Application of 4,4-bis-1,3,2-dioxazothiophene-2,2-dioxide, and electrolyte and lithium ion battery

A technology of dioxide and electrolyte, which is applied in the field of lithium-ion batteries and electrolytes, can solve the problems of high film resistance and difficulty in effectively improving the fast charging performance and safety performance of lithium-ion batteries, achieve low impedance performance, and improve fast charging performance. Good charging performance and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation of electrolyte specifically comprises the following steps:

[0027] Mix ethylene carbonate (EC), diethyl carbonate (DEC) and propylene carbonate (PC) in a mass ratio of 1:1:1 as an organic solvent; add additives to the organic solvent, mix well, add lithium hexafluorophosphate ( LiPF 6 ), to get LiPF 6 The mixed solution with a concentration of 1.1mol / L is the electrolyte.

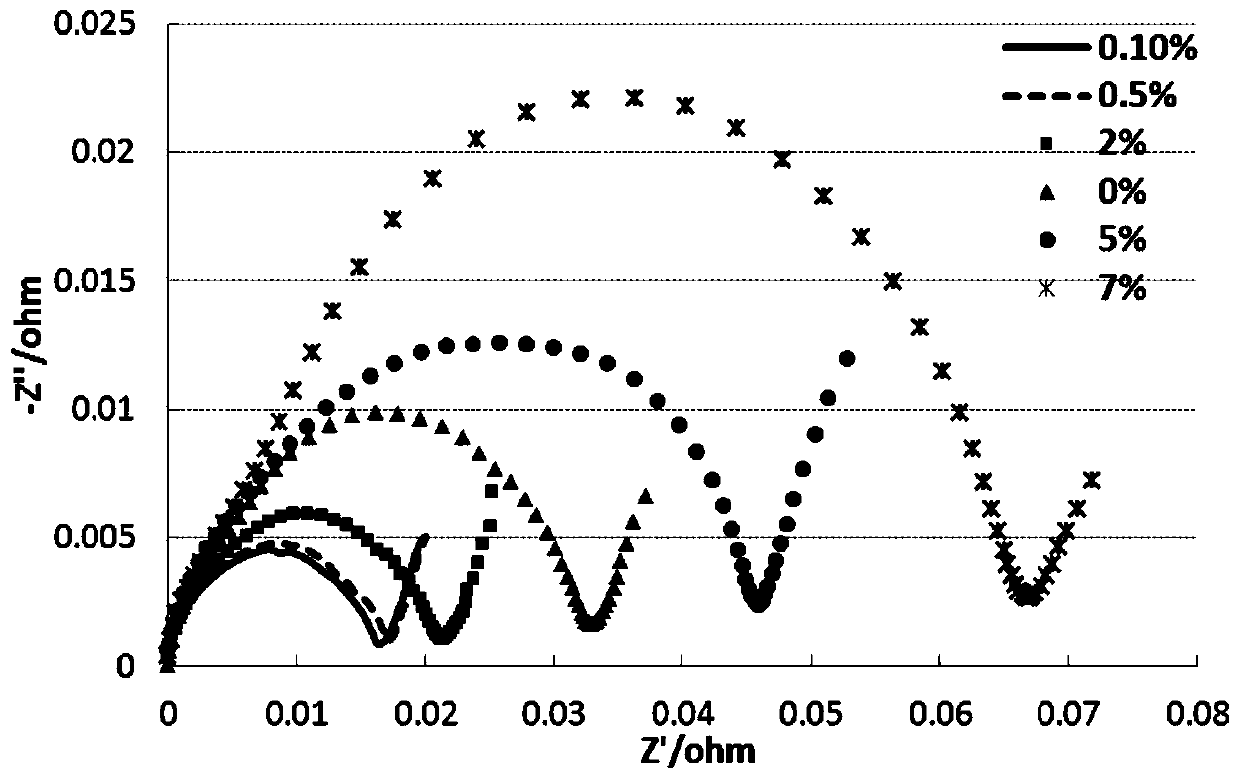

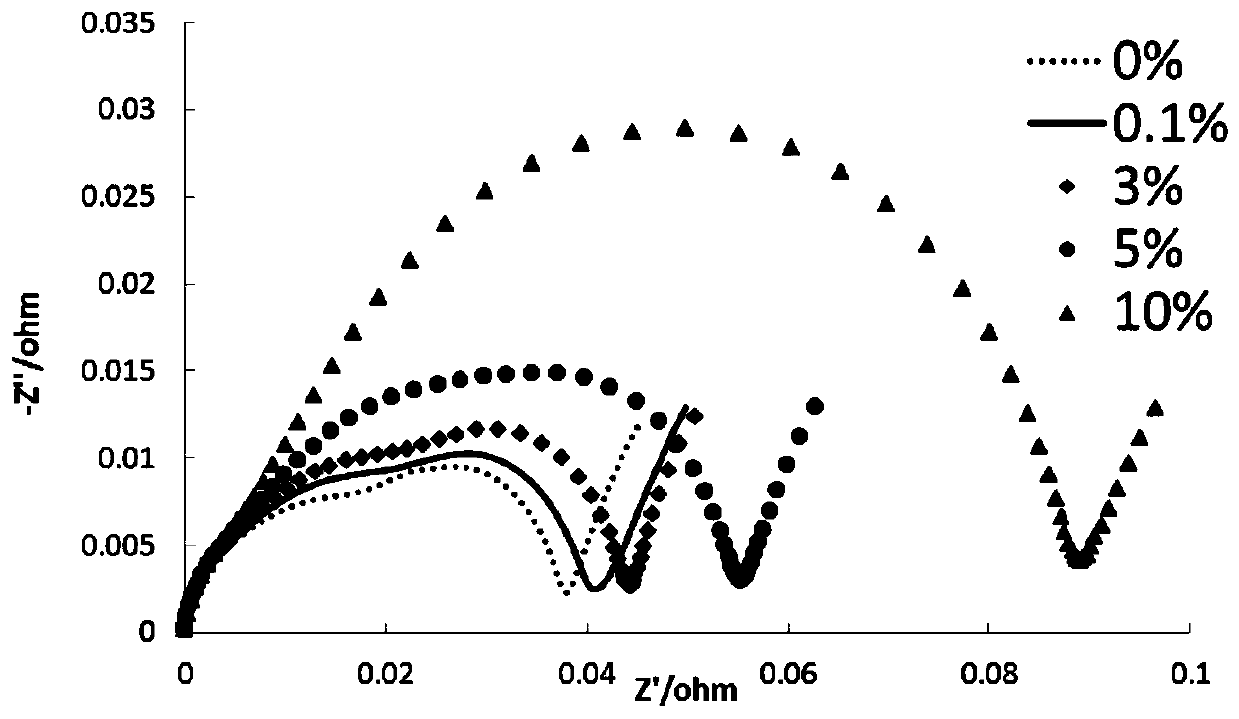

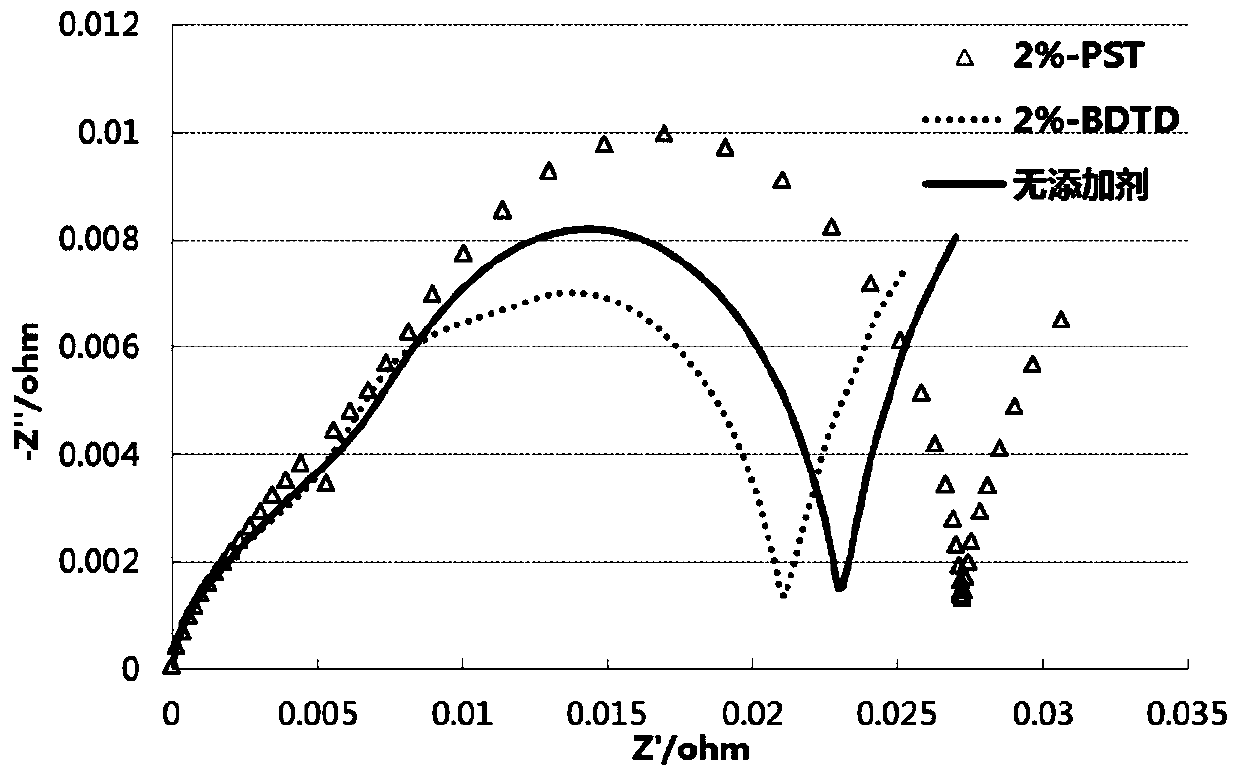

[0028] Specifically, the additive raw material components and dosage (ie, the mass percentage in the electrolyte) were added as shown in Table 1 to prepare different electrolytes. Among them, BDTD is 4,4-bis-1,3,2-dioxazolethiophene-2,2-dioxide; PS is sodium propargylsulfonate; DTD is 1,3,2-dioxazolethiophene -2,2-dioxide; PST is phthalosulfathiazole.

[0029] Raw material components and consumption of additives in different electrolytes in table 1

[0030]

Embodiment 2

[0032] The preparation of lithium ion battery comprises the following steps:

[0033] (1) Production of positive electrode sheet

[0034] According to the positive electrode active material lithium cobalt oxide (LiCoO 2 ), conductive agent CNT, binder polyvinylidene fluoride in a weight ratio of 97:1.5:1.5, and then fully stirred and mixed with N-methylpyrrolidone solvent to form a uniform positive electrode slurry; The material is coated on the positive electrode current collector Al foil, dried, and cold pressed to obtain the positive electrode sheet.

[0035] (2) Production of negative electrode sheet

[0036] According to the mass ratio of negative electrode active material graphite, conductive agent acetylene black, binder styrene-butadiene rubber, and thickener sodium carboxymethyl cellulose to 95:2:2:1, take the material, and then fully stir it with an appropriate amount of deionized water Mixing to form a uniform negative electrode slurry; coating the slurry on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com