Circulating fluidized bed gas generator system

A coal gasifier and coal flow technology, applied in the direction of granular/powdered fuel gasification, energy input, etc., can solve the problem of high coal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

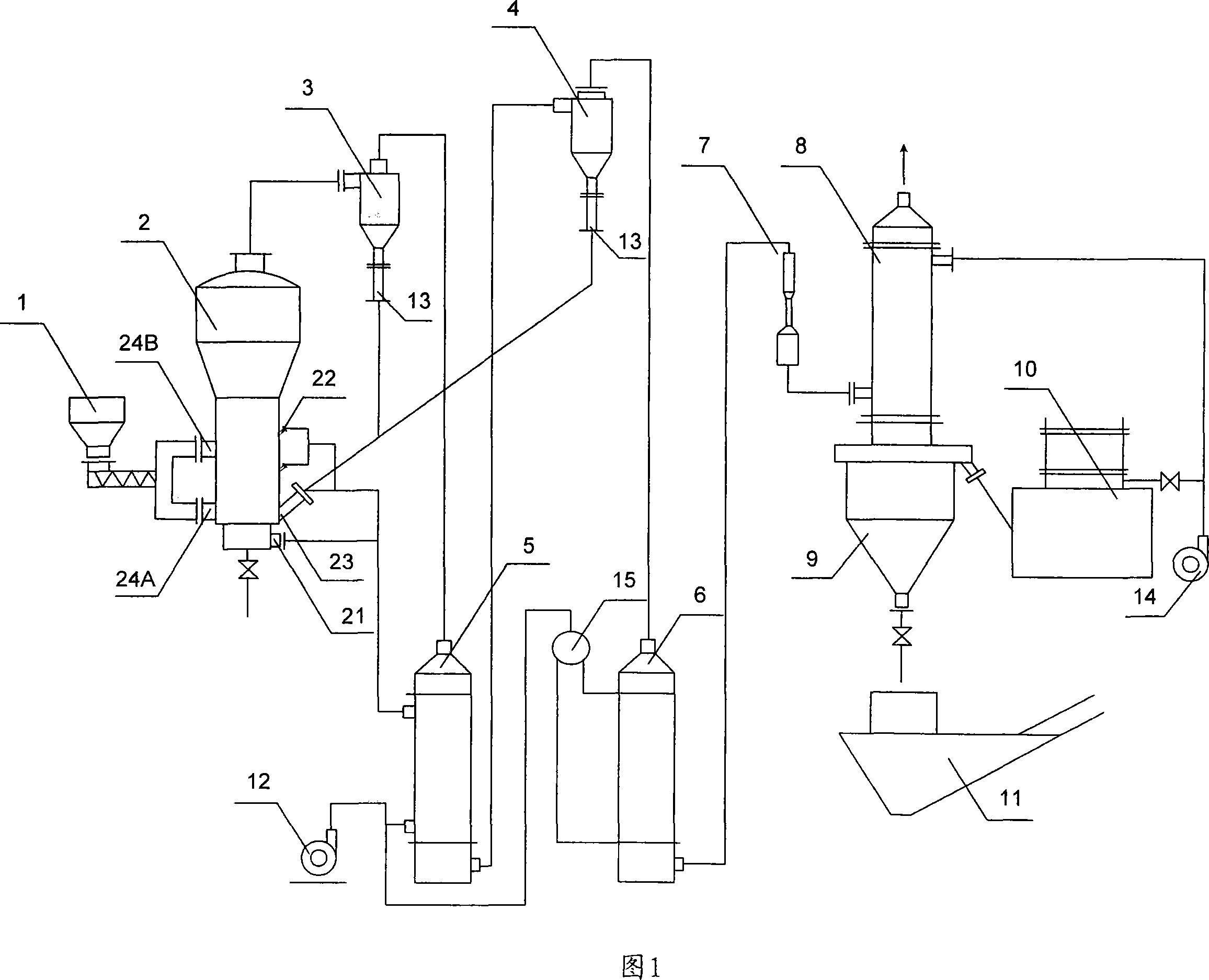

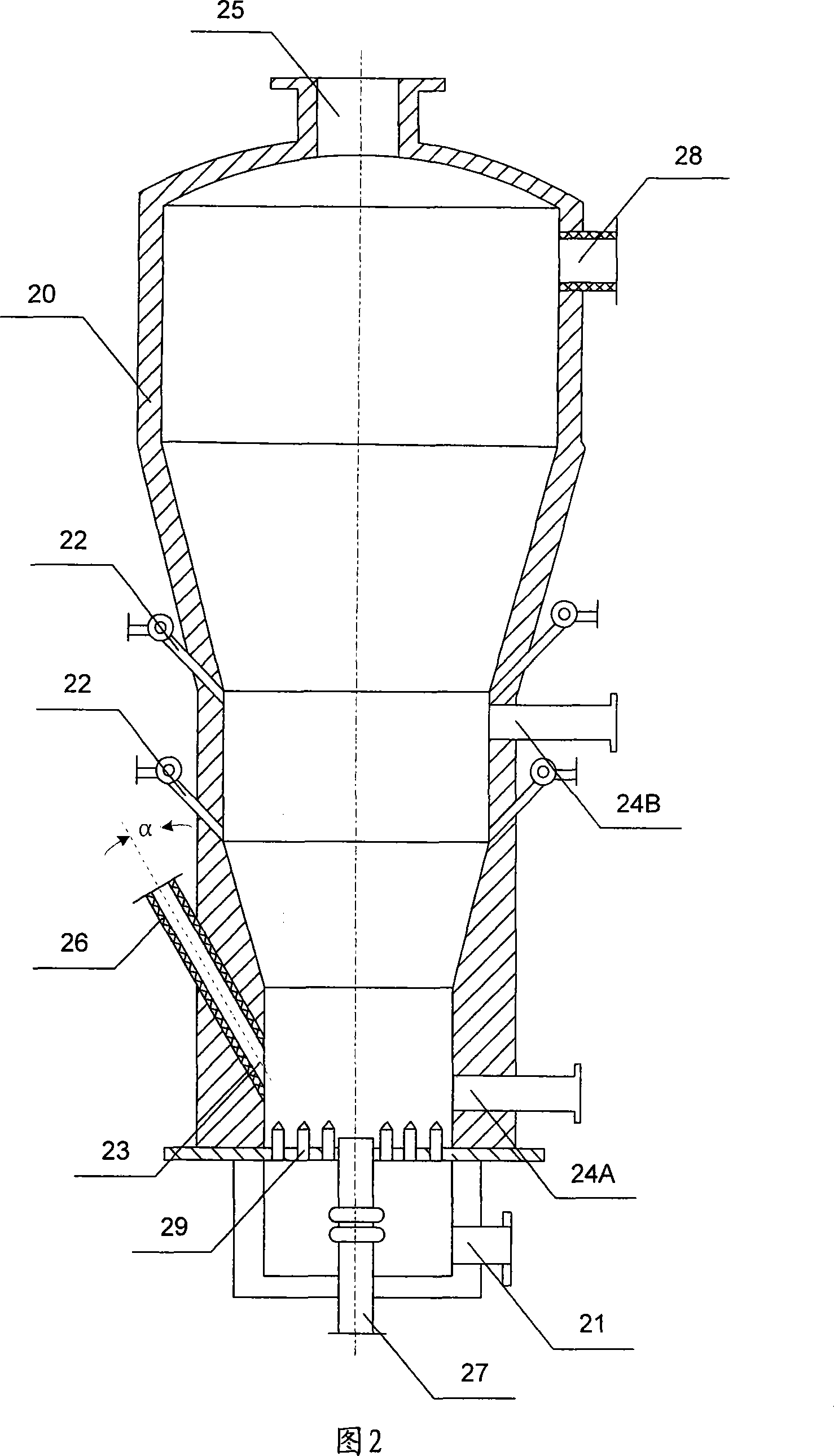

[0034] Figure 1 is a schematic structural diagram of the present invention. As shown in Figure 1, the main structure of the circulating coal fluidized bed gas generator system of the present invention includes a coal feeder 1, a gas generator 2, a high temperature separator 3, a heat exchanger 5, a low temperature separator 4, and a waste heat boiler connected in sequence. 6. Venturi dust collector 7 and washing tower 8, raw coal is sent from coal feeder 1 to gas generator 2 to react to generate coal gas, which is separated into coal powder in high temperature separator 3 and heated and gasified in heat exchanger 5 In the low temperature separator 4, the pulverized coal is separated again, and the steam is produced in the waste heat boiler 6. Finally, the Venturi dust collector 5 and the washing tower 6 are used for dust removal and washing, and then transported to the user. The gas generator 2 is provided with a primary tuyere 21, at least one secondary tuyere 22 and a circul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com