Lithium battery composite electrode active material and application thereof

An active material and composite electrode technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, lithium batteries, etc., can solve the problems of poor cycle performance, severe volume expansion and contraction, structural collapse, etc., to achieve high energy density, high fast charging effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

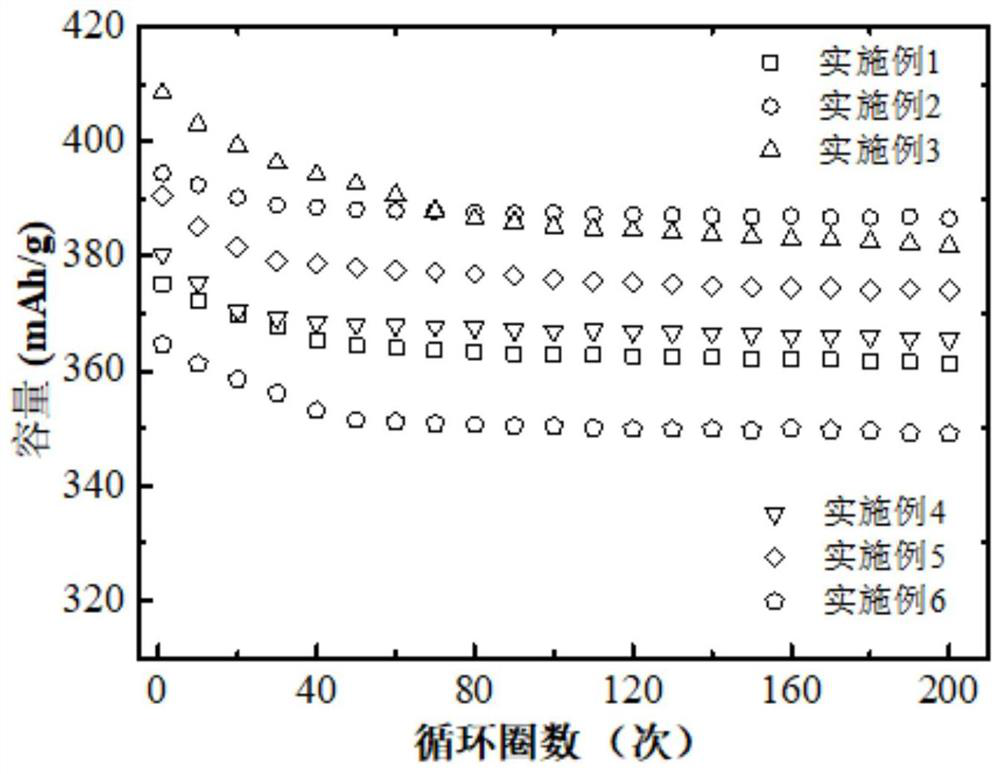

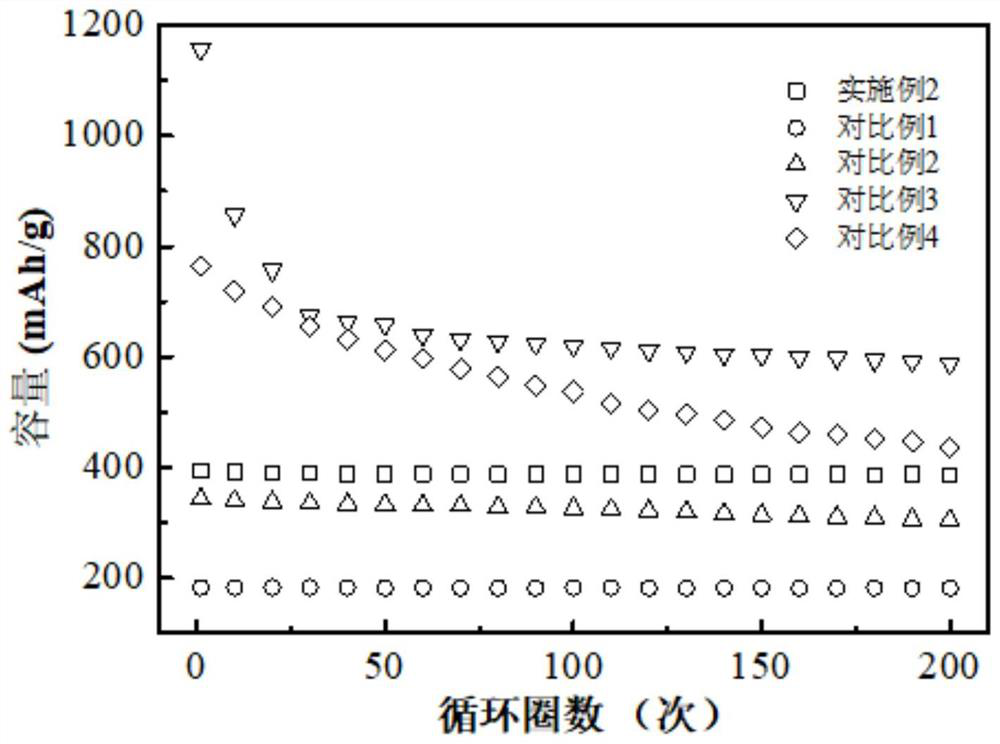

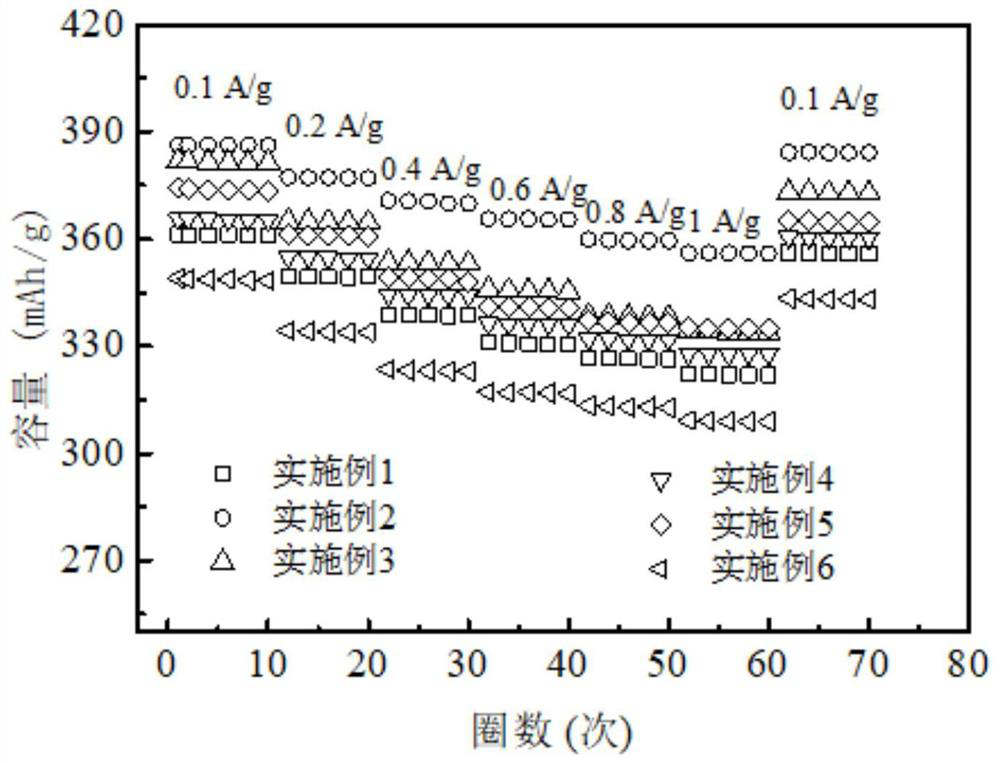

[0038] Example 1: Preparation of a lithium-ion battery natural graphite / lithium titanate / tin disulfide composite electrode and its button battery

[0039] First weigh 15.3g of PVDF and add it to 860g of NMP and stir for 3 hours to obtain a colorless and transparent glue solution, then add 200g of natural graphite, 400g of lithium titanate, 400g of tin disulfide negative electrode active material and 5.1g of conductive agent acetylene black, first Stir slowly for 1 hour, then stir rapidly for 3 hours; measure the viscosity with a viscometer, add 10 g of water to adjust the viscosity at 4200 cps; finally, the ratio of active material: binder: conductive agent is 98:1.5:0.5, and the solid content is 54%.

[0040] Coat the electrode paste obtained in the above steps on a 6 μm thick copper foil, and dry it in an oven at 55°C; roll and punch it to the size of the pole piece required by the 2032 button battery.

[0041] Packaging of button cell: stack the pole piece, lithium piece, a...

Embodiment 2

[0042] Example 2: Preparation of a lithium-ion battery natural graphite / lithium titanate / tin disulfide composite electrode and its button battery

[0043] Referring to the method of Example 1, the difference is that the composition of the active material is 300g of natural graphite, 400g of lithium titanate, and 300g of tin disulfide.

Embodiment 3

[0044] Example 3: Preparation of a lithium-ion battery natural graphite / lithium titanate / tin disulfide composite electrode and its button battery

[0045] Referring to the method of Example 1, the difference is that the composition of the active material is 300g of natural graphite, 300g of lithium titanate, and 400g of tin disulfide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com