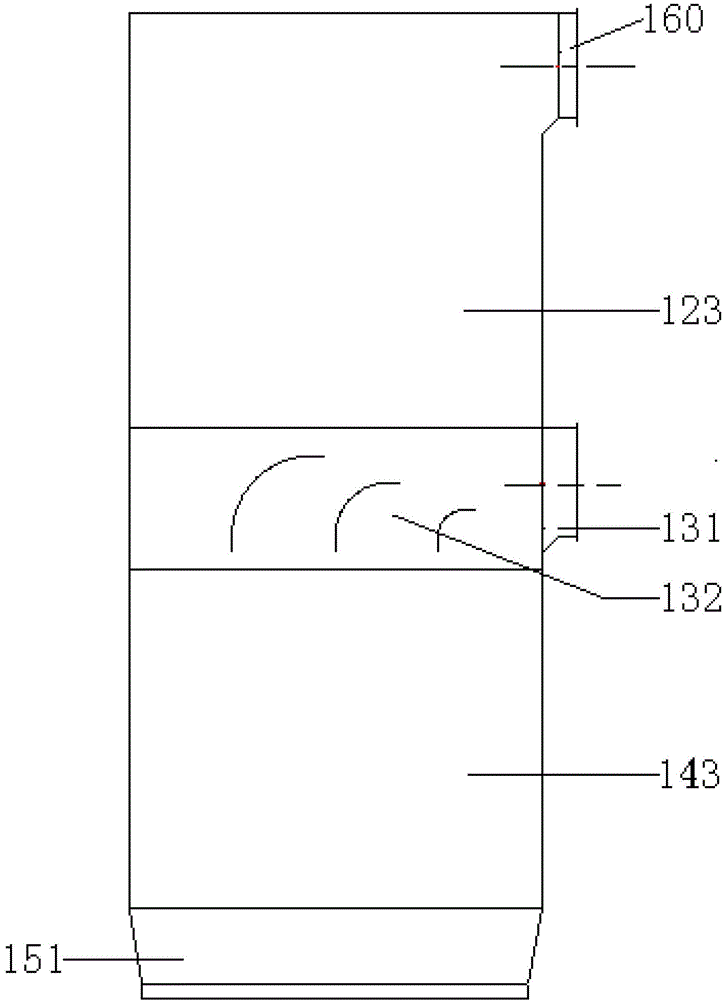

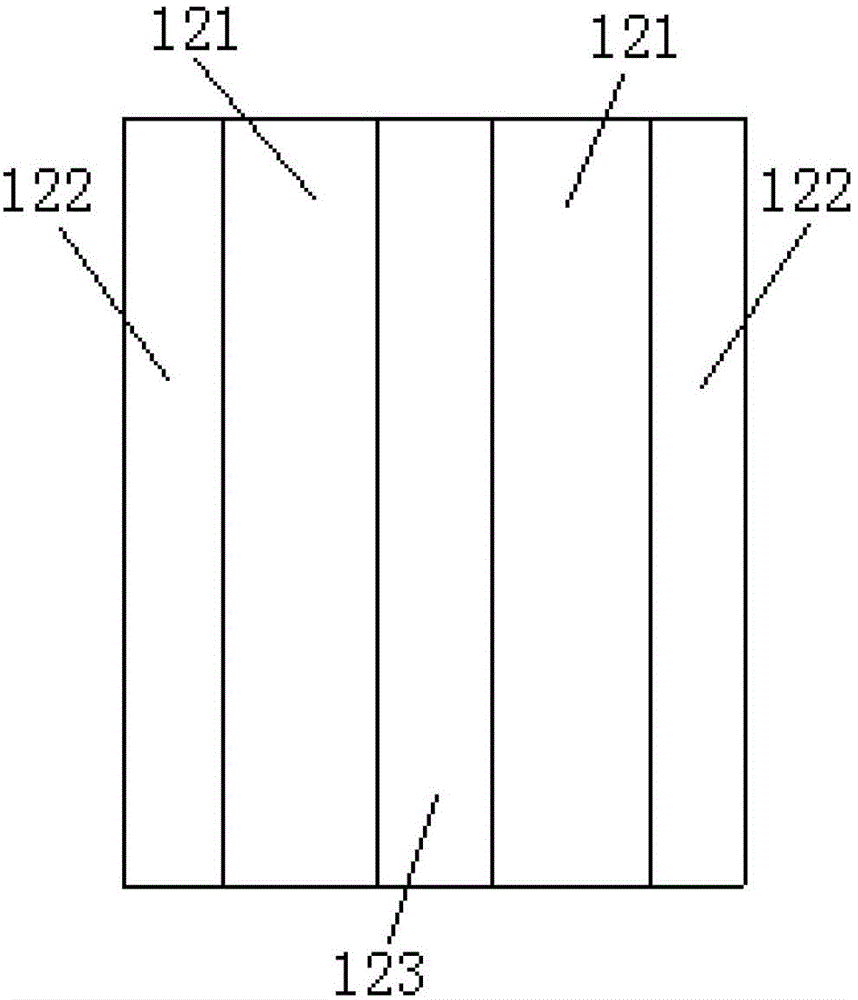

Cross-flow type two-stage moving bed active coke waste gas integrated purification tower

ActiveCN103349892AImprove the utilization rate of adsorption sulfur capacityReduce circulationDispersed particle filtrationTowerMoving bed

The invention discloses a cross flow type two-stage moving bed active coke waste gas integrated purification tower which comprises a purification tower main body, wherein the purification tower main body is provided with an active coke feeding region, a denitration region, a transitional layer, a desulfuration region and a discharging layer sequentially from top to bottom; the denitration region comprises a denitration region active coke bed layer, a denitration region inlet chamber and a denitration region outlet chamber; the desulfuration region comprises a desulfuration region active coke bed layer, a desulfuration region outlet chamber and a desulfuration region inlet chamber; the transitional layer comprises an inlet chimney flue with a waste gas inlet, and a discharge hopper, the inlet chimney flue is arranged above the desulfuration region inlet chamber in a conducting manner, the denitration region active coke bed layer is connected with the desulfuration region active coke bed layer through the discharge hopper, and the desulfuration region outlet chamber is connected with the denitration region inlet chamber in a conducting manner. According to the invention, the pollution purification efficiency is high, the active coke utilization ratio is high, and the circulation volume is small; airflow distribution is uniform and the resistance is small; the flowing of the active coke is unobstructed and uniform, the denitration efficiency is high, and the operation is stable.

Owner:SHANGHAI CLEAR ENVIRONMENTAL PROTECTION SCI & TECH

Mine water glass reinforced water shutoff material

The invention relates to a mine water glass reinforced water shutoff material which is composed of two independent components, namely component A and component B, wherein the component A comprises following raw materials by weight: 51-99.9% of water glass A, 0-50% of water glass B, 0.1-2% of catalyst C and 0-50% of plasticizer D; and the component B comprises the following raw materials by weight: 51-100% of curing agent A, 0-50% of curing agent B and 0-50% of polyether polyol C. The mine water glass reinforced water shutoff material has the effects of high flame resistance, low reaction heat and adjustable curing time; and environmental water basically does not influence the reaction. By utilizing the mine water glass reinforced water shutoff material, the safety of production of a coal mine can be improved to a great extent.

Owner:SHANXI YUBANG NEW POWER SCI & TECH

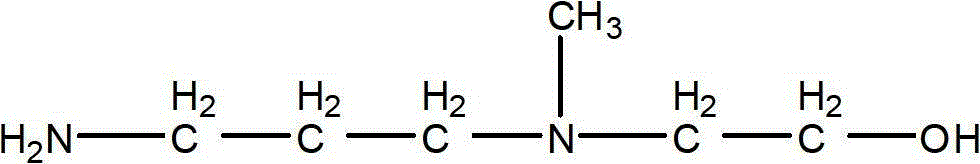

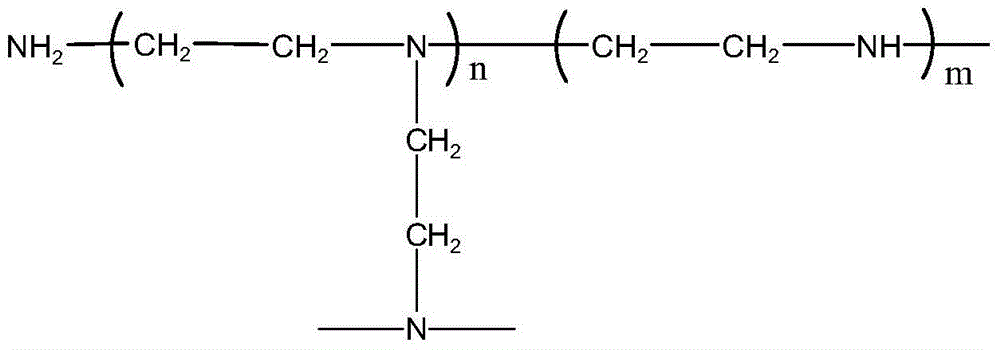

Novel absorbent for capturing and separating carbon dioxide

ActiveCN102974203AReduce heat of reactionImprove stabilityDispersed particle separationBy chemical separationAbsorption capacityDesorption

The invention belongs to the technical field of gas separation and purification and relates to a novel absorbent for capturing and separating CO2 in mixed gas. An active amine compound aqueous solution with a special structure is used as an absorbent; two functional groups, namely a primary amine functional group and a tertiary amine functional group, are contained in the active amine molecules; primary amine is mainly used for improving the absorption rate, and tertiary amine is mainly used for increasing the absorption amount and reducing the desorption temperature; and the two types of amine can promote activation. The active amine compound aqueous solution comes into contact with treated gas to purify gas; and the concentration of the absorbent is 5-80wt%. The absorbent provided by the invention is wide in amine concentration range, high in CO2 absorption rate, large in absorption capacity and low in desorption temperature and causes little corrosion to equipment. The novel absorbent can be widely applied to separation and purification of CO2 in natural gas, transformation gas, flue gas and synthesized gas.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

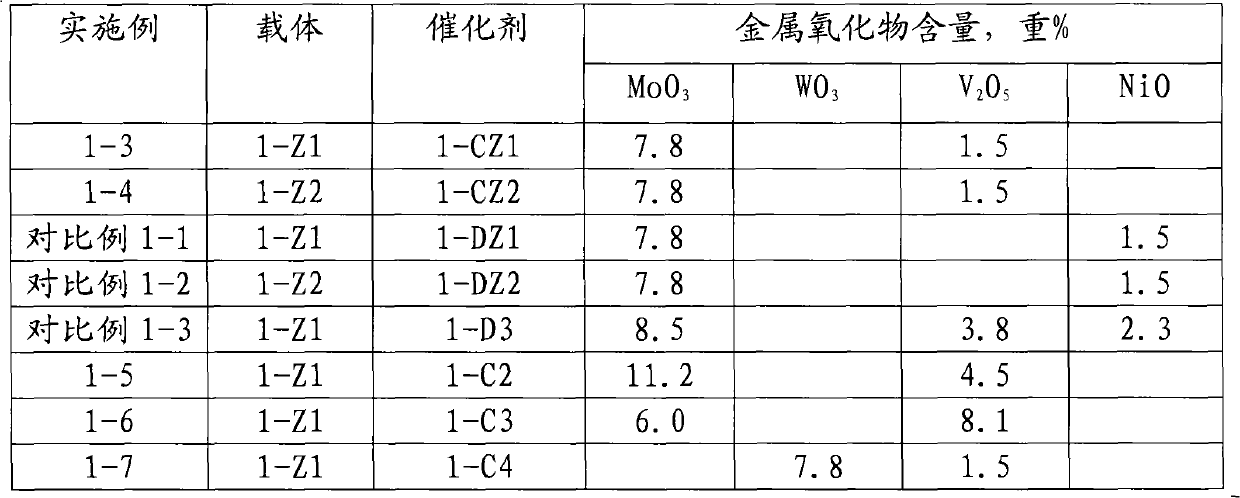

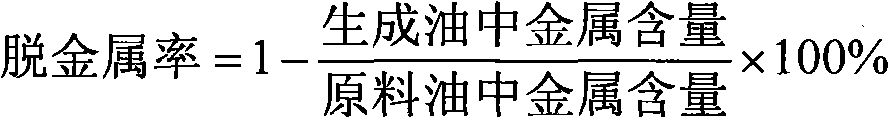

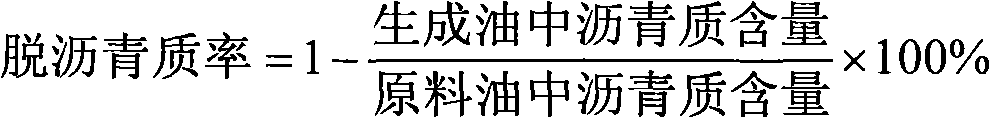

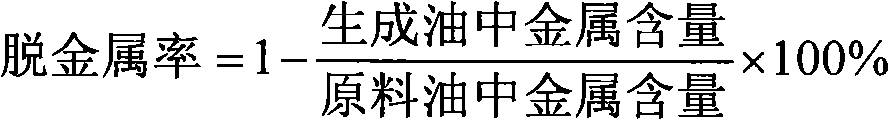

Heavy oil hydrotreating method

InactiveCN103374390AHigh activityProtection stabilityRefining to eliminate hetero atomsFuel oilMetal

The invention discloses a heavy oil hydrotreating method in which raw oil contacts with a hydrodemetallization catalyst and a hydrotreating catalyst in sequence under heavy oil hydrotreating reaction conditions. The heavy oil hydrotreating method is characterized in that the hydrodemetallization catalyst contains a carrier and a hydrogenation reactive metal ingredient carried on the carrier, wherein the hydrogenation reactive metal ingredient is a combination of at least one metal ingredient selected from of VIB group and at least one metal ingredient selected by VB group, counted by oxide and with the hydrodemetallization catalyst as benchmark, the content of the VIB group metal ingredient is 0.2-15wt% and the content of the VB group metal ingredient is 0.2-12 wt%.

Owner:CHINA PETROLEUM & CHEM CORP +1

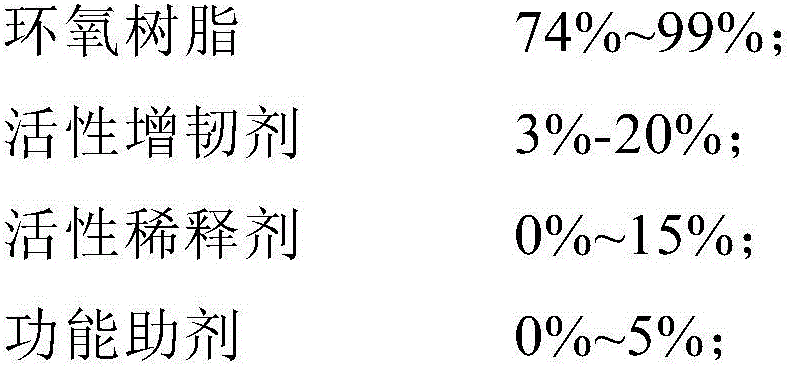

Epoxy-based pouring sealant for end capping of PVDF ultrafiltration membrane assembly and preparation method of epoxy-based pouring sealant

ActiveCN106753131AAbandon the corrosion discoloration effectCorrosion discoloration effect eliminationMacromolecular adhesive additivesEpoxy resin adhesivesFatty amineSewage treatment

The invention discloses an epoxy-based pouring sealant for end capping of a PVDF ultrafiltration membrane assembly and a preparation method of the epoxy-based pouring sealant. The epoxy-based pouring sealant comprises a component A and a component B. The component A is prepared from epoxy resin, an active flexibilizer, an active diluent and a functional assistant. The component B is prepared from degenerative aromatic fatty amine, a flexible amine curing agent, special phenolic aldehyde amine and an accelerant. Degenerative aromatic fatty amine is degenerated based on m-xylylenediamine. Epoxy glue has high toughness, certain flexibility is achieved for the root of membrane silk of the ultrafiltration membrane assembly, and therefore the silk breakage problem is relieved; corrosion of the epoxy glue to the PVDF membrane silk is eliminated, the reddish brown blackening phenomenon of the membrane silk of the ultrafiltration membrane assembly is eliminated, and the membrane silk is kept intact. The requirements of the end capping process of ultrafiltration membrane assemblies of multiple types can be met, adhesion is excellent after end-capping curing is completed, chemical medium resistance is good, the durable ultrafiltration membrane assembly can be prepared, and the ultrafiltration membrane assembly is suitable for being applied to the field of industrial sewage treatment of wide occasions.

Owner:康达新材料(集团)股份有限公司

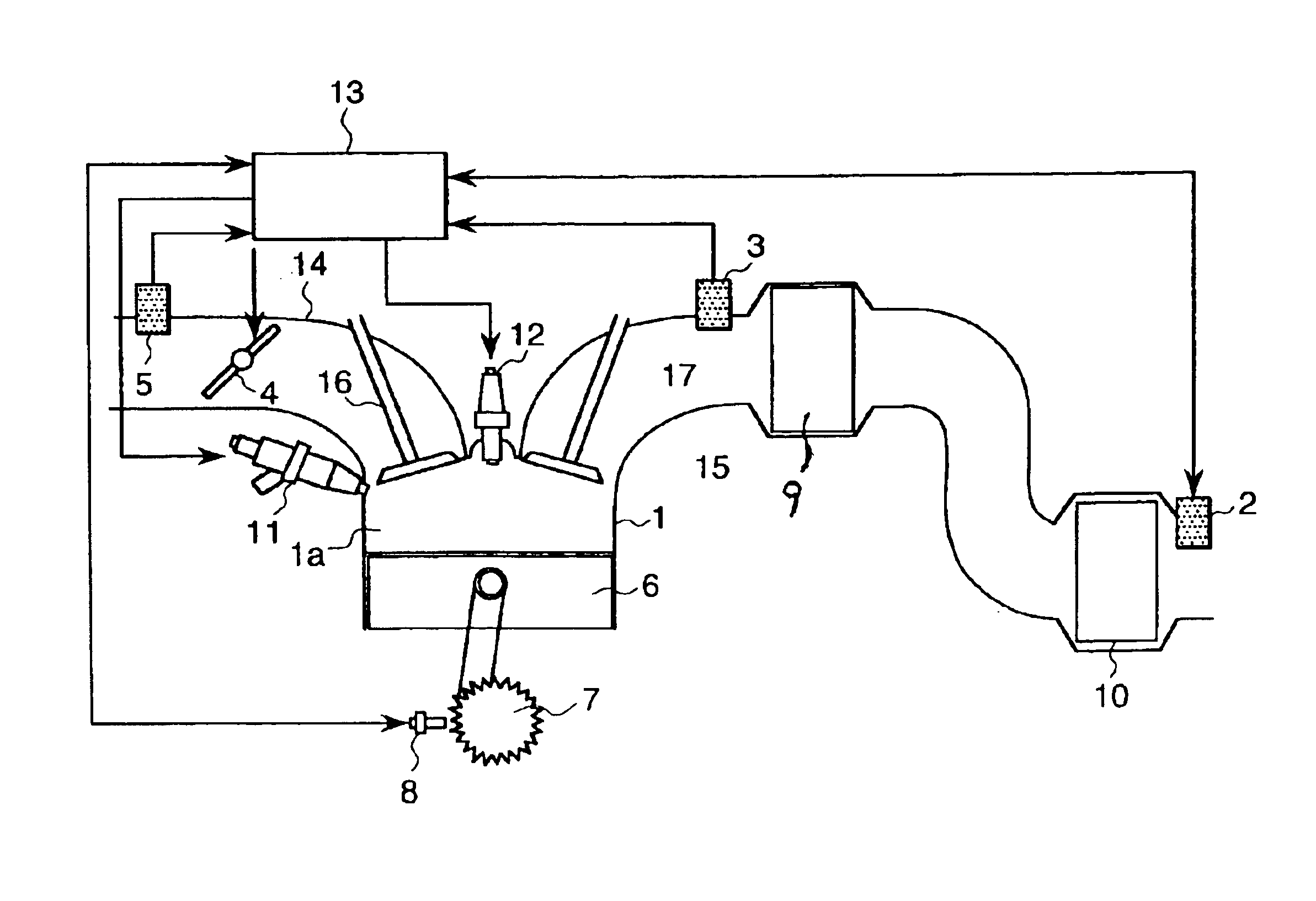

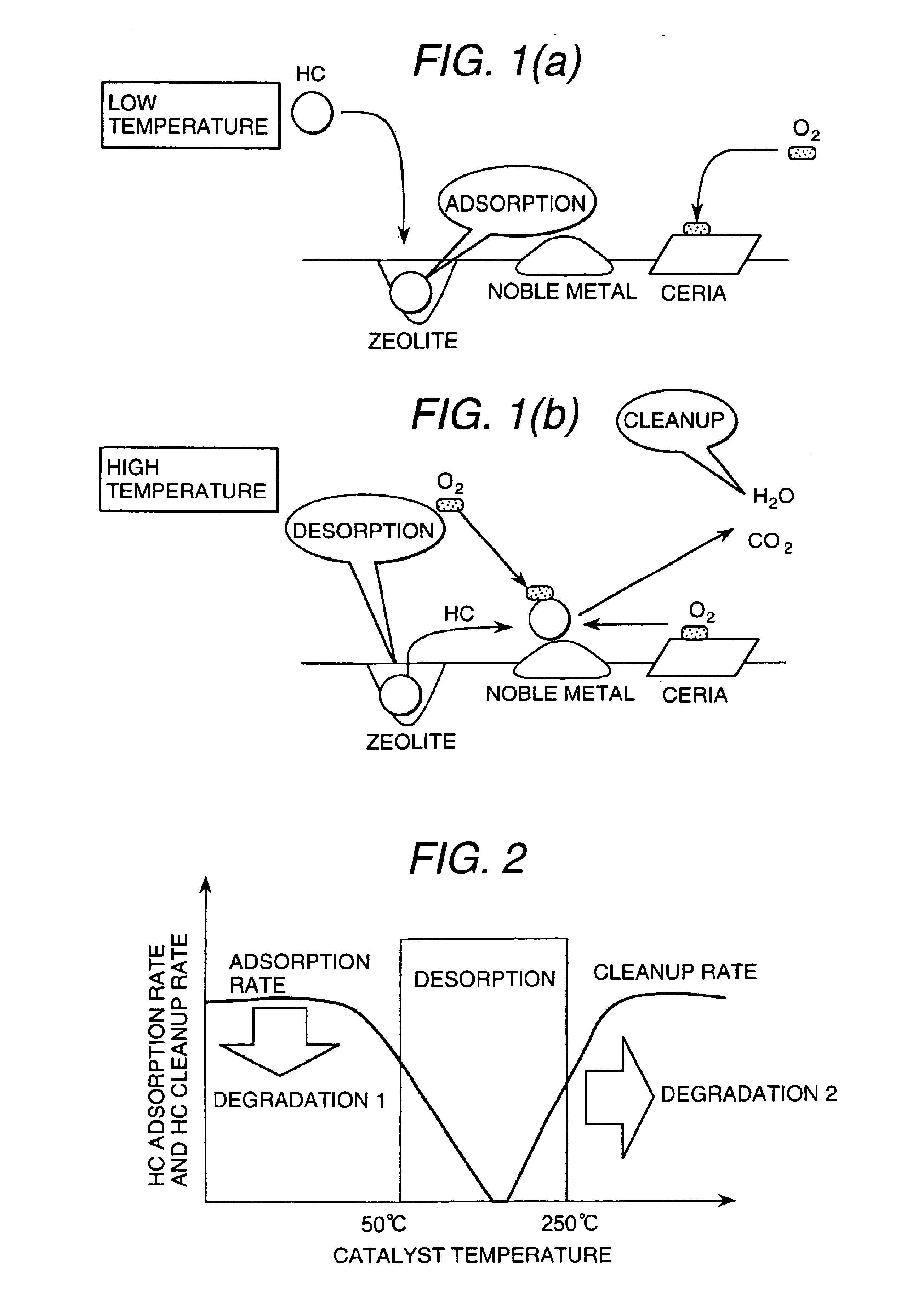

Diagnosis apparatus for internal combustion engine

InactiveUS6883307B2Ensure correct executionAccurately diagnose degradationElectrical controlInternal combustion piston enginesEngineeringInternal combustion engine

In an internal combustion engine diagnosis apparatus comprising a cleanup catalyst arranged on an exhaust pipe of an internal combustion engine and an HC adsorption catalyst arranged downstream of and in parallel to the cleanup catalyst, degradation and failure of the HC adsorption catalyst is accurately diagnosed. The internal combustion engine diagnosis apparatus comprising the cleanup catalyst arranged in the exhaust pipe of the internal combustion engine; and the HC adsorption catalyst arranged in parallel to and downstream of the cleanup catalyst, during high temperature period the HC adsorption catalyst desorbing and cleaning up HC desorbed during low temperature period, wherein degradation of the HC adsorption catalyst is diagnosed based on a gradient of temperature of the HC adsorption catalyst during a period when temperature of the HC adsorption catalyst is within a range of 50° C. to 250° C.

Owner:HITACHI LTD

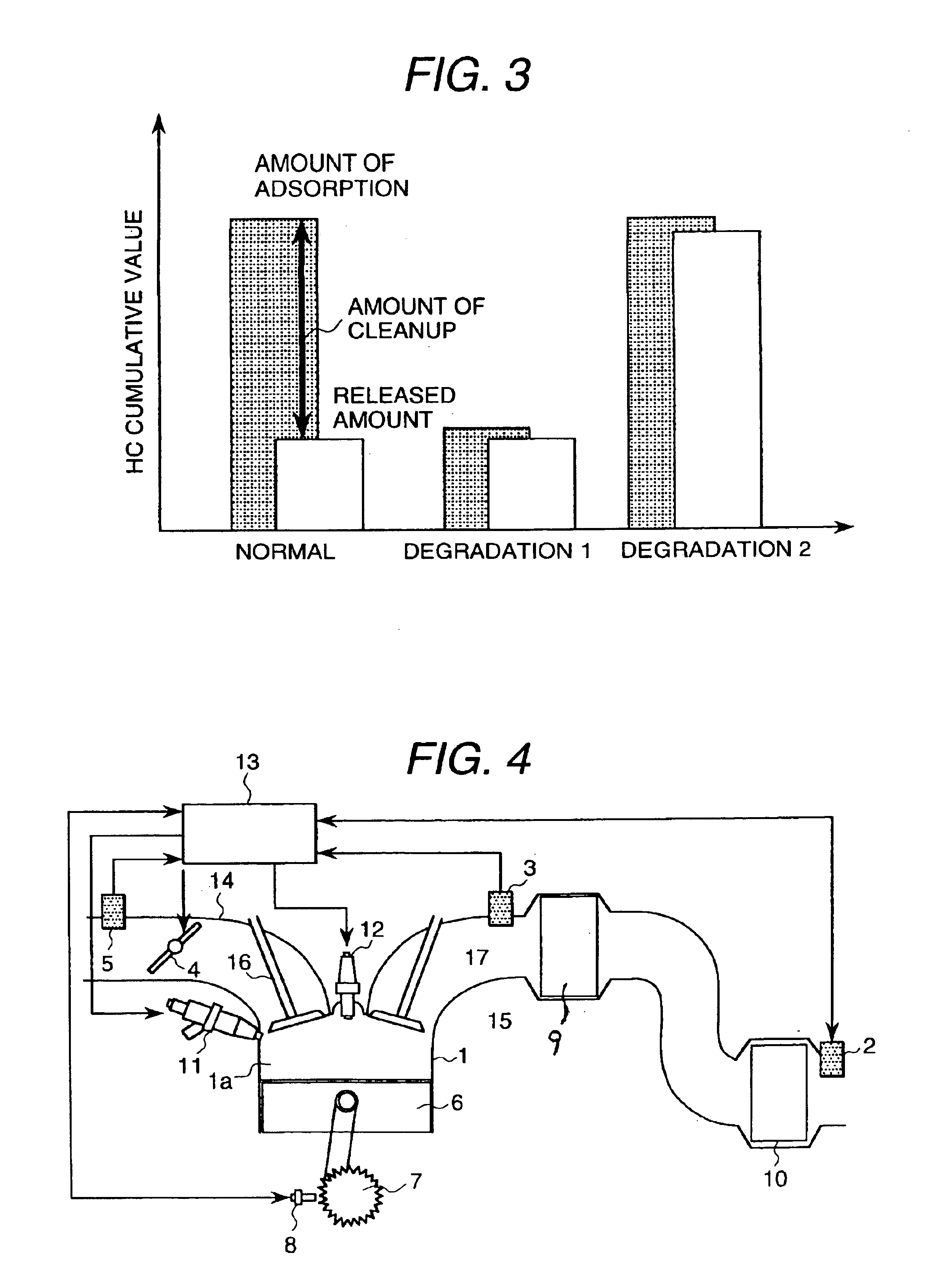

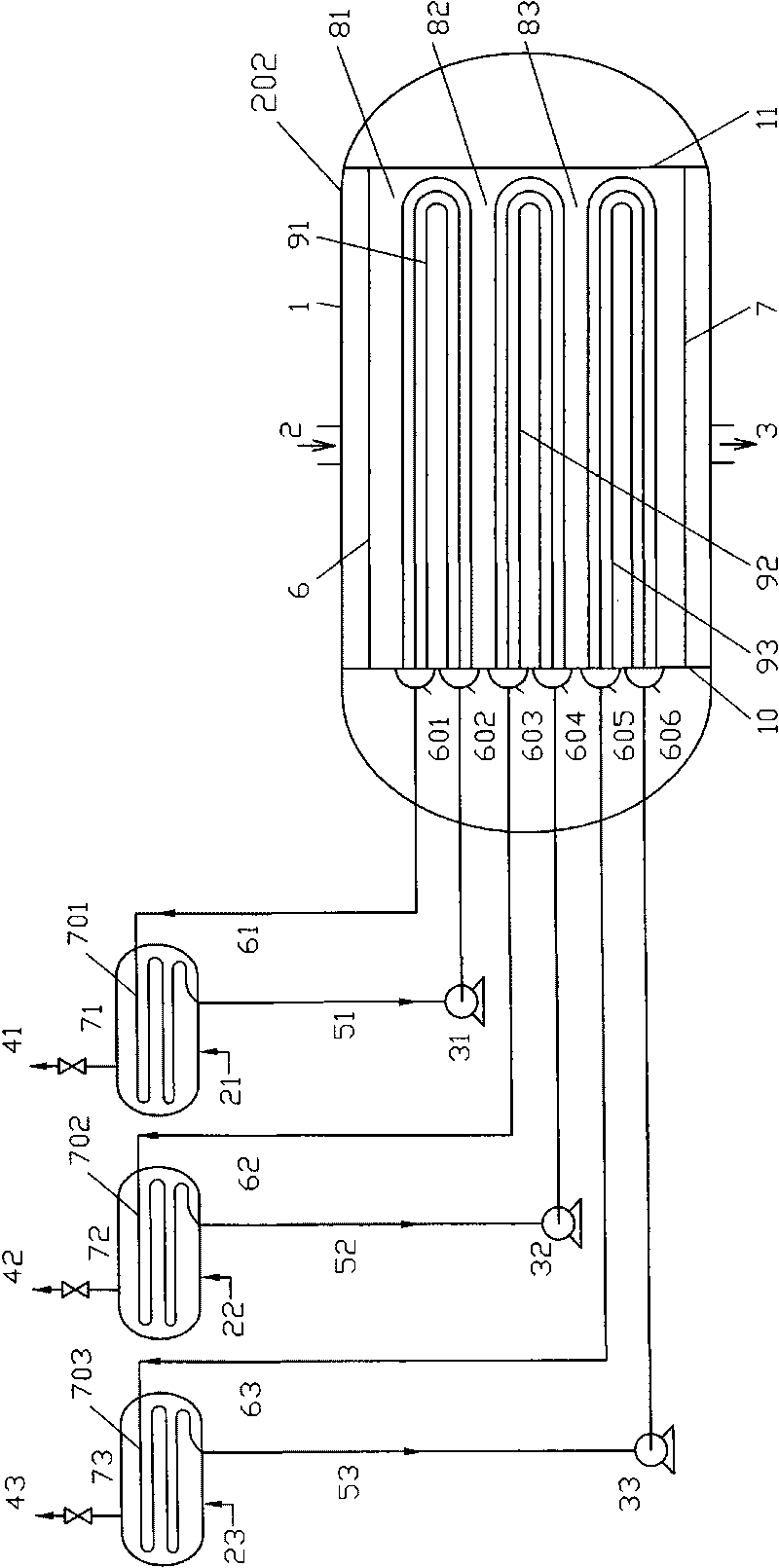

Method and equipment for preparing hydrocarbon by methyl alcohol or/ and dimethyl ether

ActiveCN101723775AImprove heat transfer abilityRelease more heat of reactionHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionAlcoholFixed bed

The invention discloses a method and equipment for preparing hydrocarbon by methyl alcohol or / and dimethyl ether. The invention is mainly characterized in that raw material gases, such as methyl alcohol or / and dimethyl ether and the like pass through fixed bed reaction composition equipment for catalysis to generate hydrocarbon, wherein the fixed bed reaction combination equipment is at least provided with two reaction zones, and each reaction zone is provided with a heat exchange tube set capable of independently adjusting heat exchange medium temperature; after reaction gases separate target product hydrocarbon and water by heat exchange and cooling, expect that less chillout recycle gas is mixed with raw material gas, reaction for generating target product hydrocarbon is carried out.The invention has the beneficial effects of small catalyst layer temperature difference, low recycle ratio, high synthetic ratio, small investment, high output, energy saving and consumption reduction.

Owner:杭州林达化工技术工程有限公司

Preparation method of transparent self-toughening dicyandiamide/epoxy resin-based composite material

The invention belongs to the technical field of application of high performance epoxy resin and particularly relates to a preparation method of a transparent self-toughening dicyandiamide / epoxy resin-based composite material, in particular to a preparation method of a transparent self-toughening epoxy resin composition with low heat release, a heavy-thickness prepreg unidirectional tape and a composite material. The composition comprises the following raw materials in parts by weight: 60-100 parts of liquid epoxy resin, 0-40 parts of solid epoxy resin, 1.0-12 parts of a dicyandiamide curing agent and 0.5-6 parts of an accelerant. The epoxy resin is prepared by adopting a solution reaction manner; compared with a general dicyandiamide / epoxy resin system, a system in the invention has the advantages that the peak heat flux is decreased by 48% or higher, the heat release is decreased by 38% or higher, and the reaction heat is low; moreover, a resin casting body has 3.5% or more of breaking elongation, 80MPa or higher of tensile strength and 24kJ / m<2> of higher impact strength and has good toughness without adding a toughening agent; 130-DEG C medium temperature curing can be realized, and a cured product is transparent.

Owner:AVIC BASIC TECH RES INST

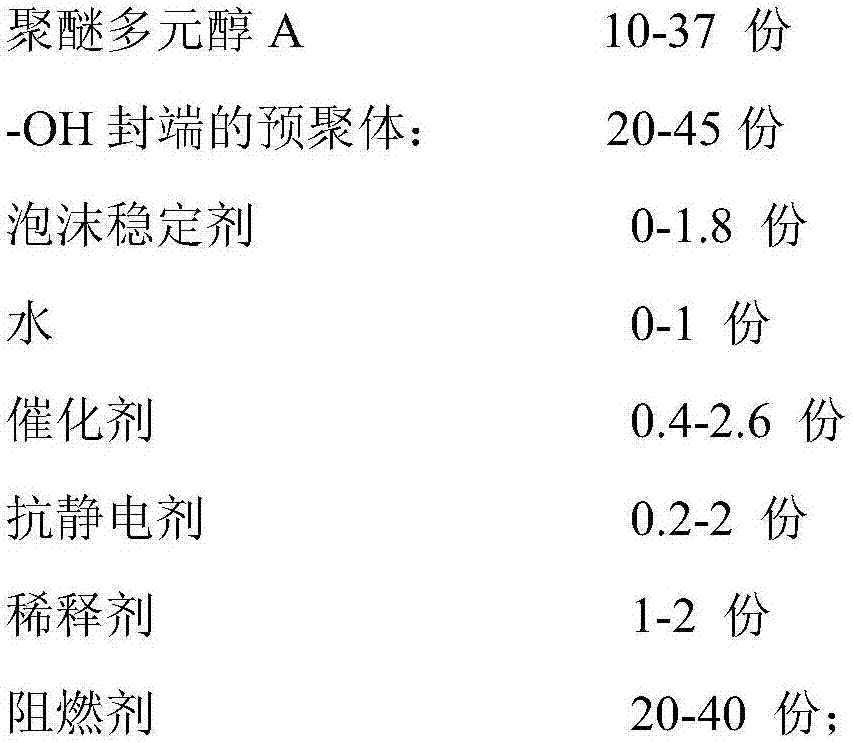

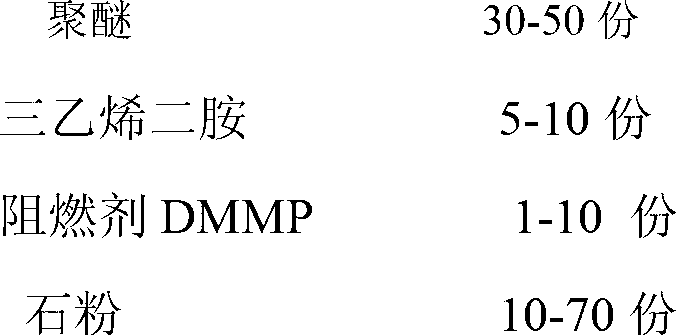

Macromolecule grouting reinforcement material for coal mines and preparation method of macromolecule grouting reinforcement material

InactiveCN107417876AReduce heat of reactionLow reaction temperatureReaction temperatureFire retardant

The invention relates to a macromolecule grouting reinforcement material for coal mines and a preparation method of the macromolecule grouting reinforcement material. The macromolecule grouting reinforcement material contains a component A and a component B, wherein the component A contains the following components in parts by weight: 10-37 parts of polyether polyol A, 20-45 parts of a -OH-terminated prepolymer, 0-1.8 parts of a foam stabilizer, 0-1 parts of water, 0.4-2.6 parts of a catalyst, 0.2-2 parts of an antistatic agent, 1-2 parts of a diluent and 20-40 parts of a flame retardant; and the component B contains the following components in parts by weight: 10-25 parts of polymethylene polyphenyl isocyanate, 50-75 parts of a -NCO-terminated prepolymer, 1-2 parts of a diluent and 10-30 parts of a flame retardant. According to the macromolecule grouting reinforcement material, the reaction heat is greatly reduced, so that the reaction temperature in the use process of the material is decreased, and the safety hazards in the use process of the material are eliminated; the mechanical property and flame-retardant anti-static property of the material can meet underground use requirements; and the material is low in odor, non-toxic, non-corrosion and harmless to a human body.

Owner:山东润义金新材料科技股份有限公司

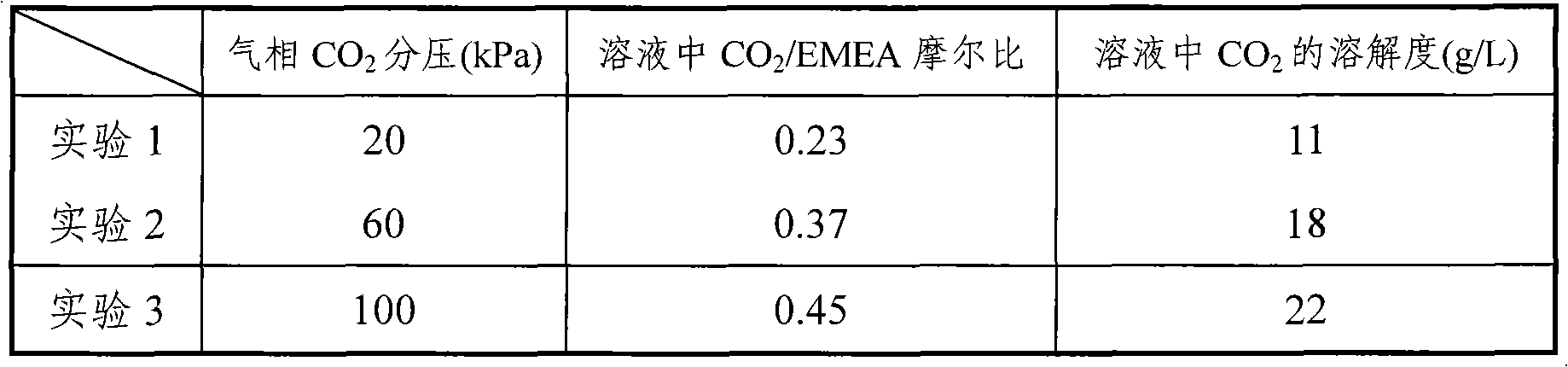

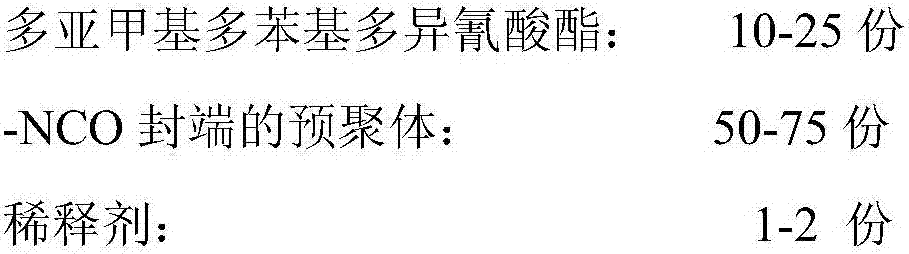

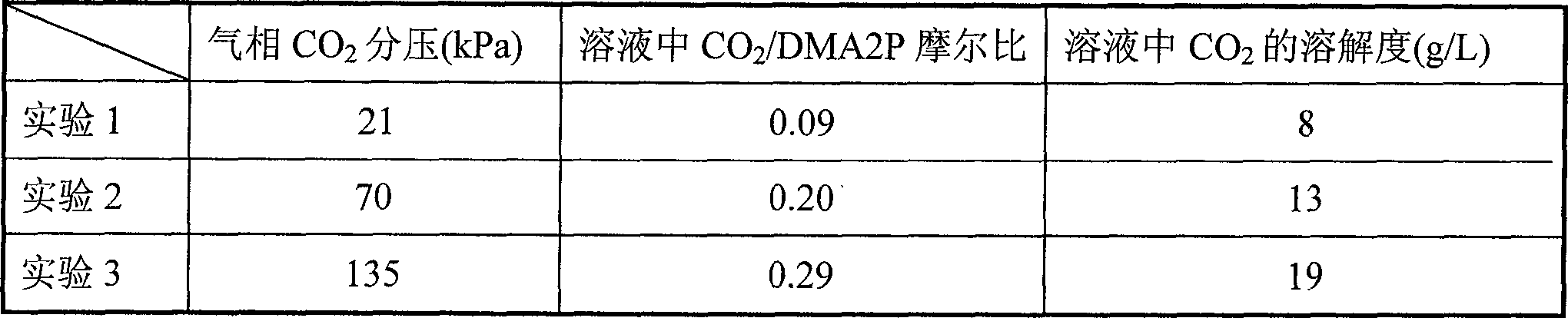

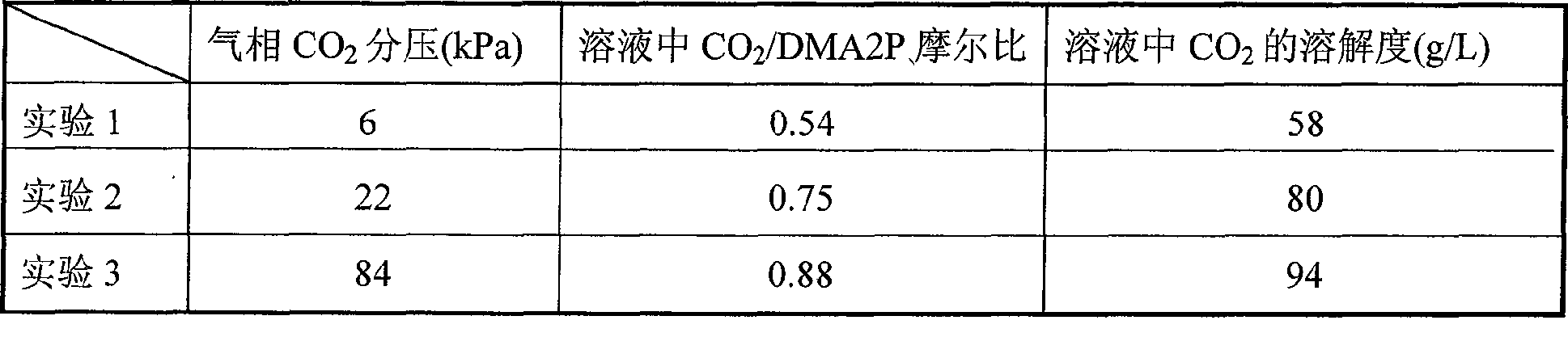

Absorbing solvent for capturing or separating carbon dioxide from gas mixture or liquid gas

InactiveCN101480556AImprove solubilityImprove the desorption effectDispersed particle separationBy absorptionSolubilityDesorption

The invention belongs to the field of chemical materials, in particular relates to an absorbing solvent for catching and separating carbon dioxide from gas mixture or liquefied gas. The solvent comprises 15 to 60 weight percent of 1-dimethylamino-2-propanol (DMA2P for short) and 40 to 85 weight percent of other components. The other components comprise one or more of monoethanol amine, normal propyl alcohol amine, hydroxyethyl piperazine, 2- methyl piperazine, water, physical solvent, inorganic salt or addition agents. The 1-dimethylamino-2-propanol has large solubility to the carbon dioxide, good desorption effect, lower reaction heat of absorption reaction and lower energy consumption to the catching and the separation of the carbon dioxide. Meanwhile, the 1-dimethylamino-2-propanol is a tertiary amine, has better molecule stability and can reduce the degradation loss of the solvent in the using process.

Owner:TSINGHUA UNIV

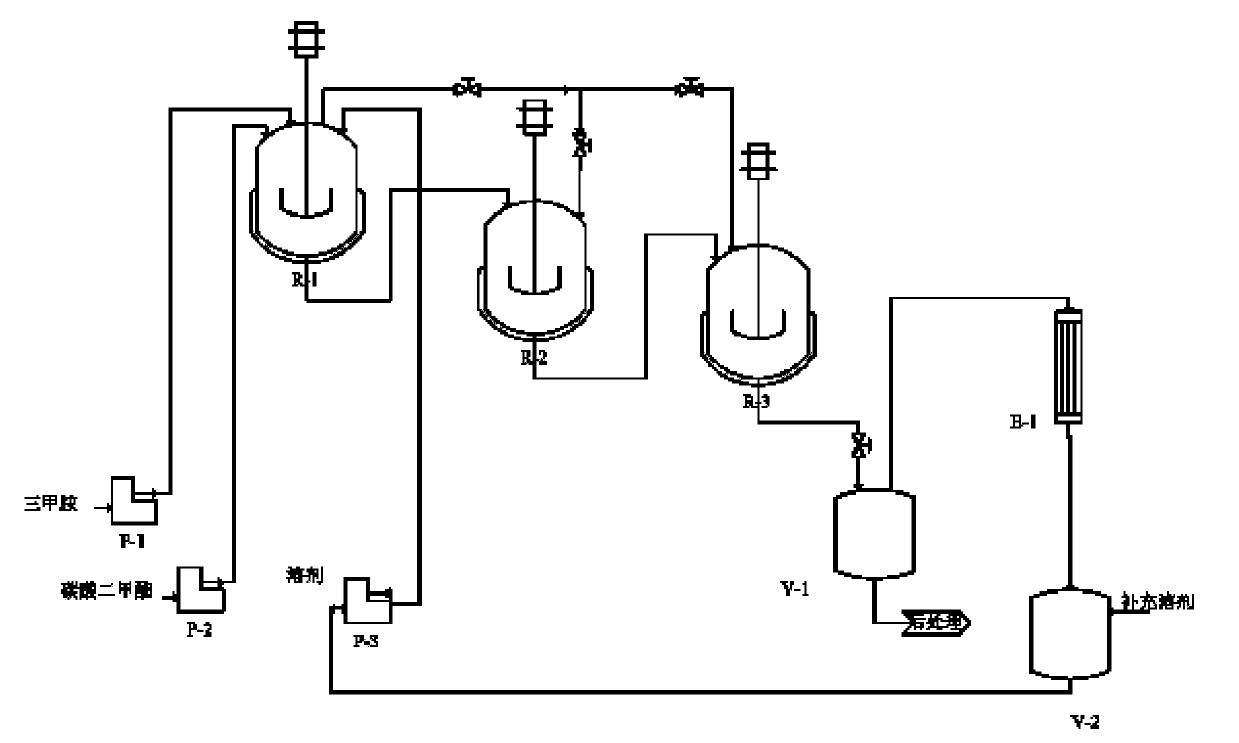

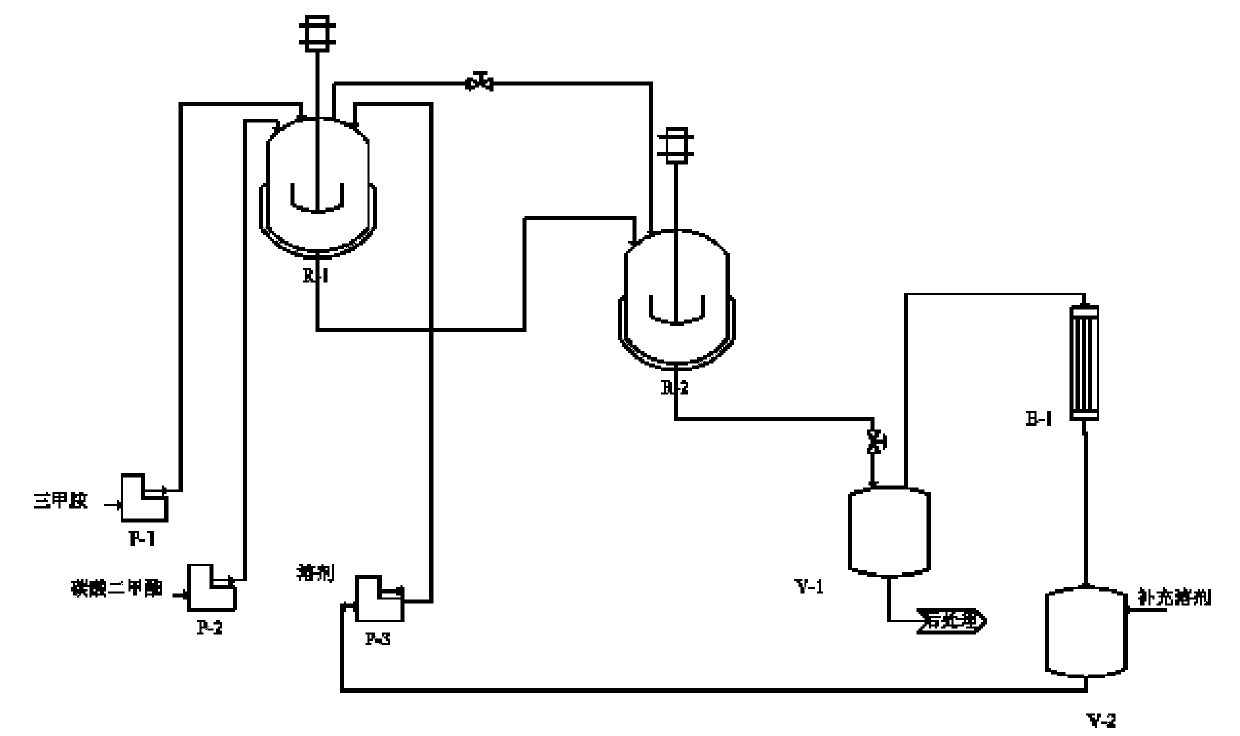

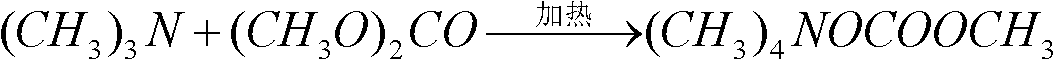

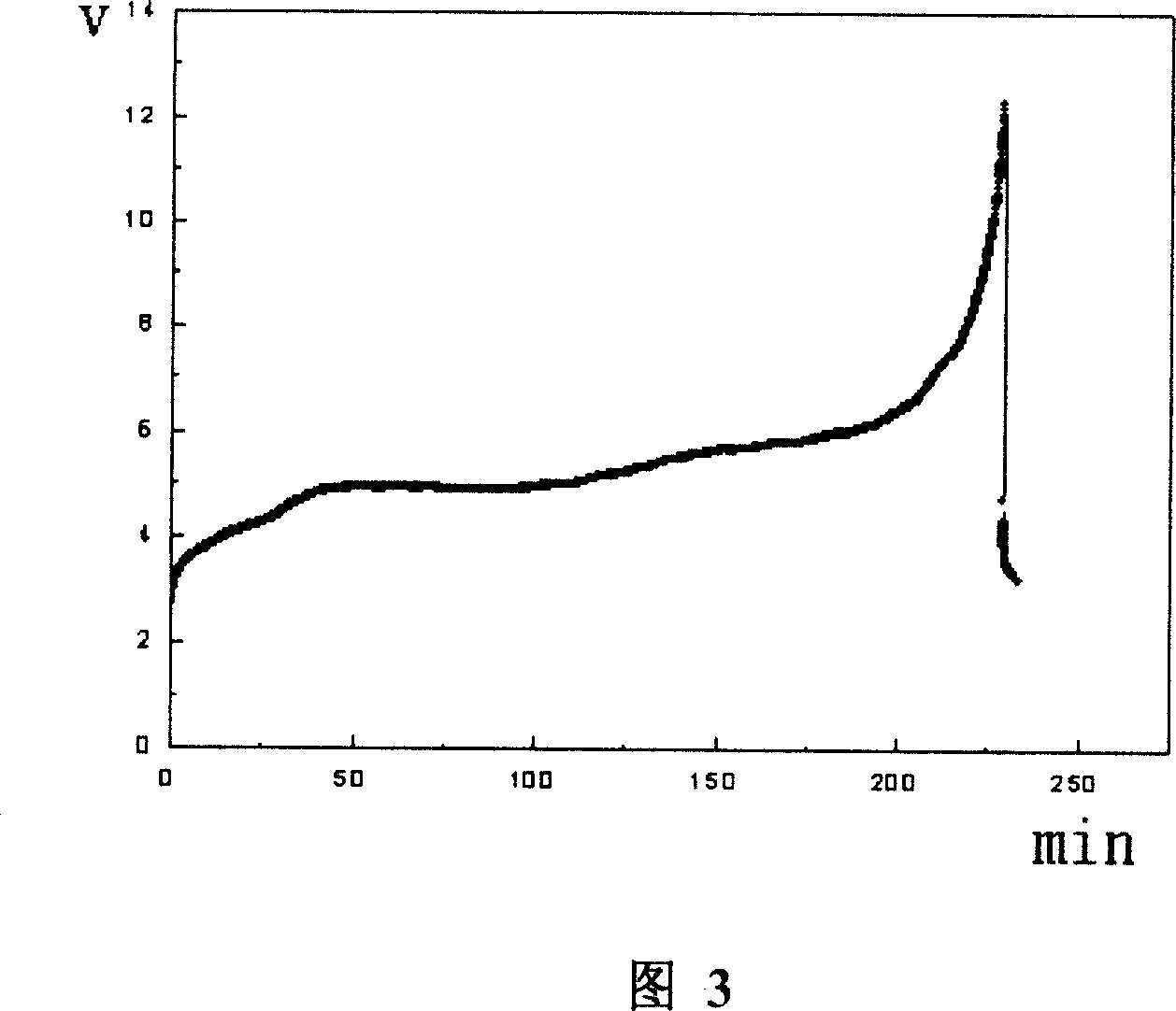

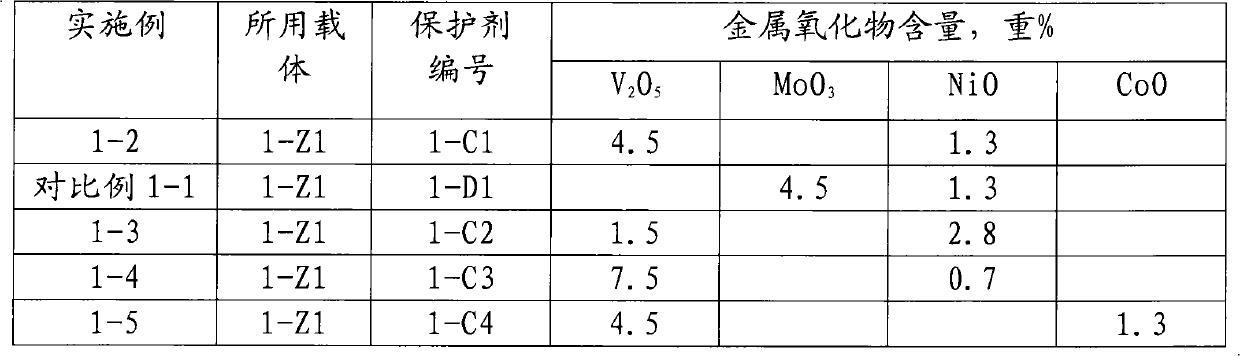

Method and device of continuously synthesizing tetramethyl ammonium carbonate by multi-reactors in series

InactiveCN101992055ASimple designMild reaction conditionsAmino preparation from aminesChemical/physical/physico-chemical stationary reactorsAutomatic controlGas phase

The invention discloses a method and a device of continuously synthesizing tetramethyl ammonium carbonate by multi-reactors in series. Liquid-phase reaction materials in each reactor are connected in series through a pipeline. Gas-phase reaction materials are connected in parallel to keep the pressure between reactors balanced. The reaction materials flow into a next stage reactor from a previousstage reactor through the difference of liquid level in the reactors. The two stage reactors have a difference of liquid level of 0.5-1.0 m. The tetramethyl ammonium carbonate is prepared by continuously adding raw materials including dimethyl carbonate, trimethylamine and solvent methanol to a first stage tank reactor in a mole ratio of 1:0.8:3-1:1.5:8, leading a reaction mixture to continuouslyflow out from the last stage tank reactor, recycling a reaction solvent and an unconverted reactant by flash evaporation, then re-adding to the first stage tank reactor for recycling, and finally removing the solvent and the unconverted reactant. The operation pressure of the invention is the lowest, the reaction is stable, and continuous operation and automatic control are realized. Simultaneously, the reaction materials are heated to a reaction temperature by reaction heat, so the energy is saved and the production cost is reduced.

Owner:CANGZHOU SUNHEAT CHEM

Electro-chemistry energy storing and converting device

ActiveCN101110477ALarge capacityReduce heat of reactionActive material electrodesSecondary cellsIonElectrochemical energy storage

The present invention relates to an electrochemical energy storage and conversion device belonging to the technical field of lithium ion battery, which comprises a positive electrode, a negative electrode, a diaphragm and electrolyte and is characterized that the positive electrode is composed of transitional metal lithium ion compound capable of absorbing / discharging lithium ions. The negative electrode is composed of active lithium ion battery material with oxidation and reduction potential higher 1.0V vs. Li / Li+ and mixture or composite of active carbons. The present invention provides a novel energy storage device characterized by safety and high specific energy during high-power discharge and has the advantages of high specific power, great safety and long service life, etc.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

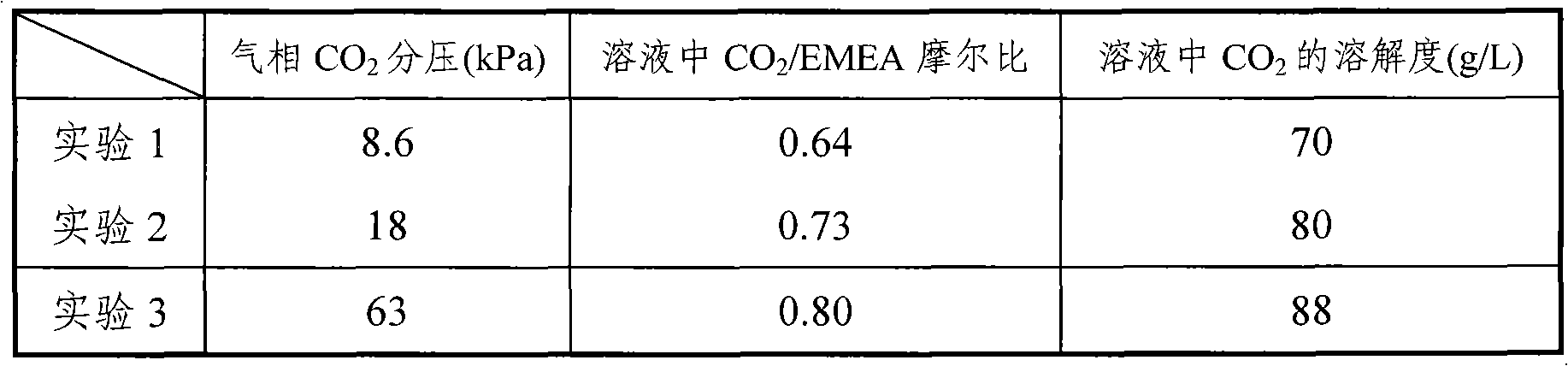

Mixed absorbent for gathering or separating carbon dioxide

The invention relates to a mixed absorbent for gathering or separating carbon dioxide from a gas mixture, which mainly comprises the following components in percentage by weight: 21 to 45 percent of diethylethylenediamine, 5.0 to 9.9 percent of primary amine containing one nitrogen atom and / or secondary amine containing one nitrogen atom, and the balance of water. The absorbent has high solubility and good desorption effect on low-pressure carbon dioxide, simultaneously absorbs less reaction heat, and has low energy consumption for gathering or separating the low-pressure carbon dioxide; because the diethylethylenediamine is tertiary amine and has high boiling point and better molecular stability than the primary amine and secondary amine, so the degradation loss of a solvent in the using process can be greatly reduced. The mixed absorbent can be used for gathering or separating various normal-pressure gas mixtures, such as carbon dioxide in flue gas discharged from coal fired power plants, and enterprises in the steel, cement, petrochemical engineering and other industries.

Owner:TSINGHUA UNIV

Heavy oil hydrotreating method

ActiveCN103374391AMaintain stabilityReduce heat of reactionRefining to eliminate hetero atomsFuel oilMetal

The invention discloses a heavy oil hydrotreating method, comprising a step of sequentially contacting raw oil with a hydrogenation activity protective agent and a hydrotreating catalyst under heavy oil hydrotreating reaction conditions. The heavy oil hydrotreating method is characterized in that the hydrogenation activity protective agent contains a carrier and a hydrogenation reactive metal ingredient carried on the carrier, wherein the hydrogenation reactive metal ingredient is a combination of at least one metal ingredient selected from of VIII group and at least one metal ingredient selected by VB group, counted by oxide and with the protective agent as benchmark, the content of the VIII group metal ingredient is 0.2-15wt% and the content of the VB group metal ingredient is 0.2-15 wt%.

Owner:CHINA PETROLEUM & CHEM CORP +1

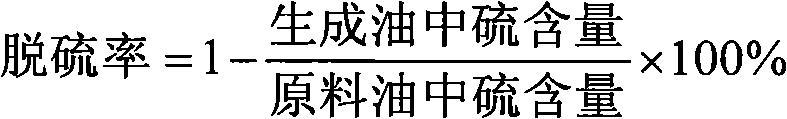

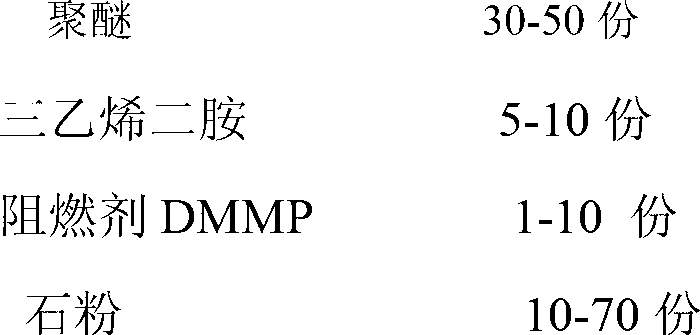

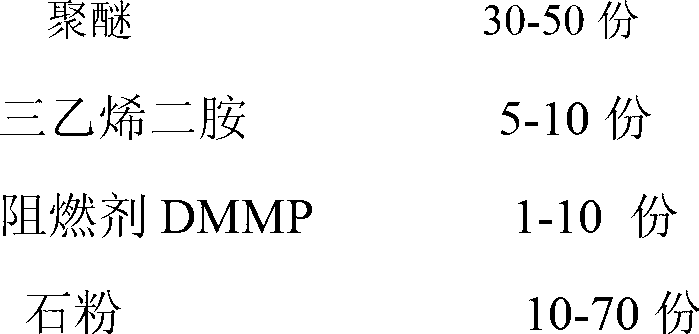

Polyurethane composite material and preparation method thereof

InactiveCN102993403AImprove flame retardant performanceReduce heat of reactionElastomerFire retardant

The invention relates to a polyurethane composite material and a preparation method thereof. The polyurethane composite material is formed by a group A material and a group B material, wherein the group A material contains the following components in parts by mass; 10-70 parts of polyether, 5-10 parts of triethylene diamine, 1-10 parts of fire retardant DMMP (Dimethyl Methyl Phosphonate) and 70-10 parts of stone powder; the group B material contains the following components in parts by mass; 10-90 parts of isocyanate and 90-10 parts of the stone powder; the equal mass of the group A material and the equal mass of the group B material are mixed uniformly to obtain the polyurethane composite material. Compared with the existing polyurea elastic body, the polyurethane composite material has the characteristics of high inflaming retarding, low reaction heat, anti-static electricity and the like. The polyurethane composite material can replace the traditional polyurea elastic body to be widely applied to the fields of coal mine anchor-plate retaining, anchoring, rock mass reinforcing, closing, plugging, emergency, water resistance, buildings, water and electricity, tunnels, metros and the like.

Owner:ANHUI JIATAI COAL MINING TECH

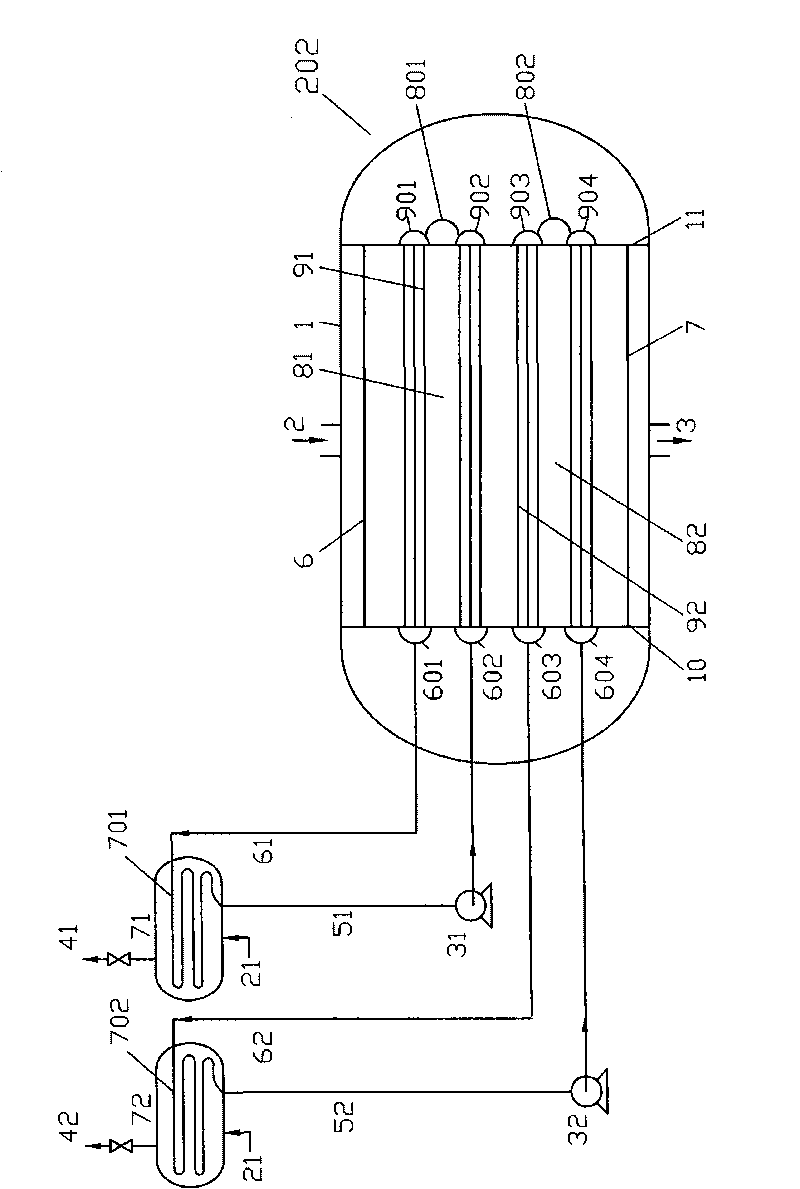

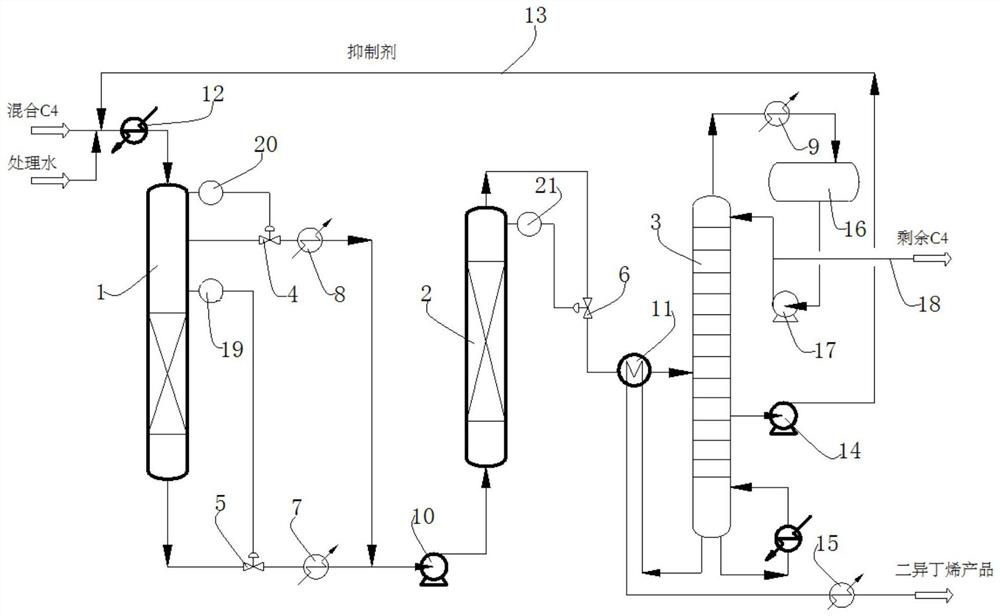

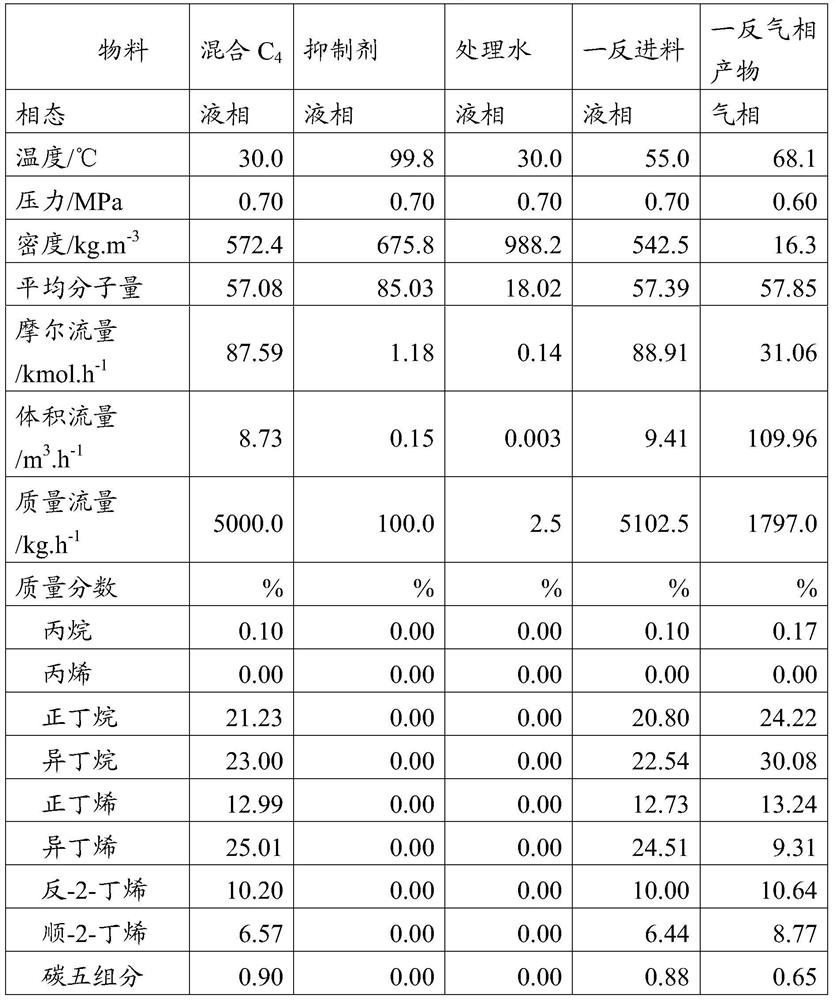

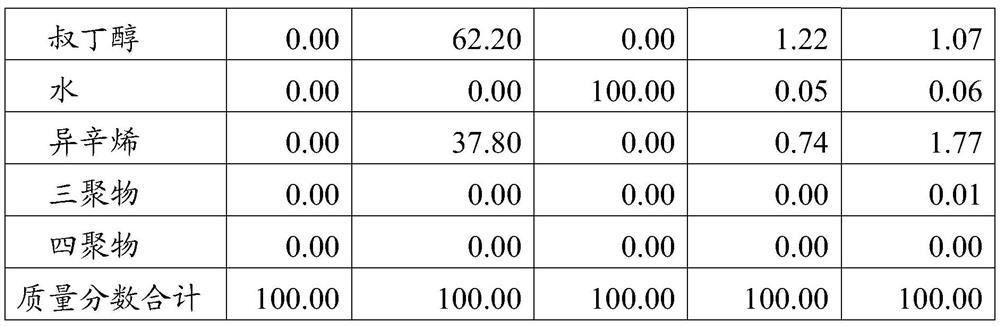

Isobutene polymerization reaction method and device

ActiveCN111606772AImprove conversion rateLow costChemical industryDistillation purification/separationPhysicsChemistry

The invention discloses an isobutene polymerization reaction method and device, and belongs to the field of petrochemical engineering. The reaction method comprises the following steps: carrying out afirst superposition reaction on a reaction material containing mixed C4 in a first superposition reactor at a first set pressure and a first set temperature; cooling the first reaction product from the first overlapping reactor to a second set temperature, and carrying out a second overlapping reaction in a second overlapping reactor under a second set pressure; and fractionating the second reaction product from the second superposition reactor to obtain a diisobutylene product. Wherein the first set temperature is the bubble point temperature of the mixed C4 under the first set pressure, andthe first set temperature is lower than the deactivation temperature of the catalyst in the first superposition reactor; the second set pressure is greater than the first set pressure. By utilizing the method, the conversion rate of converting isobutene into diisobutene can be remarkably improved, and the cost can be reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

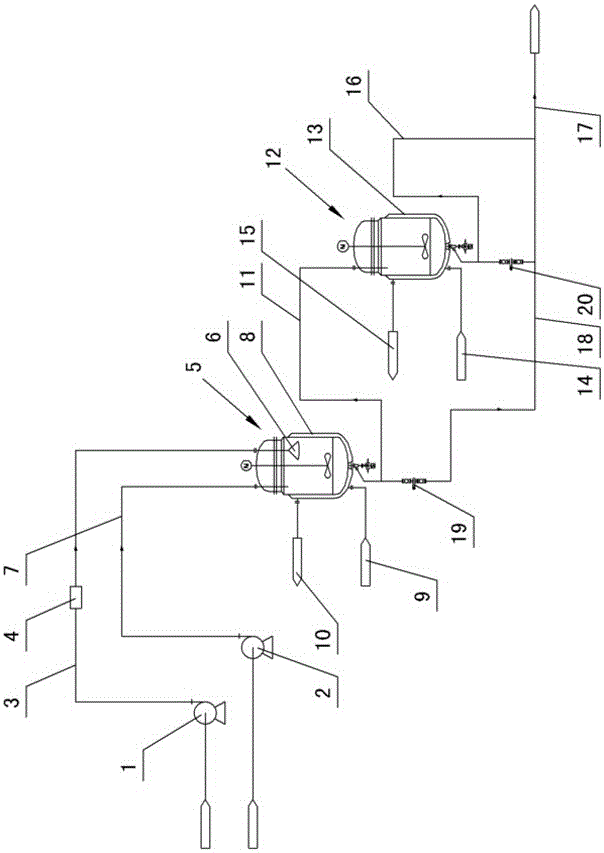

Double-kettle type continuous nitration reaction device

ActiveCN105013418AHigh yieldReduce heat of reactionChemical/physical/physico-chemical nozzle-type rreactorsNitrationFeed pump

The invention relates to a double-kettle type continuous nitration reaction device. The double-kettle type continuous nitration reaction device is characterized by comprising a nitric acid feed pump and a concentrated sulfuric acid feed pump, wherein the nitric acid feed pump is connected to a nitric acid feed pump; a flowmeter is arranged on the nitric acid feed pipe; the other end of the nitric acid feed pipe is connected to a primary reaction kettle; a spray head is arranged in the primary reaction kettle; the spray head is connected with the other end of the nitric acid feed pipe; the concentrated sulfuric acid feed pump is connected to the primary reaction kettle through the concentrated sulfuric acid feed pipe; a primary jacket is arranged outside the primary reaction kettle; the primary jacket is connected to a primary cooling water inlet and a primary cooling water outlet; the lower part of the primary reaction kettle is connected to a primary U-shaped bend pipe; the other end of the primary U-shaped bend pipe is connected to a secondary reaction kettle; the height of a nitric acid inlet of the secondary reaction kettle is lower than that of a nitric acid inlet of the primary reaction kettle; a secondary jacket is arranged outside the secondary reaction kettle; the secondary jacket is connected to a secondary cooling water inlet and a secondary cooling water outlet; the lower part of the secondary reaction kettle is connected to a secondary U-shaped bend pipe; and the secondary U-shaped bend pipe is connected to a discharge pipe.

Owner:JIANGSU LIANHE CHEM TECH +1

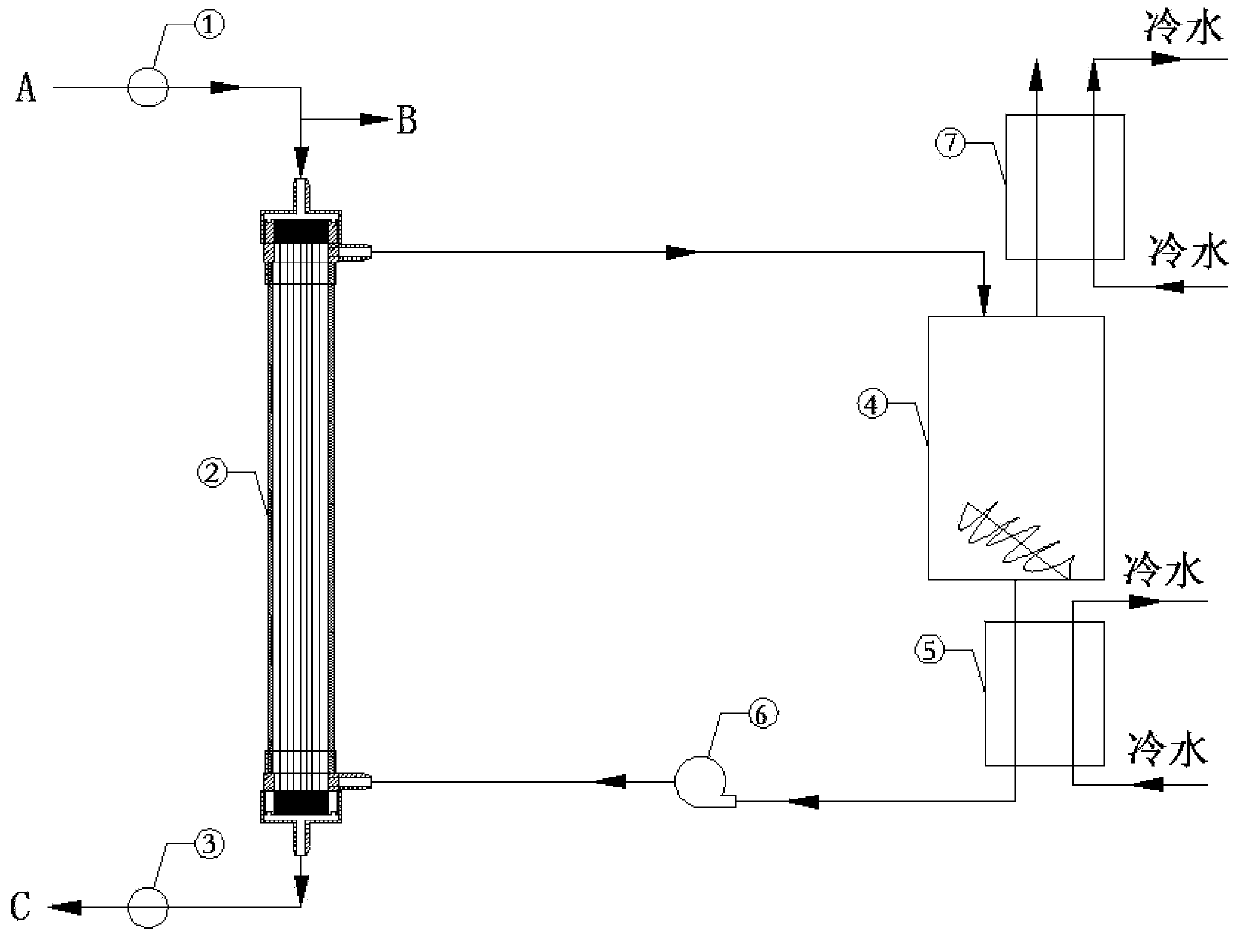

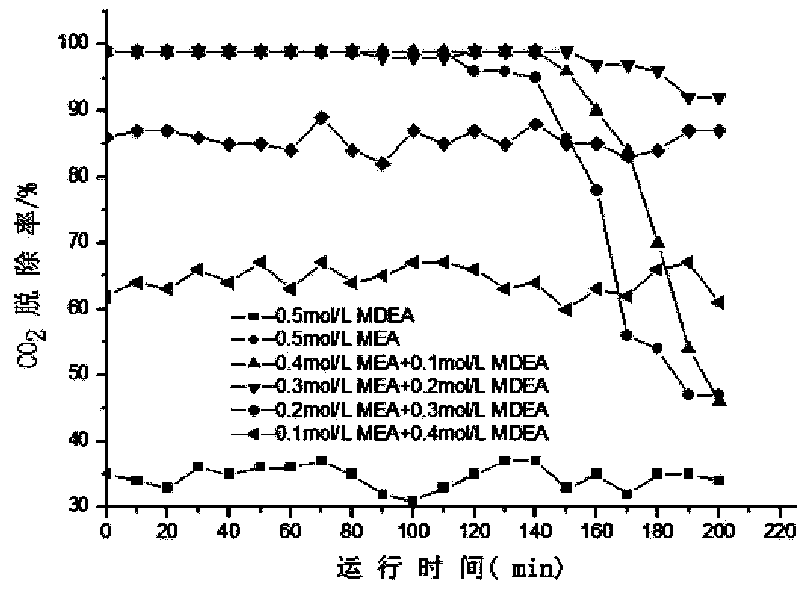

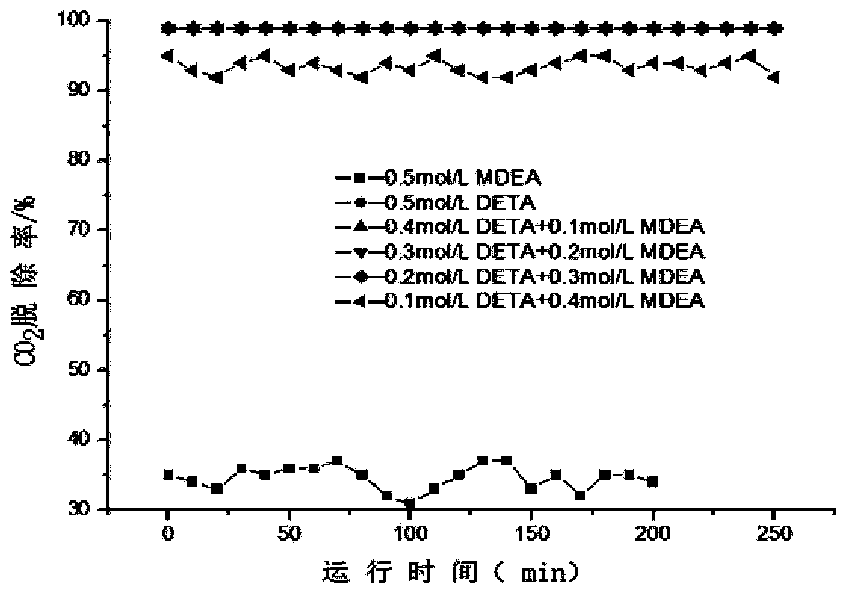

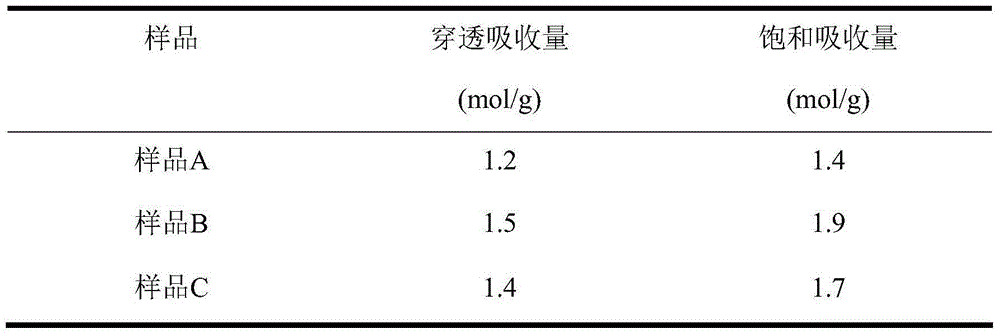

Composite absorbent for capturing carbon dioxide in flue gas based on membrane contactor and use method thereof

ActiveCN103357248AStrong absorption capacityReduce heat of reactionDispersed particle separationBy membranesDesorptionFlue gas

The invention relates to the technical field of resource environment and chemical engineering and especially relates to a composite absorbent for capturing carbon dioxide in flue gas based on a membrane contactor and a use method thereof. The composite absorbent is obtained by compounding of methyldiethanolamine and an alcohol amine. The alcohol amine is a polyamine containing 1-4 amido groups or imino groups. The composite absorbent can be mixed with water according to different ratios. A total amine concentration is in a range of 0.1-1mol / L. For the balance of economy and effects, the optimal total amine concentration is 0.5mol / L. The composite absorbent has a strong capability of absorption of acid gas such as CO2 under a certain condition, is superior to the traditional absorbent containing ethanol amine as a main ingredient, has the advantages of less reaction heat, low desorption temperature, stable chemical properties and no toxicity, and is conducive to industrial application.

Owner:BEIJING JIAOTONG UNIV

Carbon dioxide absorbent used for capturing after combustion

ActiveCN104645782APromote absorptionImprove stabilityDispersed particle separationAir quality improvementAntioxidantCo2 absorption

The invention relates to a carbon dioxide absorbent used for capturing after combustion. The carbon dioxide absorbent is characterized by being composed of a main absorbent polyethyleneimine (PEI), auxiliary absorbents TEPA, MEA, MDEA, DEA and PZ, an antioxidant sodium sulfite, potassium sulfite or ammonium sulfite, a corrosion inhibitor sodium molybdate, sodium chromate, sodium vanadate or ammonium molybdate, and water. The molecular weight of polyethyleneimine (PEI) is 300-500; polyethyleneimine has a branch shape, and the molecule comprises three amino groups including primary amine, secondary amine and tertiary amine; and compared with other types of organic amines, polyethyleneimine has higher amine density. A compound absorption solution has relatively high carbon dioxide absorption amount, relatively rapid absorption speed, low regeneration energy consumption and high stability, so that the absorbent has a very great application prospect in the aspect of capturing carbon dioxide after combustion.

Owner:SHANGHAI BOILER WORKS

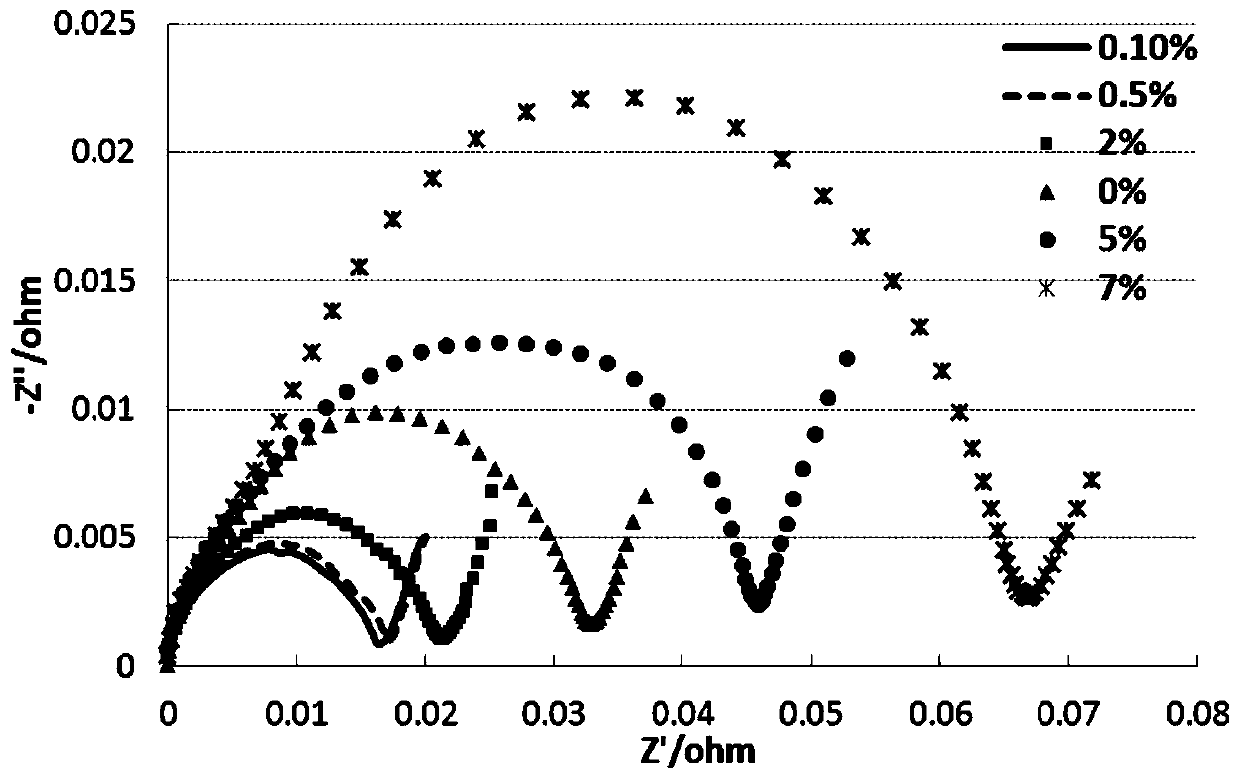

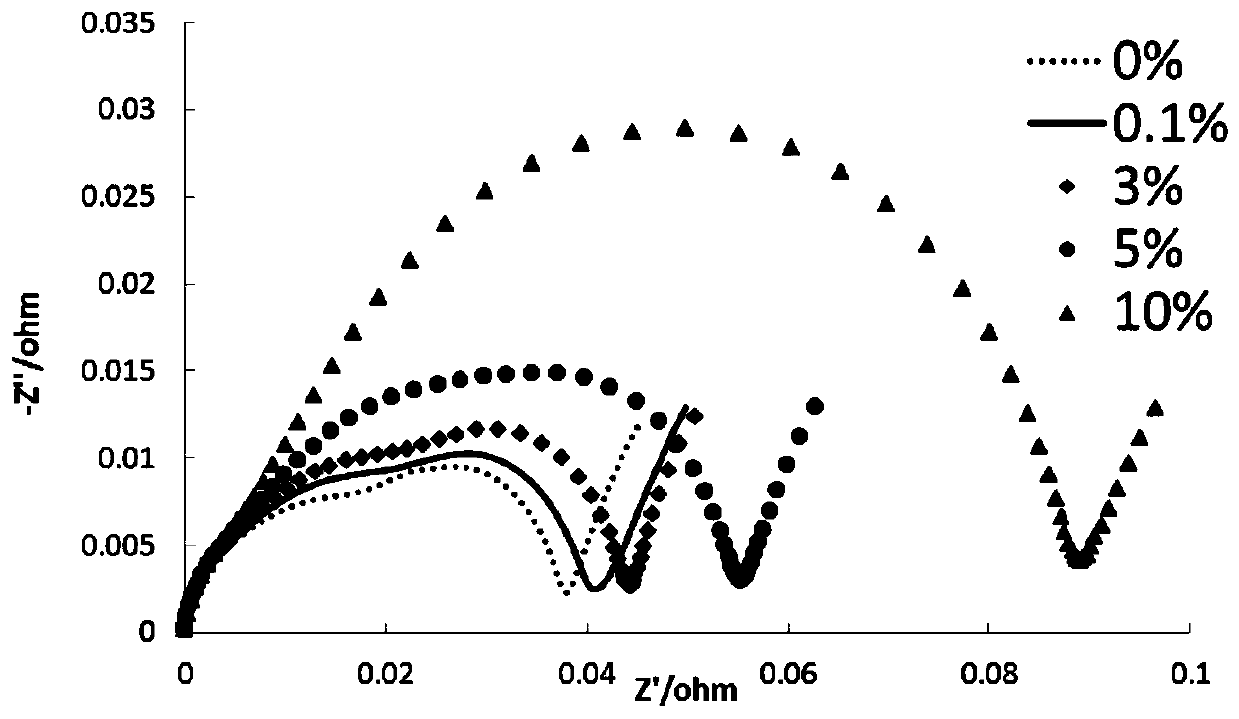

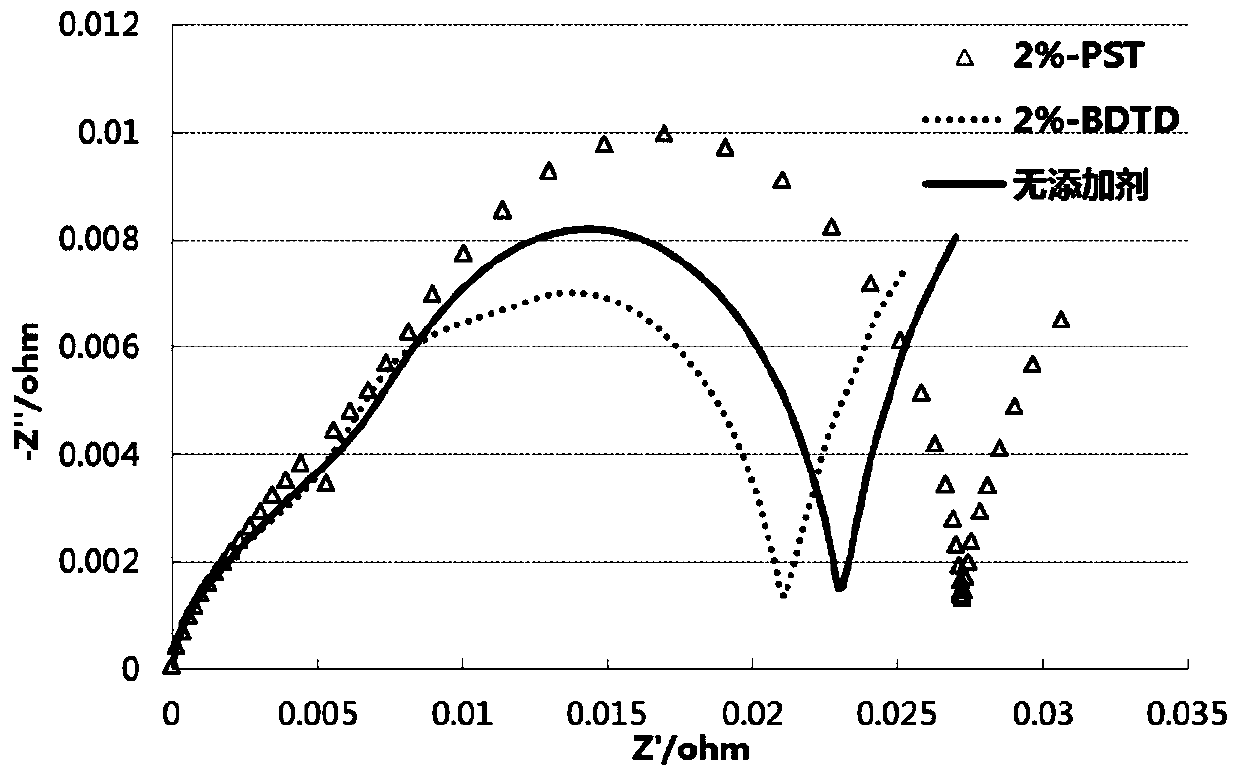

Application of 4,4-bis-1,3,2-dioxazothiophene-2,2-dioxide, and electrolyte and lithium ion battery

ActiveCN110190329AImprove fast charging performanceImprove securityFinal product manufactureSecondary cells servicing/maintenanceFast chargingLithium-ion battery

The invention discloses an application of 4,4-bis-1,3,2-dioxazothiophene-2,2-dioxide, and electrolyte and a lithium ion battery. The 4,4-bis-1,3,2-dioxazothiophene-2,2-dioxide can be applied to preparation of the electrolyte, when the prepared electrolyte is utilized in the lithium ion battery, the 4,4-bis-1,3,2-dioxazothiophene-2,2-dioxide in the electrolyte can enhance film formation property ofpositive and negative electrode interfaces under the high voltage, a stable passivation film can be formed on positive and negative electrodes of the battery, the passivation film has low impedance property, fast charging property of the lithium ion battery can be improved, film thickness is thin, compactness is good, stability is high, the positive and negative electrode interfaces can be protected, stability of the electrolyte is improved, internal electronics of the battery can be absorbed during the hot box test, heat of reaction is reduced, and safety of the battery is improved.

Owner:HIGHPOWER TECH HUIZHOU

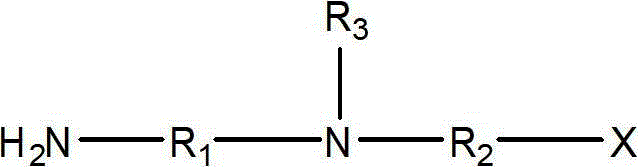

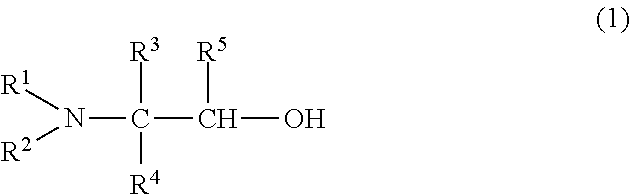

Acidic gas absorbing agent, method for removing acidic gas and apparatus for removing acidic gas

InactiveUS10046269B2Reduce the amount of solutionFacilitate desorptionGas treatmentDispersed particle separationHydrogen atomOrganic chemistry

There are provided an acidic gas absorbing agent that is large in recovery amount of an acidic gas. The acidic gas absorbing agent comprising an amine compound represented by general formula (1), and an acidic gas removing method and an acidic gas removing apparatus using the absorbing agent:wherein R1 represents a cycloalkyl group having 3 to 6 carbon atoms; R2 represents an alkyl group having 1 to 3 carbon atoms or a hydrogen atom; R3 and R4 each independently represent an alkyl group having 1 to 3 carbon atoms or a hydrogen atom; and R5 represents an alkyl group having 1 to 3 carbon atoms.

Owner:KK TOSHIBA

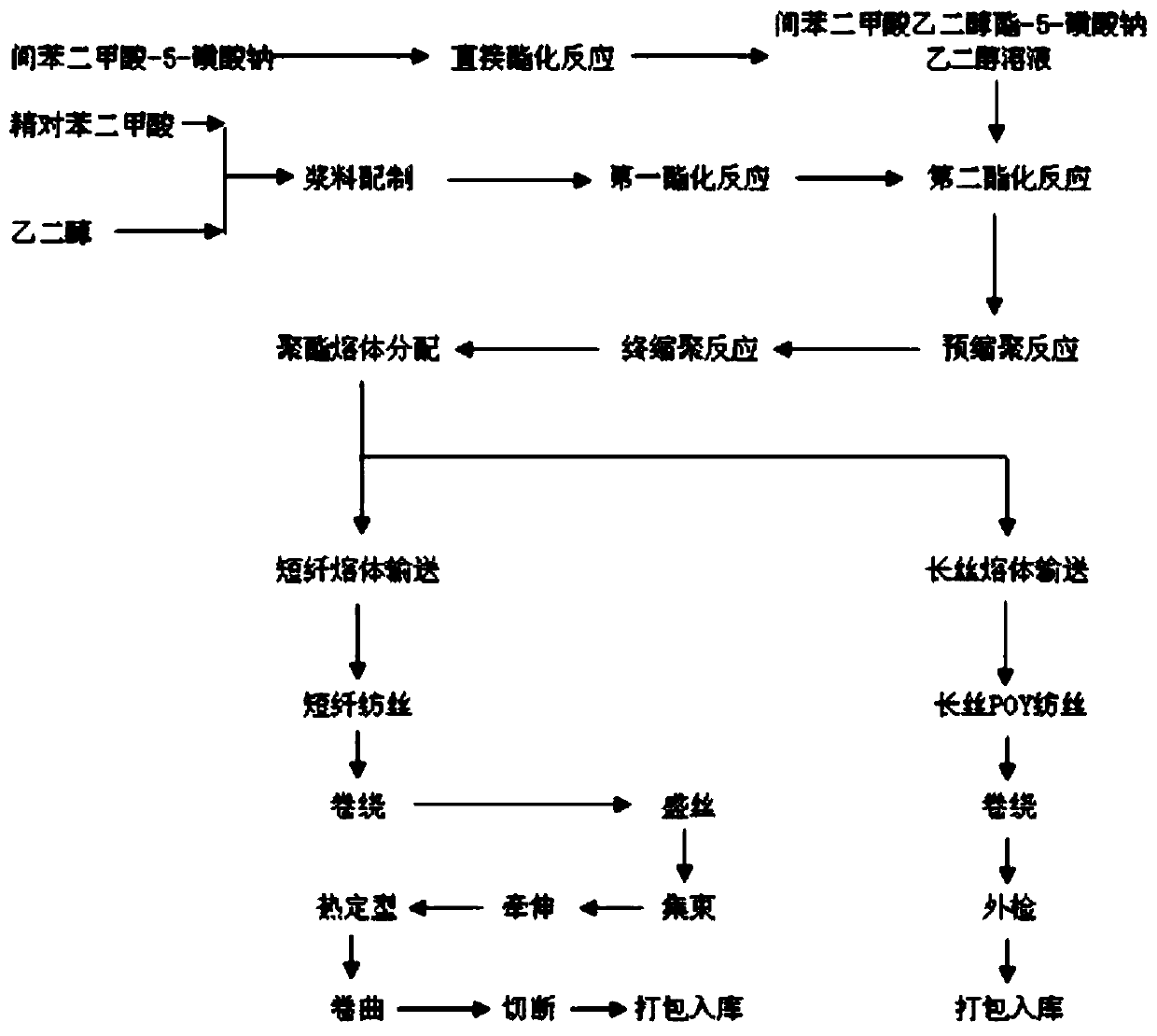

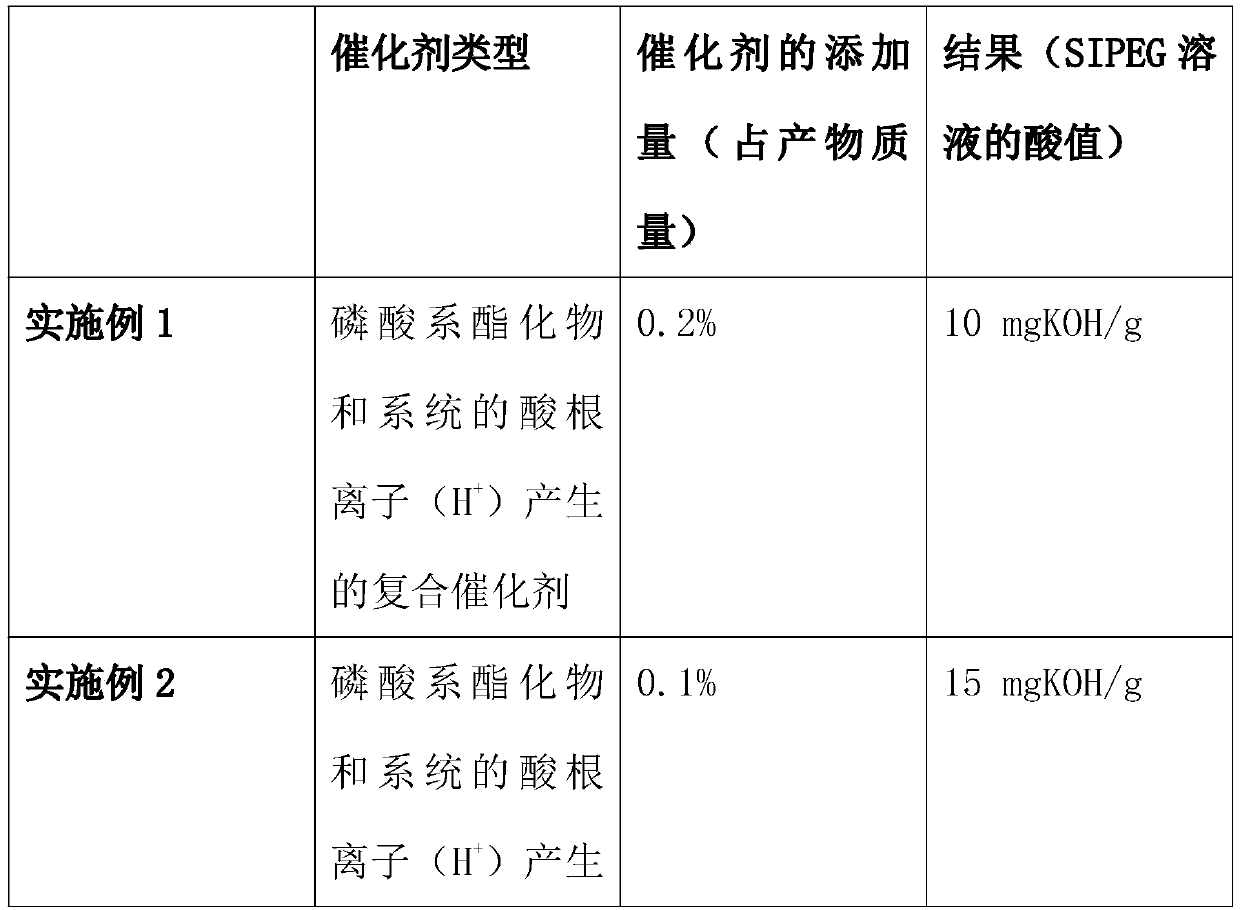

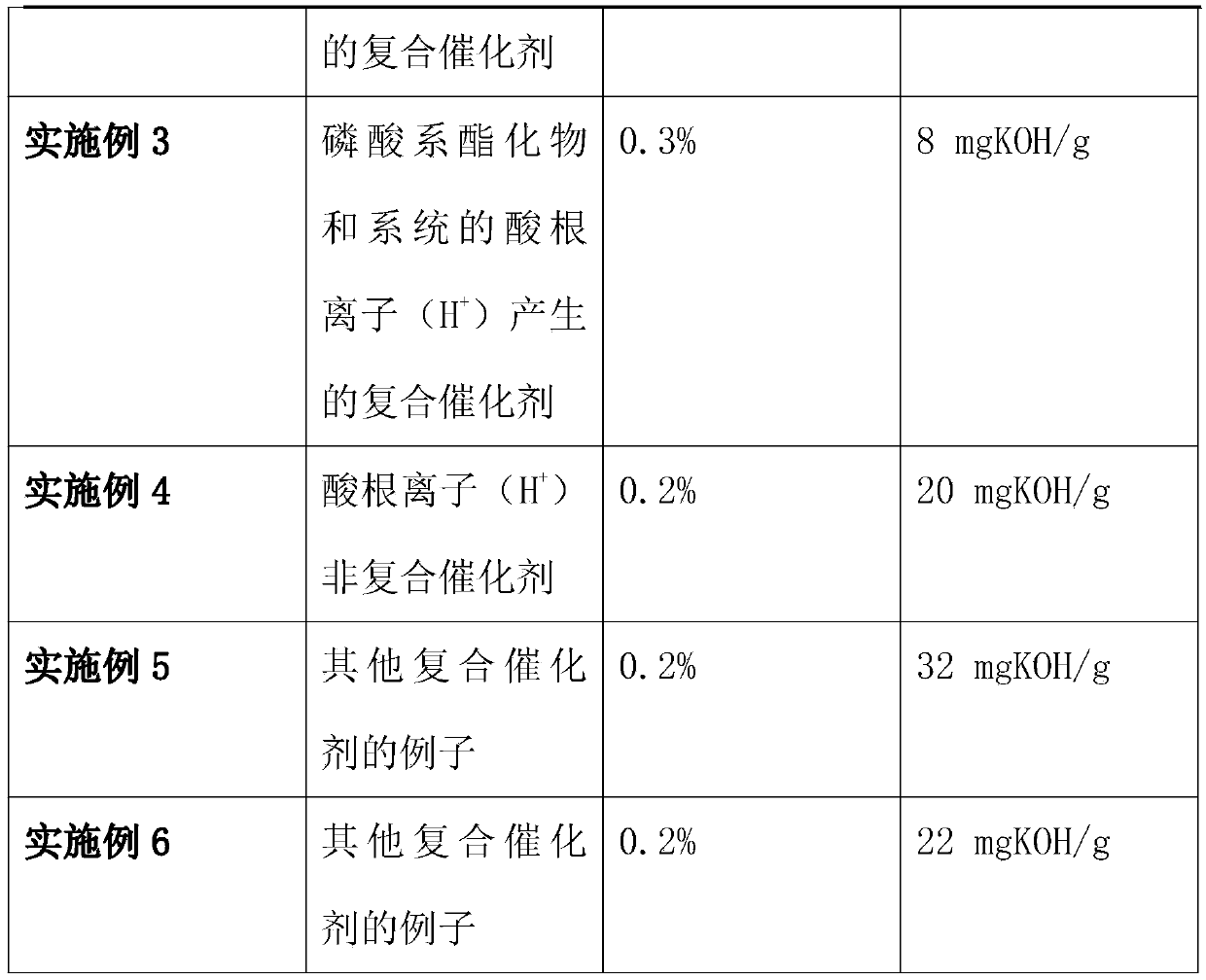

Production process for cationic polyester melt and application method for cationic polyester melt

ActiveCN110760058AHigh strengthControl degree of aggregationMonocomponent copolyesters artificial filamentMelt spinning methodsPolyesterChemical synthesis

The invention relates to the field of processing of fibers for direct spinning of cationic polyester filaments and chopped fibers and particularly relates to the technical field of chemical synthesisof a polyester third monomer, i.e., sodium ethylene glycol-5-sulfonate m-phthalate by a direct esterification method through processes of esterification synthesis, polycondensation synthesis and the like. A production process for a cationic polyester melt is disclosed by the invention and comprises the following steps: (1) obtaining an esterified substance, i.e., sodium ethylene glycol-5-sulfonatem-phthalate; (2) obtaining an esterified substance, i.e., ethylene glycol terephthalate; (3) obtaining a mixed esterified substance; (4) enabling the mixed esterified substance obtained in the step (3) to reach certain inherent viscosity, and completing a prepolycondensation reaction, so as to obtain a prepolycondensation reactant; and (5) enabling the prepolycondensation reactant to enter a final polycondensation reactor, reaching inherent viscosity of a polymer under the action of further improving a reaction temperature and a degree of vacuum, and completing a final polycondensation reaction, thereby obtaining the polyester melt required for production of the cationic polyester filaments and the chopped fibers through melt direct-spinning.

Owner:杭州观晨实业有限公司 +1

Preparation method of zirconium ball carrier, and application of zirconium ball carrier to manganese-based desulfurizing agent

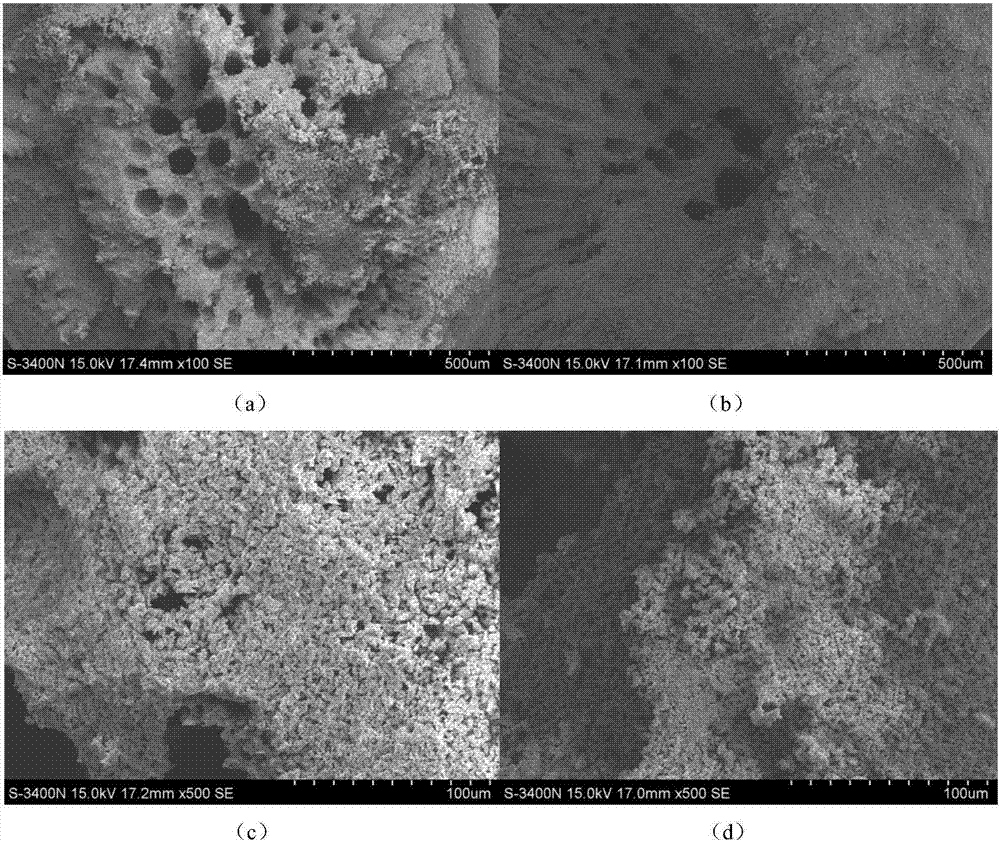

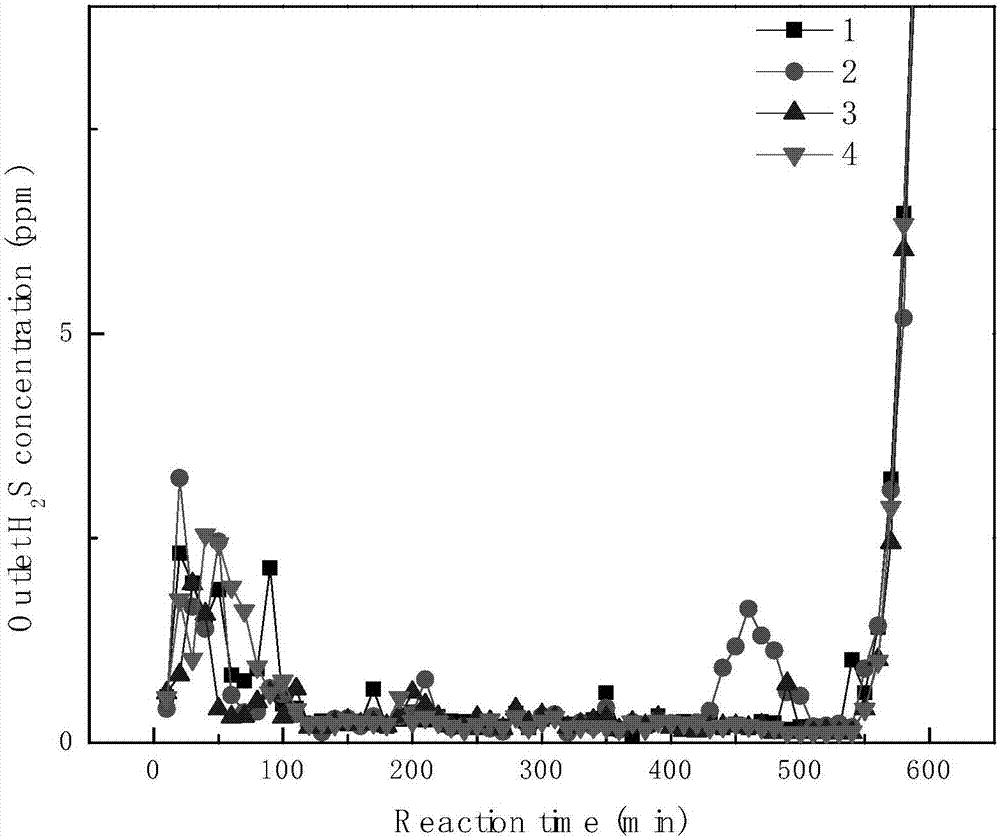

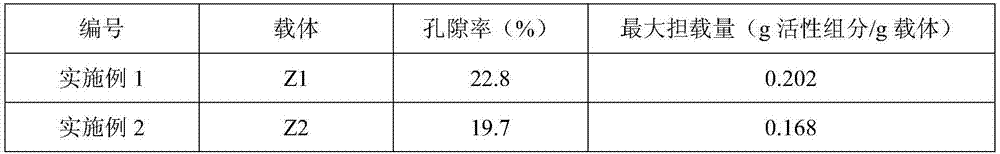

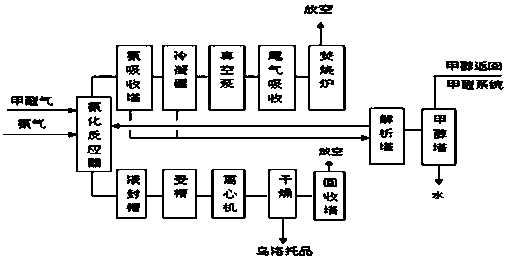

ActiveCN107213918AHigh fracture toughnessImprove toughnessCatalyst carriersOrganic-compounds/hydrides/coordination-complexes catalystsHigh energyWear resistant

The invention discloses a preparation method of a zirconium ball carrier, and application of the zirconium ball carrier to a manganese-based desulfurizing agent. During the preparation, zirconia is used as a carrier support body; polyether sulfone is used as a bonding agent; polyvinylpyrrolidone is used as a dispersing agent; through two-way substitution of N-methyl pyrrolidone and water, a sphere is formed by a wet process in water; after high-temperature sintering, a spherical wear-resistant carrier of a porous structure is formed, i.e., the zirconium ball carrier is obtained. A bran-new carrier preparation method is used; the porous wear-resistant spherical carrier is prepared by a phase inversion method; the spherical carrier is suitable for the preparation of all impregnated catalysts; the problems that the air resistance of a conventional powder catalyst is great, so that the spherical carrier can be swept and taken away by airflow during experiment, and the like are solved. When the carrier is used for preparing a high-temperature manganese-based desulfurizing agent, a high-precision renewable desulfurizing agent is obtained; the desulfurizing agent can be used for removing H2S in an IGCC (Integrated Gasification Combined Cycle); the technical support is provided for electric field electricity generation of an SOFC (Solid Oxide Fuel Cell) with high energy utilization efficiency.

Owner:CHINA UNIV OF MINING & TECH

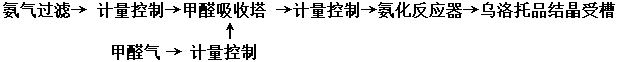

Method of continuously preparing urotropine mother liquid by means of coproduction with formaldehyde absorption column

PendingCN108329323AReduce heat of reactionReduce unit consumptionOrganic chemistryChemical industryChemical reactionAbsorption column

The invention discloses a method of continuously preparing an urotropine mother liquid by means of coproduction with a formaldehyde absorption column. In the method, ammonia tail gas is fed into the formaldehyde absorption column in order to treat the ammonia tail gas. The method particularly includes the steps of: 1) feeding filtered ammonia gas into the formaldehyde absorption column to prepareammonia water solution; 2) performing column circulation to the ammonia water solution and feeding formaldehyde gas, so that temperature of the column is rapidly increased to perform a reaction to obtain the urotropine mother liquid, of which the content is 20-35%; 3) metering the mother liquid and feeding the urotropine mother liquid into an ammoniation reactor of an urotropine apparatus, temperature, pH value and vacuum degree being controlled; 4) performing continuous concentration or intermittent concentration in the ammoniation reactor until the concentration of the mother liquid is 38-42%, and discharging the mother liquid to a mother liquid crystallizing trough. By means of the method, chemical reaction absorption is carried out with the circulating pump in the formaldehyde absorption column without increase of any power cost. The method has high efficiency and is flexible and convenient to adjust, can reduce reaction heat in the reactor and save circulating water, and satisfiesindustrial policy of saving energy, reducing consumption and protecting environment in our country.

Owner:呼图壁县锐源通化工有限责任公司

A cross-flow dual-stage moving bed active coke waste gas integrated purification tower

ActiveCN103349892BImprove the utilization rate of adsorption sulfur capacityReduce circulationDispersed particle filtrationTowerMoving bed

Owner:SHANGHAI CLEAR ENVIRONMENTAL PROTECTION SCI & TECH

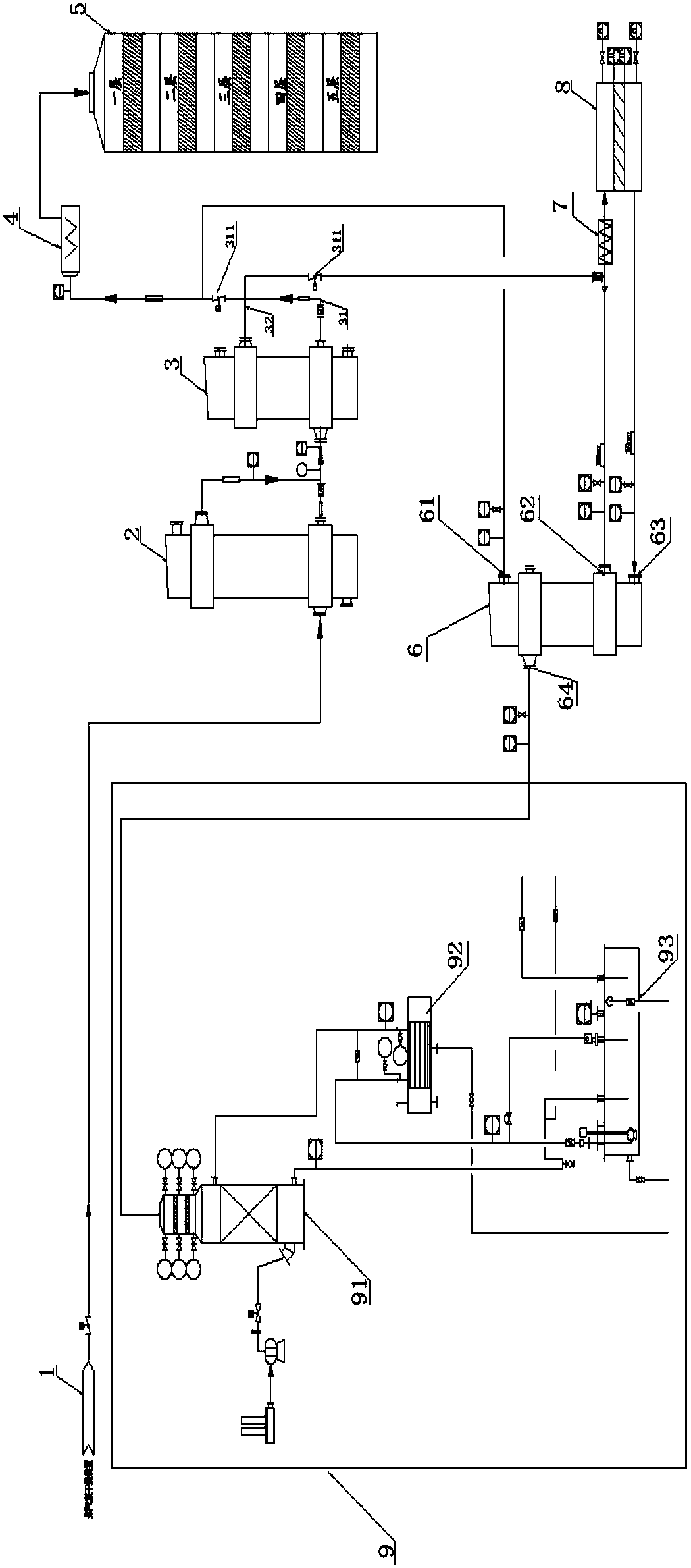

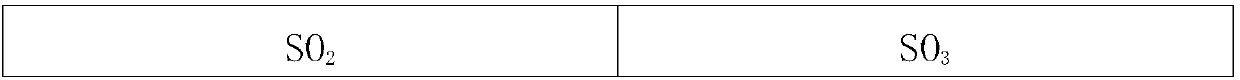

Method and device for transforming high-concentration SO2 flue gas to prepare sulfuric acid

InactiveCN107840313AReduce heat of reactionImprove conversion rateSulfur compoundsHigh concentrationFlue gas

The invention provides a method and a device for transforming high-concentration SO2 flue gas to prepare sulfuric acid and belongs to the field of sulfuric acid preparation. The method and the deviceare suitable for transforming the high-concentration SO2 flue gas to prepare the sulfuric acid and the problems that reaction heat of one section of transforming the high-concentration SO2 flue gas toprepare the sulfuric acid is too high and a catalyst is inactivated due to high temprature are solved. According to the method and the device, dry air and part of high-concentration SO2 flue gas aremixed and diluted; the concentration of the diluted SO2 flue gas is controlled to be 10 percent+ / -0.5 percent; the diluted SO2 flue gas is pre-transformed to obtain SO3 flue gas with a certain concentration; then the flue gas containing SO3 and the residual part of main flue gas are mixed and mixed gas enters a main transforming device and is transformed. By adopting the method and the device, provided by the invention, the concentration of SO2 is controlled to be 10 percent+ / -0.5 percent through mixing with the dry air, and the SO3 flue gas with the certain concentration is transformed through pre-transformation. The transformation rate of each phase can be controlled very well and the stable and reliable sulfuric acid can be produced through utilizing the high-concentration SO2 flue gas;meanwhile, the catalyst in the transforming device is ensured not to be damaged.

Owner:JIANGSU TIANRUN CHEM EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com