Macromolecule grouting reinforcement material for coal mines and preparation method of macromolecule grouting reinforcement material

A grouting reinforcement and polymer technology, applied in the field of new materials, can solve the problems of high internal temperature and safety hazards, and achieve the effects of low reaction heat, elimination of safety hazards and low reaction temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

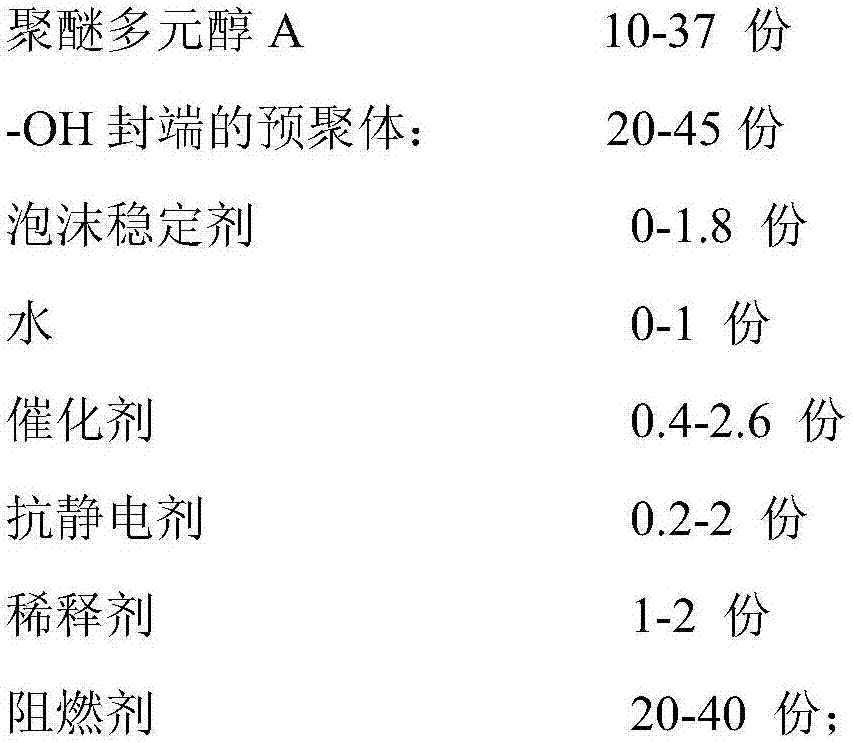

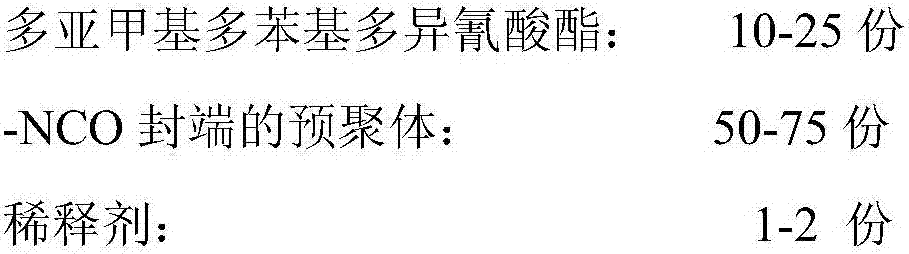

Method used

Image

Examples

Embodiment 1

[0036] Prepare 100kg of component A material, weighing respectively: polyether polyol A 28kg, polyether polyol B 25kg, toluene diisocyanate 15kg, catalyst 0.5kg, antistatic agent 1.5kg, diluent 1kg, flame retardant 29kg.

[0037] Polyether polyol A is SA430.

[0038] Polyether polyol B is MN350.

[0039] The flame retardant is TCPP.

[0040] The catalyst is an organometallic catalyst.

[0041] The antistatic agent is Basionics LQ 01 produced by BASF.

[0042] The diluent is N,N-dimethylformamide.

[0043] First, add polyether polyol B into the polymerization kettle and raise the temperature to above 95°C for vacuum dehydration; after the dehydration is completed, add toluene diisocyanate into the polymerization kettle and react at 80°C for about 1.5 hours, then take samples for testing; after passing the test , reduce the temperature of the material to below 50°C, then add the formulated amount of polyether polyol A, catalyst, antistatic agent, diluent, flame retardant and...

Embodiment 2

[0052] Prepare 100kg of component A material, weighing respectively: polyether polyol A 28kg, polyether polyol B 25kg, toluene diisocyanate 15kg, water 0.3kg, catalyst 0.6kg, antistatic agent 1.3kg, diluent 1kg, flame retardant Dosage 28.8kg.

[0053] Polyether polyol A is SA635.

[0054] Polyether polyol B is MN470.

[0055] The flame retardant is TCP.

[0056] The catalyst is an organic amine catalyst.

[0057] The antistatic agent is Basionics LQ 01 produced by BASF.

[0058] The diluent is N,N-dimethylformamide.

[0059] First, add polyether polyol B into the polymerization kettle and raise the temperature to above 95°C for vacuum dehydration; after the dehydration is completed, add toluene diisocyanate into the polymerization kettle and react at 80°C for about 1.1h, then take a sample for testing; after passing the test , reduce the temperature of the material to below 50°C, then add polyether polyol A, catalyst, water, antistatic agent, thinner, flame retardant and st...

Embodiment 3

[0068] Prepare and prepare 100kg of component A material, weighing respectively: polyether polyol A 28kg, polyether polyol B 25kg, toluene diisocyanate 15kg, water 0.7kg, foam stabilizer 0.5kg, catalyst 0.6kg, antistatic agent 1.2kg , thinner 1kg, flame retardant 28kg.

[0069] Polyether polyol A is SA470.

[0070] Polyether polyol B is MN700.

[0071] The flame retardant is TCPP.

[0072] The foam stabilizer is AK-8807.

[0073] The catalyst is an organometallic catalyst.

[0074] The antistatic agent is Basionics LQ 01 produced by BASF.

[0075] The diluent is N,N-dimethylformamide.

[0076] First, add polyether polyol B into the polymerization kettle and raise the temperature to above 95°C for vacuum dehydration; after the dehydration is completed, add toluene diisocyanate into the polymerization kettle and react at 80°C for about 2 hours, then take samples for testing; after passing the test, put The temperature of the material is lowered to below 50°C, then polyethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com