Isobutene polymerization reaction method and device

A superposition reaction and isobutene technology, applied in the field of isobutene superposition reaction methods and devices, can solve problems such as unfavorable conversion and product quality decline, and achieve the effects of improving conversion rate and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

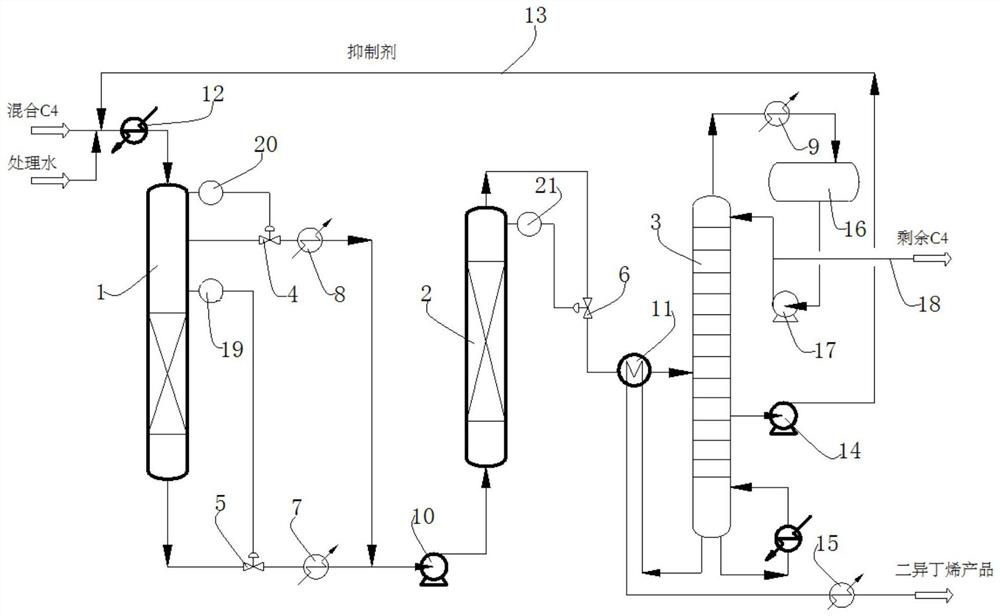

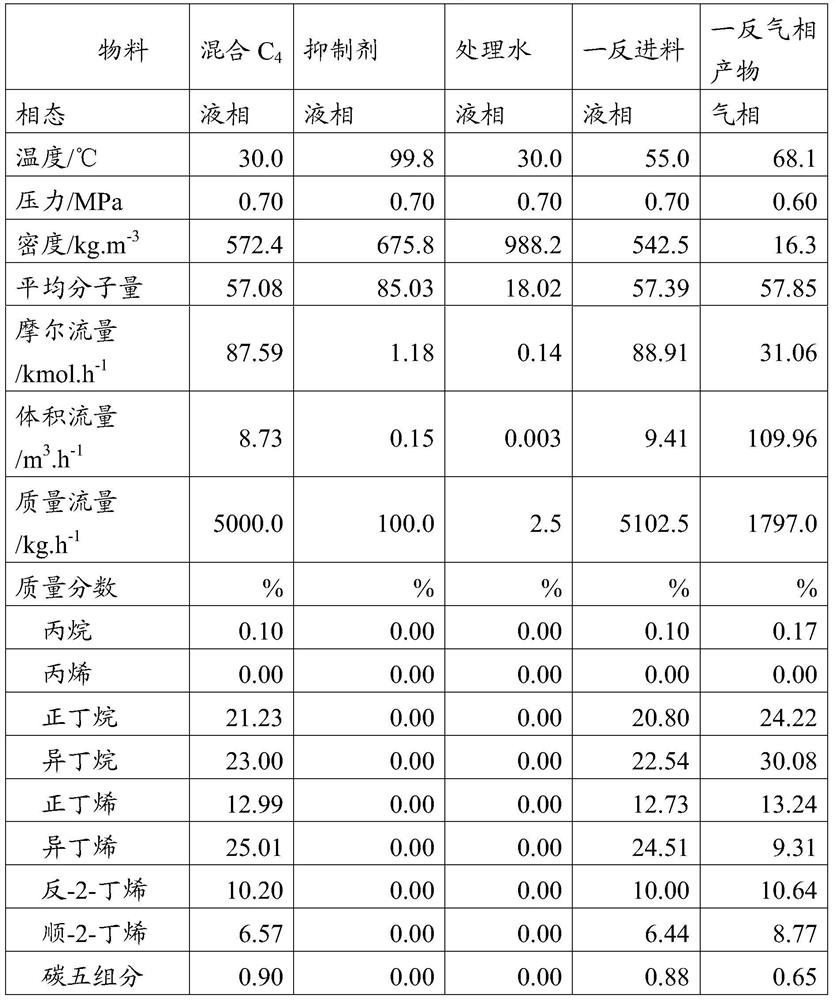

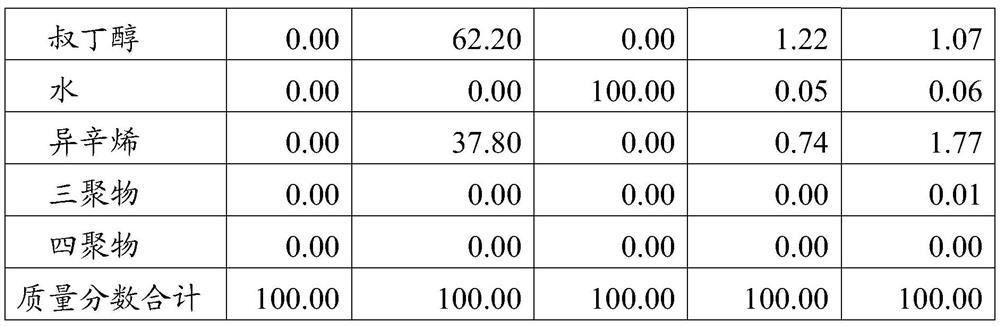

[0114] combined with figure 1 , the temperature is 30.0℃, the pressure is 0.70MPa, and the flow rate is 5000.0kg / h mixed C 4The temperature from the inhibitor recovery pipeline 13 is 98.8°C, the pressure is 0.70MPa, and the flow rate is 100.0kg / h circulating inhibitor, and the temperature from outside the device is 30.0°C, the pressure is 0.70MPa, and the flow rate is 2.5kg / h. Water (demineralized and deoxidized water) is mixed, and the mixture is heated to 55° C. by the heater 12 and enters the first superposition reactor 1 from the top inlet to perform the first superposition reaction.

[0115] Among them, the liquid hourly volume space velocity during the first superposition reaction is 1.0h -1 , the reaction pressure is controlled at 0.6 MPa, under this pressure the bubble point temperature of the mixed C4 is 68.1° C., and the temperature of 68.1° C. is the reaction temperature of the reaction materials in the first stacked reactor 1 . The heat of reaction produced by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com