Electrolytic solution and lithium ion battery containing same

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of destroying negative electrode carbon materials, shortening fast charging time, large battery resistance and polarization, etc., so as to improve cycle performance and service life, and improve low-temperature discharge. Power performance and the effect of improving the co-insertion phenomenon of anode graphite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Provide an electrolyte, an organic solvent composed of quaternary components of 25% EC, 55% EMC, 13% DMC, 7% EP (based on the total mass of the four organic solvents as 100%), and fully mix with lithium hexafluorophosphate Finally, add 0.2% VC and 1% MMDS, and mix well to obtain the lithium iron phosphate fast-charging lithium-ion battery electrolyte. The concentration of lithium hexafluorophosphate in the electrolyte is 1.1mol / L. Based on the total mass of the electrolyte as 100%, the content of VC in the electrolyte is 0.2%, and the content of MMDS is 1%.

[0023]A lithium-ion battery is assembled by using the above-mentioned electrolyte, lithium iron phosphate positive electrode and graphite negative electrode, and the specific preparation process is as follows. Based on the total mass of the positive electrode material as 100%, 97% lithium iron phosphate material, 1% conductive agent SP and 2% binder are mixed with solvent NMP to form positive electrode slurry. Ba...

Embodiment 2-30 and comparative example 1-12

[0025] Except that the composition of the electrolyte was different from that of Example 1, other methods of assembling the battery were the same as that of Example 1 to obtain a lithium ion battery.

Embodiment 31

[0027] The composition of the electrolyte in Example 1 is the same, and the positive electrode material is a ternary material of nickel-cobalt-lithium-manganese-oxide. Specifically, based on the total mass of the positive electrode material as 100%, 97% nickel-cobalt lithium manganate material (LiNi 0.66 co 0.08 mn 0.26 o 2 , NCM622), 1% conductive agent SP and 2% binder and solvent NMP slurry to be positive electrode slurry. Afterwards, in the same manner as in Example 1, a negative electrode was formed and assembled to obtain a lithium-ion battery.

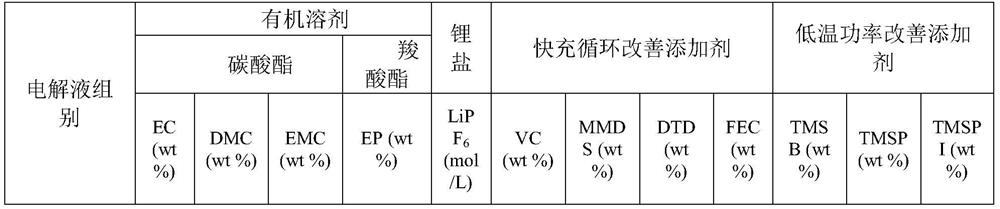

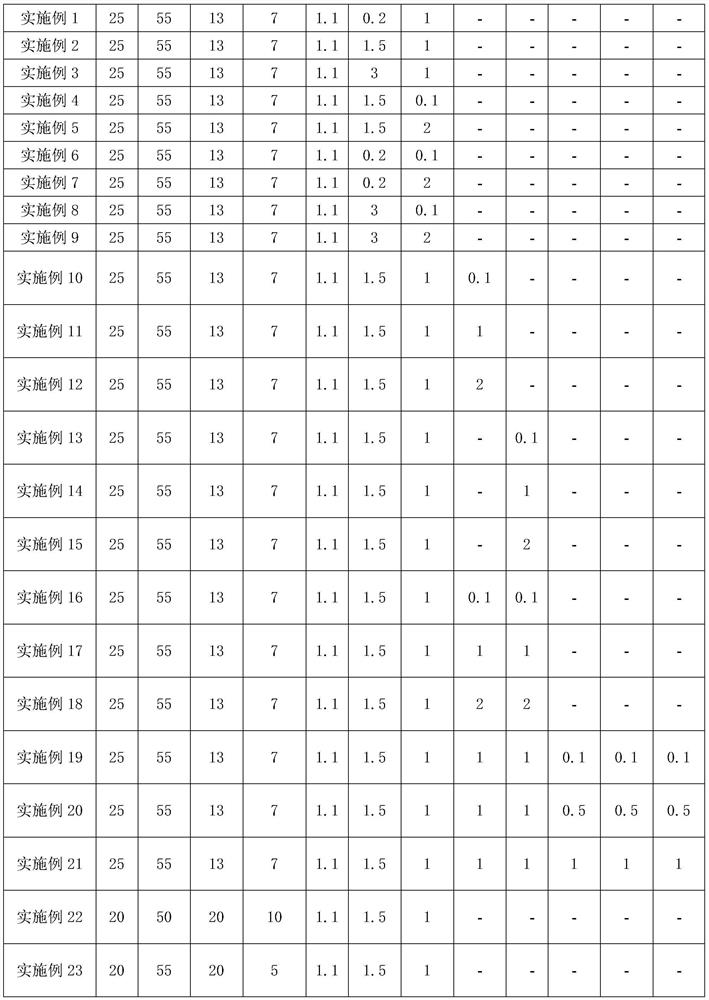

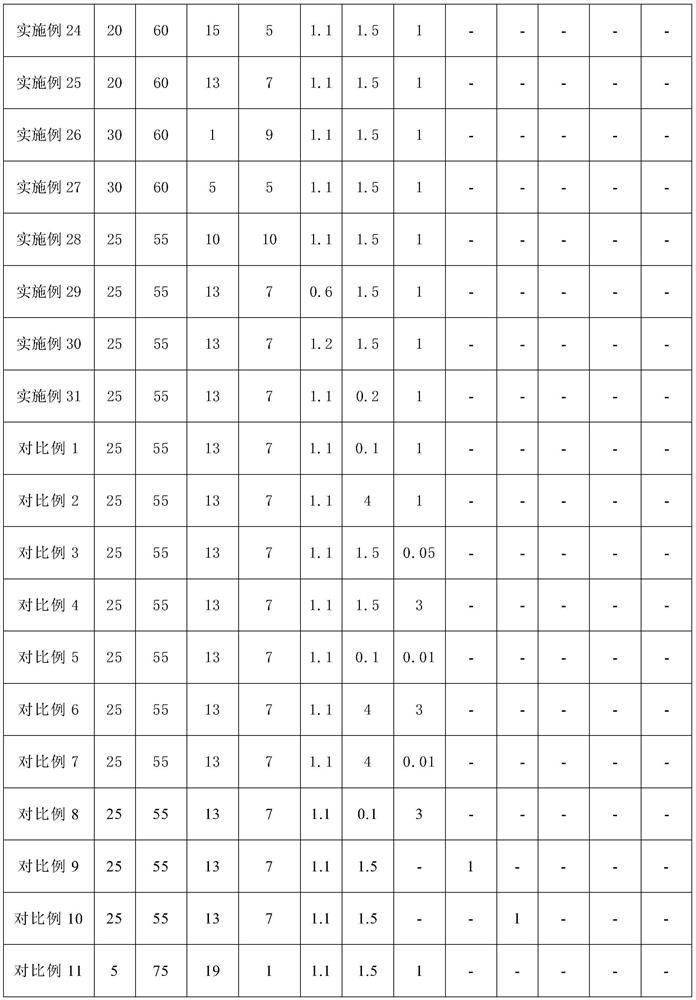

[0028] The compositions in the electrolytes of Examples 1-31 and Comparative Examples 1-12 are shown in Table 1.

[0029] Table 1

[0030]

[0031]

[0032]

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com