Method and device for transforming high-concentration SO2 flue gas to prepare sulfuric acid

A SO2, high-concentration technology, applied in chemical instruments and methods, inorganic chemistry, sulfur compounds, etc., can solve the problems of large conversion, catalyst deactivation, high reaction heat, etc., and achieve the effect of ensuring that it will not be destroyed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

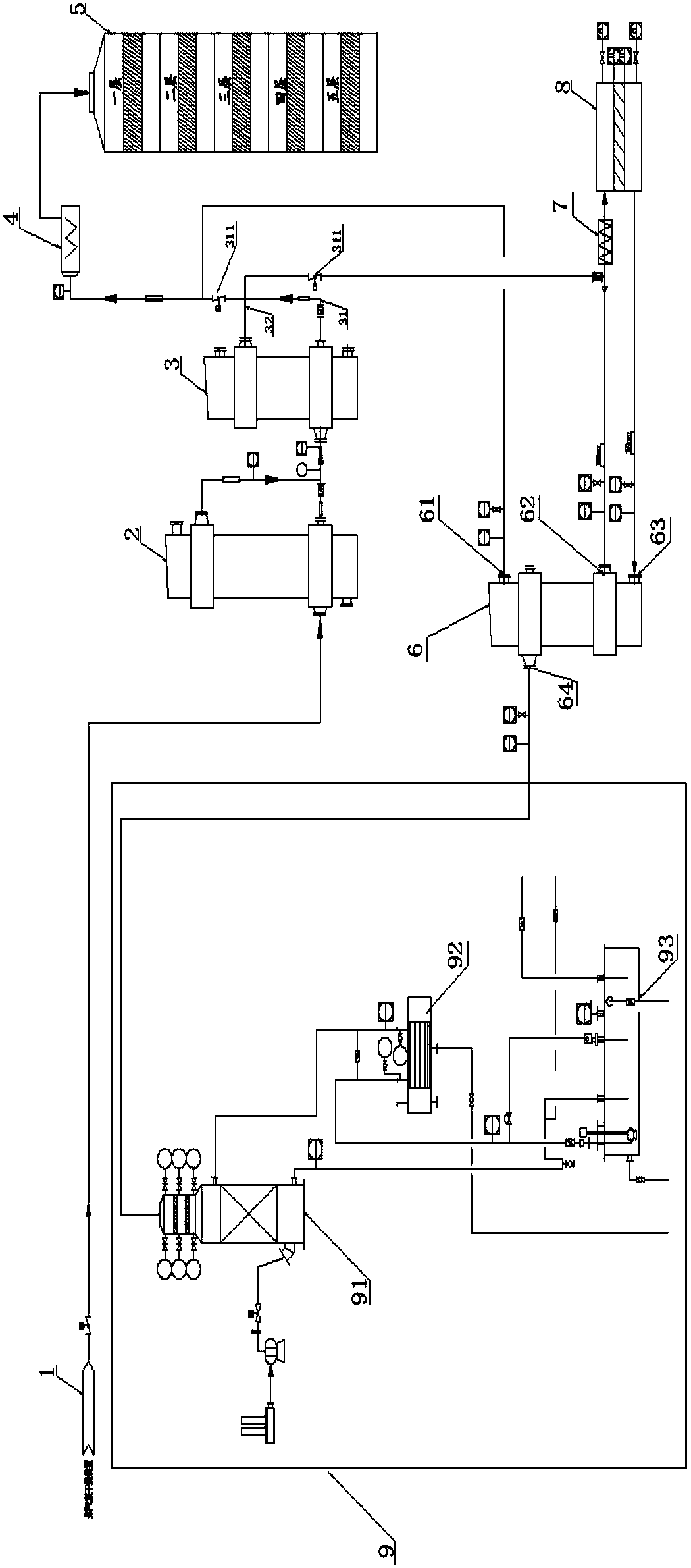

Method used

Image

Examples

Embodiment 1

[0035] 100 tons of SO 2 20% volume concentration of SO 2 Flue gas, sulfuric acid is produced through this method and this device

[0036] Here, the values of V1, V2 and V3 are as follows:

[0037] V 1

V 2

V 3

50

50

50

[0038] Volume is V 1 SO 2 SO 2 When the concentration is 10%, the conversion rate in the pre-reformer is 65%, and the SO in the mixed flue gas after conversion 2 with SO 3 The concentration is as follows:

[0039] SO 2

SO 3

3.5%

6.5%

[0040] The pre-reformed flue gas has a volume of V 2 SO 2 After the flue gas is mixed in the first branch, SO 2 with SO 3 The concentrations are as follows:

[0041] SO 2

SO 3

9%

4.3%

[0042] After the mixed flue gas enters the converter, the conversion rate of each layer is as follows:

[0043] one turn

Embodiment 2

[0045] 100 tons of SO 2 16% SO by volume 2 Flue gas, sulfuric acid is produced through this method and this device

[0046] Here, the values of V1, V2 and V3 are as follows:

[0047] V 1

V 2

V 3

50

50

30

[0048] Volume is V 1 SO 2 Flue gas with volume V 3 The dry air SO after mixing in the first outlet of the preheater 2 When the concentration is 10%, the conversion rate in the pre-reformer is 65%, and the SO in the mixed flue gas after conversion 2 with SO 3 The concentration is as follows:

[0049] SO 2

SO 3

3.5%

6.5%

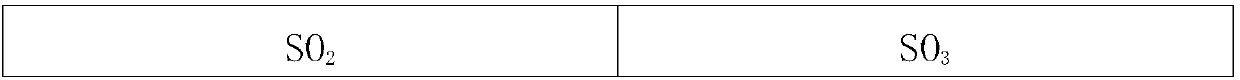

[0050] The pre-reformed flue gas has a volume of V 2 SO 2 After the flue gas is mixed in the first branch, SO 2 with SO 3 The concentrations are as follows:

[0051]

[0052]

[0053] After the mixed flue gas enters the converter, the conversion rate of each layer is as follows:

[0054] one turn

Embodiment 3

[0056] 100 tons of SO 2 30% volume concentration of SO 2 Flue gas, sulfuric acid is produced through this method and this device

[0057] Here, the values of V1, V2 and V3 are as follows:

[0058] V 1

V 2

V 3

50

50

100

[0059] Volume is V 1 SO 2 SO 2 When the concentration is 10%, the conversion rate in the pre-reformer is 65%, and the SO in the mixed flue gas after conversion 2 with SO 3 The concentration is as follows:

[0060] SO 2

SO 3

3.5%

6.5%

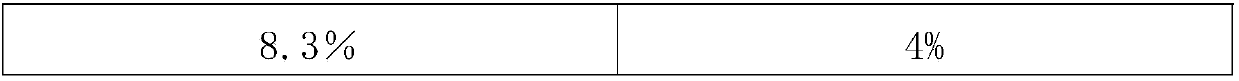

[0061] The pre-reformed flue gas has a volume of V 2 SO 2 After the flue gas is mixed in the first branch, SO 2 with SO 3 The concentrations are as follows:

[0062] SO 2

SO 3

10.1%

4.8%

[0063] After the mixed flue gas enters the converter, the conversion rate of each layer is as follows:

[0064] one turn

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com