A cross-flow dual-stage moving bed active coke waste gas integrated purification tower

A technology of activated coke and purification tower, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc. Effective control and other issues to achieve the effect of improving utilization, avoiding local overheating, and reducing circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

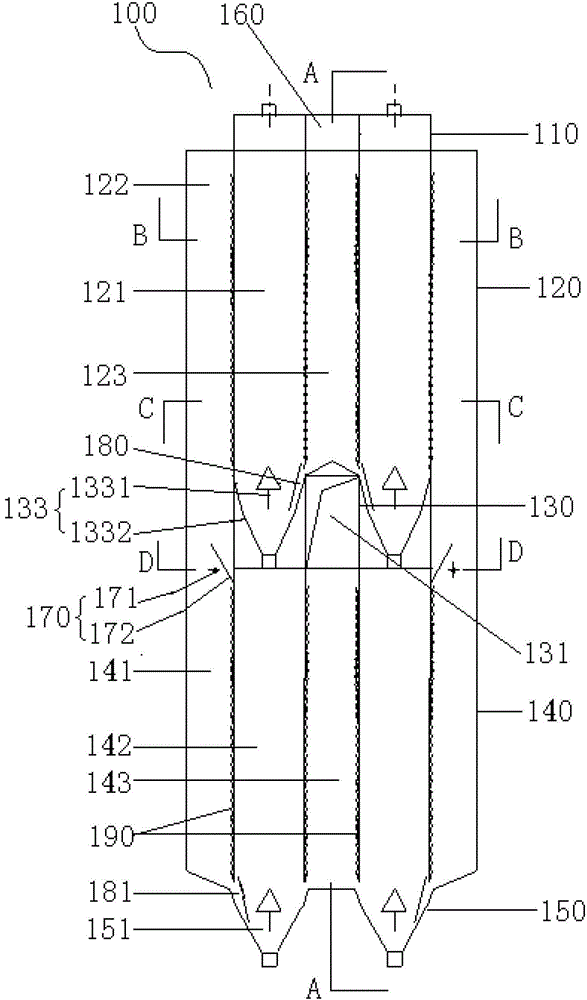

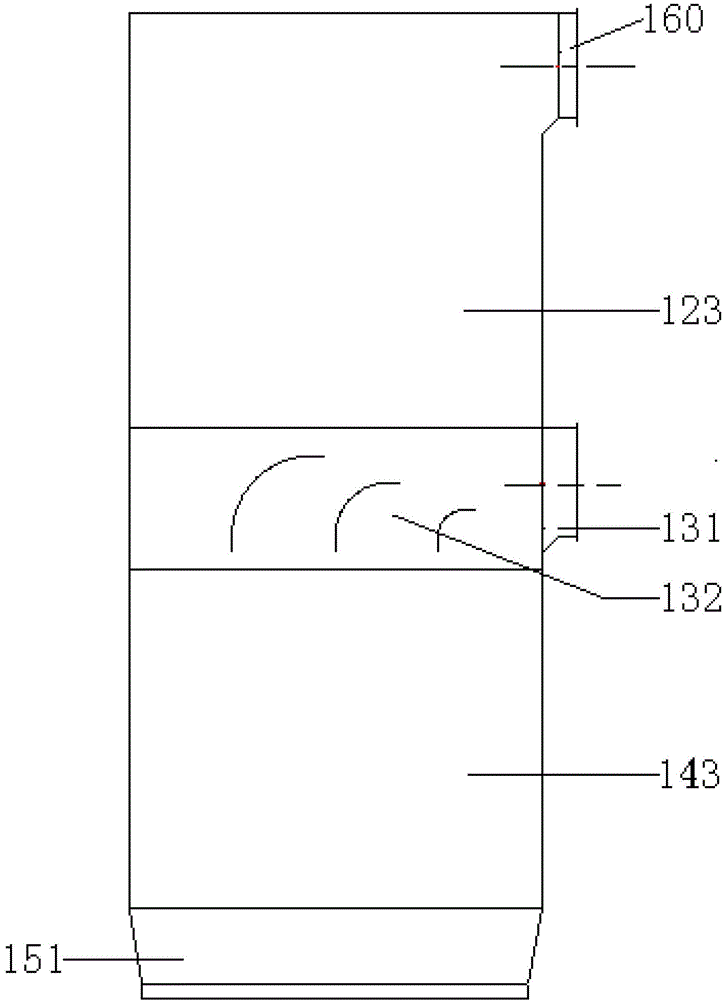

[0045] figure 1 Specific Embodiments A schematic diagram of the structure of a cross-flow two-stage moving bed activated coke waste gas integrated purification tower. like figure 1 As shown, a cross-flow two-stage moving bed activated coke waste gas integrated purification tower proposed in this embodiment includes a purification tower main body 100, and the purification tower main body 100 is provided with an active coke feeding area 110 and a denitrification area in sequence from top to bottom. 120 , transition layer 130 , desulfurization zone 140 and discharge layer 150 .

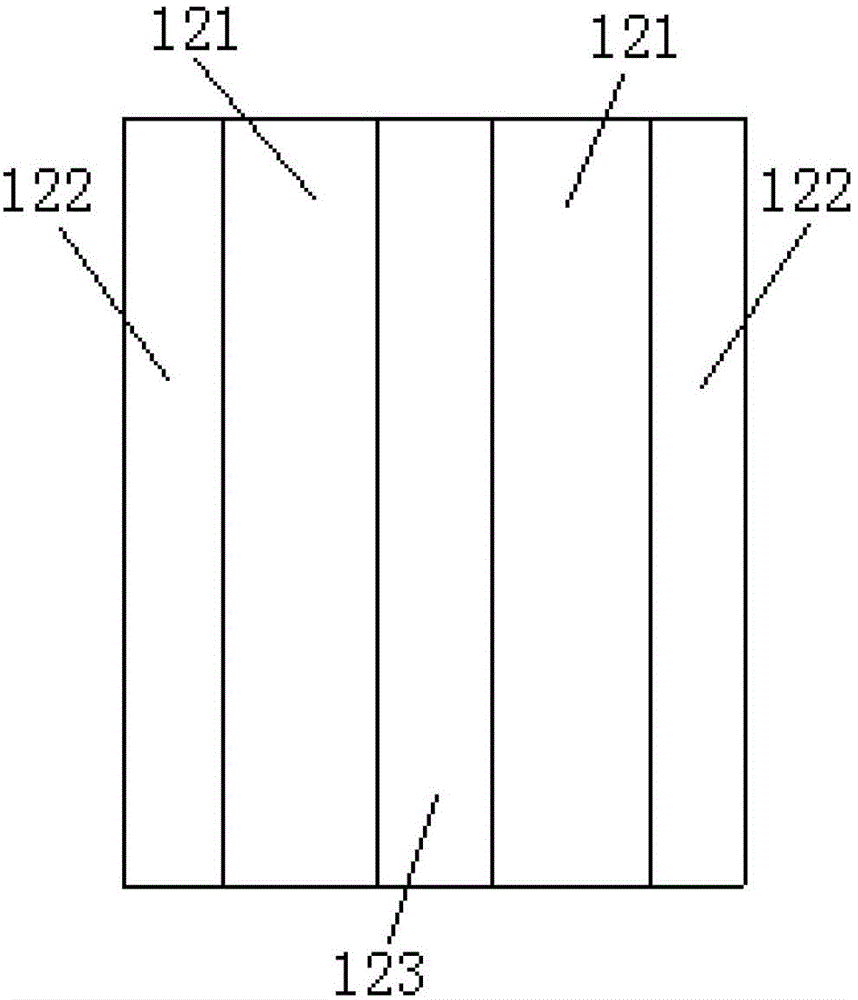

[0046] The denitrification zone 120 includes an active coke bed layer 121 in the denitrification zone, an air inlet chamber 122 in the denitrification zone, and an air outlet chamber 123 in the denitrification zone. There is an active coke bed layer 121 in the denitrification area between the chamber 123 and the air inlet chamber 122 in the denitrification area. 123 is turned on, and a purified gas ou...

Embodiment 2

[0060] This embodiment is an industrial furnace flue gas desulfurization system in the nonferrous metal industry using the integrated purification tower of the present invention for flue gas desulfurization. The overall structure of the integrated purification tower is basically the same as that of Embodiment 1, except that no ammonia injection components are added.

[0061] The design of this embodiment handles flue gas volume 2×10 4 Nm / h, SO 2 Concentration 14000mg / m 3 , the intake air temperature is 130°C, and the design flue gas air velocity is 300h -1 , to achieve a high concentration of SO 2 The high-efficiency removal of waste gas and the discharge of waste gas meet the standards, eliminating the high reaction heat of high-concentration gases and realizing stable operation of the device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com