Polyurethane composite material and preparation method thereof

A polyurethane composite material and material technology, applied in the field of concrete and its preparation, to achieve the effects of low heat of reaction, lower reaction temperature, and uniform heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The polyurethane compound material of the present invention, it is made up of A group material and B group material, wherein:

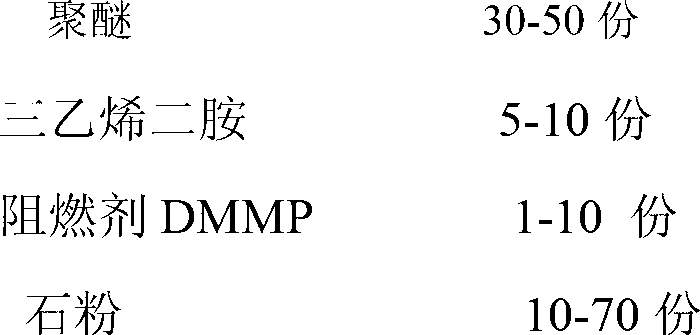

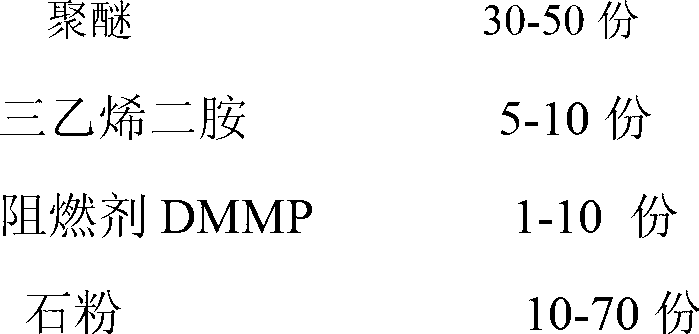

[0025] The composition of group A materials by mass parts is as follows:

[0026]

[0027] The components of group B materials by mass ratio are as follows:

[0028] 10-70 parts of isocyanate

[0029] Stone powder 70-10 parts

[0030] Mix the above-mentioned group A materials of equal quality with the above-mentioned group B materials of equal quality to obtain the polyurethane composite material of the present invention.

[0031] The hydroxyl value of polyether is between 1 and 1000. It is a mixture of one or several polyethers; such as the polyether produced by Jiangsu Zhongshan Chemical Co., Ltd., its trade name can be N-403, ZS-4110, etc. One or a mixture of several of them. Isocyanate is any kind of polyurethane black material, such as MDI M20S, 5005, 44V20, PM-200, M200 and so on. The stone powder mesh number should be above 20 me...

Embodiment 2

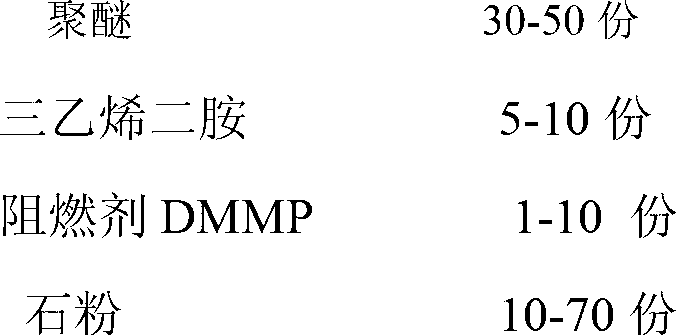

[0039] The composition of group A materials by mass parts is as follows:

[0040]

[0041] The components of group B materials by mass ratio are as follows:

[0042] 10-70 parts of isocyanate

[0043] Stone powder 70-10 parts

[0044] Conductive graphite 1-30 parts

[0045] Mix the above-mentioned group A materials of equal quality with the above-mentioned group B materials of equal quality to obtain the polyurethane composite material of the present invention.

[0046] The hydroxyl value of polyether is between 1 and 1000. It is a mixture of one or several polyethers; such as the polyether produced by Jiangsu Zhongshan Chemical Co., Ltd., its trade name can be N-403, ZS-4110, etc. One or a mixture of several of them. Isocyanate is any kind of polyurethane black material, such as MDI M20S, 5005, 44V20, PM-200, M200 and so on. The stone powder mesh number should be above 20 mesh. The mesh number of conductive graphite should be above 80 mesh.

[0047] The method for p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com