Negative electrode sheet and lithium ion battery comprising same

A negative electrode sheet and negative electrode technology, which is applied in the field of polymer lithium-ion batteries and lithium-ion batteries, can solve the problems of lithium analysis, mismatch between lithium ion diffusion rate and insertion rate, large local polarization, etc., and meet the needs of industrial applications. High application value and practicability, the effect of high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

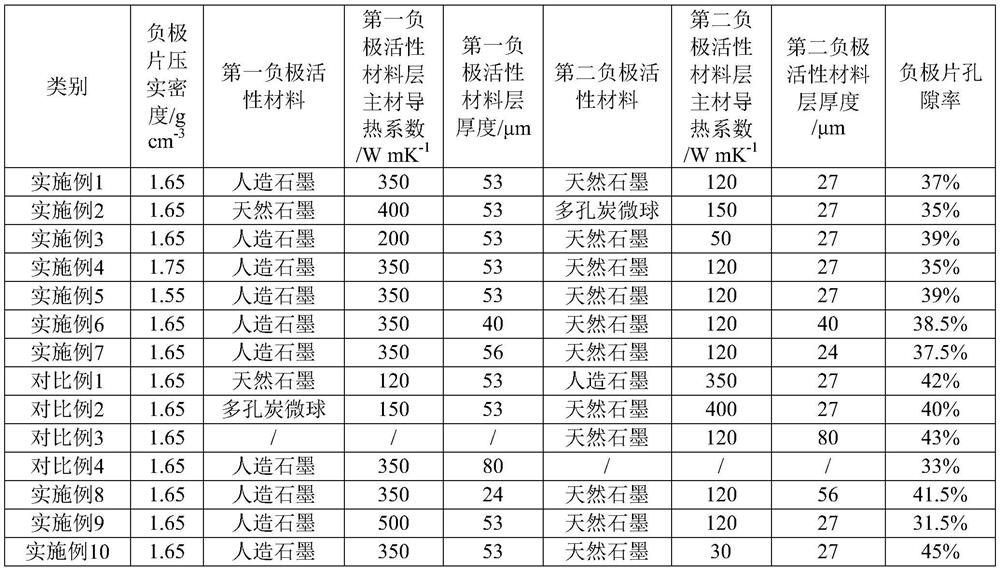

Embodiment 1

[0044] (1) Preparation of positive electrode sheet:

[0045] The cathode active material LiCoO 2, the binder PVDF, and the conductive agent Super P are mixed according to the mass ratio of 97%: 1.5%: 1.5%, dispersed in N-methylpyrrolidone (NMP) and stirred evenly to make a slurry, and evenly coated on the aluminum foil of the positive electrode current collector On both sides, bake at 100-150°C for 4-8 hours, then cold-press and cut to make positive electrodes for lithium-ion batteries, with a compacted density of 4.1g / cm 3 , the thickness of the positive electrode active material layer on one side is 60 μm.

[0046] (2) Preparation of the first negative electrode active material layer slurry:

[0047] Artificial graphite, conductive agent SP, SBR and CMC are mixed according to the mass ratio of 97:0.5:1.5:1, dispersed in water and stirred evenly to make the first negative electrode active material layer slurry, the particle diameter of the artificial graphite is D 50 ≤25μm...

Embodiment 2

[0055] The difference between this embodiment and embodiment 1 is:

[0056] The first negative electrode active material in the first negative electrode active material layer is natural graphite, D 50 ≤30μm, thermal conductivity λ 1 =400W / mK; The second negative electrode active material in the second negative electrode active material layer is porous carbon microspheres, D 50 ≤10μm, thermal conductivity λ 2 = 150W / mK.

Embodiment 3

[0058] The difference between this embodiment and embodiment 1 is:

[0059] The first negative electrode active material in the first negative electrode active material layer is artificial graphite, D 50 ≤20μm, thermal conductivity λ 1 =200W / mK; The second negative electrode active material in the second negative electrode active material layer is natural graphite, D 50 ≤10μm, thermal conductivity λ 2 = 50W / mK.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com