Method of continuously preparing urotropine mother liquid by means of coproduction with formaldehyde absorption column

A formaldehyde absorption tower and urotropine technology, which is applied in the field of continuous preparation of urotropine mother liquor by using formaldehyde absorption tower co-production, can solve the problem of reactor liquid level fluctuation and pressure pulsation, short production process route, incomplete reaction, etc. problems, to achieve the effects of huge economic and environmental protection and social benefits, flexible and convenient adjustment, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

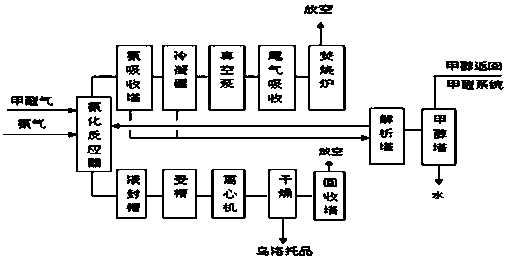

Image

Examples

Embodiment 1

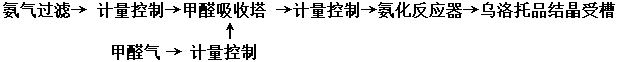

[0031] A method for continuously preparing urotropine mother liquor by co-production of formaldehyde absorption tower, the ammonia tail gas is introduced into the formaldehyde absorption tower, and the ammonia tail gas is processed, the specific steps are as follows:

[0032] (1) Meter the filtered ammonia gas and pass it into the distributor at the bottom of the formaldehyde absorption tower, and evenly disperse it in the desalted water to prepare an ammonia solution with a pH value of 8.0;

[0033] (2) The above-mentioned ammonia solution is circulated in the tower, and then gas formaldehyde is introduced, the tower temperature rises rapidly, the tower temperature is controlled at 75 ° C, the pH value is controlled at 8.5, and the reaction is carried out to form a mother liquor with a content of 25% urotropine;

[0034] (3) The mother liquor is metered into the ammoniation reactor of the urotropine plant, and the temperature of the ammoniation reactor is controlled at 85°C, t...

Embodiment 2

[0053] A method for continuously preparing urotropine mother liquor by co-production of formaldehyde absorption tower, the ammonia tail gas is introduced into the formaldehyde absorption tower, and the ammonia tail gas is processed, the specific steps are as follows:

[0054] (1) Measure the filtered ammonia gas and pass it into the distributor at the bottom of the formaldehyde absorption tower, and evenly disperse it in the desalted water to prepare an ammonia solution with a pH value of 9.0;

[0055] (2) The above-mentioned ammonia solution is circulated in the tower, and then the gas formaldehyde is introduced, the tower temperature rises rapidly, the tower temperature is controlled at 50°C, the pH value is controlled at 9.5, and the reaction is carried out to form a mother liquor with a content of 20% urotropine;

[0056] (3) The mother liquor is metered into the ammoniation reactor of the urotropine plant, and the temperature of the ammoniation reactor is controlled at 95°...

Embodiment 3

[0075] A method for continuously preparing urotropine mother liquor by co-production of formaldehyde absorption tower, the ammonia tail gas is introduced into the formaldehyde absorption tower, and the ammonia tail gas is processed, the specific steps are as follows:

[0076] (1) Meter the filtered ammonia gas and pass it into the distributor at the bottom of the formaldehyde absorption tower, and evenly disperse it in the desalted water to prepare an ammonia solution with a pH value of 7.5;

[0077] (2) The above-mentioned ammonia solution is circulated in the tower, and then gas formaldehyde is introduced, the tower temperature rises rapidly, the tower temperature is controlled at 85°C, the pH value is controlled at 8.0, and the reaction is carried out to form a mother liquor with a content of 35% urotropine;

[0078] (3) The mother liquor is metered into the ammoniation reactor of the urotropine plant, and the temperature of the ammoniation reactor is controlled at 75°C, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com